i

MAN - RTFO - REV: Org

Manual Contents

A. Introduction...................................................................................................................................1

A.1 Unpacking ............................................................................................................................................................1

A.2 Warranty Information...........................................................................................................................................1

A.3 After Sale Support ...............................................................................................................................................1

B. Safety.............................................................................................................................................2

B.1 For Owners, Operators, and Maintenance...........................................................................................................2

B.2 Warnings..............................................................................................................................................................3

B.3 Cautions................................................................................................................................................................4

C. System Overview..........................................................................................................................5

C.1 General Description .............................................................................................................................................5

Product Specications...................................................................................................................................5

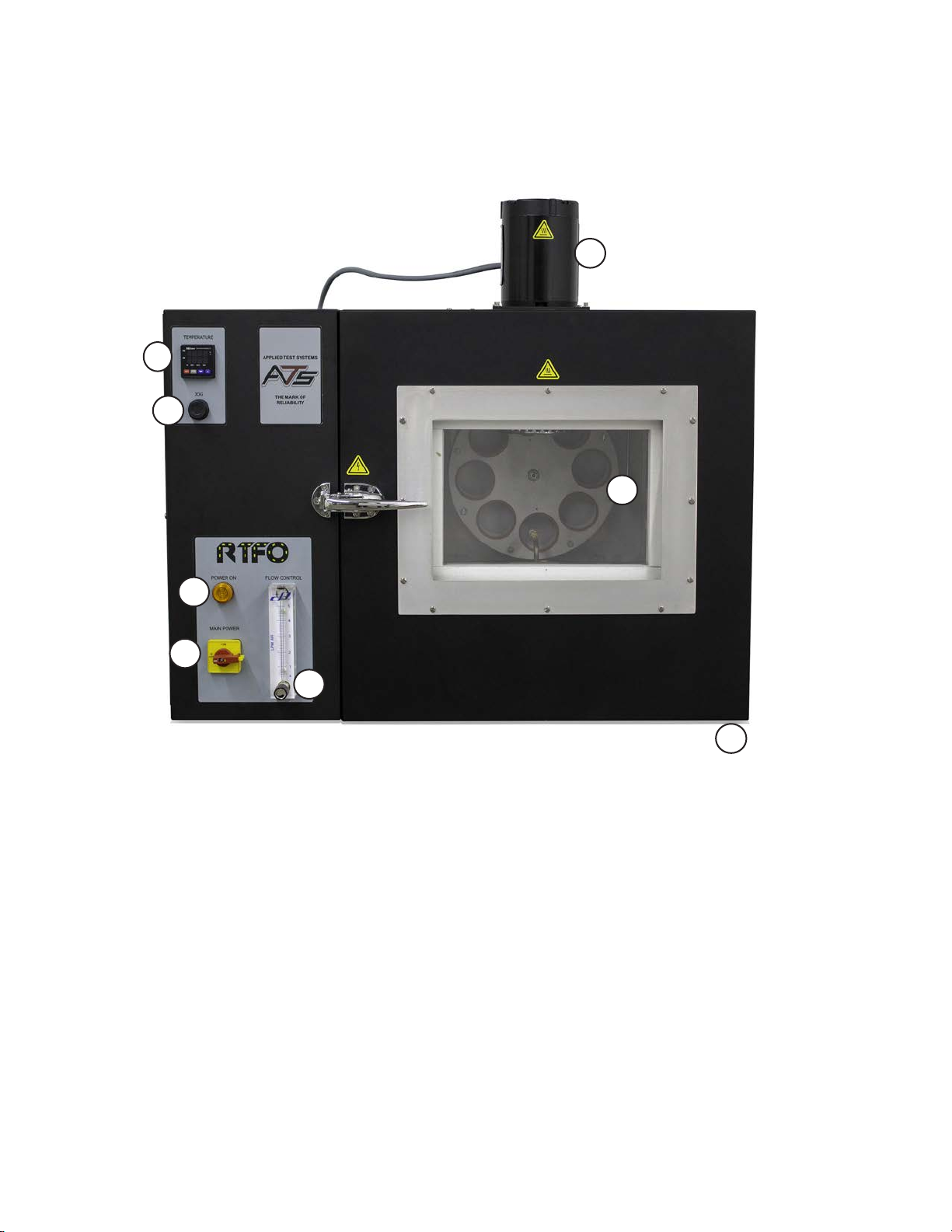

C.2 RTFO Layout........................................................................................................................................................6

RTFO Front.................................................................................................................................................... 6

RTFO Back.................................................................................................................................................... 7

RTFO Chamber............................................................................................................................................. 8

Panel Layout and Components.....................................................................................................................9

Temperature Controller ............................................................................................................................... 10

D. Installation...................................................................................................................................11

D.1 General Installation.............................................................................................................................................11

D.2 Adjusting the Air Flow.........................................................................................................................................11

D.3 Setting the Temperature .....................................................................................................................................12

D.4 Leveling the Machine..........................................................................................................................................13

E. Verication ..................................................................................................................................14

E.1 Temperature Verication .................................................................................................................................... 14

E.2 Verication of Air Flow ........................................................................................................................................14

F. Operation .....................................................................................................................................15

F.1 Basic Operation .................................................................................................................................................. 15

G. Troubleshooting .........................................................................................................................16