Table of contents

1. Safety instructions.......................................................................5

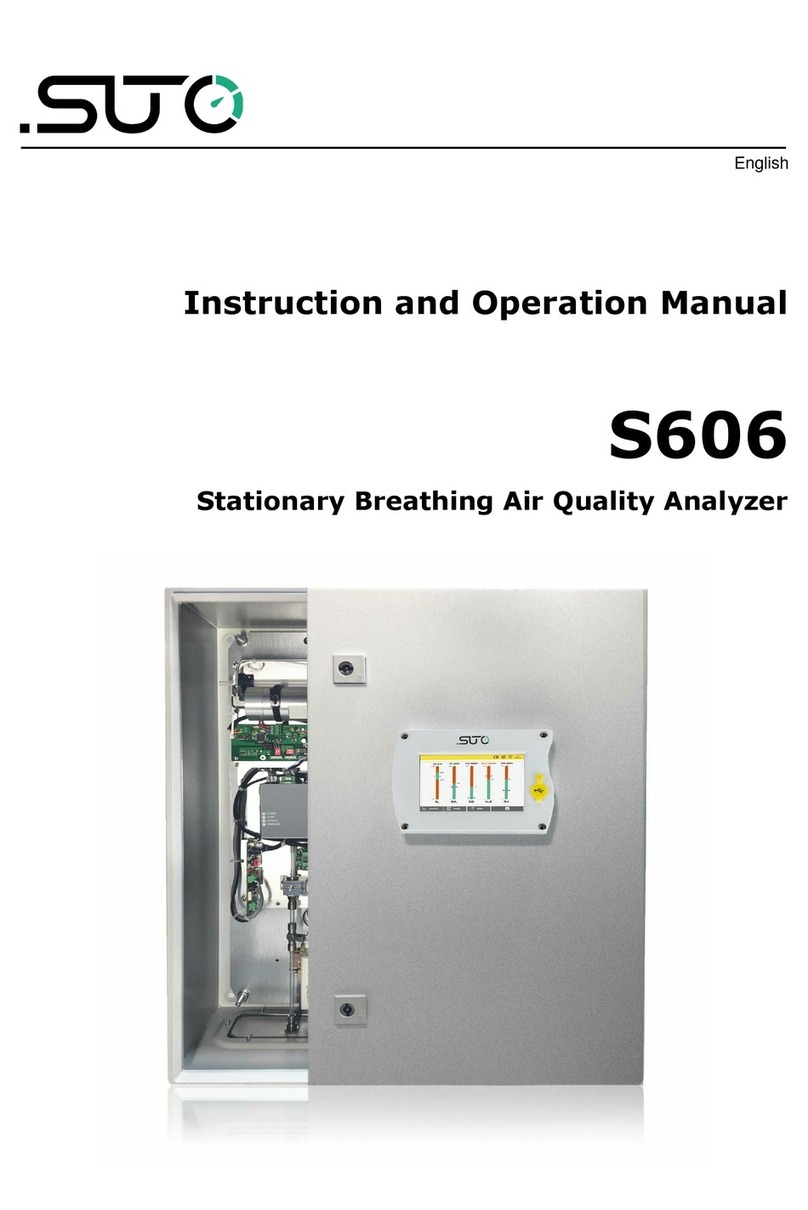

2. Application.................................................................................7

3. Features.....................................................................................7

4. Technical Data............................................................................8

4.1 General.................................................................................8

4.2 Electrical Data........................................................................8

4.3 Input-Signals.........................................................................8

4.4 Output-Signals.......................................................................8

5. Installation ................................................................................9

5.1 Installation Requirements........................................................9

5.2 Installation Procedure ............................................................9

5.3 Electrical connection ............................................................10

6. Configuration ...........................................................................13

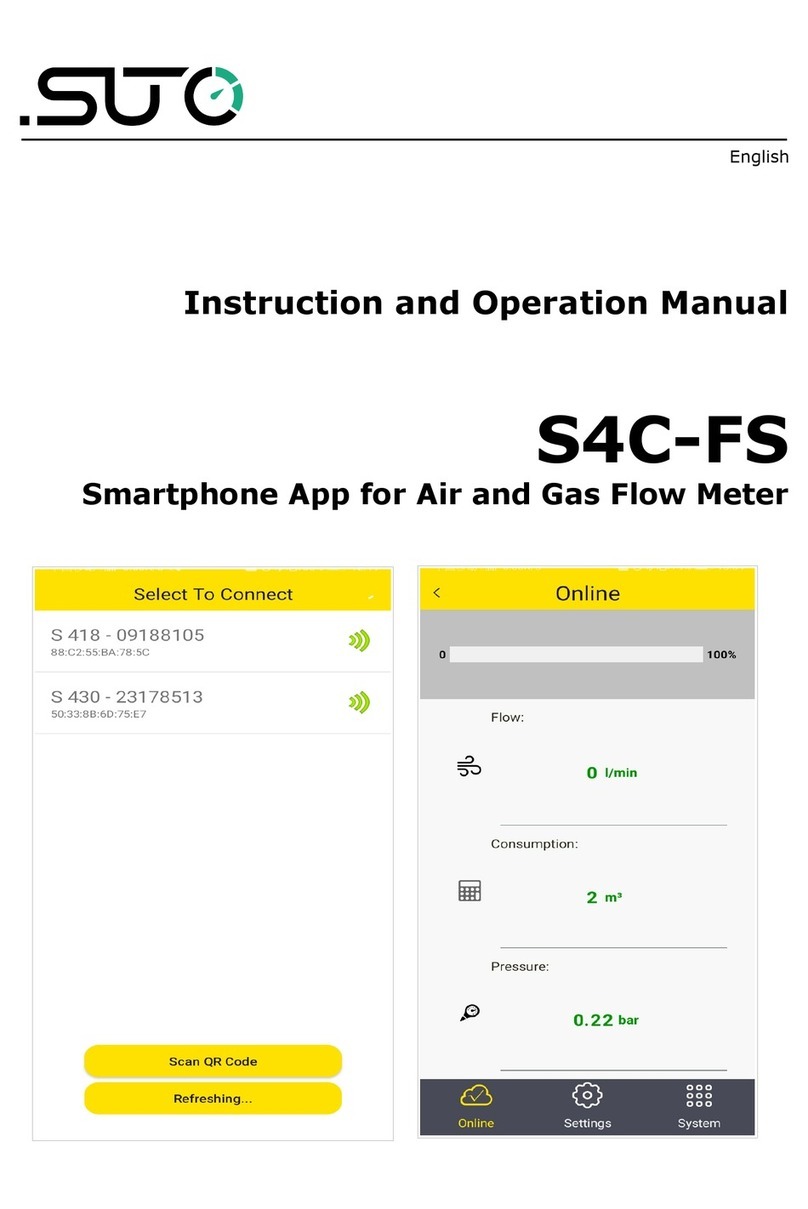

