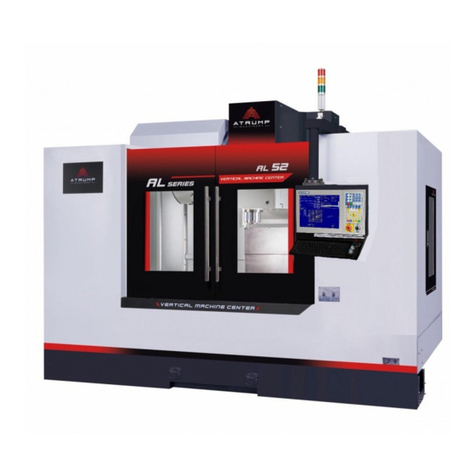

Atrump KL Series Installation and operation manual

鼻

ATRMP

MAC HIN ERY

KL 洹匣

Operator's Manual

& Parts List

Content

1

SAFETY INSTRUCTIONS …………………………………………………..……….

P

1-1

1.1

General safety instructions for operating the machine ……………………………

P

1-2

1.1.1

Safety instructions for work holding ………………………………………….

P

1-4

1.2

Maintenance safety instruction ………………………………………………………………

P

1-6

1.3

Installation precautions ………………………………………………………………………...

P

1-6

1.3.1

Wiring ……………………………………………………………………………………….

P

1-6

1.3.2

Grounding …………………………………………………………………………………

P

1-7

1.3.3

Environmental conditions …………………………………………………………

P

1-8

1.4

Safety precaution …………………………………………………………………………………….

P

1-8

1.4.1

Before switching on ………………………………………………………….………

P

1-10

1.4.2

Routine inspections ………………………………………………………….………

P

1-11

1.4.3

Warm up …………………………………………………………………………….….…

P

1-11

1.4.4

Preparations …………………………………………………………………….…….…

P

1-11

1.4.5

Operation ……………………………………………………………………………………

P

1-12

1.4.6

To interrupt machine ……………………………………………………………….…

P

1-13

1.4.7

Completing a job …………………………………………………………………….…

P

1-14

1.4.8

Safety devices ………………………………………………………………………….…

P

1-14

1.4.9

Maintenance operation preparations …………………………………………

P

1-14

1.4.10

Maintenance operation …………………………………………………………

P

1-15

1.4.11

Unit operation is begun after maintenance ……………………………….

P

1-16

1.5

Warning signs plate on the machine …………………………………………………….

P

1-16

1.6

Hazard List and Solution …………………………………………………………………………

P

1-19

2

MACHINE SPECIFICATIONS ………………………………………………………………………

P

2-1

2.1

Dimensional drawing ………………………………………………………………………………

P

2-2

2.1.1

Main features ……………………………………………………………………………

P

2-2

2.1.2

General layout ……………………………………………………………………………

P

2-3

2.1.3

Specification ………………………………………………………………………………

P

2-4

2.1.4

Interrupted diagram of tool rack…………………………………………………

P

2-5

2.2

Check list ………………………………………………………………………………………………

P

2-7

2.2.1

Check list for operation ………………………………………………………………

P

2-7

2.2.2

Check list for maintenance ……………………………………………………….

P

2-7

3

INSTALLATION ……………………………………………………………………………………………

P

3-1

3.1

Foundation ………………………………………………………………………………………………

P

3-2

3.1.1

Foundation Layout ………………………………………………………………………

P

3-3

3.1.2

Layout & Floor Plan ………………………………………………………………………

P

3-5

3.2

Connection of power line ……………………………………………………………………….

