Atmos A70 Petro User manual

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-1

GB

Operation and

maintenance

manual

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

2-GB

GB

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-3

GB

CONTENTS

1. GENERAL INFORMATION 4

INTRODUCTION 4

DESIGN AND APPLICATION FIELD 4

TECHNICAL DATA 5

2. BURNER DESCRIPTION 5

Key: 6

Description of the burner main parts 6

3. FUNCTION SPECIFICATIONS 7

Conveying system 7

4. PUTING APPLIANCE IN OPERATION AND SAFETY 7

Structural amendments leading to increased safety 7

5. BURNER, BOILER, FLUE-GAS DUCT AND CHIMNEY MAINTENANCE 8

Carry out the inspection and maintenance operations in regular intervals based on the

following instructions: 8

6. BOILER ROOM AND BURNER TO BOILER CONNECTION REQUIREMENTS 12

7. ENVIRONMENT TYPE AND BOILER PLACEMENT IN BOILER ROOM 13

8. ELECTRICAL CONNECTION 13

9. BOILER WIRING DIAGRAM 14

10. BURNER WIRING DIAGRAM 15

11. CONTROL PANEL 15

12. START-UP – OPERATION – SHUT-DOWN 16

Boiler and burner operation preparation 16

BURNER START-UP 16

AUTOMATIC IGNITION – START MODE 16

Parameters of the START + - mode 17

NORMAL OPERATION 17

Parameters of the RUN mode 18

Parameters of the STOP mode 19

Parameters of the SERVICE mode 19

13. SETTING THE BURNER FOR VARIOUS FUEL TYPES 19

Recommended settings for particular fuel types and outputs. Information on the cleaning intervals

. 20

Wood pellets 20

Rape straw pellets 20

Poppy straw pellets 21

Sugar-beet cuttings pellets 21

Pellets from grain-cleaning procedure waste (so called „tailings“) 21

Pellets from rape straw, poppy straw and grain-cleaning procedure waste (so called „tailings“) 22

Peat pellets 22

Other important information - conveyors 23

14. TROUBLESHOOTING 23

15. ERROR MESSAGES 24

16. SOME ADVICE ON USING PELLETS AS FUEL 25

17. LIST OF MAIN SPARE PARTS 26

GUARANTEE CONDITIONS 27

BOILER INSTALLATION REPORT 28

ANNUAL INSPECTIONS RECORDS 29

RECORDS OF GUARANTEE PERIOD AND POST-GUARANTEE PERIOD REPAIRS 30

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

4-GB

GB

1. GENERAL INFORMATION

NOTE – Before operating the burner for the first time, it is necessary to get thoroughly fa-

miliarised with all the instructions included in this manual. The manufacturer is not liable

for any damage which arises as a result of incorrect operating or maintenance of the device.

The burner‘s output is calculated based on the maximum amount of pellets which fit (or

which are permitted to be burned) in the combustion chamber of the burner in the duration

of 1 hour (considered are good quality wood pellets).

CAUTION – The upper protection guard of the burner may only be removed when the

power (main lead) has been disconnected. Installation, ignition test and operator‘s training

will be carried out by an installation company trained by the manufacturer. This company

also completes the „Boiler and burner installation report“ on page 27.

INTRODUCTION

This instruction manual is designed for the burner users. It includes instructions necessary for its

installation, start-up, maintenance and safety operation.

We recommend you to pay particular attention to the safety instructions. Interventions for which it is

necessary to disconnect the burner from the boiler or during which it is necessary to enter a code for

the electronics shall only be carried out by duly qualified and authorised experts. Repairs and settings

which are not specified in this manual shall not be carried out at all.

DESIGN AND APPLICATION FIELD

The ATMOS A70 Petro burner is a new and revolutionary technical solution for burning any type of

wood pellets. The burner is designed as a cylindrical combustion chamber in which an ideal combus-

tion of all combustible material takes place. Moreover, its rotation prevents the clinkering of ash and

provides means for its easy removal from the burner nozzle.

The burner is designed for the D45P type of boiler. The nominal output of the boiler in combination

with this burner is specified as 48kW with the efficiency over 92%. The technical solution of the

D45P boiler combined with A70 Petro burner allows permanent operation of the boiler at its maxi-

mum output of 60 kW while achieving excellent efficiency of over 90%. Therefore, such combined

unit may be used for buildings with a heat loss of up to 60kW, should the need be.

The specified fuel is any type of wood pellets. However, the burner can very effectively combust

alternative pellets such as pellets made from rape straw, poppy straw, sugar-beet cuttings and

peat of 6-10mm diameter and 5-20mm length. If necessary, a combination of individual types of

fuel may be burned. However, it is always advisable to burn each type of fuel individually - only this

method makes it possible to set ideal combusting parameters which influence the quality of combus-

tion, and efficiency and service life of the boiler. When burning alternative pellets a significantly more

ash forms. Therefore, we recommend you to install the boiler with the automatic ash removal system

ATMOS. By doing so, you obtain an appliance burning cheap fuel with low operational cost and great

user comfort.

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-5

GB

TECHNICAL DATA

• Name: ATMOS A 70 PETRO

• Specified fuel: good quality wood pellets of 6-10mm diameter and 5-20mm length

• Alternative fuel: alternative pellets such as pellets made from rape straw, poppy straw, sugar-beet

cuttings and peat of 6-10 mm diameter and 5-20 mm length.