7. Operation ................................................................................13

7.1 Value screen........................................................................14

7.2 The main menu ...................................................................15

7.3 Description of display icons in status bar .................................16

7.4 Graphic screen.....................................................................16

7.5 Sensor setting .....................................................................17

7.5.1 Dew point setting ...........................................................17

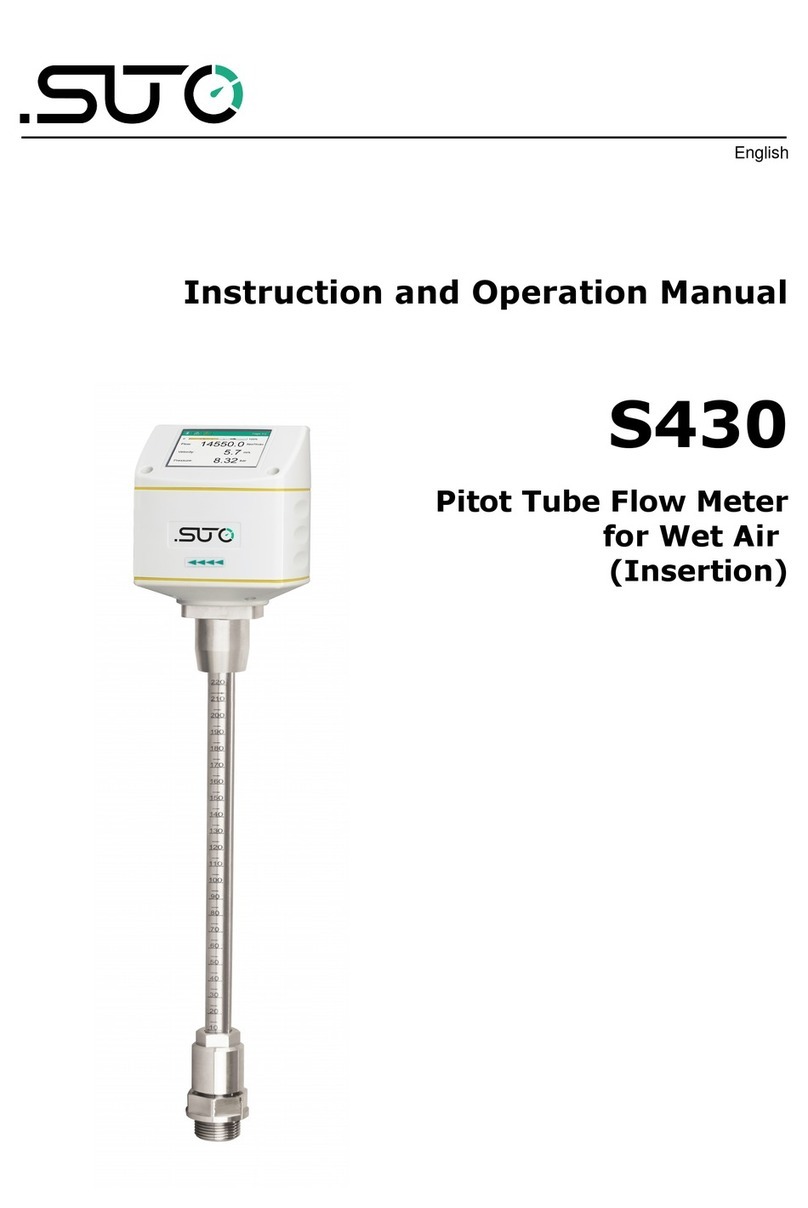

7.5.2 Flow sensor setting ........................................................19

7.5.3 Oil vapor sensor setting ..................................................21

7.5.4 Analog input setting .......................................................22

7.5.5 Power meter S 110-P setting............................................23

7.5.6 Analog e tension module.................................................23

7.5.7 Laser particle counter S 130.............................................23

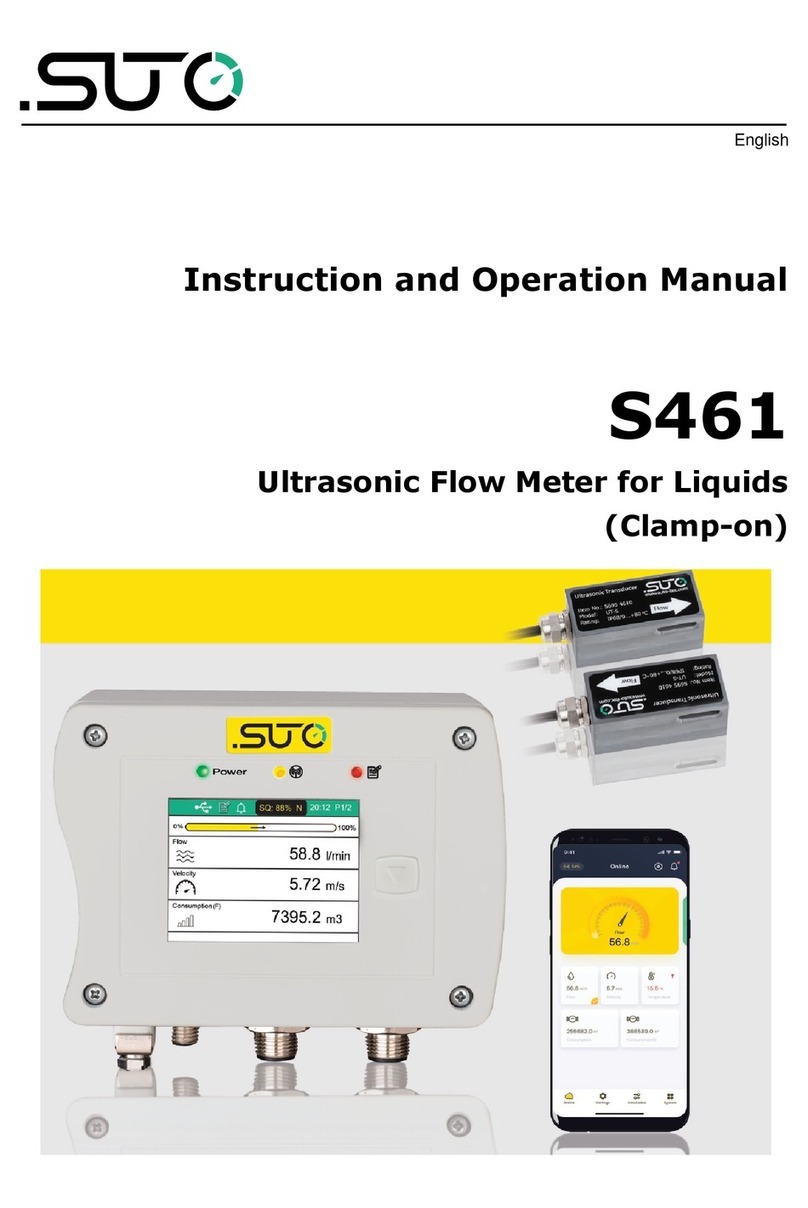

7.5.8 Ultrasound liquid flow meter S 460....................................23

7.6 Logger ................................................................................24

7.7 Files....................................................................................25

7.8 Service info..........................................................................25

7.9 System setting.....................................................................26

7.10 Communication ..................................................................26

8. Signal inputs ............................................................................28

8.1 Digital inputs........................................................................28

8.2 Analog input ........................................................................28

9. Signal outputs...........................................................................28

9.1 Interface ............................................................................28

10. Optional e tra accessories.........................................................28

11. Calibration..............................................................................29

12. Maintenance............................................................................29

13. Disposal or waste.....................................................................29

S 551 3