●Warranty standard

- In case of malfunctioning under normal operation within one year from the

date of purchase, the machine will be repaired free of charge.

●Product Replacement

- Products within one year from the date of purchase, with following conditions

· Malfunctioning under normal operation. Repaired but when the same

failure recurred.

· When repair is not possible

· If some critical parts need repairs

●Non-warranty standard

· Malfunctioning due to user’s mistakes

· User negligence

· Natural disasters (Fire, salt damage, flood, earthquake, lightning, etc.)

· User’s carelessness

·

If the product is not repaired at our service center, then an error has occurred

· If the product is arbitrarily disassembled or modified

· Malfunctioning due to the abnormal power supply or any other device

· If used beyond its intended purpose

· In case of consumable parts

· In case there is no name plate

· In case of using material flammable or which can deform the product

□Warranty Standards

Please check the followings before calling the repair center.

When the machine is not working

●Check if the power cord is plugged in.

●Check if the electricity is connected to the electrical outlet.

●Check if the voltage is 220V.

●Check the fuse.

●

If the machine is not working even after the fuse is replaced, contact your

nearest dealer or the company.

●

If the suction hose inside the tank is clogged, remove the foreign substances.

●

Please note that heat is generated in the main body even during normal

operation.

●

If, during operation, some parts are deformed due to heat, please contact

the repair center.

In order to prevent accidents during operation, please read the user’s guide

before use.

●Please use the electricity equipped with the grounded circuit breaker.

●

Do not use when the power line is wet. Do not touch the cord with wet hands.

●

Do not apply more than one plug in one electrical outlet.

●

Check the status of the power line before operation. If damaged, call the

certified technician for replacing the cord.

●

Always pull the plug out of the electrical outlet when the machine is disassembled

or not operated.

●

Disconnect power while the tank is charged.

●

When the machine is wet, never plug in the power. Let the wet parts replaced

by a certified technician.

●For the additional cable, use the proper one equipped with ground connection.

●

Do not let somebody operate the machine without wearing the proper

protective equipment.

●

Do not spray toward humans, electric appliances, and the main body.

●

Keep away from children or unauthorized persons.

●

Always use the manufacturer-recommended parts for safety of the machine.

●

To prevent damage to the objects, keep a proper distance when sprayed

with its maximum.

●Be careful of fire and shock.

●

Do not use water mixed with impurities, or flammable materials.

●

If there is unusual noise, smell or smoke in the machine, unplug immediately

and contact the A/S service center(There is a risk of fire or electric shock).

●

When cleaning the machine, unplug first, and do not use water or detergent.

●

Make sure to clean the tank after use, and keep away from children.

●

Keep the machine in a dry place away from the direct sunlight at 10~40℃.

□Before Contacting the Repair Center

□Precautions for use and storage

□Storage Precautions

●Chemicals

1. Considering the proper usage recommended by the supplier, plants and

working conditions, apply the chemicals.

2. In order to minimize the damage of the chemicals, the workers should wear

protective equipment like a gas mask.

●Power line

1. It is convenient to have an additional power line of 150~200 meters

connected firmly to the main body according to working conditions.

2. For the additional power line, hire 250V/15A/3C(Earth) or higher.

3. Always be careful of the electric accidents as the work is usually done in

humid surroundings.

□Tip for users

● By spraying the ultra-fine particles, it is applied evenly to the entire object

due to the long suspension time and rotary atomization effect.

● Rather than smoke or fume, the ultra-fine particles of the solution is sprayed

through the high speed rotating nozzle.

● Consumption of solution is minimized while pest or diseases control effect is

maximized due to the spray system of the ultra-fine particles.

●It relieves the fatigue of wrists by moving the injection nozzle up and down.

●The built-in design of the injection nozzle makes its storage easy.

●The speed, distance, and amount of spray is simply controllable.

● It can be used for fumigation and sterilization in large buildings, offices,

toilets, public buildings, and hospitals.

□Features

Warranty Complaints type

Compensation details

Within the warranty

period After the warranty

period

In case of

malfunctioning

under

normal operation

Asking repair after purchase Repair free of charge Repair free of charge

Same failure recurred

(three times) Product replacement Non-warranty

Repair is not possible even

when parts are available Product replacement -

If repairs necessary on critical

parts after purchase Product replacement -

Malfunctioning

due to

user’s mistakes

When repair possible Charged repair Charged repair

When repair impossible

Charged replacement

-

▒ The Company is not responsible for accidents caused by customer’s mistakes.

▒ This guide is subject to change without a prior notice. Please check at the time of

purchase.

