Attonic AD-FG Series User manual

Digital Force Gauge

Operation Manual

AD-FG Series

ATTONIC CO., LTD.

Standard type

・

After reading this manual, be sure to keep it in a place where the users can refer to it whenever necessary.

WARNING

1-18.If a situation other than the contents of this manual occurs, stop using this gauge immediately and contact us.

substances.

1-16.Our products use nickel-hydrogen rechargeable batteries. It is a recycled resource.

If you need to replace the battery, please leave it to us.

1-17.Turn off the power of all devices before connecting to an external device.

Failure to do so may result in electric shock or equipment damage.

malfunction.

・Do not use a DC power supply or engine generator. It may cause a malfunction or fire.

・Recharge the battery in a well-ventilated place. Do not cover it with any sheet like a cloth while charging.

1-14.Be careful of electric shock. Do not touch the power plug with wet hands. It may result in electric shock.

1-15.Do not throw the battery (built into the main body) into a fire. The battery will explode or release harmful

This gauge is a precision equipment, do not disassemble it.

If equipment malfunctions occur due to excessive impact or vibration, it will not only fail to perform adequately,

but also cause accidents and injuries.

1-13.Charge it properly.

・

Use only the supplied AC adaptor for charging. Using an AC adaptor other than the one supplied may cause a

1-11.Ask your dealer for repairs.

・Do not modify this gauge.

・Be sure to contact the dealer where you purchased this gauge for repairs. If it is repaired by a person without

repair knowledge or skills, it will not only fail to perform adequately, but also cause accidents and injuries.

1-12.Do not disassemble this gauge, or subject it to strong impact or vibration.

function.

・Check if there are any abnormalities in all parts that affect the use.

・ Replace the parts according to this manual.

1-10.Use the specified accessories, appropriate bits and sockets. Do not use any accessories or attachments not

described in this manual.

In the following cases, switch off the main body and disconnect the plug from the power supply.

・When not used or charged.

・When other danger is predictable.

1-9.Check if there are any damaged parts.

・Before use, checkitthoroughly forany damage, and ensure that it works normally and performs the designated

cords out from the outlet or connector.

1-8.For safe and efficient operation

・Check the main body and attachments, etc. regularly, and use the ones that are not deformed and worn.

・

Follow the operation manual when replacing accessories.

・Check the cords and extension cords regularly, and replace them if they are damaged.

・Use in a place where the temperature is constant (about 23 ℃) , if possible.

・Make sure the workplace is adequately lit.

・Do not use or charge in a place with flammable liquid or gas.

1-6.Keep children away. Only the operator is permitted to enter the workplace.

1-7.Don not handle the cords roughly. Do not hold the cords to carry the main body with the cords attached, or pull the

1-2.Do not use this gauge to measure an impact type fastening tool.

1-3.Make sure the main body is firmly secured so that it will not swing around when measuring.

1-4.Always keep the workplace clean. A cluttered place or workbench could cause an accident.

1-5.Also consider the surrounding conditions of the workplace.

・Do not use in a place with high temperatures, high humidity, direct sunlight, or a lot of dust or dirt.

1.Safety precautions

・To prevent accidents such as fire, electric shock and injury, be sure to observe the following "Safety Precautions".

・Read all of the "Safety Precautions" carefully before using this gauge, and follow the instructions to use it correctly.

1-1.Do not overload. If a load exceeding the allowable range is applied, the detector may be damaged, resulting in an

accident or injury.

!

2.Precautions for storage and use

charge it.

(The above information is common to almost all of our products, however, may not be fully applied to some products.)

2-7.Do not use in an environment of oil, dust, high temperature and humidity.

2-8.After use, store it in a safe place so that no load is applied to the detection shaft.

2-9.Do not use organic solvents, etc. when cleaning this gauge.

2-10.If the product is left unused for a long time, the battery may deteriorate and cannot be recharged.

Turn on the power of this gauge once a month to check the charging status, and if charging is required, be sure to fully

・Use your common sense.

・Do not use it when you are tired.

