AU Tool PR2 User manual

Automatic

Grinding Machine & Eng.

Co.

Ltd"

PADIHAM ROAD,SABDEN, BLACKBURN, LANCS.

8B69EW

E

NGLAND

.

Tal.

0282

(PadihamJ771838173821

Cables: AUTOGRIND,

PADIHAM'

( \

AUTOOL

GRINDER

,,

_M_O_D_E_L_P_R_2

__

)

Installation

and

Operating

Instructions

Parts

Identification

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page

1

'AU

TOOL

' PROFILE

GRINDER

MGDEL

PR/2

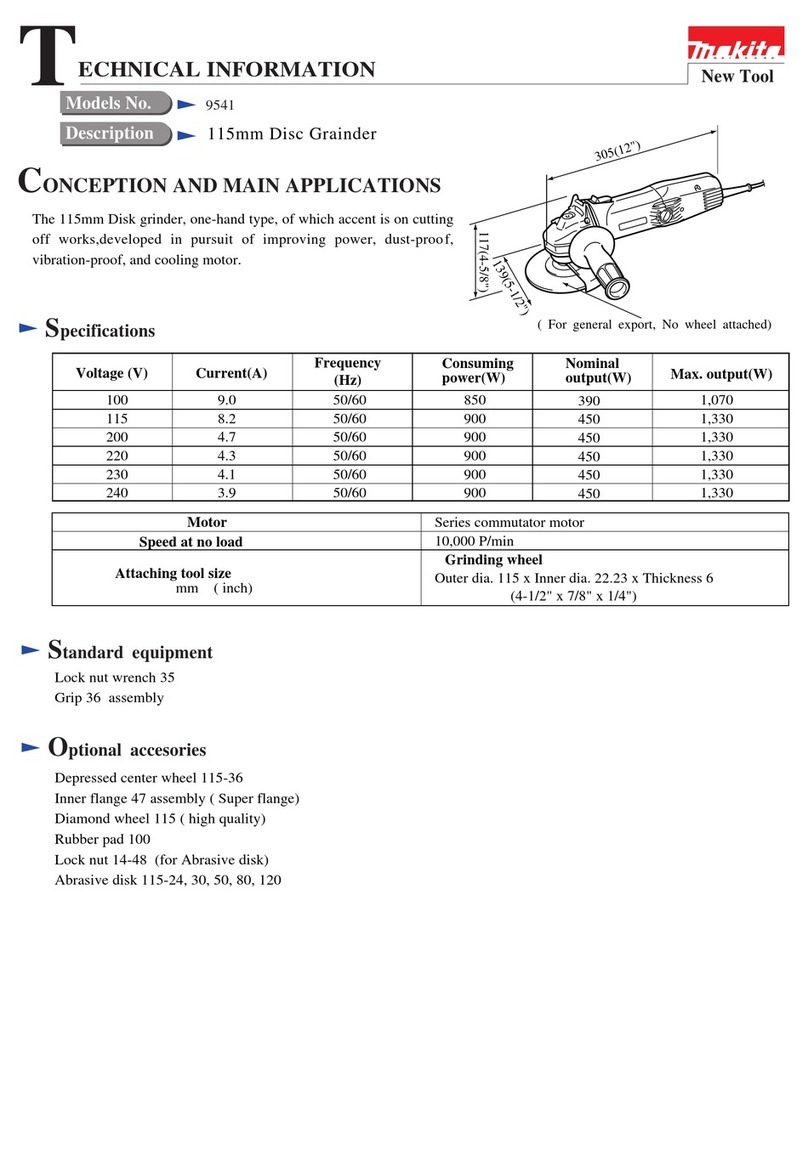

Teclmical

Specification

Grinding

W

heal

diameter

'"

~.

9

in"

)

GrinHng

Wheel

width

5

~

.

Grinding

Wh

eel

bore

"

in

••

Output

of

Grinding

Wh

eel

Mo

tor~

,

>,.

standard

It

bp

.

on

re

qu

est

.

12

ins.

Maximum

longth

of

cut t e

rb

ead

Maximum

diameter

of

cutting

circle

Output

of

coolant

pump

motor

Coolant

tank

~ap&city

14t

ins.

(standard)

O.lR

bp.

Over

..

ll

heig

ht

Vorkin

g

vidth

V

orking

depth

40

litrH

1600

mm

.

1450

m

on

.

1100

mm

.

Eloctrical

s

upply

required.

Control

voltage

220-580

volt.

3

ph

..

se

50/60Ilz

.

(Standard)

110

volts

ATT~::NTION

Safety

Precaution"

Note

th<>

various

~

af"ty

poi

nh

glVe

n b

elo

;(

and

in

the

text

and

ob

5

0rva

t h

em

when

operating

t

he

m..

chine.

Isolate

the

machine

before

touching

or

changing

a

~beel

and

vhen

setting

up

.

Carefully

fo11o"

the

the

machine

off

...

ait

s

af

ety

instructions

vhen

until

the

wb

eel

comes

to

changing

a

...

heel

.

re.t

before

mal,i"g

After

s

...

itching

any

adjugtment.