P

3-6

3.3

Unpacking ………………………………………………………………………………………………

P

3-6

Content

3.3.1

Checking for shortage …………………………………………………………………

P

3-6

3.3.2

Machine Lifting ……………………………………………………………………………

P

3-7

3.3.3

Machine Placing ……………………………………………………………………………

P

3-/

3.3.4

Machine Clean & Lubrication ………………………………………………………

P

3-8

3.4

Machine Leveling ……………………………………………………………………………………

P

3-9

3.5

Lubrication ………………………………………………………………………………………………

P

3-10

3.5.1

Lubrication pump specification ……………………………………………………

P

3-10

3.5.2

Lubrication System ………………………………………………………………………

P

3-11

3.5.3

Lubrication system on Headstock ………………………………………………

P

3-13

3.5.4

Lubrication on tailstock ………………………………………………………………

P

3-13

3.6

Chucks and chuck mounting ……………………………………………………………………

P

3-14

3.6.1

Chuck fitting on D1-6 spindle nose ………………………………….…….……

P

3-14

3.7

Tailstock center loading & unloading ………………………….…………………….……

P

3-14

3.8

Coolant ……………………….…….……………………………………………………….…….……

P

3-14

4

MAINTENANCE ………………………….…….……………………………………………….…….……

P

4-1

4.1

Lubrication System ………………………….……..……………………………..….…….……

P

4-2

4.1.1

Replacing headstock Oil ………………………………………………….…….……

P

4-2

4.1.2

Fittings ………………………….…….…………………………………….….….….……

P

4-3

4.2

Machine body ………………………….…….…………………………………………….…….……

P

4-3

4.2.1

Headstock ………………………….…….…………………………………….…….……

P

4-3

4.2.2

Cross-slide ………………………….…….……………………………….……..………

P

4-4

4.2.3

Saddle ………………………….…….………………………………………….….….……

P

4-5

4.2.4

Aligning tailstock to spindle ……………………………………………..…….……

P

4-6

4.2.5

Adjusting belt tension of X-axis ………………………….……………..….……

P

4-6

4.3

Electric equipment ………………………….…….…………………………………….…….……

P

4-7

4.3.1

Motor ………………………….…….…………………………….………………..….……

P

4-7

4.3.2

Control units ………………………….…….…………………………….…….……

P

4-7

4.3.3

Wire connectors ………………………….…….……………………….…….…….…

P

4-7

4.4

Simple trouble shooting ………………………….…….……………………………….…….…

P

4-7

4.5

Remove chip and renew coolant ………………………….…………………………….……

P

4-8

4.6

Notice for maintenance and inspection ……………………………………….…….……

P

4-9

4.7

Maintenance and Inspection List ………………………….……………………..….……

P

4-12

5

CHUCK…………………………………………………………………………………….…………………

P

5-1

5.1

Instruction Manual……………………………………………………………………………..

P

5-2

5.1.1

Safety precautios…………………………………………………………………….

P

5-2

5.2

Installation of chuck…………………………………………………………………………..

P

5-4

5.3

Maintenance and Inspection…………………….…….…………………………………

P

5-5

5.4

Trouble shooting………………..…..…………………………….…….……………………

P

5-5

Content

5.5

Independent chuck……………………….……………………………………………………

P

5-6

6

PARTS LIST ………………………………………………………………………………………….……….

P

6-1

6.1

Headstock ………………………………………………………………………………………………

P

6-2

6.1.1

Parts list of headstock.…………………………………………………………………

6.2

X-axis Transs .…….…..………………………………….….…….…….………………………...

P

6-7

6.2.1

Parts list of 42CS Saddle.......................................................

6.3

Z-axis Transs. .…….…..………………………….…….…………………………………………

P

6-11

6.3.1

Parts list of 42CS BED..............…………………………….…….………………

6.4

Tailstock Oil Motor.…….…..…………………….…….….…….…….………………………..

P

6-13

6.4.1

Parts list of 50CT tailstock (Oil Motor)…………………….…….…………..

6.5

Hydraulic Circuit Diagram……………………….…….…………………………………………

P

6-17

WARNING

Persons unable to read English must have this manual read and

explained to them before operating or maintaining the machine.

Everyone working on the machine must know how to operate it safely

and correctly to avoid possible injury.

1- 1

1.

SAFETY INSTRUCTIONS

1- 2

1. SAFETY INSTRUCTIONS

WARNING

Do not install, operate, or service this machine until:

1) You have read and understand the safety instructions on the pages that

follow.

2) You have read and understand the operator’s manual, especially knowing the

function and location of all machine controls and read manuals for any

related accessories.

3) You have read and understand all safety and instruction plates attached to

the machine and it’s related accessories.

4) Prior to install or services the machine read and understand the maintenance

manual.

