User Manual AM2011

- 6 -

- . -

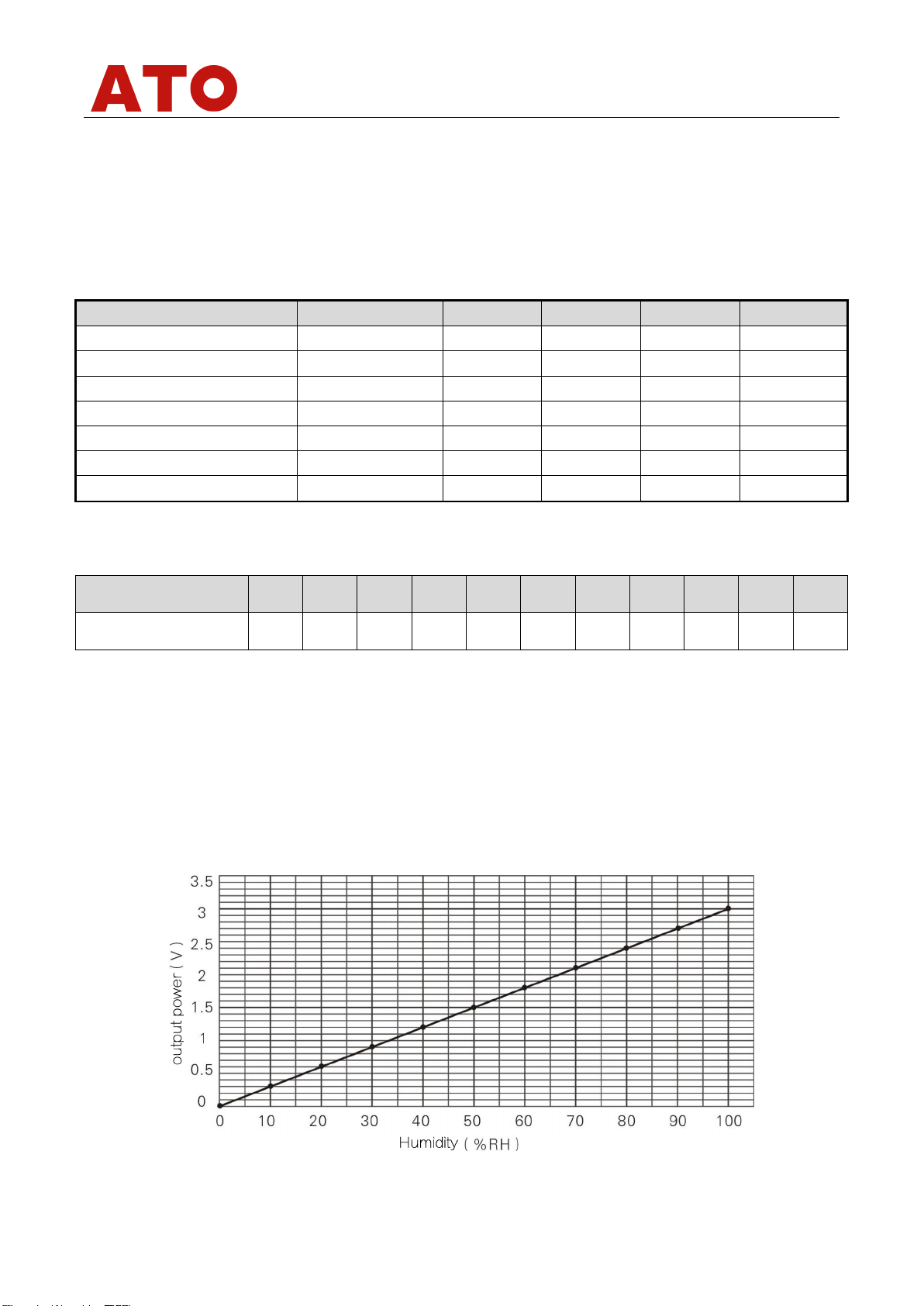