Rest

th~

o

arricge

in

th"

rm.r

position

~h

"n ~e

tting

up,

changing

over

a

cuttcrhe"d

,

"hitting

El.

knife

or

holder

and

"hen

dressing

th"

....

h

eel

.

Gently

lover

the

cutterhead

s~sembly

onto

the

machi

ne .

DO

NOT

DROP

.

These

cutters

cu

t.

" ..

tch

your

ha

nds

and

fingers

and

k

eep

th"m

out

of

the

~ay.

Do

not

fully

tighte

n

either

a

knife

or

a

holder,

nor

loo

~

en

them

from

fully

tight

vhiht

the

cutt"rhe"d

is

on

th

e

grinder.

Fully

tighten

knive~

and

holders

immediately

after

removal

fro

m

the

grinder

•

..

hen

in

th

e

area

and

u

~

ing

the

machine

V..

ar

~uit!l.bly

approved

goggle~

or

a

visor

.

Never

run

a

grinding

head

vithout

all

the

guards

in

place.

Check

the

~bcel

fo

r

~le

..

ran~

o

a.

lld

the

guards

for

security

before

starting

up.

Grind

w

et,

but

do

not

run

cool

..

nt

against

a

$t&tiona

ry

vheel.

Note

that

the

vheel

is

of

vitrified

bond

..

hich

by

its

natur"

i

~

hard

and

brit

t l e .

Becau~c

of

this,

and

it~

thickne~"

,

exe

rci

se

ca.ntion

vhen

applying

s

ide

pressure.

Read

and

f

olIo

...

the

instruction.

given

in

this

manual,

and

"ar

k

in

",ccordance

vHh

good

safety

and

oper"tional

practi

ce

s .

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

2

7-

- +

23

PW . 1

I , Ha.",\

...

heel

for

fin~

for"'ard

,n

ovemc

n t of

grinding

head

2 .

Spotl

i

ght

switc

h

3 ,

Locli

for

1

"no

fOl

'

""

,

vd

mOY"

rn

'>nt

of

grind

in

g

head

4 .

Locating

lev,,,

'

for

""ivi>!

mOv""".'llt.

5.

[.

e

veT

for

s,"ivel

rrl

o,-"ment

6 . U

pp

e r

cuoh

n t

pi

pe

7 .

Spotlight

8 .

Knit

" SlIPP01't

9 .

H"nd")",,,\

for

left_

h

and

adjubtablu

e"nt

r "

1O

.

1!"",I~·h

c

ul

Ll

"cd

to

rotal

..

""ttcrh,',,d

" h

~n

!p'inding

to

m"

in

t~in

CO

l1ouct

he

t,,,

.,,,, i

<Hif

<l

and

s u

pport

.

11

•

Cutter

)

1<'lld

12

.

T"mp

l

Rl~

holdn

13

.

]!,,"dle

for

cO

ll

trollinK

moveme

nt

of

cllrri"ge

14.Elho~·

re

.•

t

15

.

Sample

turning

16

.

nllnd"h

e

cl

for

a<l,jn.

<t

in

g

rest

po.ition

of

cn

rri

age

17

.

H

,,

" d

"h

~,,1

for

po"itioning

carriage.

18

.

I

,

ocl,scre"~

for

17.

19

.Contr

ol

pus

h bu

ttons

.

20

.

Coohwt

filter

-

"ash

out r

egu

larl

y ,

unsoro"

to

remove.

21 .

Cool

..

nt

pULlp

22

.

Conlant

t a

nk

_ ..

c

ces~

from

r"

..r

23

.

Contrel

ta

p

fur

lo"

"r

cool

..

"t

jet

24.Control

t

ap

for

upper

coola

nt

je

t

25

.

Lock

for

27.

26 ,S"

ing

,

,,,ay

cove

r

for

t

"o

_

~p~e

d

drivg.

27

.

Ha"d"h

~d

for

,,

(!j

U

~tilll(

cle!tranCd

engle

19

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page 2

IN'nlOIltlCT

I(!;

The

machine

ha

B

been

deeigned

primarily

tor

grinding

hexagon

cylinde

r

head~

ae

used

On manual

end

eutoaatic

shap

ing

l

at

h

es

.

By

using

a

ts~plate

ehaped

to

the

rev

e

r~e

of

the

turning

pToftle

requi

r

ed,

th

e kni

ves

are

accurately

fOnl~

to

the

correct

profUe

eac

h

ti_

thoy

are

ground

_

with

o

ut

r

eliance

on

the

traditional

grinding

,

kill

. .

Accuracy

and

repeatability

of

pr

ofi

le

is

gu

arsnteed

reg

ar

dh

••

at

the

ahear

.nd

cutting

angh

.

ot

the

kniv

u and

of

the

8ty

le

.nd

pa

ttern

ot

th

e

he.d

b

ein

g

used

.

