attocube attoAFM I User manual

Version:

1.0

Modified:

February 2015

Products:

Atomic Force Microscope attoAFM I

User Manuals

Atomic Force Microscope

attoAFM I/MFM/KPFM

P5788

attocube systems AG, Königinstrasse 11 A, D - 80539 München Germany

Phone: +49 89-24208888 Fax: +49 89-24208890

E-Mail: info@attocube.com www.attocube.com

For technical queries, contact:

support@attocube.com

attocube systems office Munich:

Phone +49 89 2877 80915

Fax +49 89 2877 80919

Disclaimer of Responsibility

attocube systems does not assume any responsibility for the use of

any circuitry described in this manual. attocube systems reserves

the right to change the product specifications and the

functionality, or the manual itself, at any time without prior

notice. Furthermore, attocube systems assumes no responsibility

or liability for any misinformation, errors, or general inaccuracies

that may appear in this manual.

Copyright © 2006-2015 attocube systems AG. All rights reserved.

Product and company names listed are trademarks or trade names of

their respective companies. Any rights not expressly granted herein

are reserved.

Page 3

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Table of Contents

I. Introduction .............................................................................................. 4

I.1. System Overview ..................................................................................... 5

I.1. Safety Information .................................................................................. 6

I.1.a. Warnings ............................................................................................7

II. Mode of Operation and Force Detection Scheme ................................................. 9

III. Components of the Microscope and Technical Specifications ................................12

III.1. Microscope Setup ...................................................................................12

III.2. Electronics............................................................................................14

III.2.a. ANC300: High voltage amplifier ............................................................. 14

III.2.b. ACC100: LDM1300 Laser Detector module and Break-Out Panels.................... 14

III.2.c. ANC350 Piezo controller for positioners................................................... 15

III.2.d. Laser detector module: LDM1300 ........................................................... 16

III.2.e. ASC500 SPM Controller ........................................................................ 16

III.3. (Dis-)Assembling the attoAFM I Module.......................................................17

III.3.a. Inserting (removing) the stack into (from) the microscope housing............... 17

III.3.b. Mounting the Scanner-Positioner Stack ................................................... 19

III.4. Sample Exchange and Thermal Contact........................................................19

III.5. Changing the AFM Cantilever.....................................................................20

III.5.a. The cantilever mounting platform .......................................................... 23

III.5.b. Cantilever exchange............................................................................ 23

III.5.c. Mounting the attoAFM I sensor head into the housing ................................ 26

IV. Connecting the attoAFM I Module ..................................................................27

IV.1. Electrical Connections .............................................................................27

IV.1.a. ASC500 Controller Connections.............................................................. 27

IV.1.b. Break-Out Panel Connections ................................................................ 28

IV.1.c. Pin Connections ................................................................................. 29

IV.1.d. Vacuum Feedthroughs ......................................................................... 31

IV.2. Fiber Connection ....................................................................................31

V. Measurement Procedure ..............................................................................32

V.1. Operation Modes ....................................................................................32

V.1.a. Contact Mode without Feedback (constant height)..................................... 32

V.1.b. Contact Mode with Feedback on (constant force) ....................................... 33

V.1.c. Non-Contact Mode .............................................................................. 33

V.1.d. MFM and EFM measurements ................................................................. 35

V.1.e. KPFM measurements............................................................................ 35

V.2. Performing a Scan ..................................................................................36

V.2.a. Set the Actor Scaling ........................................................................... 36

V.2.b. Non-Contact Mode .............................................................................. 37

V.2.c. Contact Mode..................................................................................... 43

V.2.d. Starting a scan................................................................................... 48

Page 4

I. Introduction

The attoAFM I is designed particularly for the use at extreme

environmental conditions such as ultra-low temperature, high magnetic

fields and high vacuum. Reliable functionality at these extreme conditions

is provided by implementing the outstanding attocube systems

nanopositioning modules as well as a force detection scheme based on an

all fiber low-coherence interferometer (explained in detail in the next

section).