• Burner nominal output: 48kW

• Burner maximum output: 60kW

• Fuel storage tank: ATMOS external tank

• Fuel dispensing: screw conveyor

• Fuel dispensing control: vane sensor of pellets level

• Combustion process monitoring: photocell

• Burner control: Electronic system with two processors

• Output regulation: one-stage

• Power supply: 230V / 50Hz

• Maximum incoming power at the start-up 2180 W

• Maximum incoming power during operation: 110 W

• Incoming power of the ignition element: 2000/1000 W

• Ignition current: 4 to 10A

• Average incoming power of the burner during operation: up to 70 W

• Burner weight: 80 kg

2. BURNER DESCRIPTION

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

6-GB

GB

Key:

Description of the burner main parts

• Rotation cylindrical combustion chamber

Is a new revolutionary solution for combusting pellets which tend to clinker. Such chamber pro-

vides ideal combustion of all combustible materials. Its rotation prevents significant clinkering of

cinder and provides means for its easy removal from the burner nozzle.

• Conveying screw 1

It transports and accurately dispenses fuel into the combustion chamber based on the pre-set output.

• Controlled fan

Regulation of the fan vanes rotation speed provides means for ideal combustion of the particular fuel.

• Ignition device

Provides means for interrupted burner operation based on the customer‘s needs. It ignites pellets

very quickly and reliably and so provides means for quick burner start-up.

CAUTION – the ignition element has two levels of operation: level one – 1000W, level two

– 2000W. Higher incoming power means shorter time necessary for fuel ignition. The burn-

er‘s factory setting is with the switch (underneath the boiler hood) in position 2 (2000 W).

This means that when installing boiler it is necessary to insert a 12.5A fusible link (instead

of the standard supplied 6.3A) into the fuse (plastic holder) placed on the boiler panel. At

the lower ignition level setting of the incoming power (1000 W, switch position 1), the igni-

tion of the fuel is not guaranteed. Therefore, we do not use this lower level. In the ignition

stage, there are other important factors; the fan setting at the start-up, characteristics of the

chimney which, if it has a significant air draught, may increase the volume of air that passes

through the ignition element and thus decrease the temperature of the ignition air necessary

for successful ignition of the pellets.

• Photocell

Provides means for monitoring the flame at the ignition stage and during operation. If necessary,

it must be cleaned.

• Rotational clack-valve

It is an important element of the burner safety. It effectively prevents reversed burn-through of

the fuel (i.e. if combustion chamber gets blocked, the fuel burning does not spread back into the

conveyor or tube).

• Vane-type sensor of pellets level

It detects the level of pellets in the burner above the rotational clack-valve and thus regulates the

fuel supply from the storage tank into the burner by means of the external conveying screw.

• Control electronics

It provides means for accurate setting of combustion quality and burner output for a particular

1. Rotation cylindrical combustion chamber

2. Turbo-chamber

3. Heatproof bearings

4. Sealing partition with a heatproof bearing

5. Ignition device

6. Controlled fan

7. Vane-type sensor of pellets level

8. Pellet supply

9. Motor-transmission 40W/ 230V /50HZ

10. Rotational clack-valve

11. Conveying screw 1

12. Optical sensor - photocell

13. Control electronics

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-7

GB

fuel type by twenty continuously adjustable variables. It also monitors operation hours, number

of start-ups and number of cleaning operations carried out by the user.

3. FUNCTION SPECIFICATIONS

Burning pellets with the ATMOS A70 Petro burner installed has many things in common with burn-

ing fuel oils. The major difference is that when burning pellets a certain amount of ash forms which

must be in certain interval removed (based on the burner and boiler shape) so that the burner‘s ef-

ficiency or functionality does not suffer.

The ATMOS A70 Petro pellet burner is normally supplied with automatic fuel ignition and with

appropriate dispensing system that functions fully automatically during the burner operation. The

burner operation is regulated via the flame sensor – a photocell. Inside the burner, the fuel and com-

bustion air are dispensed in a way providing complete, effective and environmentally friendly pellets

combustion of high efficiency degree.

Conveying system

The conveying of pellets from the internal storage tank into the burner is carried out automatically

by a screw conveyor which is adjusted and regulated by the burner electronic unit. The system is

based on the safety principle of interrupting the fuel supply into the burner by means of gravity flow

of pellets into the burner (empty tube above the burner). The motor-transmission of the burner‘s fuel

conveying system as well as the external screw-conveyor motors are fitted with thermal protection

against jamming and following overheating, during which a shut-down of the conveyor occurs.

CAUTION – The burner should only be used with the recommended dispensing system as

utilising a different system may lead to overfilling of the fuel supply tube.

4. PUTING APPLIANCE IN OPERATION AND SAFETY

Structural amendments leading to increased safety

The burner is constructed based on the knowledge of basic principles which are known from the

field of heating by combusting fuel oils. The advantage of this system is the ease of its handling - the

storage tank does not have to be placed in a special boiler room. As far as the safety is concerned;

the separation of the burner from the fuel storage tank with separated fuel supply between these two

provides a high degree of protection against ignition of fuel outside the combusting appliance. In case

of a fault, the boiler safety thermostat shuts down the power supply into the burner and thus prevents

overheating of the boiler and burner. Moreover, the burner is constructed in a way assuring that it

automatically returns to normal operation mode after power shut-down.

In case that a fault occurs that leads to a burner operation shut-down, such fault is indicated on the

burner display.

• The ignition, combustion and shut-down processes are controlled by a microprocessor logic cir-

cuit with two processors with optical separation of power outputs to 5kV. The first processor

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

8-GB

GB

regulates and controls the burner operation. The second processor checks on the main processor

so that safety operation is assured.

