16

Start Up Burner/Set

Combustion

Explosion and Fire Hazard

Failure to follow these instructions could

lead to equipment malfunction and result

in heavy smoke emission, soot-up, hot

gas puff-back, fire and asphyxiation

hazards.

Do not attempt to start the burner when excess oil

has accumulated in the appliance, the appliance is

full of vapor, or when the combustion chamber is

very hot.

Do not attempt to re-establish flame with the burner

running if the flame becomes extinguished during

start-up, venting, or adjustment.

Vapor-Filled Appliance: Allow the unit to cool off

and all vapors to dissipate before attempting another

start.

Oil-Flooded Appliance: Shut off the electrical

power and the oil supply to the burner and then clear

all accumulated oil before continuing.

If the condition still appears unsafe, contact the Fire

Department. Carefully follow their directions.

Keep a fire extinguisher nearby and ready for use.

y

y

y

y

y

y

partially open air shutter. This is an initial air setting

for the pump bleeding procedure only. Additional

adjustments must be made with instruments to prevent

smoke and carbon monoxide generation.

Set the thermostat substantially above room

temperature.

Close the line voltage switch to start the burner. If the

burner does not start immediately you may have to

reset the safety switch of the burner primary control.

Bleed air from fuel unit as soon as burner motor starts

rotating.

To bleed the fuel unit, attach a clear plastic hose

over the vent fitting. Loosen the fitting and catch the

oil in an empty container. Tighten the fitting when all

air has been purged from the oil supply system.

If the burner locks out on safety during bleeding,

reset the safety switch and complete the bleeding

procedure. Note — Electronic safety switches can

be reset immediately; others may require a three- to

five-minute wait.

If burner stops after flame is established, additional

bleeding is probably required. Repeat the bleeding

procedure until the pump is primed and a flame is

established when the vent fitting is closed.

For R7184 primary controls, see Technician’s Quick

Reference Guide, part number 61351 for special

pump priming sequence.

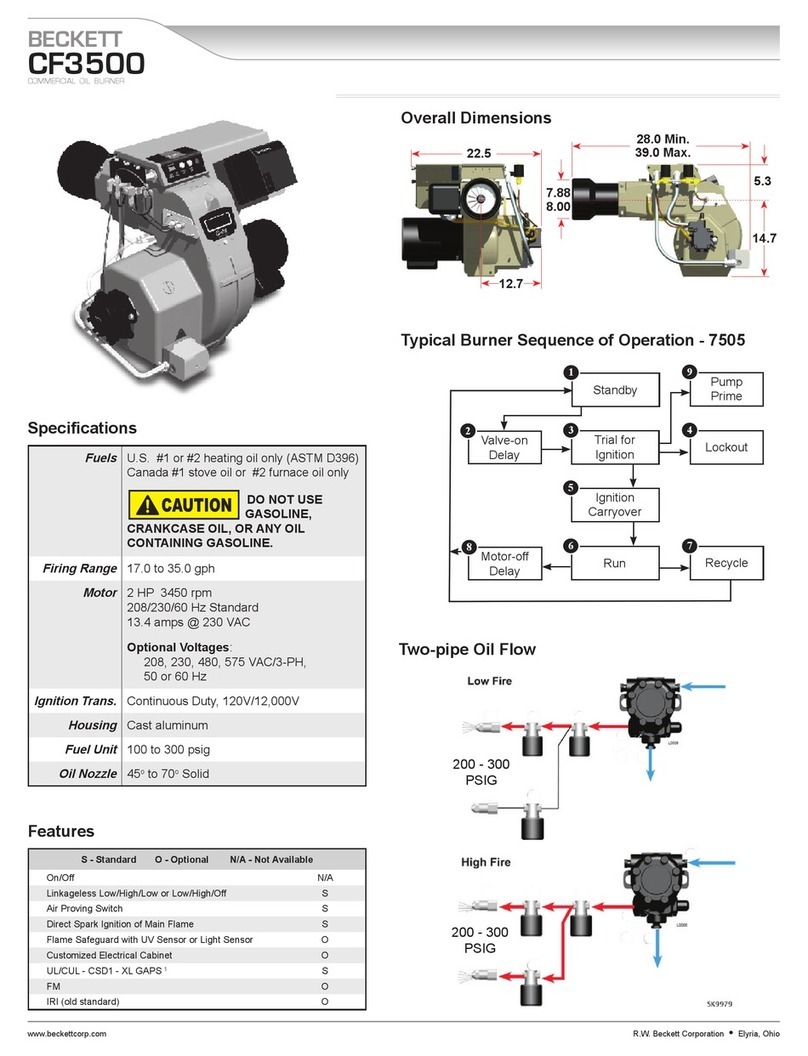

For 7505 primary controls, see Technician’s Quick

Reference Guide, part number 61666 for special

pump priming sequence.

Prepare for combustion tests by drilling a ¼”

sampling hole in the flue pipe between the appliance

and the barometric draft regulator.

Initial air adjustment — Test the flue gas for smoke.

Adjust the air shutter (and air band, if necessary) to

obtain a clean flame. Now the additional combustion

tests with instruments can be made.

Cad Cell Resistance Measurement

If the Beckett 7505 control is equipped with the

GeniSys Display Module, part 52067U, the cad cell

resistance can be selected and read on the LCD

screen. Also, the GeniSys Contractor Tool, part

52082U, can be used for this purpose.

If these are not available, the cad cell leads can

be unplugged from the control and the resistance

measured with a meter in the conventional way.

Conduct these tests with flame present.

Flame Detection Range

Normal = 0 to 1600 ohms

Limited = 1600 ohms to lockout

Resetting From Restricted or Hard Lockout

If the control continues to lockout without a satisfied

call for heat, or fails the motor relay check, the control

3.

4.

5.

○

○

○

○

○

○

6.

○

○

○

Section: Start-up Burner/Set Combustion

Wire Burner

Some Thermostats Are Polarity

Sensitive. Reversed polarity

could cause erratic cycling of the burner control.

Connect the wire from the RHor R terminal on the

thermostat to the TR terminal on the control. Connect

the wire from the W terminal on the thermostat to the TW

terminal on the control.

Make connections to the control’s terminals as

shown in Figures 9a and 9b. Refer to the label on

the underside of the control for wiring details.

Note: Motor-off delay on a 7505P will be disabled if

the safety and operating limits as shown in Figures

9a and 9b interrupt power to the control terminal L1.

Connect thermostat leads to the TR and TW

terminals on the control or jumper the TR and TW

terminals on the control, as directed by the appliance

wiring diagram.

- Thermostat anticipator Current: 0.1 amp

- Thermostat voltage: 24 volts AC

Note that if the thermostat short cycles or operates

improperly, it may require an isolation relay for proper

operation. The Beckett A/C Ready Kit (part no. 51950U)

provides this function. Wiring instructions are included with

the A/C Ready Kit.

○

○

○

Open the shutoff valves in the oil supply line to the

burner.

If the air control is not preset, close air band and

1.

2.