5) To service the machine must be done only by competent and trained

personnel.

NOTICE

The following safety instructions are general recommendations for most

common operations on a turning machine.

Additional safety measures may be required for your particular application.

Therefore, makes no warranty or representation as the absolute correctness of

sufficiency of the instructions.

1.1 General safety instructions for operating the machine

1) The best defense against injuries on a turning machine is to be alert. Never

initiate a machine function unless you completely understand what the

function will cause the machine to do.

2) Never operate the machine with any cover or shield opened or removed.

3) Never reach into the work area when the spindle is rotating or if the machine

is in automatic mode.

4) Put the machine in manual mode and be sure last programmed function has

been Completed before reaching inside of the work area.

5) The functions of the machine make it impossible to eliminate all pinch points.

Be particularly aware of the following pinch points:

1- 3

* Spindle and chuck rotation

* Indexing of turret and tools

* Carriage and cross-slide movement

* Tailstock movement, both quill and body

6) Keep machine and area around it clean and well lighted. Never allow chips ,

coolant or oil to remain on the floor. Do not leave loose objects on around

machine.

7) Clothing :

* Wear safety glasses with eye shields at all times. Protect your eyes. Never

use a compressed air house to remove chips from a machine.

* Never wear loose fitting clothing. Remove all jewelry (rings, watches,

necklaces…etc.). They can be caught in moving parts of the machine.

* Gloves are easily caught in moving parts. Take them off before turning the

machine on.

* Always wear safety shoes with steel toes and oil-resistant soles.

* Wear a safety helmet when working near overhead hazards.

* If operator has long hair, hair should always be tucked under a cap or tied

back and up.

8) Turning machine are designed to be run by one person. Persons other than

the designated operator should stay out of the machine area during

operation.

9) Take care, not to bump or accidentally touch the machine control. Doing so

can initiate an unintended machine movement which could cause an injury

or a wreck.

10) Do not paint, alter, deface or remove any warning plates from the machine.

11) Report any loose, worn or broken parts to your supervisor. The same action

should be taken if any unusual noise or machine action occurs.

12) Never operate the machine after taking strong medication, using

non-prescription drugs, or consuming alcoholic beverages. Persons with

illness, which might cause dizziness or fainting, should never operate this

machine.

13) The electric components are protected from normal moisture resulting from

humidity use of water base soluble coolant, etc. Do not, however, use water

house to clean the machine or the area around it.

14) Never touch a machine control device or electrical component when your

hand is wet. Keep flammable liquids and materials away from the work

area and chips.

15) Never clean up chips while the machine is running or is in automatic mode.

16) Do not file work pieces being rotated under power.

17) At the end of the work day the machine should be placed in either “control

1- 4

off” or “power off” modes.

18) When restarting a machine after it has been shut down, always assume it

has been tampered with. Recheck all phases of the job as though you were

running the first piece.

19) Never touch spindle start or spindle jog control until hands, feet, and body

are well clear of the work area.

20) Coolant and oils can make surfaces on the machine slippery. They can also

present an electrical hazard if the machine has power on. For these reasons

do not stand on any part of the machine at any time.

21) Never extend an unsupported bar out of the rear the spindle or hydraulic

cylinder a distance from a concentric support more than 10 times of it’s

diameter. Doing so can cause the bar to bend or break. When any bar is

extended, a large sign should be placed to warn people to stay away from

the area.

22) If your turning machine has a bar-feeder interfaced to it , keep yourself and

others away from the exit end of the bar-feeder when the machine running.

1.1.1 Safety instructions for work holding

1) Never run a job on this machine until you are 100% sure the work piece is

being held in such a manner as withstand the centrifugal force from rotation

and cutting forces of the tooling. If there is any doubt , whatever , consult

with your supervisor.

2) A chuck is the most common work holding device used on this machine.

Some of the factors affect the holding device used on this machine. These

factors which affect the holding ability of a chuck are :

* Clamping force of jaws

* Rotational speed of the spindle

* Type of jaw surface (serrated , smooth , etc.)

