Table of Contents

PART 1 - INTRODUCTION................................4

1.1 General................................................4

1.2 Standard System.................................4

1.3 Features...............................................5

1.4 Q46/76 Auto-Clean System

Specifications.......................................7

1.5 Q46/76 Performance Specifications....8

1.6 Q-Blast Assembly................................8

PART 2 –ANALYZER MOUNTING..................9

2.1 General................................................9

2.2 Wall or Pipe Mount ............................9

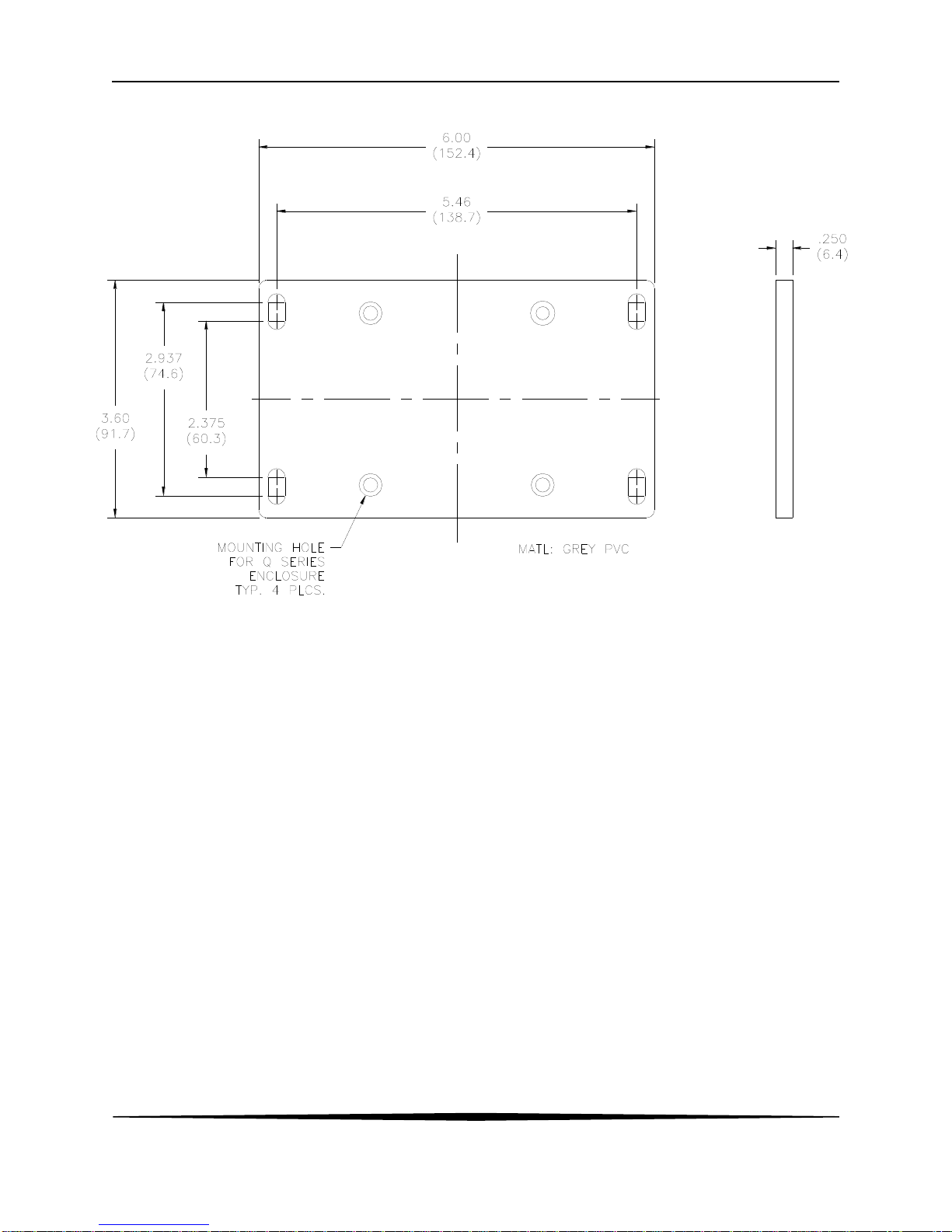

2.3 Wall Mount Dimensions..................10

2.4 Railing Mount...................................12

2.5 Sensor Assembly...............................13

2.6 Sensor Installation...........................14

PART 3 –ELECTRICAL INSTALLATION......16

3.1 General..............................................16

3.2 Connections.....................................16

3.3 Sensor Wiring....................................19

3.4 Q-Blast to Q46 Connection................20

3.5 Analog Output Connections...............23

3.6 Relay Connections.............................23

PART 4 –CONFIGURATION..........................24

4.1 User Interface ....................................24

4.11 Keys ...............................................25

4.12 Display ...........................................25

4.2 Software.............................................26

4.21 Software Navigation......................27

4.22 Measure Menu [MEASURE] ..........29

4.23 Calibration Menu [CAL]....................30

4.24 Configuration Menu [CONFIG]......30

4.25 Control Menu [CONTROL]............32

4.26 Diagnostics Menu [DIAG] ...............36

PART 5 –CALIBRATION ...............................40

5.1 Turbidity Calibration ..........................40

5.11 Cal Zero.........................................40

5.12 Cal Span........................................40

5.2 Temperature Calibration....................41

PART 6 - SENSOR AUTO-CLEAN SYSTEM.43

6.1 General.............................................43

6.2 Cleaner Sequence ...........................43

6.3 Cleaner Programming.....................44

PART 7 –PID CONTROLLER DETAILS........45

7.1 PID Description .................................45

7.2 PID Algorithm ....................................45

7.3 Classical PID Tuning.........................47

7.4 Manual PID Override Control............47

7.5 Common PID Pitfalls .........................47

PART 8 –SYSTEM MAINTENANCE..............49

8.1 General..............................................49

8.2 Analyzer Maintenance.......................49

8.3 Sensor Maintenance .........................49

PART 9 –TROUBLESHOOTING ...................50

9.1 General..............................................50

9.2 External .............................................50

9.3 Analyzer.............................................51

9.31 Display...............................................52

SPARE PARTS ...............................................53