• The second processor monitors potential fault of the conveying screw 1 underneath the rotational

clack-valve. If, for instance, this screw conveys fuel continuously for over 3 minutes (which is

unusual) then it switches the reverse-relay, stops conveying fuel into the rotation combustion

chamber of the burner. The burner burns out and the combustion chamber becomes empty. A

warning sign ERROR MOTOR is indicated and the device waits for the operator‘s interven-

tion.

• The processor continuously checks the flawlessness of the fan operation by means of a feed-back

loop. If, for some reason, the fan does not operate, the processor assures that the pellets are emp-

tied from the rotation combustion chamber of the burner and the burner is shut-down. A warning

sign ERROR AIR is indicated and the device waits for the operator‘s intervention.

• The first processor continuously monitors the level of fuel by means of pellets-level sensor.

• The burner is fitted with a rotational clack-valve which protects it against reversed burn-through

of the fuel. The complete emptying of the burner from fuel at its shut-down protects it against the

same thing.

• At every start, the burner is ready for re-ignition. If the re-ignition fails, the burner is automati-

cally put out of operation and the device waits for the operator‘s intervention. A warning sign

ERROR START is indicated and the device waits for the operator‘s intervention.

• If the device runs out of pellets during combustion, the burner gets shut-down. A warning sign

ERROR PELETS is indicated and the device waits for the operator‘s intervention. (Please al-

ways remember to feed the pellets into the conveyor before each start of the burner)

• The flexible see-through tube connecting the burner with the external conveyor is made of special

material.

5. BURNER, BOILER, FLUE-GAS DUCT AND CHIMNEY MAINTENANCE

Carry out the inspection and maintenance operations in regular intervals based

on the following instructions:

Recommended intervals of ash removal from the boiler as well as the boiler, chimney and flue-gas

duct cleaning operations are described in general terms in the boiler instruction manual and also in this

manual, in the chart on page 43. The exact intervals which your system actually needs shall however be

observed and determined by the user in order to achieve a reliable and safe operation of the boiler and

burner. The burner itself is designed in a way assuring that only minimum maintenance operations are

needed. The frequency of maintenance operations is influenced by the quality and type of burned fuel

and, understandably, by the burner settings.

The maintenance operations may be divided into:

1. Regular cleaning of the rotation combustion chamber with a wire brush is recommended to carry out

at least once a month. When combusting lower-quality fuel during which sticking of ash to the rotation

combustion chamber or clogging of openings for combustion air inlet occur, the recommended cleaning

interval is once a week. Cleaning of the rotation combustion chamber is only permitted after the fuel

has burned out and the rotation combustion chamber has cooled down; i.e. with the control thermostat

switched off and after the TIME STOP and TIME END periods have elapsed. Then press the ESC

button and hold it for several seconds. Thus the burner fan is switched on and the rotation combustion

chamber will keep rotating for the period of two minutes. Use a wire brush, insert it in the rotation com-

bustion chamber and clean it thoroughly from ash and clinker layers. If necessary, repeat the process

until the combustion chamber and openings for combustion air supply are completely clean.

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-9

GB

CAUTION – never clean the rotation combustion chamber with a wire brush if the chamber

does not rotate and if the burner fan does not operate. Otherwise you may clog the openings

for combustion air supply even more and also fill the turbo-chamber with cinder resulting in

damage of the burner.

2. Annual maintenance - it is first necessary to remove the burner from the boiler and to remove the

front guard of the burner. After these removals carry out the following steps:

- Clean all the parts from dust.

- Inspect and lubricate the chain transmissions by thin oil.

- Check the tension of driving chains and adjust their tension by means of tensioning pulleys.

- Check that all the fixing elements (bolts and nuts) are tight and if not, tighten them.

- Inspect the fan.

- Inspect the photocell. If it needs cleaning, clean it.

- Inspect and tighten (if necessary) the vane pellets level sensor.

Then remove the front burner hood (cover) and remove the two round lids on the turbo-chamber and

clean the area behind it. This is the area where the burner rotation combustion chamber with its bear-

ings is located. Always remember to check and if necessary clean the tube placed next to the rotation

combustion chamber through which the photocell monitors the flame. Check also its securing against

turning and against sliding out of the other side of the burner. Also check if the burner rim is tightened

to the turbo-chamber behind which graphite sealing is placed (however, never over-tighten). After

this procedure, place all the parts back to its original positions, seal and tighten all well so that com-

bustion air or waste gas cannot escape into the boiler room.

NOTE – although burning pellets is an automatic process, it requires a little bit more main-

tenance and operating interventions than the process of burning fuel oil or natural gas. It

provides the operator with invaluable experience. Always remember to regularly maintain

and clean the boiler, chimney and flue-gas ducts (once every 14-30 days or as necessary).

Pay particular attention to the pellets quality if it is a new supply or if you receive them

from a new supplier. When handling ashes, always remember that it may be hot. Ash must

be stored in a fire-proof container.

Picture 1. - Inner part of the rotary com-

bustion tube chamber with holes where the

primary and seconadary airs are intaken.

Should be cleaned by steel brush.