2-5.Do not apply large twisting forces, lateral bending forces, and forces that exceed a tolerance to the detection shaft,

otherwise, the detector will be damaged.

2-6.Do not use this gauge for any purpose other than measurement.

operation.

2-3.Do not work in an unnatural working posture. Keep proper footing and balance at all times.

2-4.Do not be negligent in using this gauge, and handle it with great caution.

・When using this gauge, operate it very carefully while paying full attention to the method of handling and operation,

the surrounding conditions and so on.

2-1.Store this gauge properly when it’s not in use. Store in a dry place, high place or locked place out of the reach of

children. Also, please use the original packing box that contained this gauge when transporting.

2-2.Wear proper clothes. Do not wear loose clothing, necklaces, or other jewelry as they may interfere with the

!

⑨Charge Pilot Lamp

⑩USB Connector (Mini USB Type-B)

※Please keep the screw length which inserted into main unit should be under 10mm.

If you insert the screw more than 10mm, it is possible that the internal board is broken and cause

malfunction.

⑥Battery fixing screws (2places)

⑦Display

⑧DC IN (Power Jack)

③FUN Switch ⑬Detection shaft

④RES Switch

⑤Mounting screws for the main

body (M4 3places)

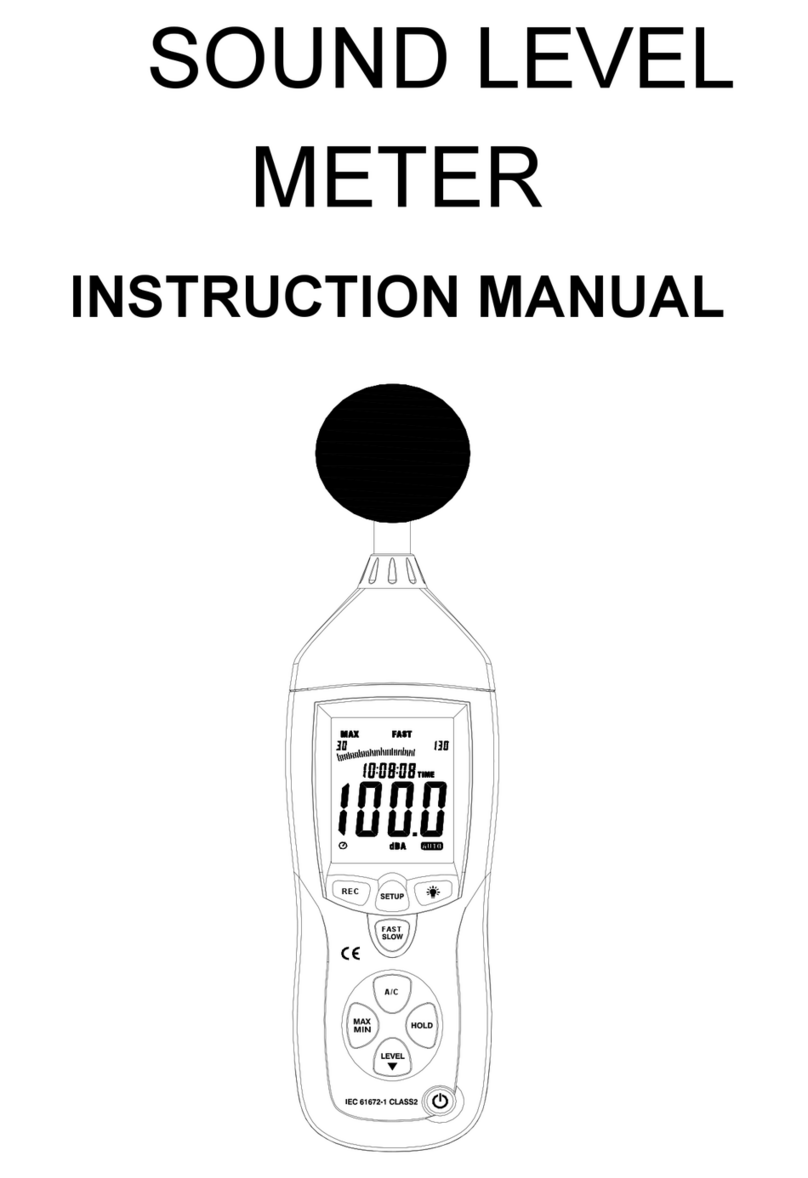

3.Parts names

3-1.The name and application area of parts

①POW Switch ⑪I/O Socket

②DAT Switch ⑫ANALOG Output Jack

⑤⑦

⑥

①

②

③

④

⑧

⑩

⑪

⑫

⑬

⑨

3-2. Attachments

S-2 (V type B) S-3 (Cone type) S-4 (Flat type)

S-6 (Extension rod type)

S-1 (V type A)

S-5 (Hook type)

S-7 (Double-hook type)

4.Specifications

FG1 FG5 FG10 FG50

±1.000

~

±10.00N

±5.00~

±50.00N

±10.00

~

±100.0N

±50.0

~

±500.0N

±100.0~

±1000gf

±500~

±5000gf

±1.000~

±10.00kgf

±5.00~

±50.00kgf

±0.220~

±2.200

lbf

±1.10~

±11.00

lbf

±2.20~

±22.00

lbf

±11.0~

±110.0

lbf

PEAK

TRACK

Compression

Peak/Tension Peak

(P-P)

Accessorie

Materials

AD-

FG

1

~

5

Aluminum

AD-

FG

10

~

50

Iron

S-1、S-2、S-3、S-4、S-5、S-6、S-7

Measurement

mode

Measurement range

AC adaptor (AD-20)

USB cable (AD-USB-1.5)

Net weight About 800g

Attachments Others

S-1、S-2、S-3、S-4、S-5、S-6、S-7

Data output ASCII format (Baud rate: 19200)

Dedicated charger IN:AC100V~240V OUT:DC9V

Dimension About 187(208 with the shaft included)(L)×80(W)×42(H)

