SAFETY PRECAUTIONS

3

As with any power tool, the

use of any rotating tiller may

be dangerous. It is important

that you read, fully understand, and observe the

following safety precautions and warnings. Re-read

this operator’s manual and the safety instructions

periodically. Read and understand all labels attached

to tiller.

!WARNING

Do not lend, rent or sell this

machine without the

operator’s manual. Be

sure that anyone using this unit understands the

information contained in this manual before use.

!WARNING

As with any power tool,

some special safety pre-

cautions must be observed to

reduce the risk of personal injury. Careless or improper

use may cause serious or even fatal injury.

!WARNING

Safe use of an Atom Garden Tiller involves:

1. The Operator.

2. The Atom Tiller.

3. The use of the Atom Tiller.

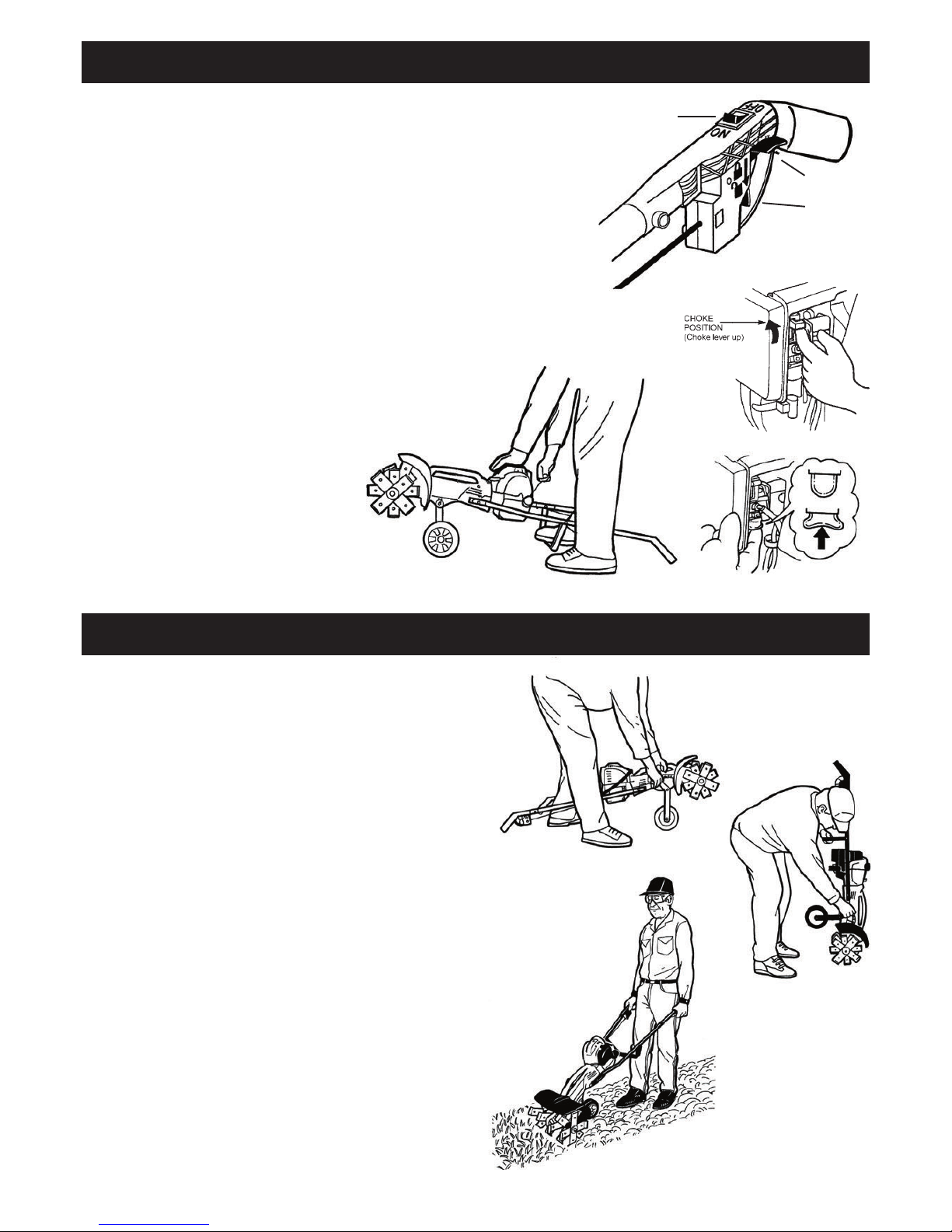

THE OPERATOR

PHYSICAL CONDITION

Operator must be in good physical

condition and mental health, and not

under the influence of any substance

(drugs, alcohol, etc.) which might impair

vision, dexterity or judgement (Fig.3).

This Tiller

must not be

operated by

minors. Bystanders, especially children

and animals should not be allowed in

this area where a machine is in use at

least 15 metres (50 feet) away (Fig. 4).

Never let the unit run unattended.

!WARNING

Electrical shock. Never

touch electrical wires or

components while the engine

is running. They are sources of high voltage and can

give you an electrical shock. Replace immediately

any faulty tension lead or spark plug cap.

!WARNING

Prolonged use of any hand-

held powered machine

exposing the operator

to vibrations may produce whitefinger disease