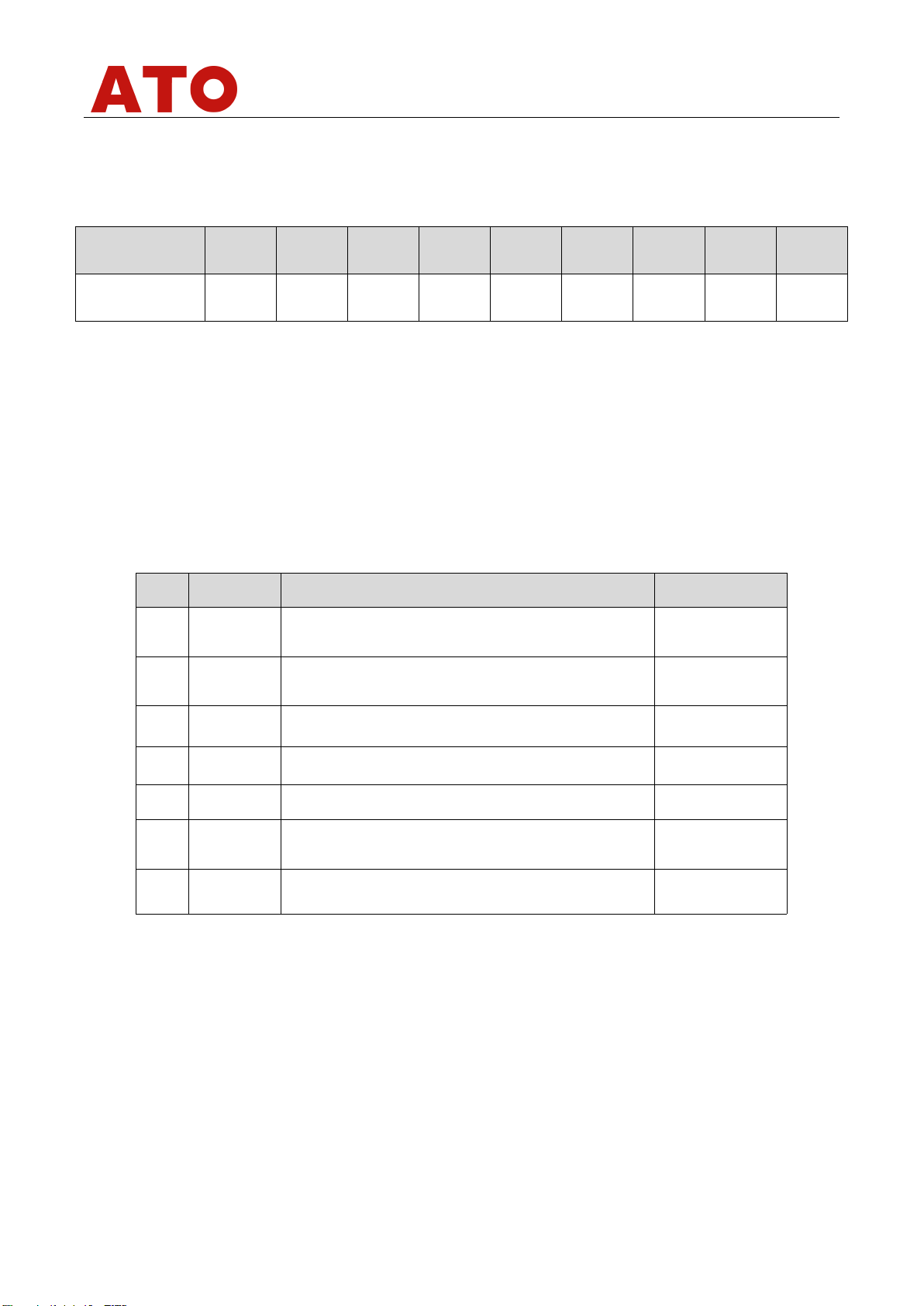

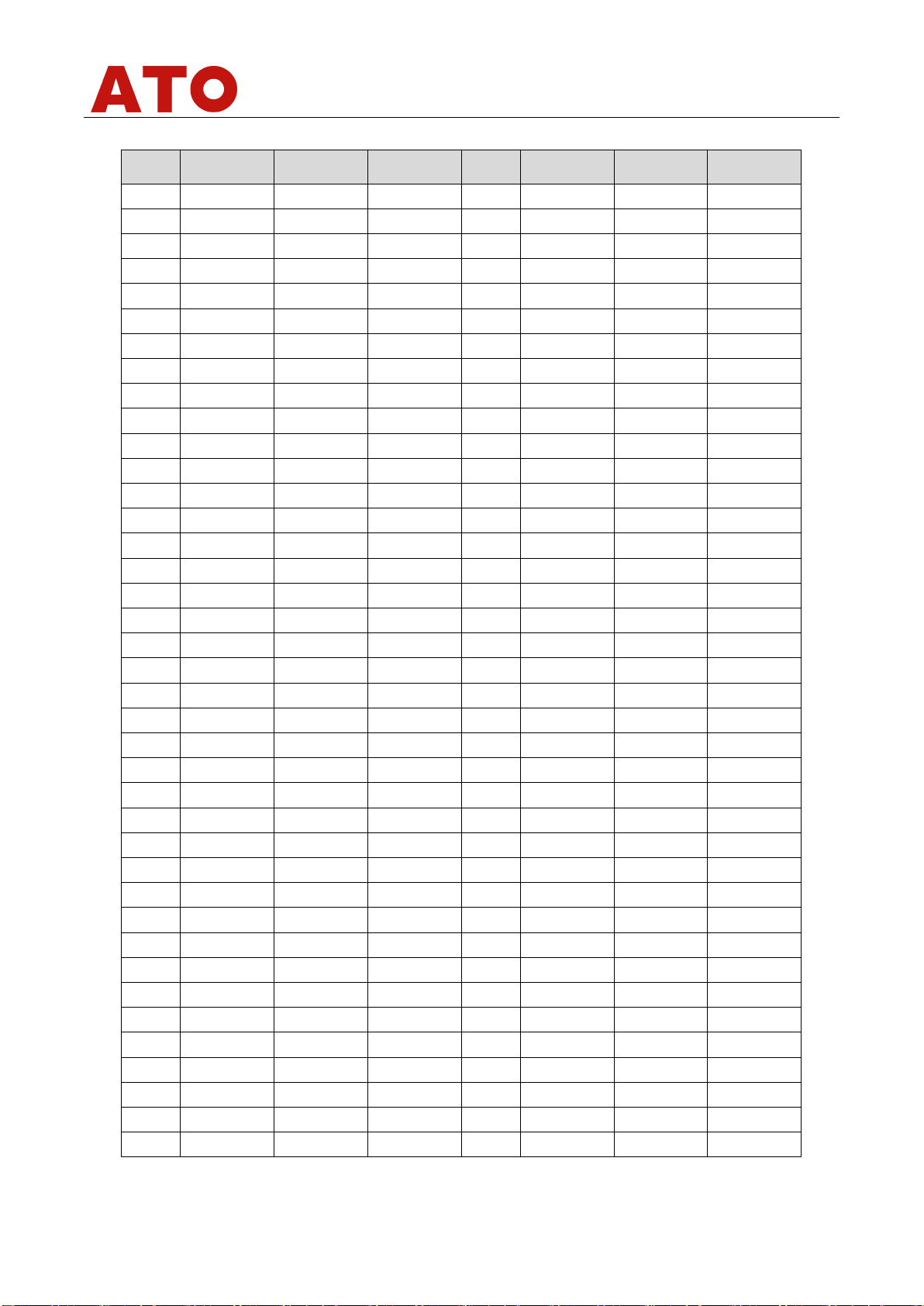

