・After reading this manual, be sure to keep it in a place where the users can refer to it whenever necessary.

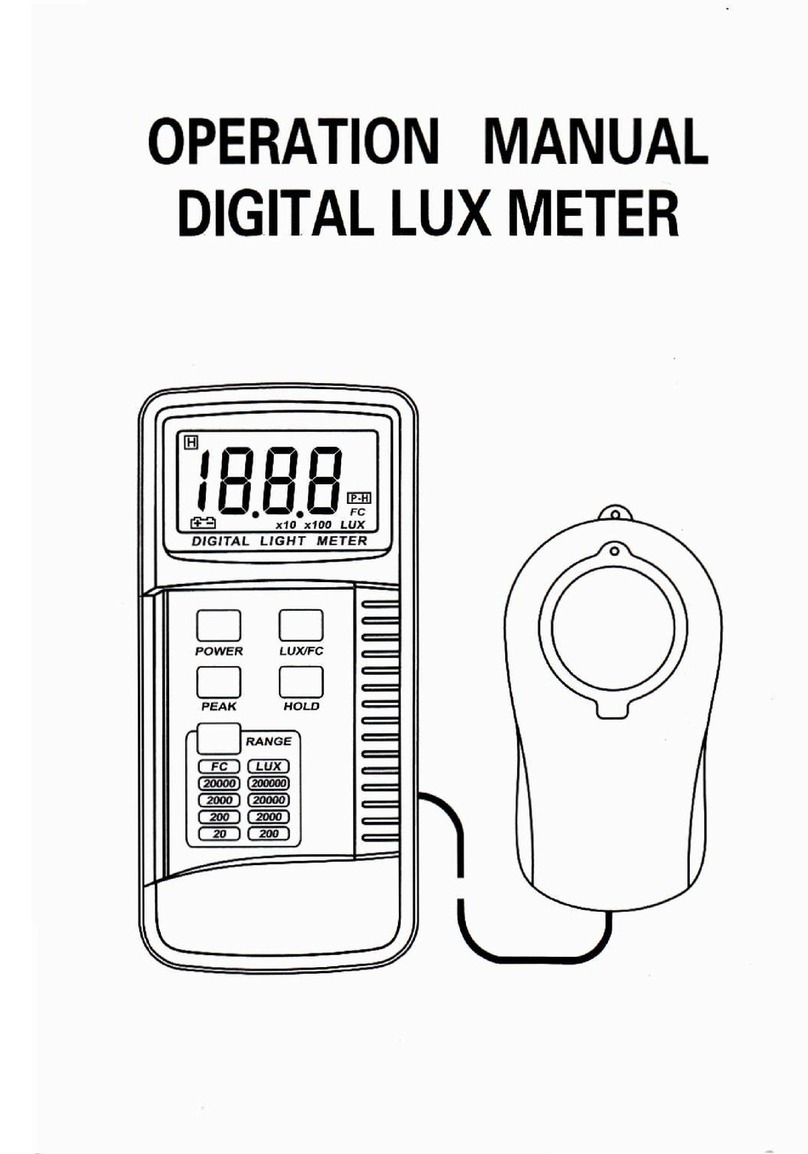

WARNING

1-16.Our products use nickel-hydrogen rechargeable batteries. It is a recycled resource.

1-18.If a situation other than the contents of this manual occurs, stop using this meter immediately and contact us.

substances.

If you need to replace the battery, please leave it to us.

1-17.Turn off the power of all devices before connecting to an external device.

Failure to do so may result in electric shock or equipment damage.

・Do not use a DC power supply or engine generator. It may cause a malfunction or fire.

・Recharge the battery in a well-ventilated place. Do not cover it with any sheet like a cloth while charging.

1-14.Be careful of electric shock. Do not touch the power plug with wet hands. It may result in electric shock.

1-15.Do not throw the battery (built into the main body) into a fire. The battery will explode or release harmful

This meter is a precision equipment, do not disassemble it.

If equipment malfunctions occur due to excessive impact or vibration, it will not only fail to perform adequately,

but also cause accidents and injuries.

1-13.Charge it properly.

・

Use only the supplied AC adaptor for charging. Using an AC adaptor other than the one supplied may cause a

1-11.Ask your dealer for repairs.

・Do not modify this meter.

・Be sure to contact the dealer where you purchased this meter for repairs. If it is repaired by a person without

repair knowledge or skills, it will not only fail to perform adequately, but also cause accidents and injuries.

1-12.Do not disassemble this meter, or subject it to strong impact or vibration.

function.

・Check if there are any abnormalities in all parts that affect the use.

・ Replace the parts according to this manual.

1-10.Use the specified accessories, appropriate bits and sockets. Do not use any accessories or attachments not

described in this manual.

In the following cases, switch off the main body and disconnect the plug from the power supply.

・When not used or charged.

・When other danger is predictable.

1-9.Check if there are any damaged parts.

・Before use, checkitthoroughly forany damage, and ensure that it works normally and performs the designated

cords out from the outlet or connector.

1-8.For safe and efficient operation

・Check the main body and attachments, etc. regularly, and use the ones that are not deformed and worn.

・

Follow the operation manual when replacing accessories.

・Check the cords and extension cords regularly, and replace them if they are damaged.

・Use in a place where the temperature is constant (about 23 ℃) , if possible.

・Make sure the workplace is adequately lit.

・Do not use or charge in a place with flammable liquid or gas.

1-6.Keep children away. Only the operator is permitted to enter the workplace.

1-7.Don not handle the cords roughly. Do not hold the cords to carry the main body with the cords attached, or pull the

1-2.Do not use this meter to measure an impact type fastening tool.

1-3.Make sure the main body is firmly secured so that it will not swing around when measuring.

1-4.Always keep the workplace clean. A cluttered place or workbench could cause an accident.

1-5.Also consider the surrounding conditions of the workplace.

・Do not use in a place with high temperatures, high humidity, direct sunlight, or a lot of dust or dirt.

・To prevent accidents such as fire, electric shock and injury, be sure to observe the following "Safety Precautions".

・Read all of the "Safety Precautions" carefully before using this meter, and follow the instructions to use it correctly.

1-1.Do not apply a torque that exceeds the allowable load. If a torque exceeding the allowable range is applied,

the detector may be damaged, resulting in an accident or injury.

!