To perform low temperature microscopy, the attoAFM I is cooled by a

controlled exchange gas atmosphere in a liquid Helium bath cryostat or a

variable temperature insert or a closed cycle cooling system.

The instruments may be surrounded by both liquid helium and liquid

nitrogen radiation shields, separated by vacuum insulation.

Figure 1

: The attoAFM I standard setup

Page 5

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

I.1. System Overview

The attoAFM I microscope is a tool to image, characterize, analyze, and

manipulate materials surfaces on a nanometer scale in low temperatures

as well as high magnetic fields. This short chapter wants to give a rough

overview on the concepts of the system.

The attoAFM I consists of the measurement head which is inside a housing

suspended on the lower end of the microscope stick, which itself is placed

in a vacuum tube. Before cooling down the system, this vacuum tube is

evacuated and backfilled with some He exchange gas for coupling to the

temperature outside of the vacuum tube. Typically, this vacuum tube is

then cooled by insertion into a He bath cryostat, a Variable Temperature

Insert (VTI), a pulse tube cooler, or by other means.

The main part of the attoAFM I measurement head is the AFM cantilever, a

thin bar typically made from silicon and possibly functionalized with

different coatings, which is placed before the end of an optical fiber,

hence forming an optical cavity, the length of which can be measured by

a laser/detector system.

The sample to be examined is placed (in standard setups) on an

ANPxyz101 positioner stack for coarse motion (5 x 5 x 5 mm³) and an

ANSxyz100 scanner (typ. 30 x 30 x 15 µm³ at 4 K, for details see the

specifications page at the end of the manual). Just underneath there is

typically also a temperature sensor and a small heater, which allows

controlling the temperature of the sample precisely.

When the sample is brought into contact with the cantilever, the

interaction forces can be measured by recording the length of the cavity.

While the sample is scanned, typically the distance between -tip and

sample is kept constant by the use of a feedback loop. For these purposes,

one uses the electronic scan controller ASC500, which generates all

required voltages and records all relevant signals. Additionally, a high

voltage amplifier ANC300 is part of the system, amplifying the unipolar,

0 –10 V signals to 0 –150 V, as well as generating the signals required to

move the stepper positioners.

Regarding the optics, laser light is guided to the fiber-cantilever cavity,

and the back-reflection is then detected by a photo-receiver. The signal

generated by the photo-receiver is analyzed and recorded with the

ASC500 controller.

Page 6

I.1. Safety Information

For the continuing safety of the operators of this equipment and the

protection of the equipment itself, the operator should take note of the

Warnings, Cautions, and Notes throughout this handbook and, where

visible, on the product itself.

The following safety symbols may be used on the equipment:

Laser safety warning. Class 1M laser product.

Warning. Risk of electric shock. High voltages present.

Warning. Risk of danger. Refer to the handbook for details on this hazard.

Functional (EMC) earth/ground terminal.

The following safety symbols may be used throughout the handbook:

Warning. An instruction, which draws attention to the risk of injury or

death.

Caution. An instruction, which draws attention to the risks of damage to

the product, process, or surroundings.

Note. Clarification of an instruction or additional information.

Page 7

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

I.1.a. Warnings

Note: Please read the manual for the positioners, scanners, and the

controllers prior to initial operation! Mind the warnings mentioned in

there!

Warning. To prevent electrical shocks do not remove the cover of the

control unit. Unplug the power cord and all other electrical connections

and consult qualified service personnel before servicing or cleaning.

Operate only under dry conditions and at room temperature.

Warning. If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

Do not operate the instrument outside its rated supply voltages or

environmental range. In particular, excessive moisture may impair safety.

Warning. Any individual vacuum space must be equipped with a security

overpressure valve! In case of hidden leaks air may enter into vacuum

spaces and build up large amounts of condensate at cold walls and

interfaces. In case such system is warmed up again such ice may evaporate

quickly and easily build up extremely dangerous overpressures! If no

overpressure valve is mounted on such vacuum space or the valve is

blocked e.g. due to mounting to a recovery line, this overpressure may

cause sudden breakdowns of the container, i.e. explosions. If in doubt,

please contact attocube systems.