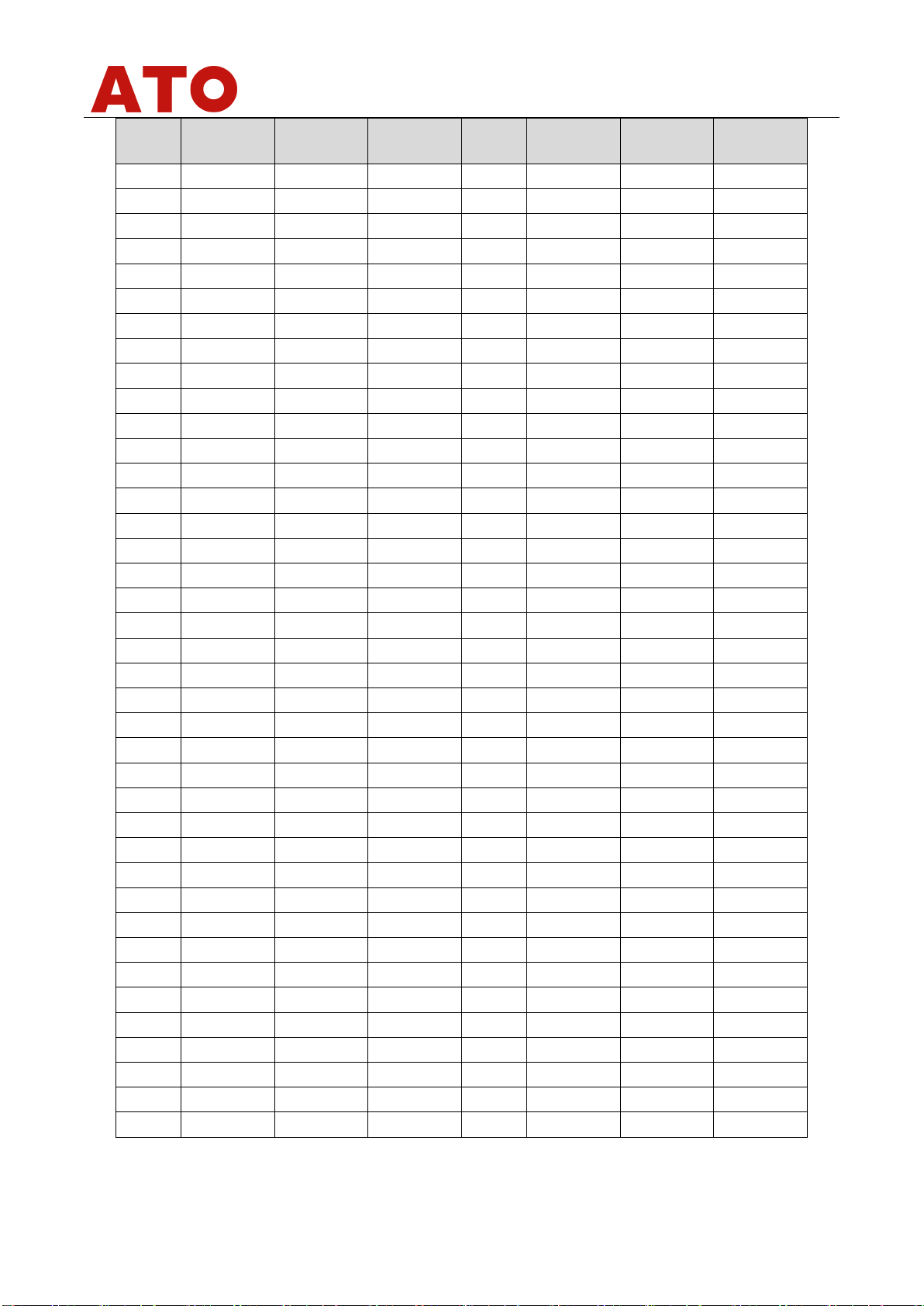

Attached table NTC 10K resistance-temperature characteristic table

T(℃) RMin(KΩ) RNor(KΩ) RMax(KΩ) T(℃) RMin(KΩ) RNor(KΩ) RMax(KΩ)

