IRTT-B User Guide

4 (8) 9836 4436 01 Revision 2010-01

GENERAL

The IRTT-B transducer provides torque measurement on a rotary

transducer, with optional angle reading.

The torque measurement is performed with a precise extensometer

bridge with special brushes to transfer the signal from the rotating

shaft to the housing; these brushes have been developed to be very

reliable and should not have the need of any maintenance through

out its life.

The angle reading is performed with a rotating magnetic sensor

providing 1024 pulses per revolution.

A built in memory stores identification and calibration data for

automatic reading from the measurement instrument.

TECHNICAL

•Torque Measurement Range: 1 ÷ 5000 Nm

•Angle (optional): 1024 pulses per turn

•Static accuracy: ± 0.25% of rated max. transducer capacity

•Overload capacity: 125% of rated max. transducer capacity

•Temperature stability: 0.1% of capacity / °C

•Bridge resistance: 350 ohm

•Operation humidity: 10-75% non condensing

•Operating temperature: 5 to 40°C

The transducer comes with Atlas Copco BLM calibration

certificate.

The calibration data is marked on the transducer label (when

installing the item always use this data, not the nominal values)

CONNECTOR PIN OUT

TRANSDUCER BUILT IN MEMORY

The built in memory consist in a eeprom, which stores the

following data:

•Identification

•Calibration (Nm)

•Full scale value (% of cal. Value)

•Sensitivity (2mV/V)

•Pulses / rev

•Serial Number.

•Date of latest calibration

•Next Calibration date

•Source of Calibration

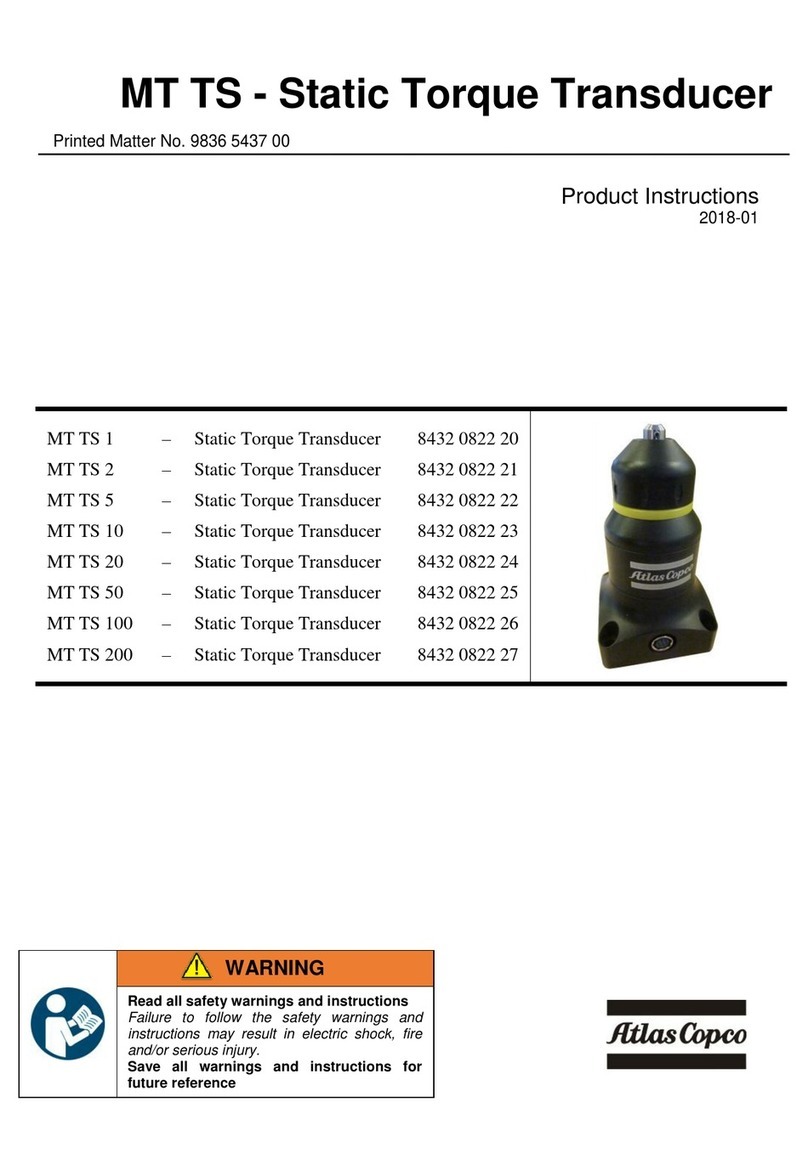

TORQUE ONLY MODELS

Model Capacity (Nm) Drive Ordering No.

5-I06 5 ¼” hex 8059 0942 05

20-I06 20 ¼” hex 8059 0942 10

20-06 20 ¼” square 8059 0942 15

25-10 25 3/8” square 8059 0942 20

75-10 75 3/8” square 8059 0942 25

180-13 180 1/2” square 8059 0942 30

500-20 500 ¾” square 8059 0942 35

750-25 750 1” square 8059 0942 40

1400-25 1400 1” square 8059 0942 45

3000-38 3000 1 ½” square 8059 0942 52

5000-38 5000 1 ½” square 8059 0942 56

TORQUE AND ANGLE MODELS

Model Capacity (Nm) Drive Ordering No.

1A-I06 1 ¼” hex 8059 0943 96

2A-I06 2 ¼” hex 8059 0943 01

5A-I06 5 ¼” hex 8059 0943 06

5A-06 5 ¼” square 8059 0943 08

20A-I06 20 ¼” hex 8059 0943 11

20A-06 20 ¼” square 8059 0943 16

25A-10 25 3/8” square 8059 0943 21

75A-10 75 3/8” square 8059 0943 26

180A-13 180 1/2” square 8059 0943 31

500A-20 500 ¾” square 8059 0943 36

750A-25 750 1” square 8059 0943 41

1400A-25 1400 1” square 8059 0943 46

3000A-38 3000 1 ½” square

8059 0943 52

5000A-38 5000 1 ½” square

8059 0943 56

OPERATIONS

Select the correct transducer having a torque capacity not less than

the maximum torque capacity of the tool used. Secure the tool

output spindle to the transducer input socket (hexagon shaft). Fit

the correct socket to the transducer output square drive (or bit in

bit-holder) and make sure it is secured.

Connect the transducer to the measuring instrument with the proper

cable. If you use an ACTA instrument the calibration data will be

loaded automatically and no manual entering of the value is

required.

If you use another measuring instrument the transducer shunt

calibration value and the angle pulses must be entered manually.

The shunt calibration value is marked on the transducer, the bridge

impedance is 350 Ohm and a 43,575 Ohm resistor is necessary.

Make sure to align the tool/transducer, to avoid any influence from

side forces which may affect the measurement.

If a tool is tested with a reaction bar the effective radial position of

the reaction bar point should not be less than a certain value (see

the next table and figure); not observing this requirement and to

exceed the maximum torque rating may cause a permanent damage

to the transducer.

Pin Function

A Excitation +

B Excitation –

C Signal +

D Signal –

E –

F Angle encoder cw trail (for versions with angle)

G Eeprom Clock

H Angle encoder cw lead (for versions with angle)

J Eeprom data

K-L-

M-N

–

P Ground (angle and eeprom)

R + 5V for angle reading (for versions with angle)

S –

T + 8/12V eeprom power supply

U-V –