2/16

Contents

Instructions for Safe Use.....................................................................................................................................1

1.Introduction to Slam® Trans.........................................................................................................................3

1.1 Technical data...........................................................................................................................................3

1.1.1 2P+E system (PELV)).............................................................................................................................4

1.1.2 2P system (SELV) ..................................................................................................................................4

1.1.3 3P system (SELV) ..................................................................................................................................4

1.2 Certification of equipment ..........................................................................................................................4

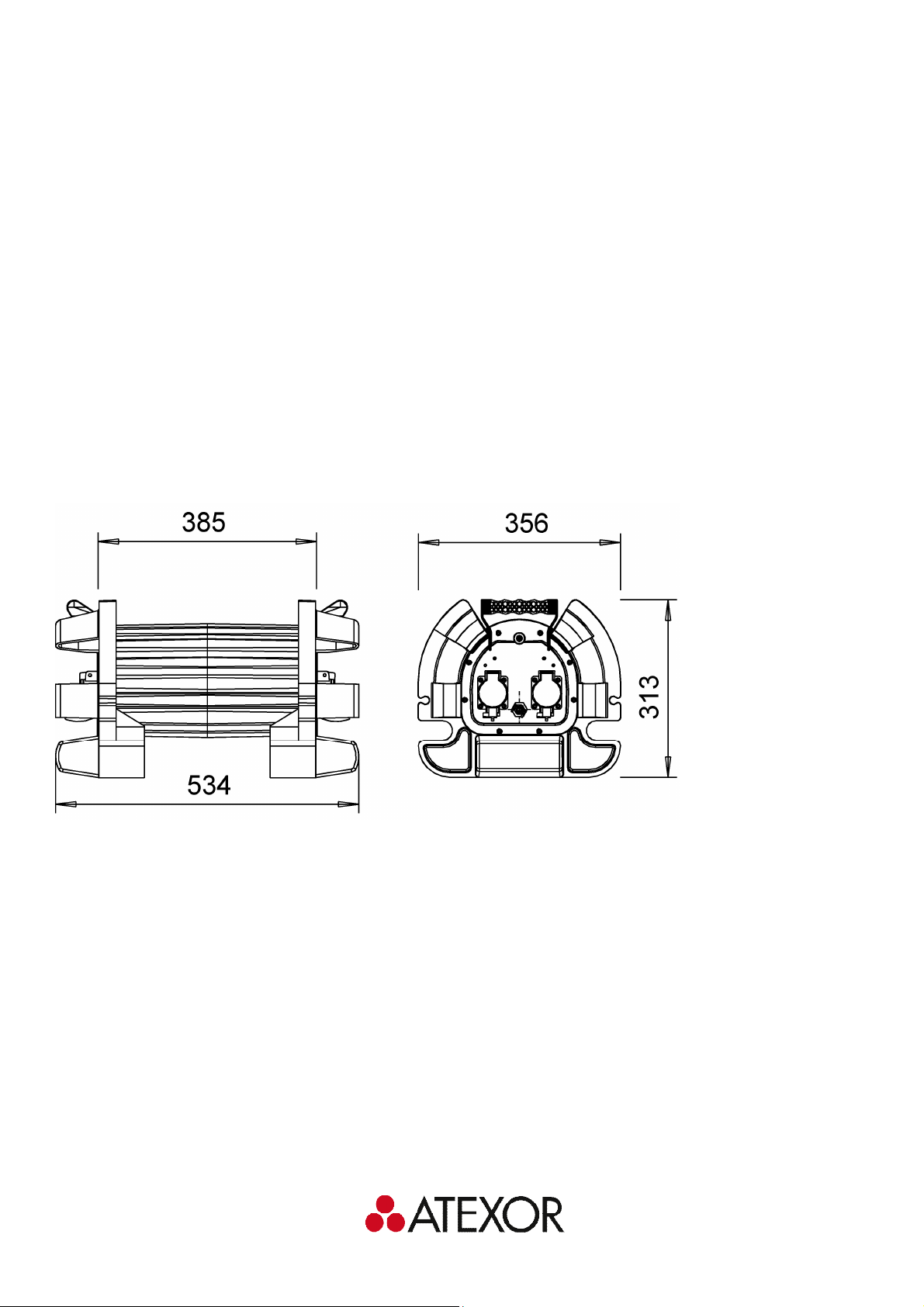

1.3 Standard unit construction .........................................................................................................................6

1.4 Quality Guaranteed ...................................................................................................................................7

1.4.1 General...............................................................................................................................................7

1.4.2 Individual testing reports .....................................................................................................................7

Prior to use.........................................................................................................................................................8

2.1 Selection of right equipment ......................................................................................................................8

2.1.1 Intended purpose of equipment...........................................................................................................8

2.1.2 Application of use (Zone XX) in accordance with equipment category..................................................8

2.1.3 Gas explosion group (IIA, IIB or IIC) in accordance with Equipment group (IIA, IIB or IIC)....................9

2.1.4 Temperature class of the equipment....................................................................................................9

2.1.5 Environmental criteria........................................................................................................................10

Operating instructions.......................................................................................................................................10

3.1 Personnel................................................................................................................................................10

3.1 Visual inspection of Slam® Trans ............................................................................................................10

3.2 Special attention on 2-pole use (24 V or 42 V) .........................................................................................10

3.3 Special attention on 3-pole use (24 V or 42 V) .........................................................................................11

3.4 Connection to the supply .........................................................................................................................11

3.4.1 Requirements for supply (electricity)..................................................................................................11

3.4.2 Connecting relating equipment to the Slam® Trans ...........................................................................11

2.Inspection & Maintenance..........................................................................................................................12

4.1 After Use.................................................................................................................................................12

4.2 Maintenance............................................................................................................................................12

4.3 Testing....................................................................................................................................................13

4.4 Repair report ...........................................................................................................................................13

Helpdesk.......................................................................................................................................................16