By

grinding

knives

'in

.

itu'

on the h

e.d

to

b,

used,

knif

e

sotting

ia

e

liminat

ed

Dnd

,

in

f a

ct

,

groater

."cur.cy

of one

knife

profile

to

the

n,.t

ia

poa.ibl.

than

"i

th

conventional

grinding

and

set

tin

g .

The

front

.nd

side

clearance

englel

ere

va

riable

and,

once

.et

,

remain

co

r

rect

for

all

s

hear

and

cutting

.ngle.

of

knive

l

in

.ny

set_up.

I n

e~pha.iz

i

ng

that

I.e.

ekill

ie

r

equi

red

to

prof

il

e

grind

using

this

..

chine

,

it

would be ia

pn

,

dent

to

e.p

loy

en

ope

rator

wi

thout

previous

grinding

knovledge

or

ski

ll

s . The

uae

of

thia

..

chi

ne ,

of

cour

se,

8t

i

ll

requir

e'

the

traditional

sk

ill

..

in

knife

.nd

holder

nhcHon

and

fitt

ing.

but

the

.ccuucy

"ith

..

hich

it

can

fa""

c","ple

" pr

ofi

lea

,

.nd

th

e

speci.l

features

it

_bod

i

..

,

in

lI.ny

c

••

oa

f~cil

it

~t8

sirnplif

i

e

~ti

on

nf

knife

8e

t_up8 by

allo~ing

knivee

to

co~plete

JIIore

than

one

8ec

tion

of

turning

.

fNSTALLATION

Vh

on

the

m~ch

i

ne

i s

to

be

i

natalled

on

n 6

in

.

thic

k

80l

id concr

ete

tloor

no

apeciel

found~tions

..

re

r"<tuired

.

Cut

4"

squo.

re

ho lee

tor

r.g

both"

sho

'om

on

tho

foundat

ion

plan.

A good

"oodon

Cloor i .

al

ae

8uitable,

and

co.ch

8crev'

..

y be

u.ed

.

.!J.tting

the

Ha

ch

i

n.

T..o

lifting

eye

• •

re

provided

.t

the

Tear

of

the

machine

and

s

ling

. ahou

ld

pass

around

the

..

achine

b~8e

..nd

to

the

in

side

of

the

support

real.

a....8

at

the

front

.

Remove

the

temporary

suppor

t s

locking

th

e movemen

ts

in

pl

ace

and

secure

the

work

table

i n

position

if

suppli

ed

.e

p..ro

,t

e

(locllt

ing s t

uds

provide

accurate

dignment)

,

Fit

ting

th~

M

,,,

,hine

CarufuUy

levol

tbe

machine.

usini

j.c:k

acre

".

in

the

t~

pped

holes

provided

,

plac

i

uB

a

level

on

the

.rbor

and

on

the

e

tylu

s vee

_"

..y• •

Grout

the

"",chin

e

in

position

"

ith

liquid

ceme

nt,

Aft

er

.llo

..

ing

time

for

the

grout

to

.et

coup

l

etely,

tighten

the

holt

••

nd

egain

check

for

l

evel

.

The

electrical

cabling

bet

..

een

",otors

and

control

gear

ia

completed

betor.

the

...

ch

ine

is

de'!"'tched

,

togethe

r

..

Hh

a

ahor

t

lead

tro",

th

e

hol.tor

fOT

connec

ti

on

to

the

factory

supply

via

a

junction

box

or

an

approv

ed 3

pha.e

plUII

Bnd

socket

.

The

colouT

codings

are

,_

Ei

thar

J

cablu

bra""

_

live

(hot)

1

cable

Greon/Ye

l

lo

" -

Eo.

rth

(groun

d )

Or

1

ceb

l .

aed

live

(hot)

1

"able

Yello..

live

(hot)

1

cable

Blu

e

live

(hot)

1

cabla

Green/lello"

-

...

rth

(ground

)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

\ \

'0

-

~

\ \

~-

,

\ \ \

FIO.2.

Pi

t

of

template

to

u.mple

.

-I-

++

-

~

---

FIG.}.

M&

rk

th

e

template

for

cylind

er end and pos

it

ion8

ot

hold

&rs and

knive.,

-\

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

o \

/A

//

E

+

~

¥,,-

_,

~

_

C

_

PIG.4.

Clearanc

..

of

cutt

i"i

I

+-

'C' r ..

"", i ,,~

"nd

sit

"on~ta,,

~

ea

r

anglee

.

\

I'

IG

.5. Tho

grindin

""gl

es B

.t

g ""

gh

,.

A & C v..

;;,:;::

;;~;;;-;;-;:::o,---

_.J

accor

di

ng

,0

cu

t

ting

F

IG.

6 .

Grind

'

1n,

"n,le

s v

...

ry

"'

''

1'0

•••

alt".

r

-c,,~

.,- "

.

....

1 • •

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page

3

Check

that

the

cabling

and

fu~e~

to

t

he

main

distribution

board

corru~pond

to

the

details

on

the

machine

electrical

plato

.

