* Units with these accessories are not currently UL listed.

Project: ___________

Item No.: ___________

Quantity: ___________

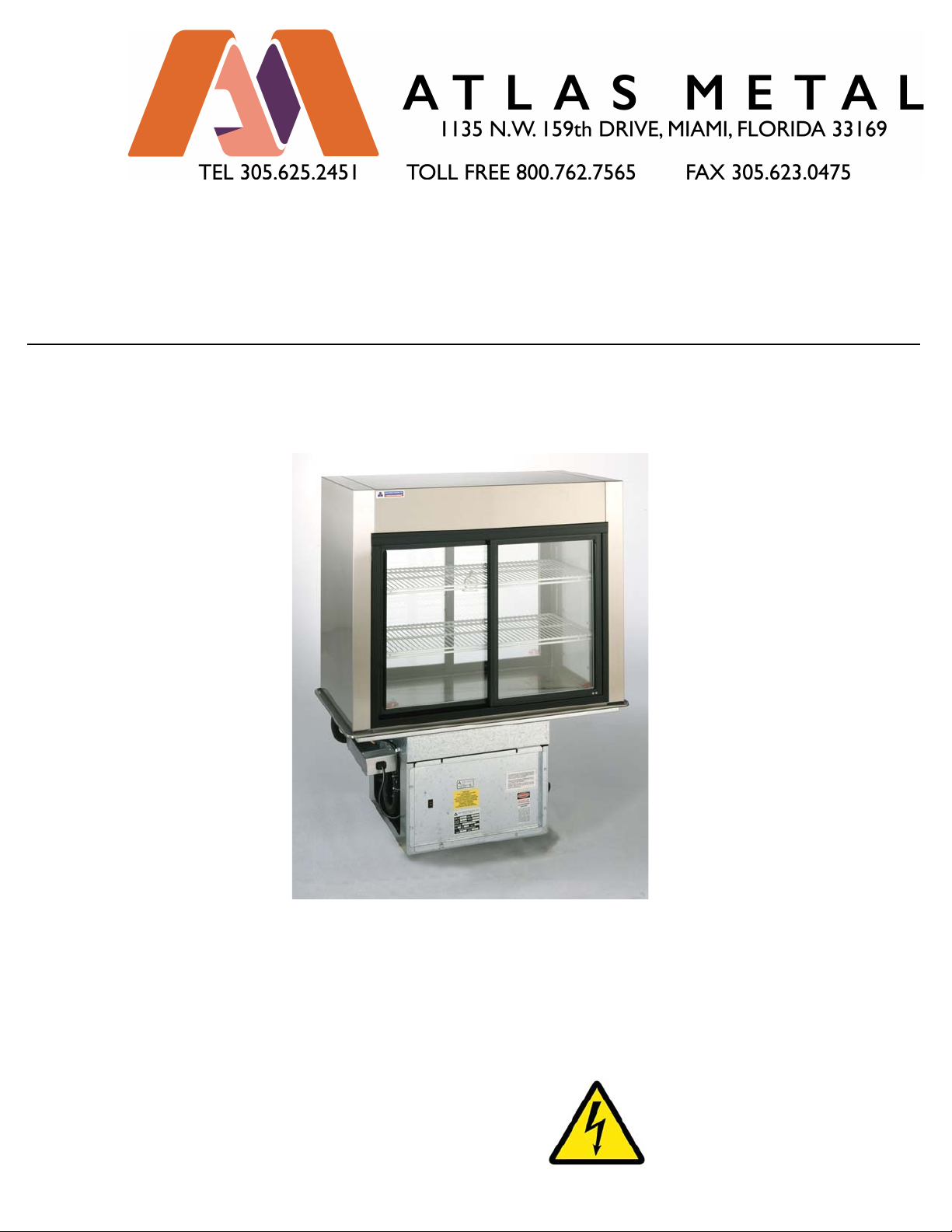

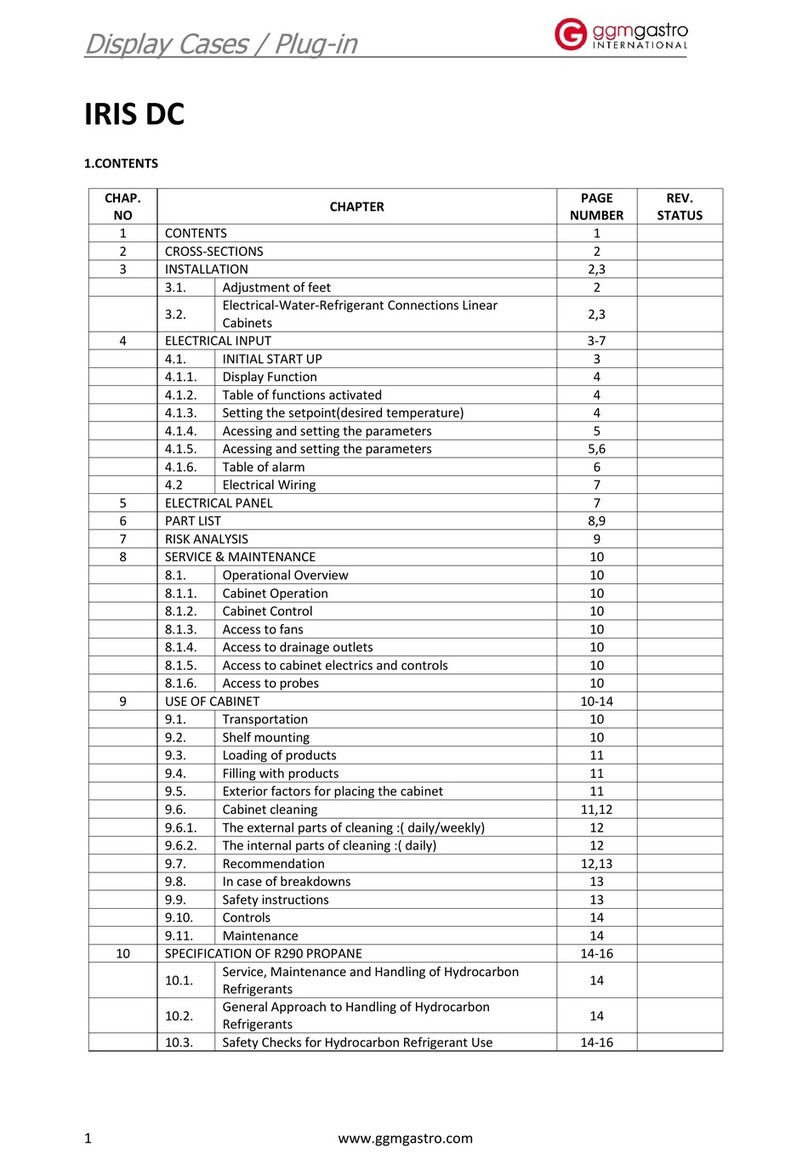

DROP-IN SERVING EQUIPMENT