Picture 2. - Eye-slit for optical photo sensor

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

10-GB

GB

Picture 3. - The rotary sensor in the feeding

pipe which checks the pellet level

Picture 5. - Actuator of the rotary sensor in

the feeding pipe

Picture 7. - Electronic control board of the

burner

Picture 4. - Control panel of the burner

Picture 8. - Heating element

Picture 6. - Connectors for connecting burn-

er and conveyor

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-11

GB

Picture 9. - Optical sensor placed under the

gear box

Picture 11. - Cleaning lid for annual cleaning

of the air intaking spaces

Picture 13. - Rear chain drive with tightening

machanism. Switcher of the heating element

input.

Picture 10. - Air blowing fan

Picture 12. - Frontal chain drive

Picture 14. - View of construction of the air

intaking space.

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

12-GB

GB

6. BOILER ROOM AND BURNER TO BOILER CONNEC-

TION REQUIREMENTS

NOTE – Before operating the burner for the first time, it is necessary to get thoroughly fa-

miliarised with all the instructions included in this manual and in the boiler manual. At the

same time, it is necessary to comply with all the effective safety regulations regarding works

involving heating appliances. It is permitted to start the appliance only if the burner has

been duly connected to the boiler, the boiler is connected to a chimney through a flue-gas

duct, the chimney has sufficient draught and there are enough pellets in the storage tank.

Requirements on the boiler room, system, burner, conveyor and pellets storage tank before the burner

may be put in operation:

• The installation site must be in a room that complies with all fire prevention regulations (stand-

ards and laws) as effective.

• The installation site must be in a room that is fitted with an opening for intake of combustion air

of minimum cross-section 350 cm2.

• The boiler and burner must be positioned in a way providing enough room for cleaning of the

burner, boiler, flue-gas duct and chimney and of ash removal from all these places.

• The burner must be installed onto the boiler through insulating and sealing material and must be

well tighten by means of nuts so that no waste gas may escape into the boiler room.

• The external screw conveyor must be placed in the storage tank in a way providing easy take-up

of pellets.

• The tube between the burner and conveyor must be stretched, well fastened and of such angle that

assures flawless gravity flow of the pellets into the burner. The tube length shall not exceed 50 cm.

The joints between the tube, burner and conveyor must be well tightened.

• The screw conveyor cable must be plugged in the socket on the burner.

1 - ATMOS A70 Petro pellet burner

2 - Sealing cord 18x32 mm - large

3,4 - Four screws M10x45 mm

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-13

GB

7. ENVIRONMENT TYPE AND BOILER PLACEMENT IN

BOILER ROOM

Boilers with the ATMOS A70 Petro burner may be used in a “basic environment” - AA5/AB5 as spec-

ified in Czech standard ČSN3320001/1995. Boilers must be placed in a boiler room with sufficient

air access necessary for combustion. Placing boilers in living areas (including halls/corridors) is not

permitted. The combustion air inlet aperture into the boiler room for boilers of 30 - 60 kW outputs

must be of minimum 350 cm2.

8. ELECTRICAL CONNECTION

After the burner has been installed on the boiler, a technician connects the burner to the electrical

power network through the boiler; never directly to the network. Use the following wiring diagram.

• After the burner has been installed, a technician connects the device to the boiler with a special

cable which is a part of the burner.

1 - Chimney

2 - Flue duct

3 - Boiler

4 - Burner

5 – Conveyor 1.7 m, 2.3 m and 2.5 m

6 – Storage tank (min. 500-1000 litres)

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

14-GB

GB

• The screw conveyor is connected by means of a special plug and socket and it is controlled by the

burner electronic system according to the signals of the vane pellets-level sensor.

CAUTION – the electrical connection may only be carried out by a duly qualified person

and special care must be paid to safe grounding of the device. For electrical connection

please refer to this manual.

A four-core cable leads from the burner and is connected to the boiler. The colour coding of the cables

is following:

• Black – phase (230V, 50 Hz) – the black conductor is to be connected on the boiler terminal which is

(providing that the main switch is ON) always under voltage, regardless of the boiler‘s control thermo-

stat. This is the burner‘s supply voltage.

• Brown - phase (230V, 50 Hz) - the brown conductor is to be connected on the terminal which is control-

led by the boiler‘s control thermostat. It brings the phase of the same polarity as the polarity of the supply

voltage which activates the burner start-up. It is considered a start-up (ignition) and shut-down signal.

• Blue-N-neutral (zero conductor) – the blue conductor must be connected to the neutral (zero c o n -

ductor)

• Yellow-green PE – Protective Earth – yellow-green conductor must be connected to the earth.

CAUTION – both phases (black and brown leads) must always be protected through the

safety thermostat of the boiler.

9. BOILER WIRING DIAGRAM

1 2 3 4 5 6 7 8 9 10 11 12

LN PE L

MM

LN

D30/45P

HLvyp2

SNvyp2

HNvyp2

SLvyp2

1 24 5

PE LN

R

BU

BL

GY

1

µ

F

poj-Cpoj-1

FUSE 12,5 A

SICHERUNG 12,5 A

POJISTKA 12,5 A

L1

N

L2

AC05-L

AC05-N AC 05

L

N

HLvyp

SNvyp

HNvyp

SLvyp

1 24 5

t

PE

T-C

T-2

T-1

t

PE

PT-1

PT-C

L

N230V/50Hz

A

a+

b-

B

C

D

F

E

H

H

G

A

B

C

D

E

F

G

L

N

t

PE

BT100-L2

BT100-L1

BT100-N1

BT100-N2

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-15

GB

10. BURNER WIRING DIAGRAM from serial number 20

11. CONTROL PANEL

The signs + and – displayed next to the START /

RUN / STOP functions indicate the following:

The first + or - indicates:

Control thermostat on the boiler panel is switched ON (+).