Usage time About 12 hours in continuous use

Battery life Rechargeable more than 300 times (depending on usage conditions)

Auto power off Power off after being left for 10 min.

(Measurement without any time limit is also available)

Battery-powered Rechargeable Ni-MH Battery 1.2v×4cells (1650mAh)

Measurement unit Switchable 3 units: N/ kgf(gf)/lbf

Charging time About 3 hours

Measurement direction Compression - Tension (+ for compression and - for tension as standard.)

Hold the maximum load

The display changes as the load changes. Used for zero adjustment, etc.

Hold the peak values of compression and tension.

Model (AD-)

Accuracy ±0.2% FS

Display 4 Digits LCD

* If you need to recharge the battery immediately, use the supplied AC adaptor to recharge the battery.

:

In good condition with more than 50% power remained.

:

Less than 50% remaining. A status that requires caution. (still usable)

・

When measuring by holding this gauge in your hand, please be careful about the surroundings.

・

When fixing this gauge, use a tool appropriate to fixing it firmly in 3 places with M4 screws.

* When fixing to a device, etc., check the fixing method and fix this gauge firmly with a tool, etc.

5-3.Attachment installation

・

Use the supplied attachments according to the measurement conditions.

* If you cannot measure with the supplied attachments, please contact us.

We also manufacture special attachments.

* Do not use attachments from other suppliers. They may cause a malfunction or injury.

Cautions

5-2.Mounting

・When the power is turned off, the stored data (N:〇〇〇) will be cleared to zero.

5.Preparation for measurement

5-1.Check the charging status

Be sure to check the charging status (battery icon) before using this gauge.

* The sign on the upper left of the screen is the battery icon.

:Recharging is required immediately.

Battery icon

* Once set, these settings are memorized

unless the battery runs out or the

settings are changed.

* The display becomes 0 (zero) when

"RES" switch is pressed.

Exit when the screen goes off.

Set other functions.

Compression test Tension test

Long press the "POW" switch

when the test is finished.

6.Basic flow of usage

Power ON

"POW" switch ON

Set measurement mode.

Set measurement unit.

* The set data will not be saved. * The set data will be saved.

maximum measured value of each model.