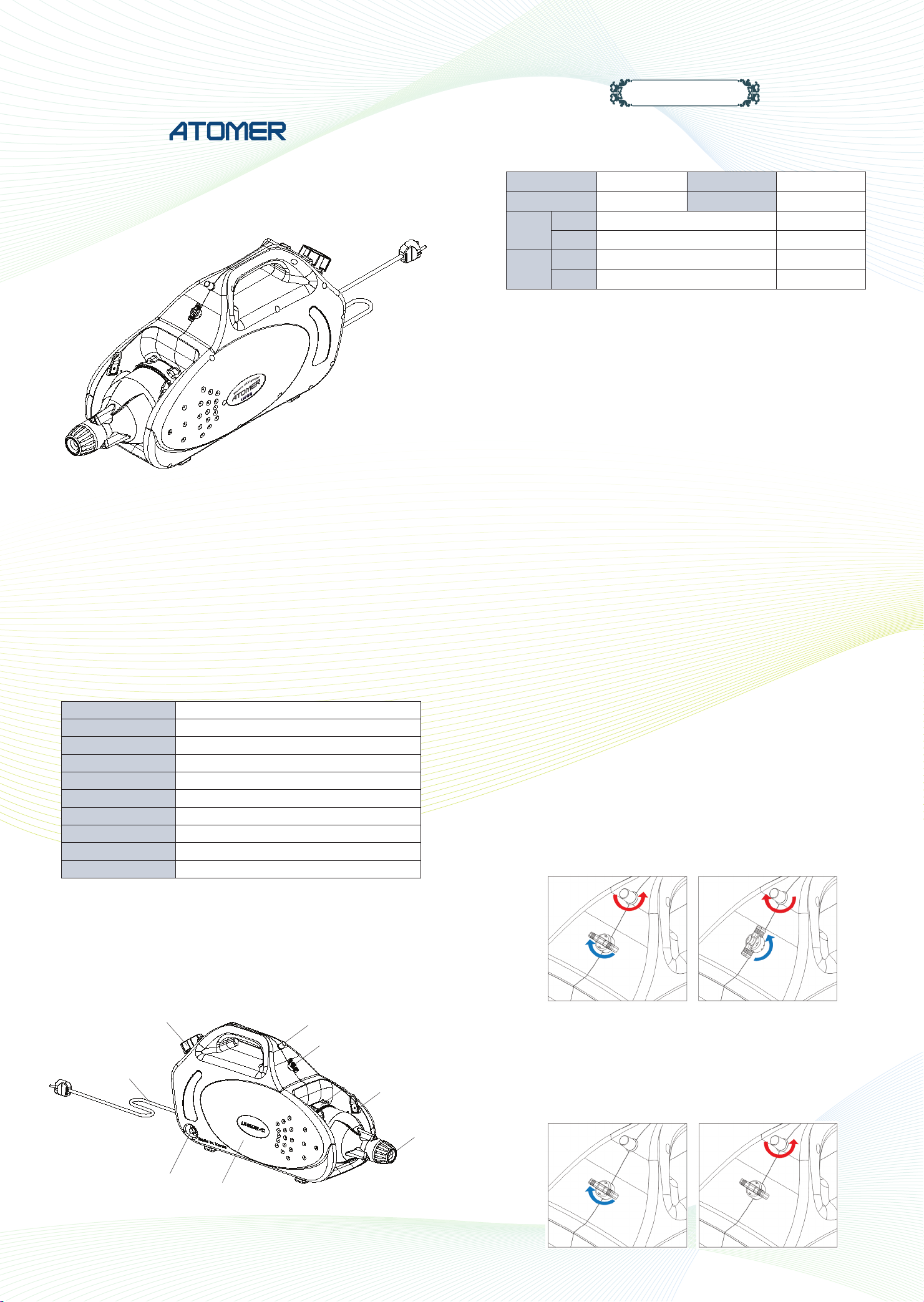

□Part Drawing

□Parts List

Module Name

No Part-Name Spec. CODE-NO Q’TY

Body set

1Cover_L APN-001 1

2Cover_R APN-002 1

4Cover case_L APN-004 1

5Cover case_R APN-005 1

8Rack APN-008 8

28 Spring 8-20 APN-028 8

39

Shoulder strap ring

APN-039 2

24 Shoulder strap pin APN-024 1

Motor housing

set

3Motor housing APN-003 1

6

Motor housing cover

APN-006 1

31 O-ring G-120 APN-031 1

Motor 13 Motor 1.4kW APN-013 1

Tank set

9Tank APN-009 1

22 Water nipple APN-022 1

23 Air nipple APN-023 1

32 O-ring G-45 APN-032 1

33 O-ring P7 APN-033 1

34 O-ring P10 APN-034 1

36 Flange nut M8 APN-036 1

37 Flange nut M10 APN-037 1

Module Name

No Part-Name Spec. CODE-NO Q’TY

Tank cap 7Tank cap APN-007 1

35 O-ring AN325 APN-035 1

Valve 10 Valve 1/4“APN-010 1

Switch 11 Switch 100k APN-011 1

12 Knob Red APN-012 1

Air nozzle 14 Air nozzle APN-014 1

Nozzle set

15 Bel cup APN-015 1

16 Bear housing APN-016 1

17 Turbine APN-017 1

18 Gasket APN-018 1

19 Bearing bush APN-019 1

20 Shaft APN-020 1

21 Tube APN-021 1

25 Bearing S6901ZZ APN-025 1

Fuse set 26 Fuse 5*20 10A APN-026 1

27 Fuse holder 5*20 APN-027 1

PCB 29 PCB

220V, 1.4kW

APN-029 1

Power code 30 Power code 10A 6m APN-030 1

Shoulder

strap 38 Shoulder strap APN-038 1