Control thermostat on the boiler panel is switched OFF (-).

The second + or - indicates:

Photocell detects (+) flame.

Photocell does not detect (-) flame.

Real values may be changed by the and buttons. By pressing the ENT button, the program

moves to the following value and so on. By pressing the ESC button, the program returns into the

main menu. Set the particular values according to instructions included further in this manual.

A70 PETRO

L1

N

L

N

M

VENTILATOR ROTANÍ HLADINOMR

DREHTANDMESSER

ROTATE LEVEL INDICATOR

FOTOCELA

FOTOZELLE

OPTICAL SENSOR

L2

ZÁSUVKA - EXTERNÍ PODAVA

STECKDOSE - EXTERNE SCHNECKE

SOCKET - OUTSIDE FEEDER ZASUVKA NAPÁJENÍ

STECKDOSE - SPANNUNG

SOCKET INLET

KONC.SPÍNA - SPAL.KOMRKY

ENDSCHALTER DER BRENNSCHALE

LIMIT SWITCH - FLAME TUBE

PEPÍNA VÝKONU ZAPALOVÁNÍ

UMSCHALTER DER LEISTUNG-ANZÜNDUNG

ALTERNATION SWITCH OF IGNITION POWER

VENTILATOR

FOTOCELA

FOTOZELLE

OPTICAL SENSOR

KONTROLA VENTILÁTORU

VENTILETORKONTROLLE

CONTROL OF VENTILATOR

VSTUPNÍ NAPÁJENÍ

EINGANGSPANNUNG

INLET POWER SUPPLY

OVLÁDACÍ NAPÁJENÍ

STEURSPANNUNG

OPERATING POWER SUPPLY

KONC.SPÍNA - SPAL.KOMRKY

ENDSCHALTER DER BRENNSCHALE

LIMIT SWITCH - FLAME TUBE

ROTANÍ HLADINOMR

DREHTANDMESSER

ROTATE LEVEL INDICATOR

ZAPAL.TLÍSKO

GLÜHSPIRALE

IGNITION ELEMENT

ROTANÍ HLADINOMR

DREHTANDMESSER

ROTATE LEVEL INDICATOR

ZÁSUVKA - EXTERNÍ PODAVA

STECKDOSE - EXTERNE SCHNECKE

SOCKET - OUTSIDE FEEDER

HLAVNÍ MOTOR + REVERSACE

HAUPTMOTOR + RÜCKGANG

MAIN MOTOR + REVERSING

HLAVNÍ MOTOR + REVERSACE

HAUPTMOTOR + RÜCKGANG

MAIN MOTOR + REVERSING

1 2 3 4 5 6

ZAPAL.TLÍSKO

GLÜHSPIRALE

IGNITION ELEMENT

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

16-GB

GB

12. START-UP – OPERATION – SHUT-DOWN

CAUTION – the first burner start up after installation must always be carried out by

a person duly qualified (fitter) and trained by the manufacturer.

NOTE – during the first burning, the surface paint and the graphite sealing of the rotation

combustion chamber get fire-burnt. As a result of this process, smoke and smell form

which however disappear after a few operating hours. This is not a fault.

Boiler and burner operation preparation

Before you start the burner up for the first time, make sure it is well fastened to the boiler in a way pre-

venting the escape of any combustion gas into the boiler room area. Check the position of the external

screw conveyor in the fuel storage tank; its angle should not exceed 45°. Then fill the tank with pellets.

Shorten the tube connecting the external conveyor with the burner to the needed length, tension it and

secure it well. Then proceed to starting up the burner; follow these instructions:

BURNER START-UP

• Switch the main boiler switch ON.

• Set the required outgoing water temperature (80-90°C) on the control thermostat.

• In the first stage, the burner checks the internal level of pellets by means of the vane sensor.

In case that the burner (and the conveyor as well) are without pellets, their automatic feed-in is carried

out. After the burner and conveyor has been filled up with pellets, the burner carries out automatic

ignition.

NOTE – we recommend that you check the state of the vanes (propeller) of the pellet-level

sensor. If the burner has no pellets, the vanes (propeller) rotate and the conveyor is getting

filled-up or is supplying pellets to the burner (the maximum permitted time of continuous

filling-up is 30 minutes). When the burner is filled with pellets, the movement of the vanes

(propeller) is blocked. Then the conveyor stops as well; however, only after the pre-set pe-

riod of FEEDR2 has elapsed.

AUTOMATIC IGNITION – START MODE

As the photocell does not detect any flame, the cylindrical combustion chamber turns automatically

into a position providing ideal access of the hot ignition air to fuel. The internal conveying screw 1

feeds the fuel (amount necessary for ignition) into the rear part of the cylindrical combustion chamber

and the electronic control unit starts-up the ignition device. As soon as the photocell detects flame

and after the pre-set run-out time elapses (characterised by the PHOTOCEL parameter) the burner

switches into normal operation mode RUN.

NOTE – if the ignition of pellets fails during the first attempt, the whole ignition cycle is

automatically repeated. If the second attempt fails as well, the burner displays a warning

sign ERROR START, shuts itself down and waits for the intervention of the operator. The

operator must determine the cause of the fault. E.g.: Is there a sufficient amount of pellets in

the storage tank? Is the external conveyor functional? Is the external conveyor or the rota-

tional clack-valve clogged with some impurity contained in the pellets? Is the pellet—level

sensor propeller blocked by a foreign object contained in the pellets?

