-8- G4000 9'' x 19'' Lathe

SSiitteeCCoonnssiiddeerraattiioonnss

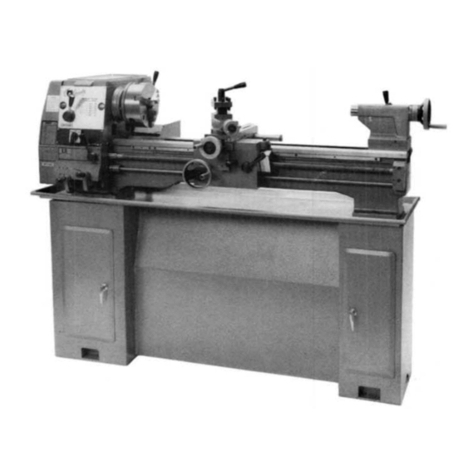

11..FFlloooorrLLooaadd::The Model G4000 can be

mounted on your existing workbench or on

an optional cabinet stand which is listed in

our current Grizzly catalog. If you choose to

use the stand, you will find the holes for bolt-

ing the G4000 to the stand are already in

place. If you are using your own bench,

ensure that it is strong enough to handle the

G4000 lathe. Keep in mind, whichever way

you choose to mount the lathe, it’s essential

that the mounting surface be perfectly flat.

Use an accurate carpenter’s level to ensure

that your bench is properly leveled.

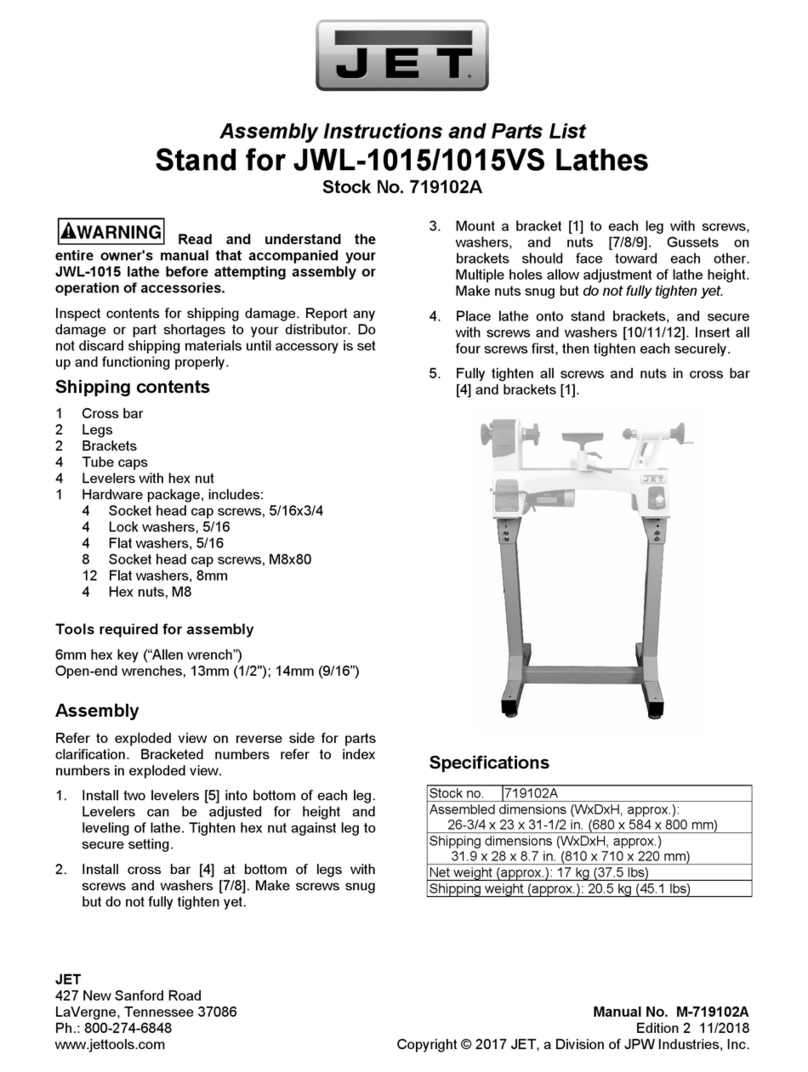

22..WWoorrkkiinnggCClleeaarraanncceess::Consider existing and

anticipated needs, size of material to be

processed through each machine, and

space for auxiliary stands, work tables or

other machinery when establishing a loca-

tion for your lathe.