DISPLAY CASE

Refrigerated,

Pass-Through

Self-Contained

WCPT-3

WCPT-4

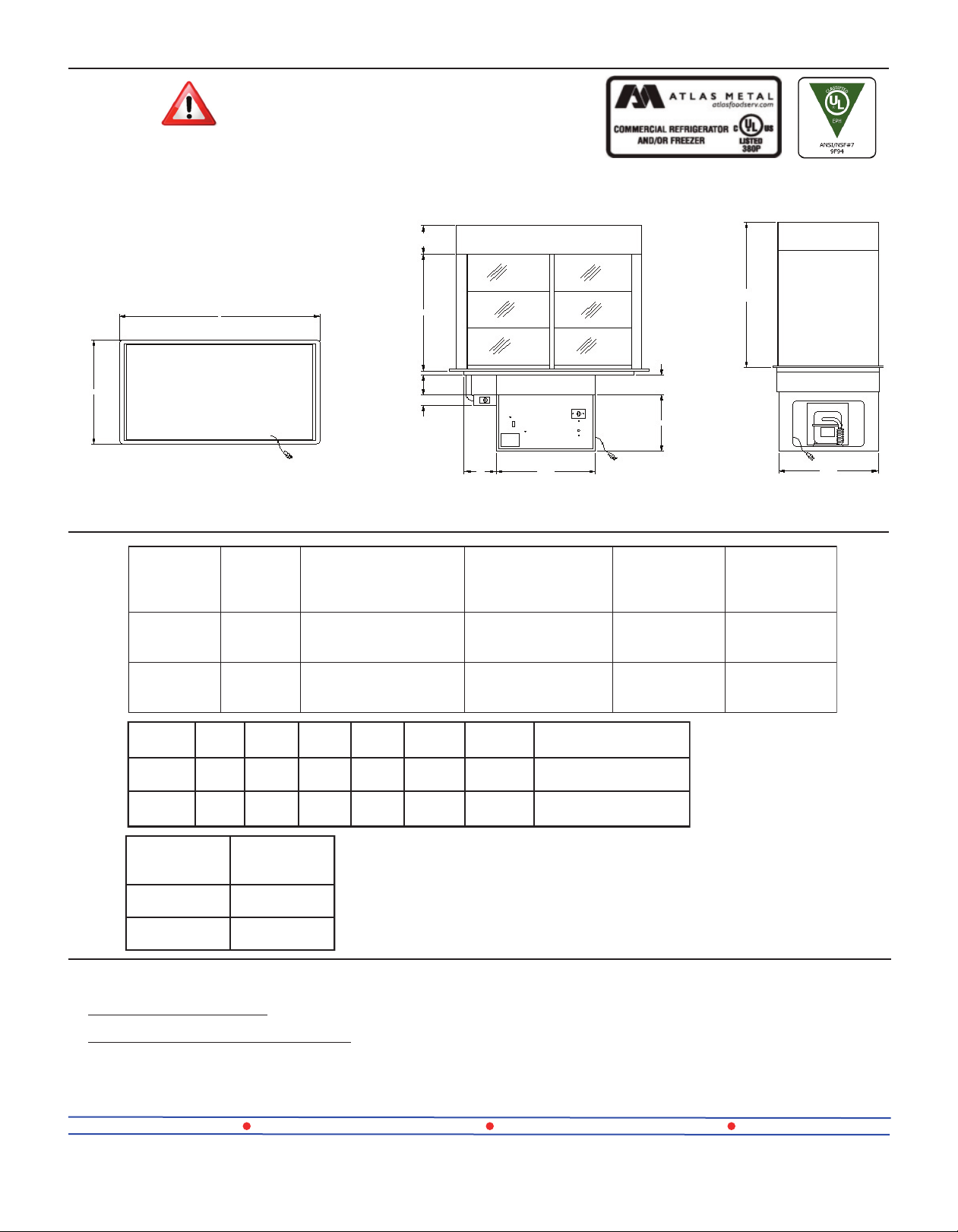

TOP: Constructed of 18 gauge, type 304 stainless steel, die stamped

with a raised perimeter bead. The top is solid, full-length, to support

the refrigerated display case. There shall be a solid vinyl gasket

under the beaded edge to form a seal to the counter top, thus pre-

venting seepage or marring of the counter top.