Laser Safety Warning. Class 1M Laser product. This device utilizes a laser

which emits invisible light. There is potential for eye damage if proper

caution is not taken. The laser assembly should not be modified in any

way. The fiber cable should never be disconnected from the laser device

for any reason. The laser's wavelength is specified at 1330 nm with a

maximum power output of 1.5 mW. Please wear protective eyewear when

the laser source is turned on and never look directly into to the laser port

or fiber.

Warning. Plugging or unplugging modules of the electronic while

connected to power line will cause damages to the electronic. For

replacing modules disconnect the electronics from power and wait at least

5 minutes. Internal components need to be discharged.

Page 8

Caution. Never connect any cabling to the electronics when contacts are

exposed! Never connect any cabling to the electronics when the

electronics is not in GND mode! The scan piezos at the heart of a positioner

unit are high voltage components and can cause serious injuries. Be

careful not to cause a short-cut between the contacts in the BNC or any

other connectors.

Caution. For laboratory use only. This unit is intended for operation from a

normal, single phase supply, in the temperature range 5° to 40°C, 20% to

80% RH. The unit must be connected only to an earthed fused supply of

100, 115 or 230 V, 50/60 Hz.

Caution. In case of failure refer to your local dealer or attocube systems.

Users are cautioned not to attempt to access, open, modify, or service any

part of the setup unless outlined herein or otherwise directed by the

technical support staff from attocube systems. Take special care if

connecting products from other manufacturers. Clean only with a dry

cloth.

Caution. Because of the inherent fragility of the positioners and scanners

and the extreme conditions they are operated in, no responsibility can be

taken by the manufacturer for breakdowns of the ceramic piezo stacks. In

case of breakage, please contact the manufacturer for details of the repair

service.

Page 9

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

II. Mode of Operation and Force Detection Scheme

The attoAFM I is an atomic force microscope built around an optical

fiber based interferometer. The sensor is compatible with any

commercial cantilever and measures the vertical deflection of the

cantilever with picometer resolution. The microscope is designed to

work both in contact and in non-contact mode.

This highly compact microscope guarantees highest resolution tip-

sample positioning and an optimized sensor adjustment suitable for

any environment: room or low temperature, high magnetic field or

high vacuum conditions.