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-17

GB

Parameters of the START + - mode

NOTE - The signs + and – displayed next to the START / RUN / STOP functions indicate

the following states: the first + or – indicates that the control thermostat of the boiler panel

is either switched ON (+) or OFF (-), the second + or – indicates that the photocell detects

(+) or does not detect (-) a flame.

AIR START [ 0 - 100%] ideal air quantity necessary for ignition in the burner. It influences the speed

of ignition of the fuel. The factory default setting is 60%. Minimum setting of 50% still assures that

no damage to the ignition element may occur.

TIME PELETS [ 0 - 100 sec] the amount of pellets necessary for ideal fuel ignition. The factory

default setting is 32 sec.

TIME START [ 0 - 100 min] period of time for which the burner attempts to ignite the fuel. If the

first attempt fails, the whole ignition cycle is automatically repeated. In case that the fuel does not

ignite during the second attempt, the burner is shut-down and an error indication ERROR START is

displayed. The factory default setting is 12 minutes.

FEEDR START [ 0 - 100 %] amount of fuel which is supplied by the internal conveying screw 1 into

the rotation combustion chamber in regular intervals during the start-up stage. The factory default

setting is 10 %.

PHOTOCELL [ 0 - 100 sec] the run-out time of the ignition device which starts from the moment

when the photocell detects a flame. The factory default setting is 30 sec.

NORMAL OPERATION

It is a fully automatic operation; the user operations are limited to regular refilling of fuel, ash re-

moval and cleaning the burner. It is not advisable (for the user) to change the main parameters of the

burner settings. Therefore, there are two access levels in the program. The first level is designed for a

common user and it features the basic functions that are fully sufficient for a reliable and comfortable

operation of the burner. The second level is designed for a service technician and is used for setting

the parameters ideal for a particular fuel-type and output. The second level is code-protected.

During normal operation, the following operational indicators are displayed:

RUN + + :

The burner gets into the RUN mode in two situations:

1. After the START and ignition of the burner.

2. After a short-time power cut-out. If in this moment the photocell detects flame, the operator auto-

matically continues operation in the RUN mode.

Within the RUN mode (I.E. during normal operation), we use variable values to set the combustion

process characteristics. For the particular values corresponding to a particular fuel please read the

chart: „Setting the ATMOS A70 PETRO burner“ on page 19.

Real values may be changed by the and buttons. By pressing the ENT button, the program

moves to the following value and so on. By pressing the ESC button, the program returns into the

main menu. Set the particular values according to instructions included further in this manual.

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

18-GB

GB

NOTE - The signs + and – displayed next to the START / RUN / STOP functions indicate

the following states: the first + or – indicates that the control thermostat of the boiler panel

is either switched ON (+) or OFF (-), the second + or – indicates that the photocell detects

(+) or does not detect (-) flame.

Parameters of the RUN mode

AIR RUN [ 0 - 100%] air quantity necessary for good-quality of combustion during operation at the

pre-set burner output. The factory default setting is 80%.

FEEDR RUN [ 0 - 100%] amount of fuel necessary for achieving the required output. The factory

default setting is 26%.

FEEDR2 [ 0 - 100 sec] run-out time of the external dispensing conveyor after the rotational sensor

of the pellets-level in the burner detests sufficient level of fuel in the supply tube (I.E. the rotational

sensor stops moving). The factory default setting is 10 sec.

TUBE RUN [ 0 - 100%] the angle at which the rotation combustion chamber‘s (cylinder‘s) position is

turned in the range up to 360°. This setting influences clinkering of fuel and quality of combustion.

The factory default setting is 10%.

TUBE TIME [ 1 - 40 min] a time period upon which the rotation combustion chamber (cylinder)

regularly slightly turns its position. This setting influences clinkering of fuel and quality of combus-

tion. The factory default setting is 4 minutes.

TIME FEEDR [ 1 - 40 sec] interval of internal fuel dispensing by the conveying screw 1. This setting

influences clinkering of fuel and quality of combustion. The factory default setting is 12 sec.

The burn-off stage (i.e. the STOP mode) progresses in the following way:

If the boiler thermostat which controls the burner operation switches off, the burner automatically

switches into the STOP operation mode. During this mode, the following happens:

1. The dispensing of fuel into the burner by an external conveyer is automatically stopped.

2. The burner switches into the mode of the fuel burn-off (in the rotation combustion chamber)

which is determined by the TIME STOP parameter.

3. After the TIME STOP period has elapsed, the burner automatically switches into the stage of

cooling and cleaning the combustion chamber. The duration of this period is determined by the

TIME END parameter.

4. After this period has elapsed, the burner automatically switches into idle mode and waits for a

new command for start-up and ignition.

CAUTION – it is only this operation state, in which it is permitted to carry out the manual

cleaning procedure of the rotation combustion chamber. Pres the ESC button and hold it for

several seconds. Thus the burner fan is switched on and the rotation combustion chamber

will keep rotating for the period of two minutes.

Real values may be changed by the and buttons. By pressing the ENT button, the program

moves to the following value and so on. By pressing the ESC button, the program returns into the

main menu. Set the particular values according to instructions included further in this manual.

Operation and maintenance manual – Burner A70 Petro

www.atmos.cz GB-19

GB

Parameters of the STOP mode

NOTE - The signs + and – displayed next to the START / RUN / STOP functions indicate

the following states: the first + or – indicates that the control thermostat of the boiler panel

is either switched ON (+) or OFF (-), the second + or – indicates that the photocell detects

(+) or does not detect (-) flame.