-40 218.9971 228.2376 237.8441 -1 28.9630 29.5745 30.1959

-39 206.2948 214.8696 223.7783 0 27.6951 28.2671 28.8480

-38 194.4226 202.3826 210.6475 1 26.4908 27.0257 27.5687

-37 183.3204 190.7126 198.3831 2 25.3463 25.8466 26.3542

-36 172.9331 179.8005 186.9219 3 24.2585 24.7264 25.2008

-35 163.2098 169.5919 176.2059 4 23.2242 23.6617 24.1051

-34 154.1034 160.0366 166.1815 5 22.2404 22.6495 23.0638

-33 145.5707 151.0884 156.7995 6 21.3044 21.6869 22.0739

-32 137.5716 142.7046 148.0144 7 20.4136 20.7711 21.1327

-31 130.0693 134.8459 139.7840 8 19.5655 19.8996 20.2373

-30 123.0294 127.4759 132.0698 9 18.7578 19.0700 19.3854

-29 116.4204 120.5608 124.8359 10 17.9884 18.2801 18.5746

-28 110.2132 114.0696 118.0492 11 17.2553 17.5276 17.8025

-27 104.3805 107.9735 111.6791 12 16.5564 16.8108 17.0673

-26 98.8973 102.2459 105.6972 13 15.8901 16.1275 16.3668

-25 93.7405 96.8620 100.0775 14 15.2547 15.4762 15.6994

-24 88.8883 91.7990 94.7955 15 14.6484 14.8550 15.0631

-23 84.3209 87.0357 89.8288 16 14.0699 14.2625 14.4564

-22 80.0197 82.5523 85.1565 17 13.5176 13.6972 13.8778

-21 75.9675 78.3306 80.7593 18 12.9903 13.1576 13.3257

-20 72.1481 74.3538 76.6191 19 12.4867 12.6425 12.7989

-19 68.5468 70.6058 72.7194 20 12.0056 12.1505 12.2960

-18 65.1498 67.0723 69.0446 21 11.5459 11.6806 11.8158

-17 61.9440 63.7394 65.5803 22 11.1064 11.2316 11.3571

-16 58.9176 60.5946 62.3132 23 10.6862 10.8025 10.9190

-15 56.0594 57.6261 59.2307 24 10.2844 10.3923 10.5002

-14 53.3589 54.8228 56.3212 25 9.9000 10.0000 10.1000

-13 50.8065 52.1745 53.5741 26 9.5249 9.6248 9.7248

-12 48.3931 49.6717 50.9791 27 9.1662 9.2658 9.3656

-11 46.1103 47.3056 48.5269 28 8.8230 8.9223 9.0218

-10 43.9502 45.0676 46.2088 29 8.4946 8.5934 8.6925

-9 41.9055 42.9503 44.0166 30 8.1803 8.2786 8.3772

-8 39.9693 40.9462 41.9428 31 7.8794 7.9770 8.0750

-7 38.1351 39.0487 39.9801 32 7.5913 7.6882 7.7855

-6 36.3970 37.2514 38.1219 33 7.3153 7.4114 7.5080

-5 34.7494 35.5484 36.3621 34 7.0509 7.1461 7.2419

-4 33.1869 33.9342 34.6949 35 6.7976 6.8919 6.9867

-3 31.7047 32.4037 33.1148 36 6.5547 6.6480 6.7420

-2 30.2982 30.9520 31.6167 37 6.3219 6.4142 6.5072