--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

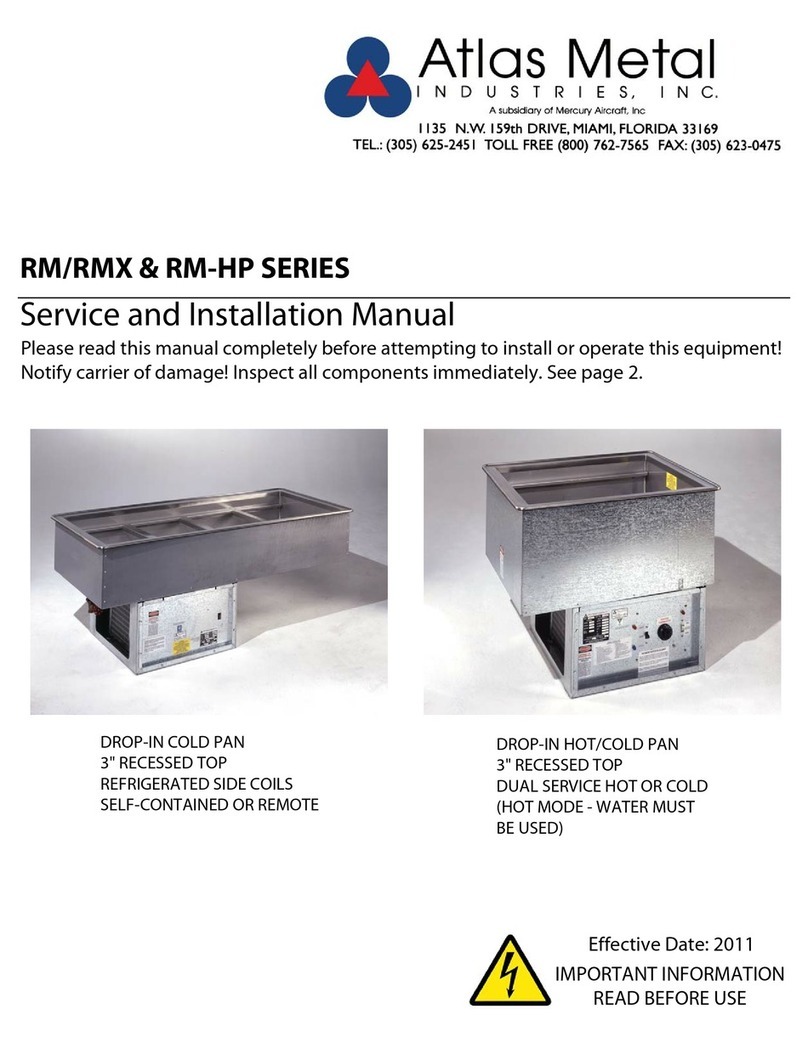

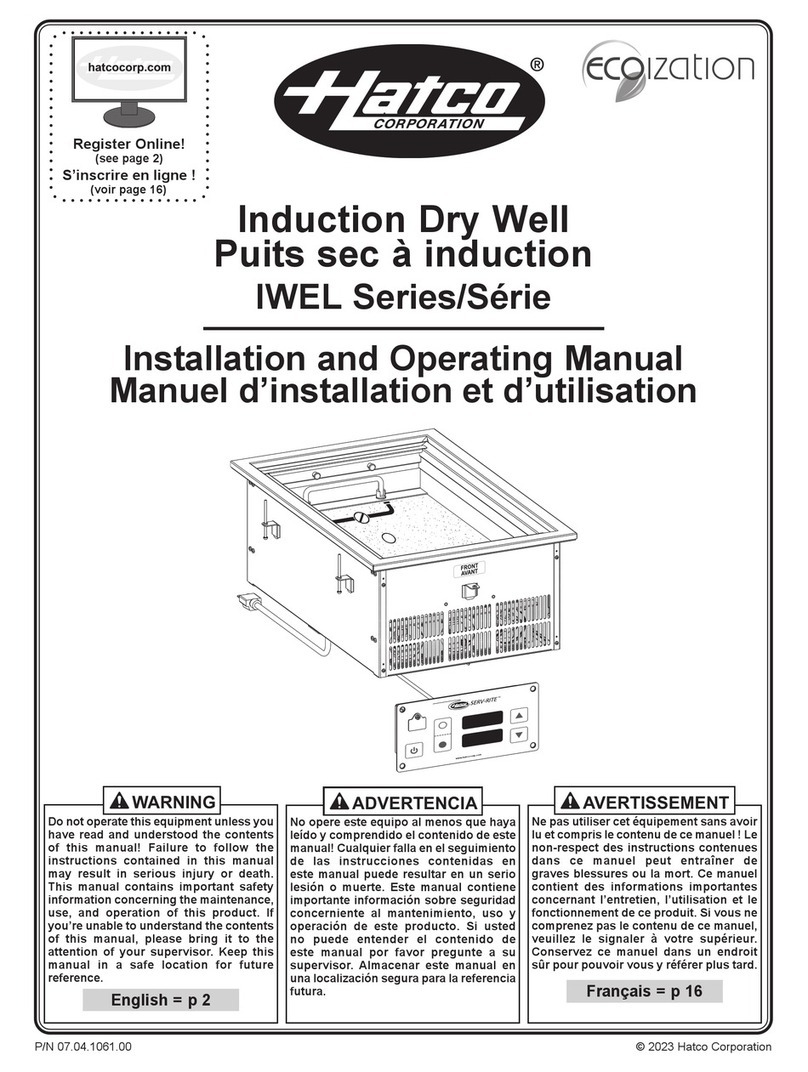

INSTALLATION

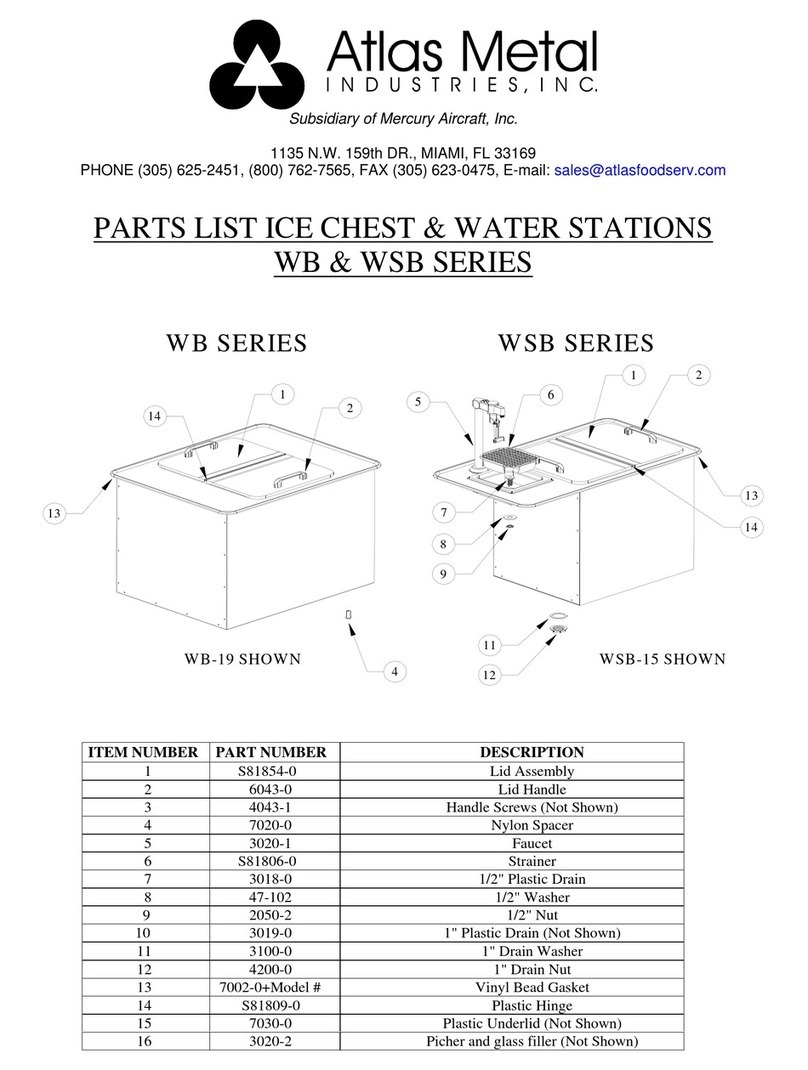

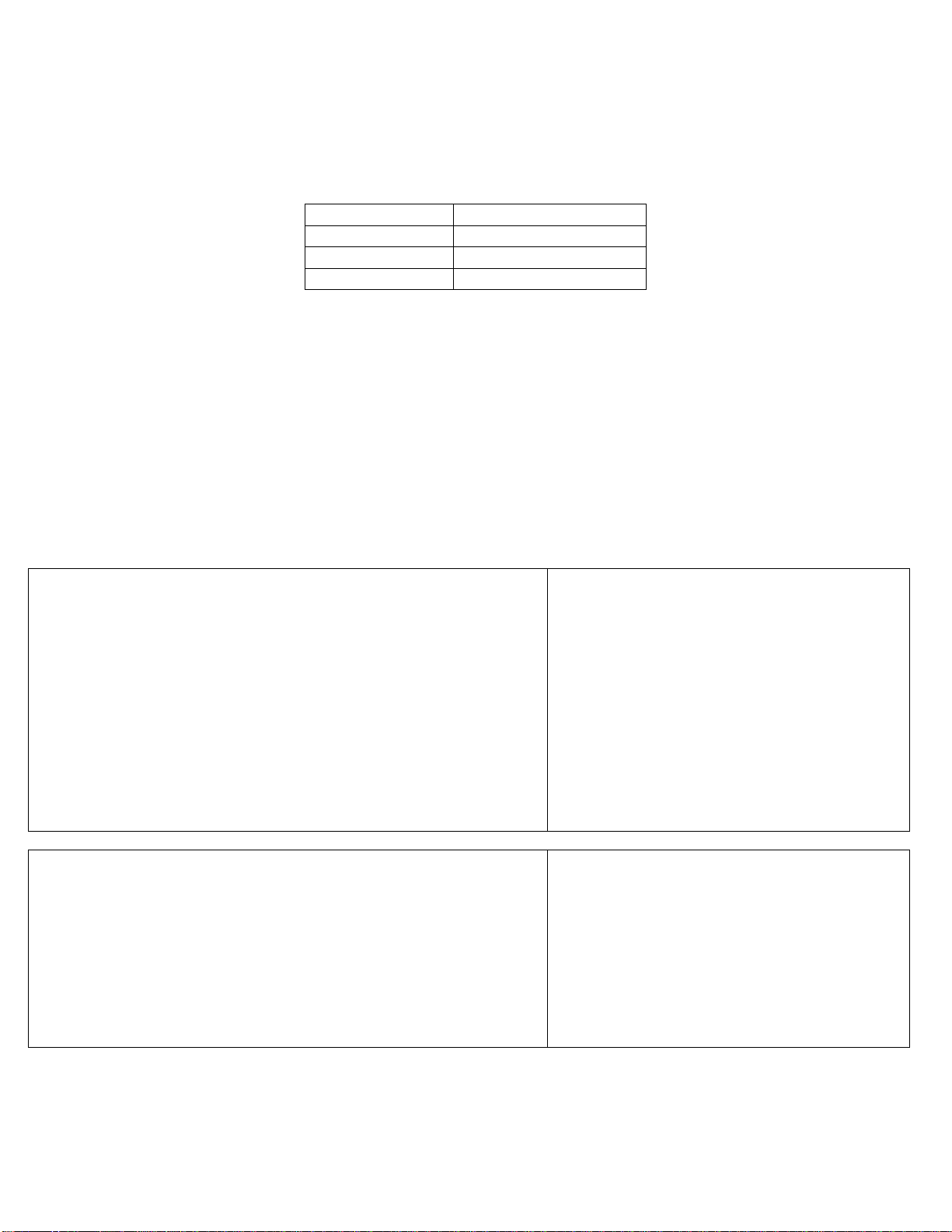

Provide the correct counter cut-out opening (see chart below), and drop in. The vinyl gasket assures complete seating.

A non-toxic silicone seal may be used between the gasket and countertop (not required).

Note: Units are supplied with a nipple and stop valve to be connected for draining.

“Wastewater connections are to conform to the International Plumbing Code 2003, International Code Council (ICC)

or the Uniform Plumbing Code 2003, International Association of Plumbing and Mechanical Officials (IAPMO)”,

or the equivalent.