33..LLiigghhttiinnggaannddOOuuttlleettss::Lighting should be

bright enough to eliminate shadow and pre-

vent eye strain. Electrical circuits should be

dedicated or large enough to handle amper-

age requirements. Outlets should be located

near each machine so power or extension

cords are clear of high-traffic areas. Observe

local electrical codes for proper installation

of new lighting, outlets, or circuits.

CClleeaannUUpp

The unpainted surfaces are coated with a waxy

oil to protect them from corrosion during ship-

ment. Remove this protective coating with a sol-

vent cleaner or citrus-based degreaser. Avoid

chlorine-based solvents as they may damage

painted surfaces should they come in contact.

Always follow the usage instructions on the prod-

uct you choose for clean up.

MMaannyyoofftthheessoollvveennttssccoommmmoonnllyyuusseeddttoo

cclleeaannmmaacchhiinneerryyccaannbbeehhiigghhllyyffllaammmmaabbllee,,

aannddttooxxiiccwwhheenniinnhhaalleeddoorriinnggeesstteedd..AAllwwaayyss

wwoorrkkiinnwweellll--vveennttiillaatteeddaarreeaassffaarrffrroomm

ppootteennttiiaalliiggnniittiioonnssoouurrcceesswwhheennddeeaalliinngg

wwiitthhssoollvveennttss..UUsseeccaarreewwhheennddiissppoossiinnggooff

wwaasstteerraaggssaannddttoowweellssttoobbeessuurreetthheeyyddoo

nnoottccrreeaatteeffiirreeoorreennvviirroonnmmeennttaallhhaazzaarrddss..

KKeeeeppcchhiillddrreennaannddaanniimmaallssssaaffeellyyaawwaayy

wwhheenncclleeaanniinnggaannddaasssseemmbblliinnggtthhiiss

mmaacchhiinnee..

DDoonnoottuusseeggaassoolliinneeoorrootthheerrppeettrroolleeuumm--

bbaasseeddssoollvveennttssttoorreemmoovveetthhiisspprrootteeccttiivvee

ccooaattiinngg..TThheesseepprroodduuccttssggeenneerraallllyyhhaavveellooww

ffllaasshhppooiinnttsswwhhiicchhmmaakkeesstthheemmeexxttrreemmeellyy

ffllaammmmaabbllee..AArriisskkooffeexxpplloossiioonnaannddbbuurrnniinngg

eexxiissttssiifftthheesseepprroodduuccttssaarreeuusseedd..SSeerriioouuss

ppeerrssoonnaalliinnjjuurryymmaayyooccccuurr..

AAllllddiiee--ccuuttmmeettaallppaarrttsshhaavveeaasshhaarrppeeddggee

((ccaalllleedd““ffllaasshhiinngg””))oonntthheemmaafftteerrtthheeyyaarree

ffoorrmmeedd..TThhiissiissggeenneerraallllyyrreemmoovveeddaatttthhee

ffaaccttoorryy..SSoommeettiimmeessaabbiittooffffllaasshhiinnggmmiigghhtt

eessccaappeeiinnssppeeccttiioonn,,aannddtthheesshhaarrppeeddggeemmaayy

ccaauusseeccuuttssoorrllaacceerraattiioonnsswwhheennhhaannddlleedd..

PPlleeaasseeeexxaammiinneetthheeeeddggeessooffaallllddiiee--ccuutt

mmeettaallppaarrttssaannddffiilleeoorrssaannddtthheeeeddggeettoo

rreemmoovveetthheeffllaasshhiinnggbbeeffoorreehhaannddlliinngg..

MMaakkeeyyoouurrsshhoopp““cchhiillddssaaffee””..EEnnssuurreetthhaatt

yyoouurrwwoorrkkppllaacceeiissiinnaacccceessssiibblleettooyyoouunngg--

sstteerrssbbyycclloossiinnggaannddlloocckkiinnggaalllleennttrraanncceess

wwhheennyyoouuaarreeaawwaayy..NNeevveerraalllloowwvviissiittoorrssiinn

yyoouurrsshhooppwwhheennaasssseemmbblliinngg,,aaddjjuussttiinnggoorr

ooppeerraattiinnggeeqquuiippmmeenntt..