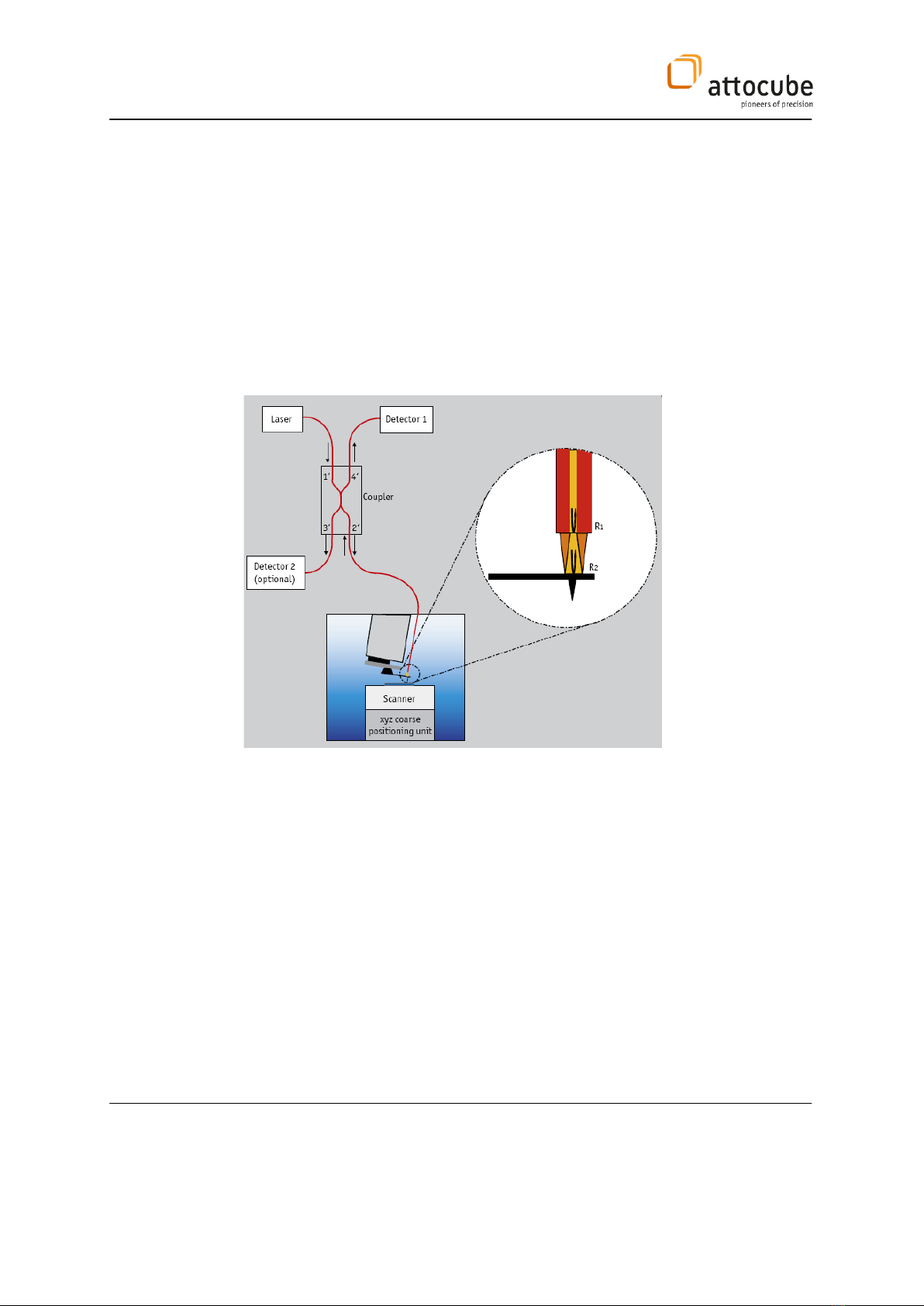

Figure 2

: Schematic drawing of the attoAFM I system.

Page 10

The force detection scheme for the attoAFM I microscope system is

based on an all fiber low-coherence interferometer (seeFigure 3).

Via a 50/50 fiber coupler, a laser beam illuminates a cavity built up

from the end-face of the fiber and the back-face of the cantilever. The

light reflected back from these surfaces gives rise to interferences that

can be seen by a detector. Due to the low reflectivity constants these

surfaces form a low-finesse Fabry-Perot cavity.

Monitoring the intensity of the interference fringes allows measuring

the tip deflection. The low coherence of the laser source has the

advantage of eliminating spurious interference signals resulting from

other reflections in the setup (e.g. the coupler), thus leading to an

increase of the signal-to-noise ratio of about 30 dB.

Figure 3

: Schematic drawing of the AFM I setup.

The periodicity of the signal corresponds to half the wavelength of the

laser source. Hence, the system can be easily calibrated and a measured

voltage difference can be translated into a height difference.

The control fiber has to be adjusted with respect to the cantilever in such a

way that the interference signal is at the quadrature point, i.e. in the

middle between two extrema values. In this case, the sensitivity of the

sensor is highest.

There are different ways to perform topographic images. Common modes

are the so-called contact- and non-contact modes.

Page 11

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Figure 4

: Schematic drawing of the interference signal.

Contact mode:

The tip is in direct contact with the sample, while the intensity is in the

middle of the intensity range. The cantilever is not oscillating. Due to a de-

tuning of the cantilever position before contacting the surface, a

compressive force is applied onto the sample. The strength of the force

corresponds to the amount of detuning times the force constant of the

cantilever.