PP

:

The screen will be displayed in two sections.

Centering on zero, the upper section is the + peak holding and the

0.2% or more of the maximum measured value of each model.

* The unit symbol changes depending on the model.

PEAK:Hold and display the maximum absolute value during

measurement. Hold a torque value from 0.2% or more of the

lower section is the - peak holding. Both hold a torque value from

* Short press the "FUN" switch to confirm the setting. Next is the setting for changing measuring unit.

7-2.Change measuring unit (Initial Unit:N or kN)

・You can change the measurement unit.

Switchable 3 units: N(kN), kgf(gf), lbf

* Short press the "FUN" switch to confirm the setting. Next is the setting for comparator HI.

* "DATA SAVE?" screen appears when you long press the "FUN" switch anywhere in the settings.

Select "OK" or "CANCEL" and press "POW" switch. The setting is complete When measurement screen appears.

7-1.Set measurement mode (Initial Setting:TRACK)

・You can switch the measurement mode.

Switch between TRACK mode and PEAK mode by pressing the "DAT" switch.

The one with a black background is the one selected.

TRACK: The torque value applied to the detector is displayed as it is.

It is used to view measurements that change constantly.

7.Function settings and descriptions

To set each function, long press the "FUN" switch until you hear a beep.

"FUN" will be displayed at the top of the screen when the gauge becomes the function setting mode.

If "FUN" is not displayed, long press the "FUN" switch again until you hear a beep.

* Please note that it is set longer so that the measurement mode will not be switched due to a malfunction during

measurement.

To complete the setting, long press the "FUN" switch again until you hear a beep.

The screen will look as follows.

Select "OK" if you want to save the data, or "CANCEL" if you don't, and press the "POW" switch.

"POW" Switch

"POW" Switch

"DAT" Switch

"POW" Switch

"DAT" Switch

"DAT" Switch

The display changes every time

the "DAT" switch is pressed.

intermittent sound continues.

* A long intermittent sound will be heard if the LO setting value (- side) is exceeded, and a short one if the HI

setting value (+ side) is exceeded. After that, even if the LO peak value is exceeded, there is still a short

intermittent sound.

* The position of the decimal point varies with each unit and each model.

* For models that increase in digits, the maximum setting value is 9999.

For example: When the unit is N in AD-FG10, the settable maximum value is 99.99(N).

* The setting value returns 0 when the mode is changed.

* Short press the "FUN" switch to confirm the setting. Next is the setting for comparator LO.

* It returns to the beginning when the "DAT" switch is pressed 4 times.

〇PP Mode

・You can change the setting value on the + side (upper section) of comparator.

For example, if you set the point of + side (HI) to 500N and the point of - side (LO) to -100N, and

gradually apply force to the + side from 0N, the display of the upper section will be changed, and

when the force exceeds 500N, a short intermittent sound will be heard.

* The setting value should be entered as the value of + side instead of an absolute value.

* A short intermittent sound will be heard if the HI setting value (+ side) is exceeded, and a long one if the LO

setting value (- side) is exceeded. After that, even if the HI peak value is exceeded, a long

〇TRACK / PEAK Mode

・You can change the HI side setting value of the comparator.

A comparator is a comparison with a set value.

For example, if you set the point of high value (HI) to 500N and the point of low value (LO) to 100 N,

and gradually apply force from 0N, LO will be indicated at first, but the display will disappear when the force

exceeds 100N, and HI will be indicated when the force exceeds 500N.

* When the HI or LO value is set, the external output is also outputted in conjunction with it.

* The setting value should be entered as an absolute value (regardless of whether it is positive or negative).

7-3.Set comparator HI (Initial value: 0000)

"POW" Switch

"POW" Switch

"DAT" Switch "DAT" Switch

This digit blinks.

The digit shifts to the

left by one place every

time the "DAT" switch

is pressed.

This digit blinks when

the "DAT" switch is

pressed 3 times.

"DAT" Switch

The value will increase if the "POW"

switch is pressed while this digit is

blinking.