* Area of chuck configuration of the work piece…shape, weight, and balance

* Jaw weight and location

3) With air or hydraulic actuated power chuck (optional accessory) , make sure

the jaws are gripping the work securely before they reach the end of their

travel. When using a power chuck, check the hydraulic or air pressure before

every operation. Low chucking pressures will diminish jaw-dripping force,

which may allow the work piece to come out of the jaws. Excessive pressure

can damage a power chuck, which could cause a loss of jaw force. The

gripping force of a power chuck can be diminished as much as 50% because

lack of lubrication or lack of periodic cleaning. Components of the chuck are

subject to wear and damage which also can lessen gripping power. Grease

1- 5

the chuck at the beginning of every shift. Use only the chuck

manufacturer’s recommended lubricant.

A. A weekly examination of the condition of chuck should be made. This

examination should include the measurement of jaw clamping force with

a jaw force gage to insure that the chuck is function , as it should.

B. Refer to manufacturer’s manual for chuck and cylinder for any other

maintenance requirements. As the spindle R.P.M. increase the gripping

force of the jaw decreases. The larger the chuck diameter the more loss

becomes. Various types of top jaws are serrated contact surfaces on

work piece. Improper usage could cause serious injury or death.

Remember-chucking a work piece safely involves many variables. If you

have the slightest doubt regarding the safety of your set-up for a job ,

consult with your supervisor.

4) Never operate spindle-mounted accessories over their rated speed. If the

chuck or accessory is not supplied by original maker, verify the safe

operating speed with the manufacturer.

5) Always be sure the chuck the chuck or accessory is located correctly on the

spindle nose and it is securely bolted the face of the spindle.

6) Be sure any item bolted or clamped to a chuck or fixture is securely fastened

before starting the spindle.

7) Proper lifting equipment should be used for heavy chucks, fixtures, and work

pieces.

8) Always is aware f that closing chuck jaws could trap fingers or hands.

9) The same safety instructions that apply to power chucks also apply to

manual operated chucks. The following additional precautions should be

taken when using a manual chuck :

A. Always use spring-loaded, self-ejecting type safety wrenches.

B. Never put an extension bar on a chuck wrench or hit with hammer.

C. Never run a gear scroll chuck without having something chucked in the

jaws. Centrifugal force can cause the scroll to unwind if the chuck is

empty. If this occurs, the jaws may come out of the chuck while the

spindle is turning.

10) If a work piece is extended from the chuck a distance of 3 to 4 times its

diameter, without being supported by the tailstock, poor cutting condition

will normally occur. Under no circumstances extend an unsupported work

piece more than this amount without supporting the work piece with the

tailstock. Doing so can cause the part to bend or break.

1- 6

1.2 Maintenance safety instruction

WARNING

High voltage is used to power the machine; only authorized electricians should

Correct any electrical component failure. Disconnect main power and lock in off

position before attempting any repair. Tag disconnect switch “DO NOT START”

1) Read and understand safety instructions for machine operator before

servicing this machine.

2) Know all points where high voltages are present on this machine and in

electrical boxes.

3) Residual voltages can exist in electrical cabinets for a period of time after

power has been turned off. Check any component inside cabinet with a meter

a before touching.

1.3 Installation precautions

To ensure the safe operation of the NC machine, note the following during

installation.

1.3.1 Wiring

1) Be sure to use electrical conductors with performance ratings equivalent or

superior to those described in the Maintenance Manual.

2) Do nut connect to the power distribution panel any power cables for device,

which can cause Line noise, such as ,are welders and high frequency

quenching machines.

3) Arrange for a qualified engineer to connect the power lines.

1.3.2 Grounding

Use a grounding wire with a cross section of more than 14 mm and a resistance

to ground of less Than 100 ohms.

This wire size should be greater than AWB (American Wire Gauge) No. 5 and

SWG (British Legal Standard Wire Gauge) No.6.

1- 7

Generally, the NC machine should be ground to a separate grounding rod. If an

independent ground cannot be provided for the machine, prepare the ground

connection as follow:

1) Connect a single conductor to it’s own grounding terminal. This will avoid

possible serious accidents resulting from ground currents ,which might

otherwise flow in the NC machine if a peripheral device , should malfunction.