For example, the cantilever position can be adjusted off contact such that

the intensity is in a minimum. Now, by engaging the feedback loop, the

sample is lifted up until the tip engages with the sample surface. While still

increasing the sample height, the smaple pushes the cantilever up until

the intensity reaches the middle intensity value. The amount of bending

corresponds in this case to a cavity length difference of /8, and hence the

force on the tip is F =

/8*k, with kbeing the force constant of the

cantilever. As the feed-back loop keeps the intensity constant, the amount

of bending is kept. Hence, the force on the tip is kept constant.

Non-contact mode:

For non-contact mode, no detuning is applied; the cavity length is such

that the signal is in the middle between the extrema. Then, the cantilever

is excited by the dither piezo at its resonance frequency. The input of the

lock-in measures the AC component of the photo-detected signal, which

reflects the oscillation amplitude of the cantilever. As the cantilever

approaches the sample, the oscillation amplitude drops rapidly with

decreasing tip-sample distance. This signal serves as the input to a feed-

back loop which maintains the cantilever oscillation amplitude at a so

called ‘set level’, which corresponds to a given force between the sample

and the cantilever. During the scan, the output signal of the feedback loop

is recorded (z-scanner piezo voltage), providing a topographic image.

d

Page 12

III. Components of the Microscope and Technical Specifications

III.1. Microscope Setup

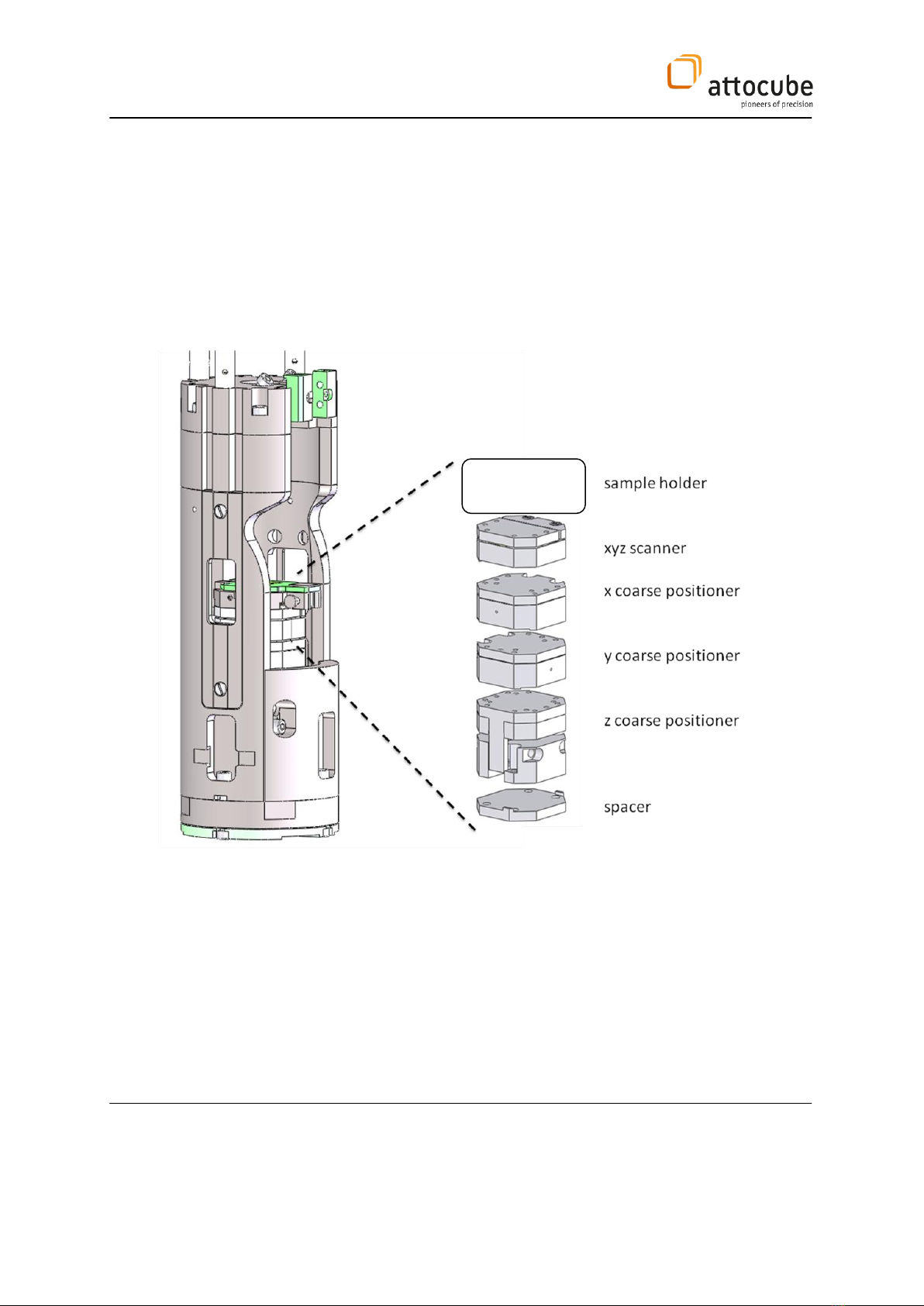

The sample is mounted onto a stack consisting of an ANPxyz101 coarse

positioning unit, an ANSxyz100 scanner and a copper sample plate that

carries heater and temperature sensor. The attoAFM I module, consisting

of the cantilever holder and the attoAFM I head together with the fiber

based deflection detection system, is fixed onto a slide which is mounted

in the microscope housing.

The microscope module is mounted below the 3He pot . The top of the 3He

insert contains all electrical connectors and feedthroughs, the vacuum

window, and the fiber feedthrough. The AFM module including the fiber-

and sample positioning units is attached to the bottom of the insert, see

Figure 5. The microscope housing is inserted into a inner vacuum chamber

(IVC) and subsequently sled into the cryostat utilizing a log G10 tube .

Figure 5:

Image of the attoAFM I housing

The positioning stage ANPxyz101 is built from three individual positioners

mounted on top of each other (please find the specifications in the