"POW" Switch

"9" is indicated when the "POW" switch is pressed 9

times.

It returns “0” when the "POW" switch is pressed again.

・

It is a function to warn the users to avoid accidental damage to the load sensor.

7-6.Set screen update rate UD (Initial value: 20)

・You can set the screen update rate (switching speed).

By decreasing the value, you can check the changing values in more real time.

However, if the update rate is too fast, the values will change quickly and it may be difficult to see.

* Update rate is in seconds. If the display value is 20, the display will be updated every 20 seconds.

* There are 4 types of settings: 20, 10, 5, and 2 seconds.

* Short press the "FUN" switch to confirm the setting. Next is the setting for flipping screen.

For example: When the unit is N in AD-FG10, the settable maximum value is -99.99(N).

* The setting value returns 0 when the mode is changed.

* Short press the "FUN" switch to confirm the setting. Next is the setting for overload.

7-5.Set overload OV (Initial value: 120)

For example, when this gauge is set on a load stand to perform a test, it can display a warning at 80% of full

scale and output a signal to stop the test so that the sensor is not damaged by applying excessive force

accidentally.

* The setting can be set by 10% up to 120%.

* Short press the "FUN" switch to confirm the setting. Next is the setting for screen update rate.

* The setting value should be entered as the value of - side instead of a absolute value.

* A short intermittent sound will be heard if the HI setting value (+ side) is exceeded, and a long one if the LO

setting value (- side) is exceeded. After that, even if the HI peak value is exceeded, there is still a long

intermittent sound.

* A long intermittent sound will be heard if the LO setting value (- side) is exceeded, and a short one if the HI

setting value (+ side) is exceeded. After that, even if the LO peak value is exceeded, there is still a short

intermittent sound.

* The position of the decimal point varies with each unit and each model.

* For models that increase in digits, the maximum setting value is 9999.

7-4.Set comparator LO (Initial value: 0000)

〇TRACK / PEACK Mode

・You can change the setting value on the LO side of comparator.

*Refer to "7-3. Set comparator HI" for the function description, setting method, and operation method.

〇PP Mode

・You can change the setting value on the - side (lower section) of comparator.

For example, if you set the point of + side (HI) to 500N and the point of - side (LO) to -100N, and

gradually apply force to the - side from 0N, the display of the lower section will be changed, and

when the force exceeds -100N, a short intermittent sound will be heard.

"POW" Switch

"POW" Switch

"POW" Switch

"POW" Switch

"POW" Switch

"POW" Switch

Increase by 10 every

time the "POW" switch

is pressed.

"POW" Switch

"POW" Switch

・Set whether to display the minimum digit or not.

The display looks more stable when the minimum digit is not displayed (OFF).

* The display range varies depending on the model. For the display range, refer to the display range table.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for buzzer.

* Short press the "FUN" switch to confirm the setting. Next is the setting for auto reset.

7-9.Set auto reset AC (Initial Setting: OFF)

・It is a setting to automatically reset after 3 seconds when the load disappears.

You don't have to press the reset button every time you run the same test over and over again.

* When reset, the data will be saved automatically.

* Work efficiency will increase when used in combination with printer output.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for the minimum digit display.

7-10.Set the minimum digit display MD (Initial Setting: ON)

For example, when measuring with the detection shaft facing up, the values are reversed and difficult to

read, but by turning on this setting, the values can be read as they are.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for auto power off.

7-8.Set auto power off AF (Initial Setting: ON)

・It is a setting to turn off the power if no operation is performed for 10 minutes.

Turn this setting OFF if you want to use the gauge for a long time.

The measurement will remain until the battery runs out.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

7-7.Set flipping screen DP (Initial

Setting

: OFF)

・It is a setting to flip the screen.

The display changes every time the

"DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for reset to initial setting.

7-12.Set backlight BL (Initial Setting: OFF)

・Turn the backlight ON / OFF.

Turn on the backlight when using in a dark place. The backlight will brighten the screen and make it easier to see.

* When the backlight is ON, it consumes a lot of battery power and shortens the usage time.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for polarity.