---------------------------------------------------------------------------------------------------------------------------------------------

The unit should be level for draining purposes. When installing unit in a counter, it is recommended that the operator

side of the counter be completely open for air circulation. When this is not possible, such as in an island counter, it is

recommended that two grill openings be provided, approximately 18” x 18” of free air for intake and exhaust, at

opposite ends of the counter, and a minimum clearance of 14” at the top, 24” at the back and 10” at each side of the

enclosure.

The unit is supplied with a power cord and NEMA plug. Refer to the data plate on the compressor housing for the

amperage and voltage information. Use a licensed electrician when installing power source.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

OPERATION

HEATING OPERATION COOLING OPERATION

Unit runs with water or without water.

With‐Wateroperation

1)TurnMasterSwitchtoONposition

2)TurnSelectorSwitchtoHOT

3)Closeindividualdrainvalves.(Reddrainhandles)

4)Filltheunitwithwater(preferablyhotwater)untilthelevelassigned.

5)TurntheT‐Stattoposition#10

6)Coverthewellwithalidandwait45minutesfortheunittoheatup.

7)Insertpanswithfood.Becautious,unitishot.

8)Checkthewaterlevelevery2hours.

9)Toturntheunitoff,switchallSelectSwitchesfromONtoOFFandsettheMasterSwitchtoOFF.

Dryoperation(with‐OutWater)

Followsteps1to3

4)TurntheT‐Stattoposition#10

5)Coverthewellwithalidandwait15minutesfortheunittoheatup.

6)Insertpanswithfood.Becautious,unitishot.

7)Toturntheunitoff,switchallSelectSwitchesfromONtoOFFandsettheMasterSwitchtoOFF.