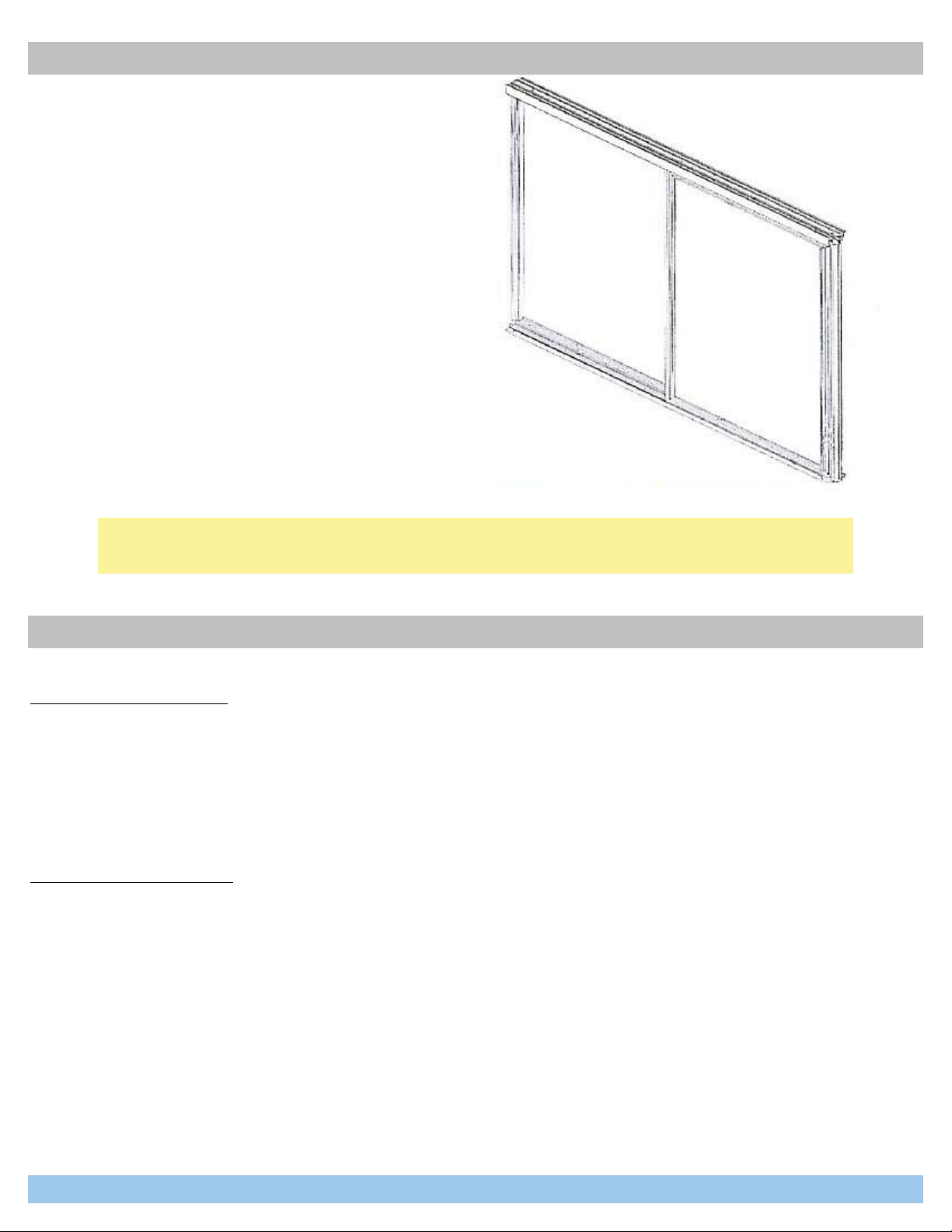

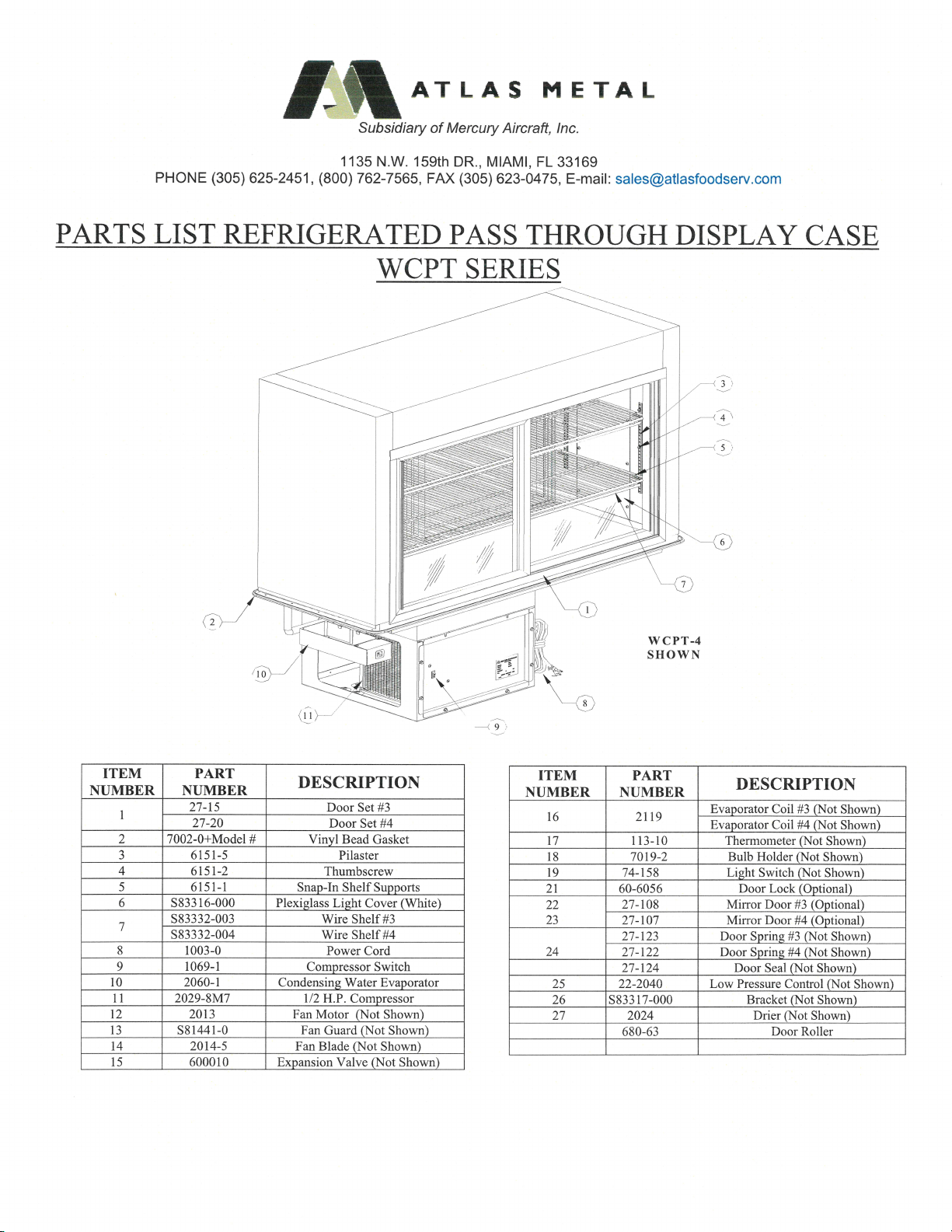

DISPLAY CASE: Double wall constructed of type 304 stainless steel

- 20 gauge, both interior and exterior, and filled with 2" of foamed-in-

place polyurethane insulation. Customer's side and operator's side

are provided with a set of two (2) sliding, self-closing, thermo-pane,

insulated glass doors. The doors are removable for ease of cleaning.

The display case is provided with two (2) plastic coated wire shelves,

adjustable on 1" increments, and two (2) sets of fluorescent light fix-

tures mounted behind plastic guards which are recessed into the

side panels. The light fixtures are provided with a separate on/off

switch. An internal thermometer is provided.

REFRIGERATION SYSTEM: The compressor housing shall be fabri-

cated from 14 gauge galvanized and bolted to the base of the unit. A

fully self-contained condensing unit is provided with a hermetically

sealed compressor and a thermostat control. The system is also pro-

vided with a forced air evaporator, for even temperature throughout

the display case, which drains into a condensate evaporator, pre-

wired in the unit. The system is fully charged with CFC free refriger-

ant and ready to operate.