It

is

important

t

hat

the

grinding

",heel

grinds

in

..

do"n"ard

direction,

i,e.

clock"ise

rotation

"'hen

vie""d

from

the

left

hand

side

of

the

machine

.

If

thi~

is

not

the

case,

reverse

any

two

connections

of

the

l

ive

(hot)

cable

• •

The

pump

motor

(21)

is

wired

prior

to

de

s

patch

and

~hould

be

correct

"hen

the

correct

direction

of

rotation

has

been

e ~

tablished

with

the

grind;ng

"'h

e"

l

motor

. Howeve

r,

check

the

rotation

by

noting

th

e

arro

w

cest

on

the

impellor

c..

~ing

.

SETTING

THE

GRINDER

Grindin

g

Coolant

The

coolant

tank

(22)

should

be

filled

with

a.

coolant

cOMisting

of

soluble

oil

and

water.

Add

oil

to

the

mixture

as

recommended,

usually

in

the

ratio

of

one

pa

r t

or

soluble

oil

to

)0

pa.rts

of

water.

Replace

the

coola

nt

by

a

fresb

mix

every

2-4

""ek~.

'AUTOOL'

~

u

pply

a

sui

t

ahle

concentrated

~

oluhlc

but

the

follo

...

ing

are

also

$uitable:_

Shell-Me

x

and

B.P.Ltd.

Vacuum

Oil

Co

.

Fitting

the

Cutterhead

Shell

Dromus

10

Solvac

Clear

T

he

cutterhead

must

be

fitted

to

an

"r

bor

prior

to

mounting

on

the

m..

chine

.

The

arbor

and

type

of

fitting

varies

according

to

the

types

of

hesd

to

be

m

ounted.

Shaping

Lathe

Cuttcrhead~

Pairs

of

short

hush

es

..

re

provided

to

correspond

to

the

size

of

the

shaping

lathe

arhor

(one

pair

is

provided

for

"nch

size

of

arbor

u

~ed).

Lock

the

se

on

the

grinding

machine

arbor,

as

needed,

to

~upport

the

ends

of

the

hesd

in

the

required

posi

t

io

n.

(Note

the

marks

on

the

arbor

indica

t

ing

the

maximum

traverse

positions

of

the

tfl.ble) .

Insert

the

arbo

r

and

hushes

into

the

cutterhcad

and

temporarily

lock

in

place

u

sing

the

securing

scre

" s

on

the

latter.

Moulder

and

Sh

aper

Cutterheads

Select

the

appropriate

arbor

and

bush"s

requir

ed

and

lock

the

head

to

the

srhor,

generfl.lly

in

a

~imi

l

ar

manner

to

that

used

on

the

parent

machine.

Us e

the

spacing

collar

snd

end

nuts

to

po

s

ition

and/or

se

cure

the

cutterheads

as

requir

ed .

Fitting

the

Arbor

Sm

ear

a

little

grea

se

in

t o

the

centre.

of

the

arbor

snd

SCre"

on

the

end

co

l

lar

s

(56)

(if

not

already

in

use

for

locking

the

cutterhead

in

po

s

itio

n).

Gently

place

the

arbor

unit

on

the

machine

table

so

that

the

e

nd

collars

reat

in

the

supports

sdjscont

to

the

centres

(57)

See

Pig

.

2L

DO

NOT

DROP

THE

ARBOR

INTO

THE

SUPPORTS

.

Screw

i n

the

lefthand

centre

(9)

to

grip

the

arbor

sufficiently

tight

to

t ..

ke

up

any

play

"hiht

retaining

a f

ree

rotnry

m

ove

m

ent

.

Rele

..

~"

screw

s

(18)

_ u

nd

er

the

rubber

cover

_ a nd

turn

handwheel

(17)

un

til

the

cutterhcad

balances

"hen

in

the

grinding

position.

Lock

8CreWS

(18)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

!!2i! T

he

e

tt

e

ct

of t i

lti

ng

the

v

heel

to

gi¥e

clearance

to

ri

ght

end

lItt.

PI

G.8

1.

Na

n

dvheel

for

fine

for

verd

feed

of

grinding

head

J .

Lock

for

I and

grindinl

~

heel

I~ivel

movement

4 .

Locating

leve

r

for

"~ivel

move

me

nt

of

grinding

head

(l

ocate.

with

~hu

l

vertica

l

or

tiltad

5

or

10

degree.

to

right

or

left

.

5.

Svivel

.avem

ent

lever

8 .

Knife

~uppo

r t

10 . Handv

heel

for

r

ot"

t

ing

cutte

r

h.ad

11.

Cutte

r

head

13 . Handle

tor

control

l

ing

.ovement

of

carriago.

2

8.

Il

an

dv

heel

f or

BlUe

..

d,i"$t

ment

of

~tylu

• •

(ind

i

cat

i

ng

collar

for

28,

lock

vi

th

zero

,..rk

oppodte

pointer

vhon

stylus

has

heen

positioned

).

29.

Loc

k

for

28 .

30 . lI"ndw

heel

for for

v

ar

d and ba

ckvard

moveme

nt

of

styl"

• •

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page

4

Templa

t e

Preparation

The

te

mplate.