AIR STOP [ 0 - 100%] air quantity necessary for ideal fuel burn-off. The factory default setting is 100 %.

TIME STOP [ 0 - 100 min] time necessary for emptying the rotational clack-valve of the internal

conveying screw 1 and ideal combustion of all pellets in the rotation combustion chamber. The fac-

tory default setting is 15 minutes.

TIME END [ 0 - 100 min] time needed for ideal cooling and cleaning of the rotation combustion

chamber. The factory default setting is 15 minutes.

Parameters of the SERVICE mode

It includes data useful for the burner operator and service technician in order to achieve optimal in-

spections and maintenance and cleaning planning.

W. HOURS (hours) number of service hours for which the appliance has been operating.

START COUNT (l) number of ignitions (start-ups) – it influences the service life of the burning element.

CLEANING COUNT (1) number of cleaning cycles during which the rotation combustion chamber

has been cleaned with a wire brush (shall be carried out once a month).

13. SETTING THE BURNER FOR VARIOUS FUEL TYPES

CAUTION – if the burner is used for burning poor-quality fuel or fuel which is not specifi-

cally stated in the following charts, the manufacturer bears no liability for any damage of

the boiler, burner, flue-gas duct or chimney. The burner is not suitable for burning coal,

grain, corn or maize.

Setting of these parameters influences combustion quality and service life of the boiler and

burner. Always remember that biological fuels contain large amount of carbon and chlorine

which significantly reduce the boiler (drum) and burner service life compared to burning fuel

composed of wood-substance. Therefore, the burner output must always be set in a way assur-

ing that the waste gas temperature during operation never drops below 130°C. This prevents

condensation of water vapour and acids which damage the boiler drum.

In case that you will be combusting alternative pellets made from rape straw, poppy straw, sugar-beet

cuttings and peat, install the boiler in combination with an automatic ash removal system ATMOS.

Real values may be changed by the and buttons. By pressing the ENT button, the program

moves to the following value and so on. By pressing the ESC button, the program returns into the

main menu. Set the particular values according to instructions included further in this manual.

www.atmos.cz

Operation and maintenance manual – Burner A70 Petro

20-GB

GB

NOTE – burner setting is done by adjustment of parameters and amount of combustion air

based on the particular conditions and requirements of the client and on the pellets type. The

setting is carried out by a person trained by the manufacturer (service technician) and utilis-

ing a waste gas analyser. This professionally done setting is a necessary pre-condition

of justifying a guarantee claim and a record of it must be made in this manual on page

45. Set the O2 content in the waste gas within the range of 7 to 10% and amount of CO

up to a maximum of 800mg/m3.

Recommended settings for particular fuel types and outputs. Information on the

cleaning intervals.

Wood pellets

Burner

output

AIR

RUN

(%)

FEEDR

RUN

(%)

TUBE

TIME

(min)

TUBE

RUN

(%)

TIME

FEEDR

(s)

Recom-

mended

content of

O2 in waste

gas (%)

35 kW 50 17 4 10 12 9-10

48 kW 80 26 5 10 12 7-8

60 kW 95 33 6 10 12 7-8

When burning this type of fuel, soft ash without agglomerates forms.

The interval of ash removal without the automatic removal system – once every 5 to 14 days.

Boiler cleaning interval – once every 14 to 30 days.

Chimney and flue-gas duct inspection interval or (if necessary) interval of chimney and flue-gas duct

cleaning – once to twice a year.

Rape straw pellets

Burner

output

AIR

RUN

(%)

FEEDR

RUN

(%)

TUBE

TIME

(min)

TUBE

RUN

(%)

TIME

FEEDR

(s)

Recom-

mended

content of

O2 in waste

gas (%)

35 kW 55 20 3,5 60 8 8-10

48 kW 87 30 3,5 60 8 8-10

60 kW 100 38 3,5 60 8 8-10

When burning this type of fuel, soft ash with small soft agglomerates forms.

The interval of ash removal without the automatic removal system – once every 1 to 3 days.

Boiler cleaning interval – once every 7 to 14 days.

Chimney and flue-gas duct inspection interval or (if necessary) interval of chimney and flue-gas duct

cleaning –three to five times a year.