respective manual). The ANSxyz100 scanners will be mounted on top of the

positioner stack, followed by a plate with integrated heater and

Page 13

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

temperature sensor. Finally, the quik exchange sample holder is mounted

to the very top of the assembly.

The stack will be delivered completely mounted. If you ever need to

disassemble and consequently reassemble it, please recheck the correct

orientation (which is given in the system specs) and the correct order of

the different parts and screws. Wrong screws may cause severe damages to

the scanners and positioners.

Figure 6:

Standard assembly of the stack with a lower coarse-positioning unit and an upper scanner unit. The

sample holder is specially designed for the 3He system.

Page 14

III.2. Electronics

III.2.a. ANC300: High voltage amplifier

The ANC300 can be used either as ‘piezo positioning controller’ or as ‘high

voltage amplifier’.

Four axes of the ANC300 controller provide the high voltages for driving

the attocube scanners for fine positioning (voltage amplifier with an

amplification factor 15).The fourth axis is another high-voltage amplifier

that drives the dither piezo of the attoAFM I.

For technical specifications please refer to the respective manual.

The axis number is counted from the right to the left.

For technical specifications please refer to the respective manual.

Figure 7

: ANC300 used as high voltage amplifier on the axes 1-4, and as a AC-DC coupler for the tip voltage.

III.2.b. ACC100: LDM1300 Laser Detector module and Break-Out Panels

The ACC100 is a 19”housing that allows to attach electrical break-out

panels as well as additional electronic modules, e.g. the LDM1300 laser

detector module.

The electrical break-out panels convert the 12- and 8-pin Fischer

connectors to easy accessible BNC connectors.

Page 15

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

Figure 8

: The ACC100 with the Break-Out-Panels and the LDM1300.

Four break-out panels serve as connector panels between the controllers

with BNC outputs and the microscope with multi-pin Fischer cables.

For details about the labelling and electrical connections see section IV.1.

III.2.c. ANC350 Piezo controller for positioners

Piezo controller driving /RES encoded attocube positioners in coarse and

fine positioning mode. Please note that for the He-3-system highly

resistive wires are taken for the resistive encoding. This is why you need to

upload a modified RESencoder-file with the extension ‘_mod’. The original

files may be taken without highly resistive wires.