(49)

u"od

to

guide

t he

table

during

grinding

can

be

made

from

.heet

iron

or

"

teel

of

a

bout

1/16"

thick

and

s bo

ul

d

be

accurately

formed

to

the

reverse

of

the

turned

profile

required

,

Le.

~o

that

the

profile

accurately

fits

t

he

turning,

see

Fig

. 2.

}'or

tur

ni

ng

g

of

abov

e

10"

in

length

the

template

is

made

in

t wo

or

mo

re

sections

each

corresponding

in

length

to

one

or

more

cylinder

up

to

a

combined

length

of

10",

plus

a s

uitable

overlap

w

here

abbutting

any

adjacent

cylinder

,

Template

width

should

be

not

less

th

an

2" a t

any

point

and

the

back

edge

must

be

paralle

l

to

the

centre

line

of

the

turning

"hen

h

eld

against

th

e

latter

.

The

distance

is

nominal

,

but

must

be

common

to

a l l

templete

.ections

f

orrJing

a

complete

""t

.

(See

aho

note

"

on

of

f_set

centres

under

'O

perating

the

Gr

inder

').

Carefully

mark

on

each

template

the

exa

ct

position

of

the

cylinder

ends

snd

,

for

convenience,

the

po.ition

of

th

e

ho

l

der

. and

knife_width

coverage

. , "

ee

Fig

.

3.

It

i.

suggested

thst

standing

.et_ups

are

reground

initially

before

attempt

i

ng

ne~

se

t_up

..

Thi

~

viII

a l

lo

w

special

t~chniqu

e~

to

be

perfected

b

efo

r e

at

t

~

mpting

cOMpletely

new

work.

During

this

time

short-cuts

in

getti

ng

sud

th

e

pO"5ibHitie

s

of

using

knives

to

cover

more

than

One

.ection

of

t

ur

ning

vi

II

become

apparent

_

to

the

benefit

of

"

ubsequent

.e

t_ups.

P

or

more

detai

l;

$ee

'

Operating

Techniques

'.

GRINDI

NG

W

HEEL

ADJUSTm.:NTS

Both

the

m..

in

..

n~

side

clearance

a

nghs

..

re

sdju ~t able

snd

should

be

s e t

according

to

the

nature

of

the

work

and

the

knife

charact

eris

tics.

Main

Cle

..

rance

AnKle

The

main

cleara

n

ce

locked

by

the

lock

above

or

belov

the

is

poss

i

ble

.

s n

gIe

is

adj

u

sted

by

lever

(25)

. A

scale

tilting

centre

line

.

haudwheel

(27)

and

t

be

m

ovemMt

is

indicates

t

he

height

of

t he

wheel

Adjustment

of

between

20

0

and

40°

Unlike

hand_ground

cutter

s ,

the

clearsnce

angle

re

mai

ns

consis

t

ant

regsrdle9

~

of

the

~

h ea r

or

cutting

angle

of

the

knife,

even

though

t he

ground

angle

on

the

knife

vsrie.

betwe

en

different

knive5

and

from

edge

to

edge

of

e..

ch

$he

sr_

cut

kn

i f e .

Th

i s

gives

a

consistant

clearance

betwe

en

the

heel

of

the

knife

and

the

stock

and

doe.

,

in

fact

,

con

s

iderably

5implify

grinding

proceedure

,

5ee

F

igs

4,

5

and

6.

For

,"

os

t

"ark

a

clearance

angle

('C',

Fil:

••

l)

of

27t

O

suffices

,

an

d

this

is

su

ggested

as

a

starting

figure

.

Below

21!Othe

cutting

edge

is

"t

ronger

(a

s

needed

for

hard

timbers)

but

clearance

is

COrre$pondingly

le

~ s

.

Angle

s

greater

thsn

27~"

a

re

u~e

d

only

for

very

"o

ft

t

im

ber

~

,

on

larger

diame

t

er

turning.

or

~

In

all

diameter

head

s ,

to

dlo"

more

hon

in

g

bet

"

een

regrind

$ ,

or

when "

subsequently

grinding

a

second

..

ry

clearsnce

angle

.

(0"

on

the

scale

i s

:!7~

clearance

angle)

.

Once

set

,

the

clesran~e

angle

needs

no

f

ur

ther

adjustment

for

sny

individual

so

t-up,

..

nd

remains

cons

t ..

nt

regard

less

of

whe

el

ve

sr

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

if

ro'

rr

""'

0 0 ®

/'

I1

PIG.9

Swive

l

locating

l

ever

in

cent

..

e

po~ition

giving

vertical

set

ting

of

grinding

wheel.

-l

0 0

@)

/ 3

4

31

32

0

FIG.lO

Swivel

loc~ting

lever

in

extreme

right

position

giving

10°

cl

e

arance

of

grinding

wheel.

3. Lock

for

sw

ivel

and

forward

feed

movement

of

grinding

wheel

.

4.Swivel

locating

lever.