7-13.Set polarity IN (Initial Setting: OFF)

・When OFF, compression side is set to + and tension side is set to -, but when ON, compression side is set to -

and tension side is set to +.

Comparator HI Intermittent sound (fast) Remove the load and press "RES" switch.

Comparator LO Intermittent sound (slow) Remove the load and press "RES" switch.

Switch operation

Short sound

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

* Short press the "FUN" switch to confirm the setting. Next is the setting for backlight.

* The following is a list of buzzer sounds.

Action

Sound The way to stop buzzer

Overload

Continuous sound Remove the load and press "RES" switch.

7-11.Set buzzer

BP

(Initial

Setting

: ON)

・Set whether to sound the buzzer or not.

The buzzer gives a warning during the main body operation or various settings.

When the buzzer sound is annoying, you can turn it off to silence the sound.

The display changes every time

the "DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

7-14 Reset to Initial Setting IV (Initial Value:OFF

)

・

Reset all setting into Initial Value

※

Change ON/OFF by pressing "DAT" switch

※

Short p

ress the "FUN" switch for confirm & Move to Printer Output Setting

※

All setting will be changed into initial value after completing the setting.

List of Initial Value

MARK Initial Setting

TRACK

UN

N or kN

HI

0

LO

0

OV 120

UD

10

DP OFF

AF ON

AC OFF

MD ON

BP ON

BL OFF

IN OFF

IV OFF

PO OFF

7-15.Set printer output PO (Initial Setting: OFF

)

・

Set whether to output to the printer or not.

When the printer output setting is ON, the display data can be outputted to the printer by pressing the "RES"

switch.

* Use Mitutoyo's Digimatic Mini Processor DP-1VA as the printer.

* You can switch ON / OFF repeatedly by pressing the "DAT" switch.

*When “TRACK” mode is chosen, it cannot be printed out even though Printer output setting is ON.

*When Printer Output Setting is ON & “PEAK” or “PP” mode is chosen, the letter “PO” is showed at the lower left

part of display.

(This letter “PO” is not shown when “TRACK” mode is chosen)

When you push Reset switch at this moment, the main unit will not be controlled while few seconds until the

display is reset because the main unit is in the mode for searching printer.

Please choose this setting “OFF” when you do not use printer.

* Short press the "FUN" switch to confirm the setting.

Returns to the first setting(7-1. Measurement mode).

FUNCTION NAME

Page to refer

Set measurement mode

7-1

Change measuring unit

7-2

Set comparator HI

7-3

Set comparator LO

7-4

Set overload OV

7-5

Set screen update rate UD

7-6

Set flipping screen DP

7-7

Set auto power off AF

7-8

Set auto reset AC

7-9

Set printer output PO

7-15

or

Set the minimum digit display MD

7-10

Set buzzer BP

7-11

Set backlight BL

7-12

Set polarity IN

7-13

Reset to Initial Setting IV

7-14

The display changes every time

the "DAT" switch is pressed.

The display changes every time

the "DAT" switch is pressed.

* The larger the number of N:

〇〇〇

, the newer the data.

* When the number is more than N

:

999 (over 1000 data), the old data will be overwritten.

* Short press the "FUN" switch to move to the batch transfer function.

* Long press the "FUN" switch to return to the measurement mode.

1000 data from N:000 to N:999 can be imported.

The "MO" in the upper right conner of the screen disappears and the gauge becomes measurement mode.

8-1.Display history data

You can check the stored data.

The N:〇〇〇 at the top center of the screen is the number of imported data.

When the display shifts to history check screen, "MO" will be displayed in the upper right corner of the screen.

If "MO" is not displayed, long press the "DAT" switch again until you hear a beep.

* Please note that it is set longer so that the measurement mode will not be switched due to a malfunction

during measurement.

To complete the setting, long press the "FUN" switch again until you hear a beep.

8.Checking method on history data and function description

Measure in peak mode and press the "RES" switch to save the value at that time.

You can go back and check the history of those values.

■Check history data

To check history data, long press the "DAT" switch until you hear a beep.