1. TurnMasterSwitchtoONposition.

2. TurnSelectSwitchtoCOLD

3. ElectronicThermostatisautomaticallysetfromfactory.

4. Coverwellwithalidandwait45minutesfortheunitto

cool.

5. Insertpans.

6. Toturntheunitoff,switchallSelectSwitchesfromON

toOFFandsettheMasterSwitchtoOFF.

HEATING TO COOLING OPERATION COOLING TO HEATING OPERATION

1. KeepmasterswitchinONposition.

2. TurnselectorswitchtoCOLD.

3. ElectronicThermostatwillchangetemperaturesautomatically.

4. Openalldrainvalves(redandbluedrainhandles)toremovehotwatercompletelyand

wait40minutes.

5. Closereardrainvalve(bluedrainhandle)

6. Thewellwillnotoperateuntilithascooled.Pleaseallowtimeforthewelltocool.

7. Removeanyhotoperationservingmaterial.(Pans,food,etc.)

8. Coverthewellwithalidandwait45minutesfortheunittocool.

9. Insertpans

10. Toturntheunitoff,switchallSelectSwitchesfromONtoOFFandsettheMaster

SwitchtoOFF.

1. KeepmasterswitchinONposition.

2. TurnselectorswitchtoHOT.

3. ElectronicThermostatwillchangetemperatures

automatically.

4. Closeindividualdrainvalves.(Redhandles)

5. Ifusingwater,filltheunitwithhotwatertothemarked

levelinthewell.

6. Coverthewellwithalidandwait15minutestoheat.

7. Insertpans

8. Checkthewaterlevelevery2hours.

9. Toturntheunitoff,switchallSelectSwitchesfromON

toOFFandsettheMasterSwitchtoOFF

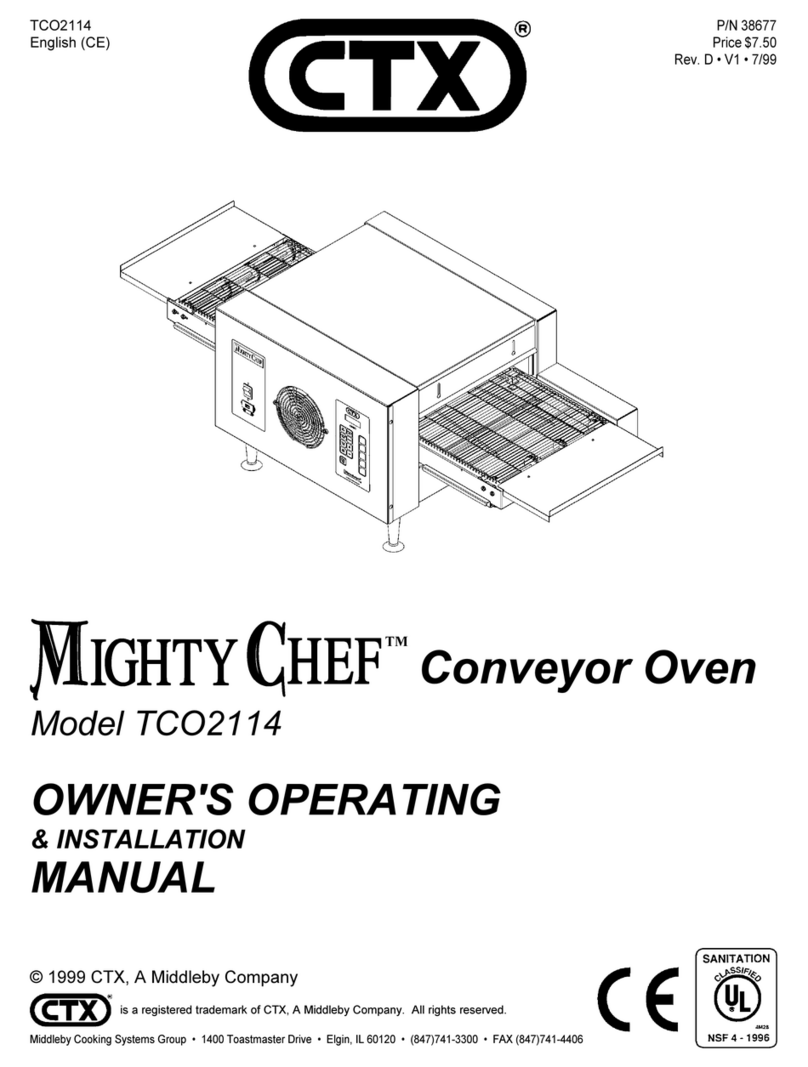

CUT-OUT SIZE

WQHC-2 36-1/8” X 24-3/4”

WQHC-3 54-1/4” X 24-3/4”

WQHC-4 72-1/2” X 24-3/4”

Digital thermostats

are NOT indicative

of well temperatures.