31.Swivel

locating

lever

locator

plate

32

Main

grinding

he

ad

support

.

FIG.

Il

Consi"tancy

of

clearance

angle~

A & B

irre

s

pective

of

varying

s

hear

angle

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page 5

Side

Clear

a

nce

A

ngh

Thia

can

be

set

for

either

SO

or

100

el.eranee

to

right

or

left

or

to

00

(vertical)

position,

a

ee

Fi

g.

1 .

The svi v

el

.o

vement

i.

controlled

by handl

ever

(5)

end

locked

by

lever

(J),

see

Pi~

$

.

8, 9 and 10 .

Lever

(4)

l

ocates

the

head

i n

th

e

vertic

al po

sition

or

to

giv

e

SO

or

100

right

or

l

.f

t

lide

cl

earance

.

Depress

the

lever

end to

roh

... e the

1001\

w

hil

s t

app

l

ying

dovn....

rd

pro

u u

re

to

lever

(5)

to

b..

lanca

the

head

auombly

.

lI"to.te

tho

hoo.d

to

the

required

poaitlon,

rele

... e

lev

er

(4)

..nd l

ock

by

lever

(3)

.

Nnrmall y

SO

cleaTance

..

ill

s

uf

f i

ce

fOT

.oat

work and

thi

a ia

suggested

as

an

initial

set

ting

.

By

tilting

th

e

head,

the

grinding

"'h

eel

gr

i

nds

at

SO

or

100

to

th

e

plan

e

of

r

otation

and

gives

..

cons

is t

ant

degree

of

clea

ran

ce

to

all

kniv

es

reg

..

rdle

..s of

shear

angle

, See

Pig

.

11.

NOTE

: No

altern

t

ion

of

t he main

or

.ide

de

..r..

nce

""gle

is

n

ece

. s..

ry

...

hen

ct'"nging

be

t"'

ee

n

l~

f t

..

nd

right

..

ngled

k

niv

es

,

or

ba

tw

een kn

iv

es

of

diff

er e

nt

sh

asr

sngle

sesting

.

MOUNTING

TIlE

VII~:F.L

Remove

the

guard

a

id

e pl..

te,

nut

and

oute

r

flange

.

Clean

all

ma

ting

faeee

.

Check

th

e

~h

.ol

for

so

undne

ss

end

,

if

correct

,

fit

",ith

•

com

pr e~

8ive

$ond

vi

ch

..

a.~her

bet~

ee

n

tho

~h ee

I

..nd

each

flange

.

Note

the

thTead

of

the

securing

nut

before

tight

e

ning

or

sl

ac

k

ening

.

Do

not

ov

er_tigh

ten when

se

cur

in

g ,

..

nd

be

sure

to

r

epl

sce

t he

sido

ilullrd .

Check

that

the

wh

oe

l

le

free

to

rot

ate

before

star

t

ing

under

power. A

llew

a

new

..

heel

t o

run

f r

ee

under

pow

er

for

a

fav

~ inut

es

with

all

personnel

s

tanding

v

ei

l

cleer

.

Should

a

grinding

wheel

dis

integrat

e

vhil

s t on

th

e

..

chine,

check

the

s

pindl

e,

flangea

and

gu

..

rd

thorOUihly

for

d

....

ge

before

fitting

a

further

wh

ee

l .

Tak

e

note

of

any

'afe

ty

regul

a.

tion

a

app

..

rot

..

ining

to

grinding

w

heel

u

sage

.

Dres

s the

wheel

be fo

re

".e

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

<

6--rn

43

FIG.12

Adjustments

of

knife

s

upport

and

dresser

,

shoving

di&mond

dre8ser

in

position

.

3

7.

Knif

e

Support

Assembly

.

38

.

Diamond

Dre~"er

.

39.

Rotary

mo

vement

of

a8~embly

to

change

f~om

knife

gupport

to

dr

es.e

r

and

vi

ce v

ers&,

also

v

hen

dressing

the

wheel

square,

at

an

angle

or

to

width,

40

.

Adjusting

"ere

"

for

alignment

of

37

_ $

ea

method

of

checking

Fi r..JG

page

16

.

41.

Ad

j

usting

screw

&8

sembly

_

rotate

dovnwards

to

allow

knife

~

uppo

..t

o.uu)"bly

to

ha

rotated.

Se

t

horizontally

to

aliw'

..

s"e,a~ly.

42.

Lock

for

rotary

movem..

nt

39

.

43

.

Knife

Support

(interchange"ble)

44.

Lock

for

8wivel

movement 45

45

.

Swivel

movemant

us

ed

w

hen

h..

U-roWld

dressing,

or

when

"..

tting

dresser

for

8qu"r~,

"ngle

or

s

ide

dreuing

of

grinding

vh

eel

.

46.

Scale

and

indicator

~hoY

~

vivel

movement

setting

.

40

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

START

ING

AND

STOPPING

mE

MACHINE

The c

ontr

oh

aru

-

I H

Control

Bo

x 19

Pu.1I

button

to

"tart

the

motor .