For technical specifications please refer to the respective manual.

Figure 9

: The ANC350 piezo controller.

Page 16

III.2.d. Laser detector module: LDM1300

The attoAFM I system includes a temperature-stabilised laser-detector

module, the LDM1300.

The wavelength of the laser diode is 1310 nm. The built-in photodetector

may be read out via the ‘DET OUT’ BNC connector.

For technical specifications please refer to the respective manual.

Figure 9

: LDM1300.

III.2.e. ASC500 SPM Controller

The modular and flexible digital SPM controller ASC500 combines state of

the art hardware with innovative software concepts to offer an unmatched

diversity of scanning-probe microscopy applications to the customer. All

desirable functions and high-end specifications for controlling the

experiment of your choice in AFM, CFM, SNOM, and STM are available. The

flexible, FPGA-based architecture allows the implementation of your

particular requirements to the system.

Figure 10

: The ASC500 SPM controller

Page 17

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

III.3. (Dis-)Assembling the attoAFM I Module

This section will describe how to assemble and align the AFM module.

Figure 11:

The assembled attoAFM I module.

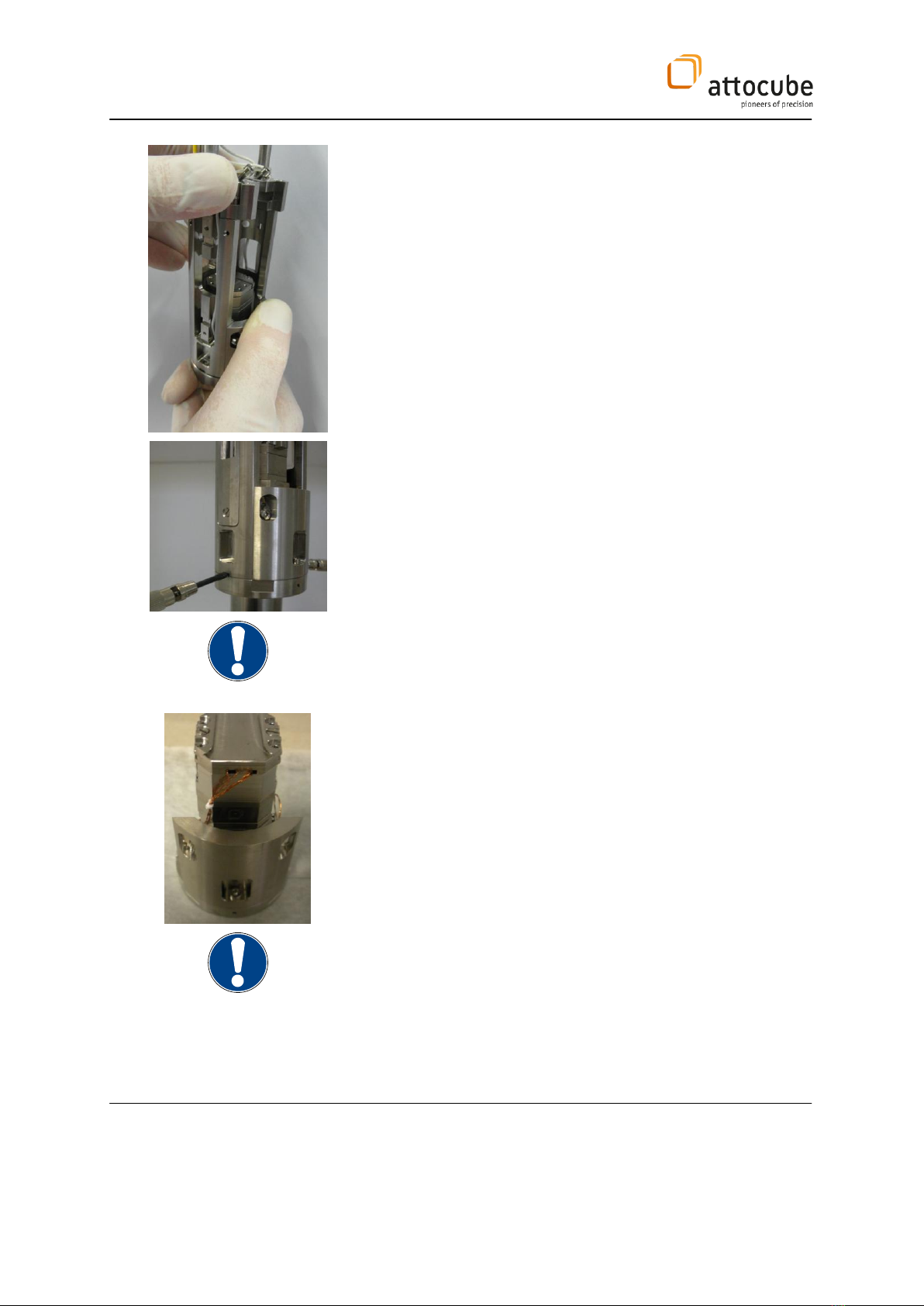

III.3.a. Inserting (removing) the stack into (from) the microscope housing

The microscope stack is fixed to the housing bottom. By loosening

the two screws in the front and opening the three screws on the

left, right and back side the whole bottom part including the

positioner stack may be pushed down and electrically disconnected

from the stick.

The stack and bottom plate may then be taken off towards the front

of the housing.

Open

bottom

screws

Loosen front

screws

Page 18

As there might be some force needed to disconnect the bottom

plate, we recommend keeping the housing with one hand and using

the thumb of the other hand to push the front plate down.

Noteworthy, two slits on the sides of the bottom plate may be used

to smoothly lever off the plate using a screw driver.

Before mounting the stack back into the housing, inspect the

cabling before pushing the bottom plate upwards. Make sure not to

squeeze any wire!

‘Bottom part’, including the housing bottom plate and positioner

stack.

You must not disassemble the stack. If there is any problem with

the stack please contact attocube AG for support.

Page 19