2) Be careful when using concrete reinforcing rods as grounding points. These

reinforcing rods often are used to ground equipment because they usually

offer a resistance to ground of less than 100 ohms. In doing so, make the

connections as follow:

A. Do not use the same grounding-reinforcing rod or grounding terminal for

other devices since this could lead to line noise such as produced electric

welders and high frequency quenching machine.

B. Use a grounding terminal with an adequate electrical performance rating

and which is durable.

3) A separate grounding wire should be used, one whose length is as short as

possible.

4) Check the resistance to ground by actual measurement. This should

measure less than 100 ohms if the single device is connected to its own

grounding rod.

Desirable Independent Grounding:

Common grounds:

Never ground equipment as shown in the left side figure (FORBADE ) :

Earth resistance: Less than 100 ohms

Resistance to ground = 100 the number

of devices connected to the grounding

(Ω)

1- 8

(Wrong Grounding)

1.3.3 Environmental conditions

Generally, the machine will be installed on the following conditions. However,

these may change over a period of time or in response to seasonal changes.

1) Supply voltage : 90% to 110% of nominal supply voltage

2) Source frequency : ± 2hz of nominal frequency

3) Ambient temperature : 0℃to 45℃(32℉to 113℉)

4) Relative humidity : Less than 80%

Temperature changes should not cause condensation.

5) Atmosphere : Free from excessive dust, acid fumes corrosive

gases and salt

6) It should be avoided to expose the machine to direct sunlight or heat rays

which can change the environmental temperature.

7) Avoid exposing the NC machine to abnormal vibration.

If it is difficult to observe meet these conditions, contact us immediately.

1.4 Safety precaution

This machine is provided with a number of safety devices to protect operator

and equipment from being injured and damaged. Operators should not,

however, rely solely upon these safety devices but should operate the machine

after fully understanding what special precautions to take by reading the

following remarks thoroughly.

Basic operating practices

DANGER

1) Some control panels, transformers, motors junction boxes and other parts

have high-voltage terminals, these should not be touched or a severe electric

1- 9

shock will be sustained.

2) Do not touch a switch witch wet hands. This, too, can cause an electric

shock.

WARNING

1) The emergency stop push-button should be well known so that it can be

operated at any time without having to look for it.

2) Before replacing a fuse, switch off the machine.

3) Provide sufficient working space to avoid hazardous. To prevent accidents all

floors should be dry and clean.

4) Water or oil can make floors slippery and hazardous. To prevent accidents all

floors should be dry and clean.

5) Before operating switches, always check that they are the right ones.

6) Never touch a switch accidentally.

7) Workbenches near the machine must be strong enough to prevent accidents.

Articles should be prevented from slipping off the bench surface.

8) If a job is to be done by two or more persons, coordinating signals should be

given at each step of the operation. Unless a signal is given and

acknowledged, the next step should not be taken.

CAUTION

1) In the event of power failure, turn off the main circuit breaker immediately.

2) Use the recommended hydraulic oils, lubricants and grease or acceptable

equivalents.

3) Replacement fuses should have the proper current ratings.

4) Protect the NC unit, operating panel, electric control panel, etc. from shocks,

since this could cause a failure or malfunction.

5) Do not change parameters, values and other electrical settings

unnecessarily. If such changes are unavoidable, record the values prior to

the change so that they can be returned to their original settings if

necessary.

6) Do not soil, scratch or remove the caution plate. Should it become illegible

or be missing, order another caution plate from the surlier. (Specifying the

part number shown at the lower right of the plate.)

1- 10

1.4.1 Before switching on

DANGER

Cables, cords or electric wires whose insulation is damaged can cause current

leaks and electric shocks. Before using these, check their condition.

WARNING

1) Be sure the instruction manual and the programming manual are fully

understood. Every function and operating should completely clear.

2) Use safety shoes, which are not damaged by oil, safety goggles with side

covers, safe clothes and other safety protection.

3) Close all electric cabinet doors, operating cover, fully guarding door before

switching machine on.

CAUTION

1) The power cable form the factory feeder switch to the machine main circuit

breaker should have a sufficient sectional area to handle the electric power

used.