(note

the

.a

fe

ty

precautions

a

bove)

.

I'u"h

button

t o

~t

..r t

the

lubricant

p"",p.

(do

not

run

th

e

pumpo

\(ith

th

e

\(h

ee

l

~tll.tio""ry

)

Po.I

eh

button

to

stop

both

grind

ing

ho..d

mo

t

or

and

p...mp

. (AutDMatic

10ck-off,

to.lrn

to

relea

se

be

f

ore

.t

..

rt

ing

...,ton

).

holator

(15)

-

(for

.atety

r"Uon~

180111.1.11.

the

machine

bofore

setting

up

).

~ING

mE

GRINDING IIlmEL

Pa

ge 6

Before

grinding

C<)IlImenCM

,

and

.. t

int

erv

..h

during

th

e

grinding

_

equenc

e ,

dress

th

e wheel

to

maintll.in i

t.

corroe

t

pro

file

and

po.ition

reletiv@

to

the

stylu$,

and

to

retain

s

cle

a

ll

cu

tting

f..

ce

,

sce

P

ig

• • 12 and

13.

The

diamond

dre

••

er

is

~oun

te

d

on

the

oppo.ite

end

of

asaembl y

(J7)

to

the

knife

support

.

To

b~ing

it

int

o

the

operat

iv

e

po,ltion

turn

ass

embly

(4

1)

dovn

to

cl

eer,

re

l

ease

l

ever

(

42)

and

r

otate

th

e

e.e

..

bly

un

til

thu

di","ond

i ~

uppaJ'nlO''\..

Turn

aue",b

l y

(41)

to

the

h"rizonl.&

l p"

"i'\.ion

and

rotld

e

(37)

until

H

abu

'\.'\.s

scre\(

(40),

'\.hell

8ecu

re by

lever

(42)

. Abut'\.

""umbly

(H)

IIgain,t

8cro

W (4

0)

bo'\.h

\(b

e

ll

drc

n

ing

~o

a

lIalt_round

~e

ction

ane1

wh

o)\

U

Si

lll:

the

kni

te

~uJlJlnrt

,

"",1

~

ecure

hy

leve

r (42

).

NOT,;

Ae

cur

..t e

abu

tt

..

ellt ag..

in

s

'\.

BCra

...

(40)

is

ah801utely

euenti

..l

wh

8n

Ilr

in

di

nr,

shear-cu

t

knives

S$

t.ilure

to

do

thi

~

llI/ly

ruult

i n

in

accuracy

of

radial

heir.ht

ot

fini

she

d

knivu.

PeriDllicaUy

chec

k t.he u

Uirtt

:

of

adju.Unll

scre

"

(40)

""

descr

i

bad

on

Pac

e

16,

rho

"he

el

can

he

d

r.'led

'\.

0

a)

a h

air

_

ro

und,

b)

8qu

are-ac

r

os,

or c )

angled

prot

i

le

,

bu'\.

tor

..

".t

wc

rk

a

half_rOund

,ec

tion

is

us

ed.

Sq

u

are-acros

s

and

angled

profil

es

ar

e

uee

d

for

internal

corners

(1I.1'\.houlI'h

..

11

overl

apping

knife

techniq

ue

can

be "

sod

)

or

",hen

grinding

extr

s

cleer

ance on kn

iv

oB.

Se

..

l

at

er

Ilotu

on

'O

perating

T

ec

hllique

s

'.

D

r

e.~in 8

to

a

half-round

sect

ion

(Fig.

1)

Relea~e

s

ecuring

SCrew

(44)

~ o

a l lo\(

the

assembly

(37)

to

. w

ivel

'\.hr

ough

180

0

(45)

. Check

that

the

diamond

clear.

the

wh

e

el

vhell

the

la'\.'\.er

is

'\.

ur

ned

by hand

and

'\.h

e

dree,er

~

viv

e

l

led

th

rou/l'h

ih

ful

l

movemen

t . If

not

, II.dju.

t.

as

la'\.er

d

08cribod

.

~i'\.h

'\.

he

wh

eel

ver

ti

c

al

and

runn

ing

, and

with

lock

(l)

released

, t ood

the

...

heel

'\.

over

da

the

dr

eue

r ,

usin

g halld

...

hq

el

(1),

vh

1h

t

I

wivel

l

ing

the

drosler

left

and

right

through

the

ful

l

180

0

rnovemen'\.

. COlltinue

until

the

whe

el

1, f

ully

dre

~_

ed,

th

on

loc

k

(l

)

and

stop

t

he

vhee

l.

Thi.

ac

t

ion

dre.

~e8

th

e

vheol

'\.0

profil

e ..nd

'\.

0 a

zero

poai'\.ion _

which

ensurea

accu

r

ate

regi e

'\.

r

ati"n

.

Do

no'\.,

therefo

r e ,

r

e~e

'\.

the

vh

eel

posi'\.ion

in

any

wa

y

except

aa

n

e.ded

fo

r s

ide

cl

ea

r

ance

grinding

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

1\ /

'-

PIG.1)

Halt_round

dreuing

.