"DAT" switch

"DAT" switch

"POW" switch

N:〇〇〇 increases every

time the "POW" switch is

pressed.

N:〇〇〇 decreases every

time the "DAT" switch is

pressed.

"POW" switch

"POW" switch

"POW" switch

"DAT" switch

"DAT" switch

8-2.Batch transfer

When this "N: 020" is set, 20 data will be transferred in a batch.

8-3.All clear

* Short press the "FUN" switch to move to history data display function.

* Long press the "FUN" switch to return to measurement mode.

* Short press the "FUN" switch to move to all clear function.

* Long press the "FUN" switch to return to measurement mode.

Delete all the stored data.

* For example, if the number of stored data is 20, "N:〇〇〇" at the top center of the screen will be "N: 020".

Transfer all the stored data to a PC, etc. in a batch.

* For example, if the number of stored data is 20, "N:〇〇〇" at the top center of the screen will be "N: 020".

* The value of "〇〇〇" in "N: 〇〇〇" cannot be changed.

* The value of "〇〇〇" in "N: 〇〇〇" cannot be changed.

The display changes every

time the "DAT" switch is

pressed.

Press the "POW" switch

to transfer the data.

* This screen

appears when the

data transfer is

finished.

To all clear function

"FUN" switch

The display changes every

time the "DAT" switch is

pressed.

Press the "POW" switch

to delete the data.

* This screen

appears when the

data deletion is

finished.

To history data display

function

"FUN" switch

If the USB data transmission

fails and then press the 「POW」

switch, the screen display will change

to "CANCEL".

mode.

The MAX/MIN/AVE values of all stored data can be displayed.

* Long press the "FUN" switch to return to the measurement mode.

* The data is displayed in absolute value.

upper right corner of the screen.

If "AV" is not displayed, short press the "DAT" switch again.

To complete the setting, long press the "FUN" switch until you hear a beep.

The "AV" display in the upper right corner of the screen disappears and the gauge becomes measurement

9-1.MAX/MIN/AVE values

9.Checking method on MAX/MIN/AVE values and function description

You can check the MAX/MIN/AVE values of all stored data.

■Check MAX/MIN/AVE values

Short press the "DAT" switch in peak mode (PE) to check MAX/MIN/AVE values.

When the display shifts to the check screen for MAX/MIN/AVE values, "AV" will be displayed in the

MAX:maximum value

MIN:minimum value

AVE:average value

"DAT" switch

"DAT" switch

"DAT" switch

10.I/O connector

■

The pin layout of I/O connector

Pin No. Name I/O

1 VBO -

2 POW I

3 COP I

4 INT I

5 RES I

7 OK O

9 OV O

10 CLK -

11 DAT -

12 RDY -

13 REQ -

14 GND -

■

Circuit diagram

Power supply circuit

* External supply voltage: max. DC24V

Input circuit Output circuit

* Max. DC24V 20mA * Max. DC24V 50mA

Digimatic REQ

External ground (circuit board ground is also possible)

* Pin No.10~13 are for Mitutoyo's printer output only.

Mitutoyo's Digimatic Mini Processor (DP-1VA)

6

8

HI

LO

O

O

(ON when the display value of - side is greater than or equal to the setting value in PP mode. )

ON when it is overloaded.

Digimatic CLK

Digimatic DAT

Digimatic RDY

RES switch

ON when the value is greater than or equal to comparator HI.

(ON when the display value of + side is greater than or equal to the setting value in PP mode. )

ON when it is OK.

ON when the value is less than or equal to comparator LO.

Function

Power input (It is also possible to output battery voltage from the circuit board.)

POW switch

Continuous output (output continues as long as it is ON)

One-shot output (output the value to the PC when the signal is LO)

1

13

2

14

External

voltage

External

voltage

Battery

voltage

Battery

voltage

Load

11.Analog output

The analog output provides an analog voltage proportional to the sensor signal.

■Analog circuit diagram

* Voltage: ± 2V

to the max.

voltage

* Please use an analog earphone jack (with shield) for connection to external devices.

* Do not short circuit. It may cause a malfunction.