2) Cables which have to lie on the floor must be protected against chips so that

short-circuits will not occur.

3) Each sliding part must be freshly lubricated before starting to operate the

machine after unpacking or keeping the machine idle for a long period

(several or more). For the lubricating and so forth, keep lubricating oil pump

working until oil oozes out form wiper. Contact our Service Station in

connection with what procedure should be taken since it depends on the type

of machine.

4) Oil reservoirs should be filled to indicate levels, check and add oil, if

necessary.

5) For lubricating points, oil brands and appropriate levels, see the various

instruction plates.

6) Switches and levers should operate smoothly.

7) Check the coolant level, and add coolant, if necessary.

8) When switching the machine on, connect the factory feeder switch to the

machine circuit breaker, and then turn power switch to the ON position in

order

1- 11

1.4.2 Routine inspections

WARNING

When checking belt tensions, do not get your fingers caught between the belt

and pulley.

CAUTION

1) Check pressure gages for proper readings.

2) Check motor, gearboxes and other parts for abnormal noises.

3) Check the motor lubrication, and sliding parts for evidence of proper

lubrication

4) Check safety covers and safety devices for proper operation

5) Check belt tensions. Replace any set of belts that has become stretched with

a fresh matching set.

1.4.3 Warm up

1) Warm up machine, especially the spindle and feed shaft by running them for

10 to 20 minutes at about half or one-third the maximum speed in the

automatic operation mode.

2) This automatic operation program should cause each machine component to

operate. At the same time check their operations.

3) Be particularly careful to warm up the spindle, which can turn up to 3500rpm.

If the machine is used for actual machining immediately after being started;

following a long idle period, sliding parts may be worm due to lack of oil. Also,

thermal expansion of the machine components can jeopardize machining

accuracy. To prevent this condition, always warm the machine up.

1.4.4 Preparations

WARNING

1) Tooling should conform to the machine specifications, dimensions types.

2) Seriously worm-out tools can cause injuries. Replace all such tools with new

ones beforehand

3) The work area should be adequately lighted to facilitate safety checks.

4) Tools and other items around the machine or equipment should be stored to

ensure good footing and clear aisles,

1- 12

5) Tools or any items must not be place on the headstock, turret, cover and

similar places.

6) If the center holes of heavy cylindrical work piece are too small, the work

pieces can jump out when loaded. Be careful about center holes and angles.

CAUTION

1) Tool lengths should be within specified tolerances to prevent interference.

2) After installing a tool, make a trial run.

1.4.5 Operation

WARNING

1) Do not work with long hair that can be caught by the machine. Tie it up at

the back, out of the way.

2) Do not operate switches with gloves on. This could cause malfunctions, etc.

3) Whenever a heavy work piece must be moved, two or more persons should

always work together if there is any risk involved.

4) Only trained, qualified workers should operate forklift trucks, cranes or

similar care should be taken to prevent collisions and damage to

surroundings.

5) Whenever operating a forklift truck, crane or similar equipment, special

care should be taken to prevent collisions and damage to surroundings.

6) Wire ropes or slings should be strong enough to handle the loads to be lifted

and should conform to the mandatory provision.

7) Grip work pieces securely.

8) Stop the machine before adjusting the coolant nozzle at the tip.

9) Never touch a turning work piece or spindle with bare hands or in any other

way.

10) While a work piece is turning, do not wipe it off or remove chips with a cloth

or by hand. Always stop the machine first and then use a brush and a

sweeper (for machine).

11) Do not operate the machine with safety front guard and chuck covers

opened.

12) Use a brush to remove chips from the tool tip not bare hands.

13) Stop the machine whenever installing or removing a tool.

14) Whenever machining magnesium alloy parts, wear a protective mask.

CAUTION

1- 13

1) The machine could not open under automatic operation. Also, the machine

front guard can’t be opened under automatic operation model.

2) When performing heavy-duty machining, carefully prevent hips from being

accumulated since hot chips can catch fire.

1.4.6 To interrupt machine

WARNING

1) When leaving the machine temporarily after completing a job, turn off the

power switch on the operation panel, and the main circuit breaker.