© 2001-2015 attocube systems AG. Product and company names listed are trademarks or trade names of their respective

companies. Any rights not expressly granted herein are reserved. ATTENTION: Specifications and technical data are subject

to change without notice.

III.3.b. Mounting the Scanner-Positioner Stack

Carefully place the stack onto the spacer plate on the bottom plate. Make

sure that the stack cannot fall down. Move the stack backwards until the

outer shape matches with the spacer plates.

Introduce two screws (M2.5 x 8) in the bottom plate in order to fix the

stack, see picture. Once the screws are tightened a little by hand, you can

use a screwdriver to tighten them further.

III.4. Sample Exchange and Thermal Contact

In order to change samples you need to take of the stack, as described

above.

A copper plate is fixed on top of the stack, electrically isolated but

thermally coupled, to the copper body that is directly connected/coupled

to the 3He-pot with copper braids.

For cleaning the sample holder acetone as well as alcohol may be used

(please take care that no conductive paste gets between the sample

plate and the lower copper body).

The sample holder may be electrically connected with a single pin

connector to set the sample potential. In the present setup the pin ‘S’ is

supposed to be connected to the sample holder (with a manganin wire) .

In order to fix the sample Apiezon N (available in the tool box) and/or

silver paste (available in the tool box) should be used.

The temperature sensor may be fixed with a headless set screw. Note that

this screw should only be fixed gently, in order to protect the sensor.

Attocube also recommends to cover the smaller top plate of the sensor

with Kapton tape (that can be found in the tool box).

For additional electrical connections, the pins X2…X6 on the housing

bottom may be accessed on the break-out panel ‘4’ of the electronic rack,

delivered with the microscope.

After the sample has been changed, the housing can be assembled again

and at last the copper rods need to be attached to the upper copper body

as shown in the picture to the left with two screws. These screws should

be tighly closed in order to give as good thermal conduction as possible.

Attocube also recommends to polish the inner surfaces of this contact

from time to time and to add a little bit of Apiezon grease (that can be

found in the tool box) before closing it.

Page 20

III.5. Changing the AFM Cantilever

Table of contents