* Do not apply voltage from outside.

12.Digimatic data transmission connection

(

Printer

(

DP-1VA

))

* The cable is available as an option.

The measured values can be printed out by Mitutoyo's Digimatic Mini Processor (DP-1VA).

External devices

F.G. shielded wire

Digital force gauge

Dedicated cable

Mitutoyo Co., Ltd.

Digimatic

Mini Processor

DP-1VA

13.Data transmission settings

You can change the settings and the output data via USB.

■

Data Transmission Protocol

Stop bit: 1 bit

Parity bit: None

Delimiter: CR + LF

Flow control: None

■

Transmission and reception code list

"Command" Contents Cautions

Example (all with CR+LF attached at the end)

The signal is transmitted at 2KHz.

(The output continues until the "STOP" signal is received.)

"STOP" Continuous transmission stop STOP

"MEMORY" Transmit all stored data MEMORY

"CLEAR"

ALL CLEAR Delete the stored data CLEAR

"FUNC_MODE"

FUNC Switching Please send first when you change the settings. FUNC_MODE

"TRACK" Change to TRACK TRACK

"PEAK" Change to PEAK PEAK

"PP" Change to PP PP

"GF" Change to gram unit system GF

"NEWTON" Change to Newton unit system NEWTON

"POND" Change to pound unit system POND

Error if more than the settable value.

Cannot exceed the maximum value.

Error if more than the settable value.

Cannot exceed the comparator HI setting.

"OVER:" Overload setting value

Error if not a settable value

.

10

~

120 in 10 increments

OVER:100

"LCD_LATE:" Screen update rate

Error if not a settable value

.

20,10,5,2 only

LCD_LATE:2

"LCD_FLIPPED:" Flip the screen vertically "ON": permission, "OFF": none LCD_FLIPPED:ON

"POWER_OFF:" Auto power off "ON": permission, "OFF": none POWER_OFF:ON

"AUTO_CLEAR:"

ALL CLEAR "ON": permission, "OFF": none AUTO_CLEAR:ON

"MIN_DIGIT:" Minimum digit display "ON": permission, "OFF": none MIN_DIGIT:OFF

"BUZZ:" Buzzer permission "ON": permission, "OFF": none BUZZ:OFF

"BACK_LIGHT:" Backlight permission "ON": permission, "OFF": none BACK_LIGHT:ON

"GAIN_INVERT:" Plus / minus inversion "ON": permission, "OFF": none GAIN_INVERT:OFF

"INIT_VALUE:" Reset to initial setting "ON": permission, "OFF": none INIT_VALUE:

"PRINTER:" Printer permission "ON": permission, "OFF": none PRINTER:ON

"SET_SAVE" Save change value Send it at last to save values. SET_SAVE

"CANCEL" Cancel the change Send it at last to cancel the change. CANCEL

"VALUE_READ" Read current value Read current value. COM_OK is not returned. VALUE_READ

* Receive a reply message of "COM_OK!!" if the command input is correct.

* Receive a reply message of "COM_ERR!!" if the command input is incorrect.

* Be sure to send "SET_SAVE" after changing the settings.

Otherwise, the settings will not be enabled and the display

will not return to the measurement screen, either.

* Once set, it cannot be returned to the original value.

* An example of send command input

Set the comparator HI to 10.0.

Command: setting value CR + LF

COMP_HI: 10.0 CR+LF

"STAT"

"CMP_HI:"

"CMP_LO:"

Continuous transmission

Comparator HI setting

Comparator LO setting

STAT

CMP_HI:2000

CMP_LO:1000

Baud rate: 19200

Character length: 8 bits

This manual suits for next models

8

Table of contents

Other Attonic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments Oyster-16 user guide

Workzone

Workzone 11334 user guide

IN DEVICE

IN DEVICE Dallas 2 user manual

Ahlborn

Ahlborn ALMEMO 204 operating instructions

Diehl Metering

Diehl Metering HYDRUS 171A Installation and user guide

ADA INSTRUMENTS

ADA INSTRUMENTS PROF X15 operating manual