2) When being a sudden power failure in the processing state, turn off the

power first. Then open the right cover, put the L-wrench into the screw

end of the Z-axis at the reverse exit from the work piece as shown as

figure.

Drop saddle cover removed. Put the L-wrench into the screw end of the X-axis,

at the reverse exit from the work piece as shown as figure.

The screw end

of Z-axis ball

screw

COVER

The screw end

of X-axis ball

1- 14

1.4.7 Completing a job

CAUTION

1) Always clean the machine or equipment. Remove and dispose of chips and

clean cover, guard and windows, etc.

2) Do not clean the machine or equipment before it has been stopped.

3) Return each machine component to its initial condition.

4) Check wipers for breakage. Replace broken wipers.

5) Check coolant, hydraulic oil and lubricant for contamination. Change them if

they are seriously contaminated.

6) Check coolant, hydraulic oil and lubricant levels. Add, if necessary.

7) Before leaving the machine at the end of the shift, turn off the power switch

on the operating panel, machine main circuit breaker and factory feeder

switch in that order.

8) Clean the oil pan filter.

1.4.8 Safety devices

1) Front guard, rear guard and chuck guard.

2) Over travel limit switches

3) Chuck barrier, tail barrier and tool barrier(NC software)

4) Stored stroke limit (NC software)

5) Emergency stop push buttons.

1.4.9 Maintenance operation preparations

1) Do not proceed any maintenance operation unless being instructed to do it

by the foreman.

2) Replacement parts, consumable (packing, oil seals, O-rings, bearing, oil and

grease etc.)should be arranged in advance.

3) Prepare to record preventive and corrective maintenance operations.

DANGER

1) Thoroughly read and understand the safety precautions in the instruction

manual.

2) Thoroughly read the whole maintenance manual and fully understand the

principles, constructions and precautions involved.

1- 15

1.4.10 Maintenance operation

DANGER

1) Those not engaged in the maintenance work should not operate the main

circuit breaker or the control power ON switch on the operating panel. For

this purpose, “Do not touch the switch, maintenance operation in progress”

or similar working should be indicated on such switches and at any other

appropriates locations, such indication should be secured by a

semi-permanent means in the reading direction.

2) With the machine turned on, any maintenance operation can be dangerous.

In principle, the main circuit breaker should be turned off through out the

maintenance operation.

WARNING

1) Maintenance operation should be done by a qualified person. Keep close

contact with the responsible person. Do not decide by yourself.

2) Over-travel limit and proximity switches and interlock mechanisms including

function Parts should not be removed or modified.

3) When working at a height, us steps or ladders which are maintained and

controlled daily for safety.

4) Fuses, cables, etc. should be made by qualified manufacturers should be

employed.

5) Main spindle motor speeds (rpm) couldn’t be over the Max. speed of

chuck

6) After boot, three-color warning light (as shown)

will blink two seconds each. In this case,

please confirm whether the three-color light

bulb is normal or not.

Three-color light represent. :

(1) Red represents: Exception/alarm malfunction

(2) Yellow represents: End processing/

Information provided

(3) Green represents: processing

RED

YELLOW

GREEN

1- 16

1.4.11 Unit operation is begun after maintenance

WARNING

1) Arrange things in order around the section to receive the maintenance,

including working environments. Wipe water and oil off and provide safe

working environments.

2) All parts and waste oil should be removed by the operator and placed far

enough away from the machine to be safe.

CAUTION

1) The maintenance person should make sure that the machine operation safe.

2) Maintenance and inspection data should be recorded and kept for reference.

1.5 Warning signs plate on the machine

Safety-related information, which must be strictly observed by all machine

operators, is given on warning signs plate. These warning signs plate are

attached to the machine.

This manual suits for next models

14

Table of contents

Other Atrump Lathe manuals

Popular Lathe manuals by other brands

Delta

Delta LA200 instruction manual

Grizzly

Grizzly G9249 owner's manual

Hafco Metalmaster

Hafco Metalmaster CL-68A instruction manual

Baileigh Industrial

Baileigh Industrial SR-5016 Operator's manual

Roller

Roller King 1,25 Series instruction manual

Rikon Power Tools

Rikon Power Tools Woodfast 70-450 owner's manual