(Raynaud’s phenomenon or carpal tunnel syndrome.

These conditions reduce the hand’s ability to feel

and regulate temperature, produce numbness and

burning sensations, and may cause nerve and

circulation damage and tissue necrosis. Extensive

hours of continuous use is not recommended.

!WARNING

Do not operate the Tiller when fatigued. Be alert – if you get

tired while operating the machine, take a break. Tiredness

may result in loss of control. Working with any power tool

can be strenuous. If you have any condition that might be

aggravated by strenuous work, check with your doctor

before operating the machine.

Proper eye protection is a

must. The tine cover may

not protect the operator

from all moving foreign objects, even though the

discharge is directed away from the operator, as

ricochets and bouncebacks may occur during

cultivating operations. Never operate an Atom Tiller

unless wearing goggles or properly fitting safety

glasses with adequate front and side protection

which comply with ANSI Z 87.1.

!WARNING

Gasoline is an extremely

flammable and

explosive fuel.

Use extreme caution when handling

gasoline. Do not smoke or bring any fire

or flame near the fuel (Fig. 6).

!WARNING

Always allow engine to cool

before refueling. Accidental

spillage of gasoline over hot

engine could cause fire or explosion to occur with

consequent possible disfigurement or fatal injury.

Wash and clean hands after fueling.

!WARNING

Replace immediately broken or cracked tine covers.

Engine noise may damage your hearing. Wear sound barriers

(ear plugs or ear mufflers) to protect your hearing. Continual and

regular users should have their hearing checked regularly.