NOTE: Proper ventilation must be provided in counter.

ELECTRICAL: The unit will be wired for 15 amps., 120 volt, single

phase operation with an on/off thermostat switch and pilot light. A 6'

long, 3-wire cord and plug (NEMA 5-15P) will be provided.

Specifications subject to change without notice.

SPECIFICATIONS STANDARD FEATURES

gLarge, lighted display area with adjustable shelves - it’s the

ideal merchandiser

gSliding glass doors on customer’s and operator’s side,

making loading and self-service move quickly

gForced air evaporator blower system for maximum efficiency

in cooling

g Factory applied gasket - makes installation a snap and seals

units to the counter top, thus eliminating seepage

g1-Year Parts & Labor Warranty

g UL Listed

ACCESSORIES

g 5YW - 5-Year Compressor Warranty

gDoor Locking Device (2 required)

g Extra Shelf

g Plastic Laminate Trim

g Sliding Doors with Reflective Tempered Vision Panel (bronze

or gray)

gSolid (1) piece Tempered Reflective Vision Panel (bronze or

gray)

g Solid Stainless Steel Back

g RS - Remote on/off switch for counter mounting

g RDVE - Rear Drain Valve Extension

g * 220 Volt - 50 Cycle Compressor

DI-39

*Please see Operation & Installation Manual for ALL operation and maintenance details.