Table of contents

Other Atmos Burner manuals

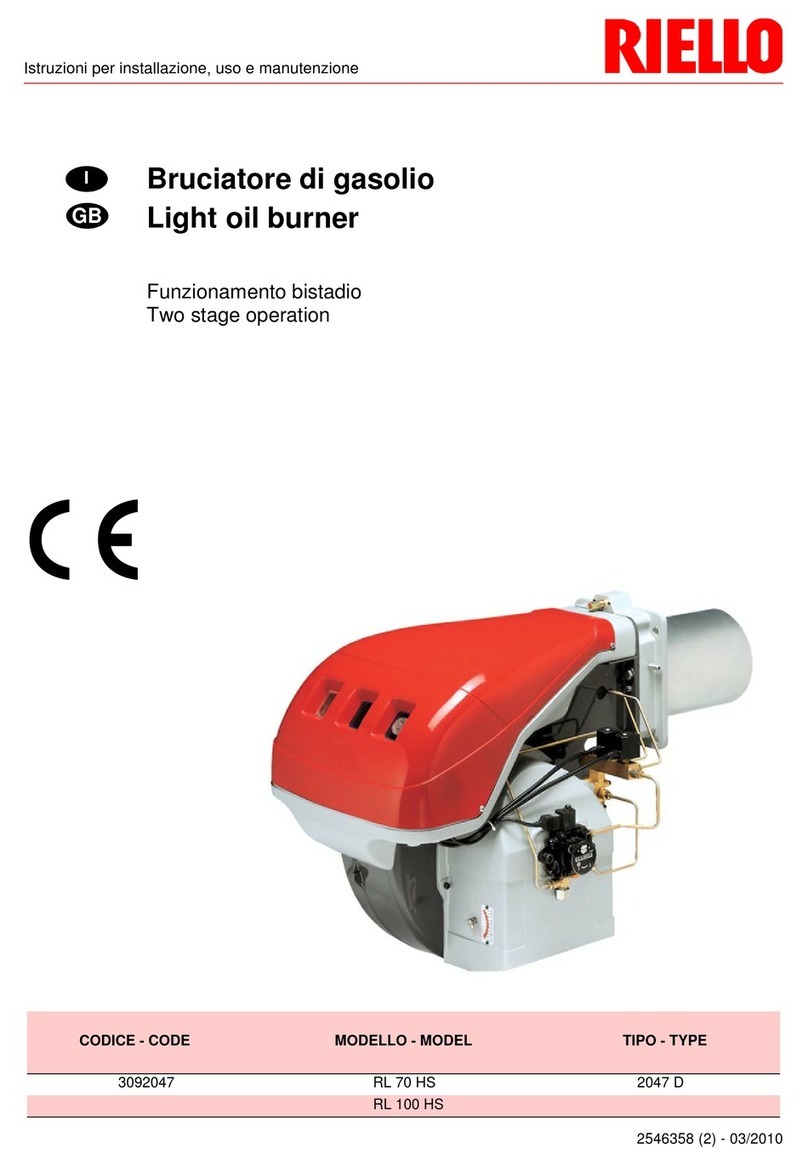

Popular Burner manuals by other brands

Napoleon

Napoleon B35NTL Installation and operating instructions

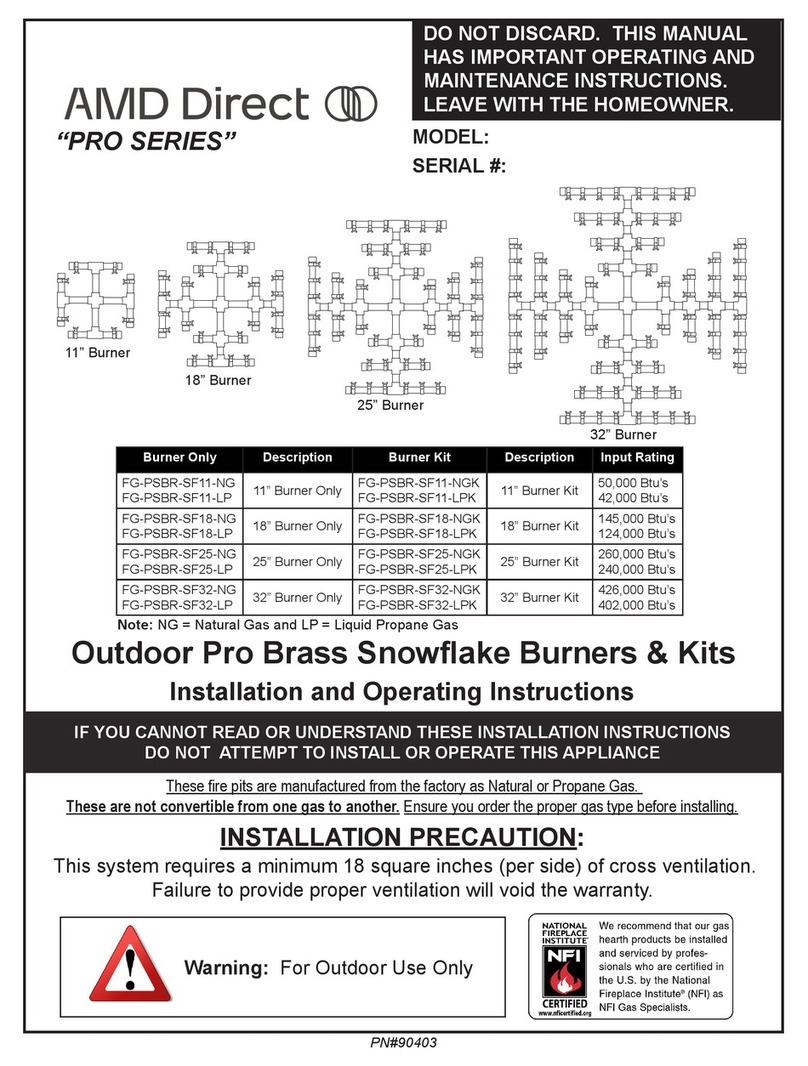

AMD DIrect

AMD DIrect Pro Series manual

Riello Burners

Riello Burners RLS 300/BP MX Installation, use and maintenance instructions

Coyote

Coyote C1CSBNG Use & care manual

GAS ONE

GAS ONE GS-3400P user manual

Art Fireplace Technology

Art Fireplace Technology AF150 manual

Nu-Way

Nu-Way ST 40 Installation & maintenance manual

Riello

Riello RLS 810/E FGR Installation, use and maintenance instructions

Eclipse

Eclipse ExtensoJet EJ025 installation guide

Ecoflam

Ecoflam MULTIFLAM 500.1 PRE manual

Riello Burners

Riello Burners PRESS 100 N Installation, use and maintenance instructions

Cuenod

Cuenod C24 H101 Technical data