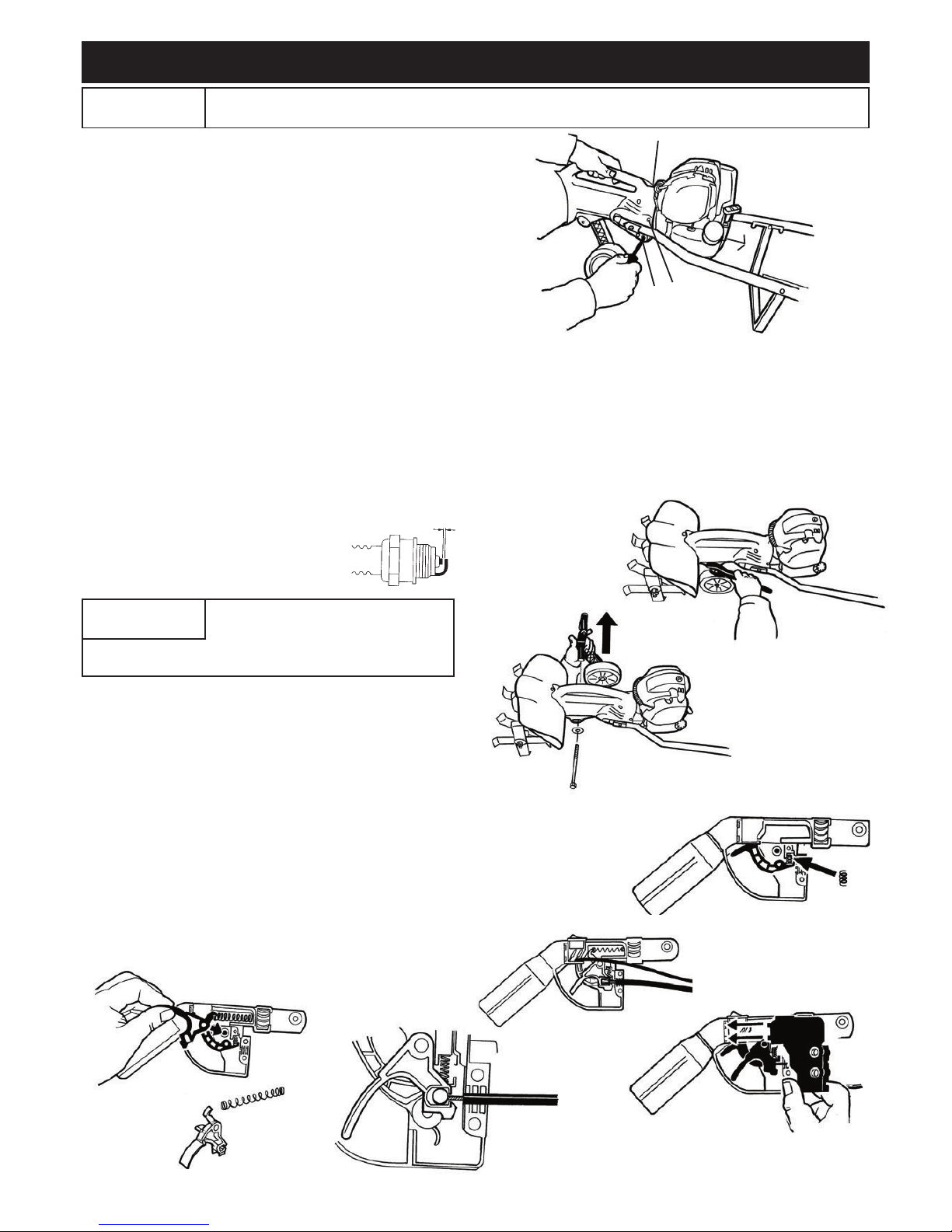

SAFE FUELING INSTRUCTIONS

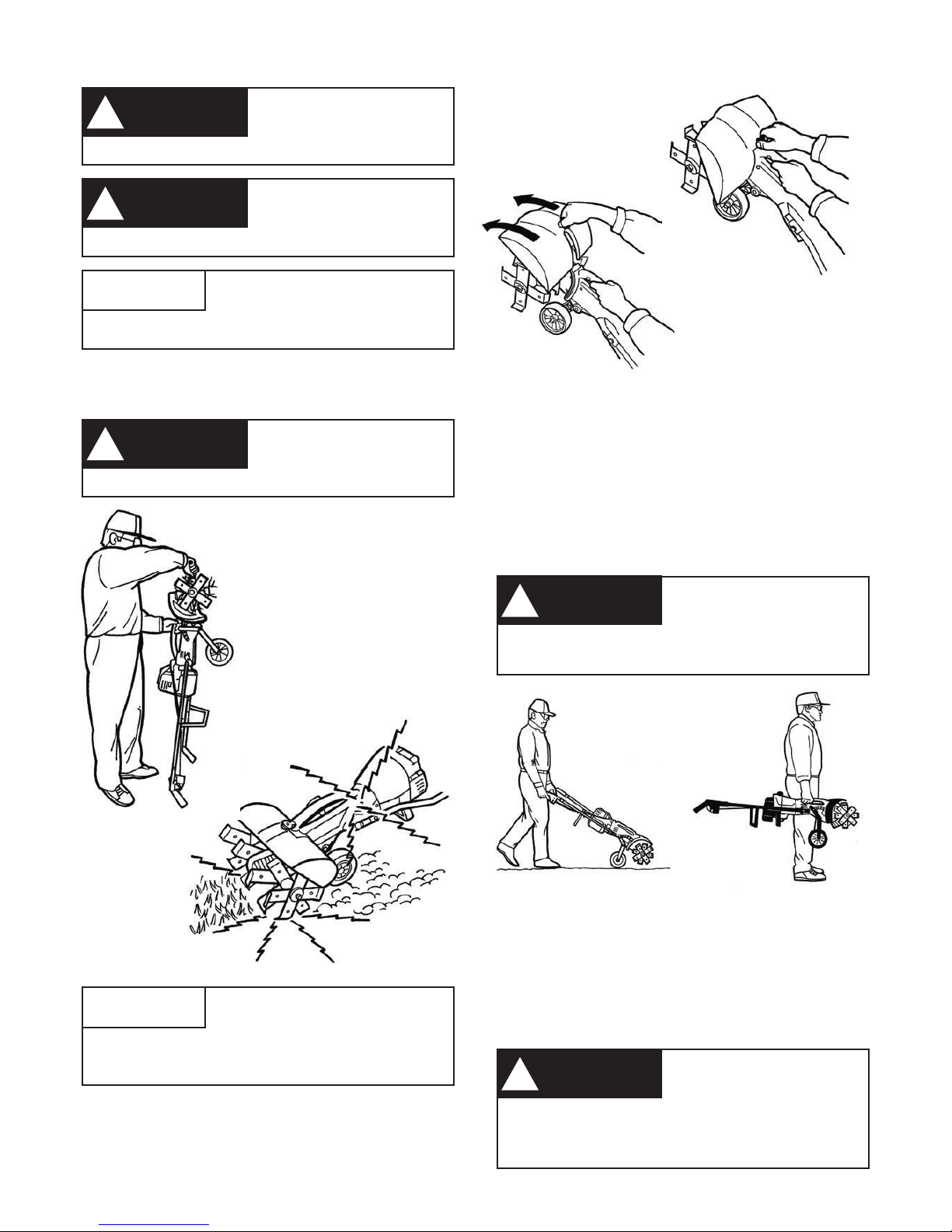

PROPER CLOTHING

Clothing must be sturdy and snug-fitting, but allow complete

freedom of movement (see Fig. 5). Avoid loose-fitting

jackets, flared or cuffed pants, or anything that could trip

the operator. Wear overalls or long pants to protect your

legs. DO NOT wear shorts. Use of gloves when working

with the Tiller is recommended.

Good footing is most important. Wear

sturdy shoes with nonslip soles. DO

NOT wear sandals or operate with bare

feet. In hot or sunny

conditions, always

wear a hat and

long sleeve shirt for

protection against

skin cancers. Use

of good brand of

sunscreen cream is

also recommended

on exposed skin

surfaces.

Refuel outdoors only. Always switch off the engine

and allow it to cool before refueling. Relieve fuel tank

pressure by loosening fuel cap slowly. Never remove

fuel filler cap while engine is running.

Select bare ground for fueling, then move at least 3 metres

(10 feet) from the fueling spot before starting the engine.

Wipe off any spilled fuel before starting your Atom Tiller and

check for leakeage. Always use a funel to fill the tank.

Always tighten fuel filler cap securely after fueling.

FIG 3

FIG 4

FIG 5