PIG 17

PIll

14

Si

de

Dr"~8

i

ng

PIG

15

Squa

r e

DUBBing

16

.

Handvheel

for

po.itionin~

carriage

.)

vhen

checking

knivee

against

pattern

,

b)

eo

that

knives

cleer

elbov

rest

vhen

resting

or,

PIG.16.

!

ngt.

Dreui"i'

t)

'0

that

knives

ere

veIL

clear

ot

vh

•

.,l

vhen

dra

••

ing

whe

e

l.

))

.

I!andlever

for

locking

bucl,,,t

34

in

PO$

i

tio

n

34.

Brackot

for

16

35 .

C&rriago

36.

he

ahart

-

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page

7

Dressing

ov~r_thick

"he

"h

(Fig.H)

Vh

eel"

may

vary

in

thickness

and

can

be

dressed

true

immediately

a

fter

fac

e

dre~sing

.

S"ivel

th

e

dre~s6r

to

its

extreme

rig

h t h!lnd

position

and

lock

~cre~

(44).

Release

lever

(42),

and

rotate

t he di!lmond

clear

of

the

vh~

el

.

Vi

t h

the

vheel

running

,

rotate

the

di!lmond

acro'

~

to

dre~s

tho

side

of

t he

"hed

.

Stop

the

"he

el

and

repeat

"ith

the

oppo~ite

side

.

Thi

s

usually

requires

doing

once

vith

each

vhe

e

l,

there!lfter

face

dres

8

only

.

Dr~~~ing

to

a squ

are

acro~g

or

an

gl

ed

~ection

(Figs

.

IS

!lnd

16)

Set

the

indicator

against

sca

l e

(46)

to

zero

for

s

qu

o.

r e

across

or

at

the

requi.red

a"gle

,

then

lock

scre~

(44)

. R

el"ase

l

ever

(4

2

).

Check

the

di(l,mond

and

..

heel

tor

clearance

and

!ldjus

t

if

neceuo.ry.

'o'ith

the

vh

ael

running

,

rot

ate

the

dr

a~~nr

acros~

the

vh

eel

until

th

e l

at

ter

i

~

fully

profiled

.

Af

t

er

dres~ing,

rotate

th

e

!l~

sem bly

until

th

e

knife

~

upport

i~

upp~rmo

st

,

~xac

t

ly

cen

tra

l , !lnd

square

to

the

arbor

,

then

lock

lever

(42)

and

(44).

NOTE :

The

m!lchine

is

primarily

designed

f.or

use

"ith

half_round

sec

tion

..

heel$

•.

Vh

aeh

of

any

othaT

~actio

n

m!ly

foul

the

knif<l

~upport

nece8~itating

!l

rear"ard

adjust

m

ent

of

the

grinding

"hee

l

before

u

se

.

KNIFE

SUPPORTS

K

nife

~upport~

(8)

are

provided

for

360, 450 a

nd

550

shesr

angle

holder~.

All

..

re

reversible

for

left

or

right

h!lnd

she!lr

.

Cle!lll

mating

faces

befor~

fitting

and

en

sure

th!lt

the

suppor

t

S~!lts

on

the

locating

do"el

before

securing

. Tho

supports

..

ro

jig

bored

for

u

se

"ith

the

special

securi

ng

bolts

provided.

U8e

only

the.e

bolts.

Grind

all

knivM

of

ident

i

c8.1

angle

!lnd

hund

of

shear

in

so

quence

before

changing

the

support

. By

dressing

the

"hoel

pr

ior

to

tin!l

l

grinding

,

accur

..

te

alignment

is

aS

$ured

r

egardless

of

the

ol

·

der

in

..

hich

knives

are

act

u

ally

ground.

ALIGNING

CU'M'ERHEAD

AND

TD

1PLATE

Set

the

cu

ttorhaad

on

the

a r

bor

so

that

i h

full

cutting

v

idth

i s

vithin

the

table

t

raverse

relative

to

the

grindinf(

"heel.

NOTE

A maximum

tr

..

ver"e

of

1 2

in

.

is

provided

.

'o'h

en

.. t

raver

se

in

excess

of

thi

~

i~

n..

"d

..

<1

,

grind

p

....

r t

of

tit

..

cutterhea,l,

then

shift

both

cutterhe

..d

an,\

tomplate

sidevays

to

r.rind

the

reCl8.ind"r.

Vith

the

,..h

",,}

upright

~e

t

the

table

~uch

that

one

end

of

the

he

x

agon!ll

disc

and

the

..

he

el

!llilln

ex

actly

USing

!l

straight

edge.

Fit

a

plain

~

tylu

~

.

Fit

th

e

corresponding

templ

at

e

(49)

..

nd

"djust

it

,

"hil

st

keeping

it

ba

ck

ugainst

the

fence

pegs

(51)

Fig

21

,

so

that

the

di

~ c

end

line

on

the

template

correctly

align

s

..

ith

the

~ty1u

s,

usin

g a

~q

uare,

Pig.

18

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

PIG.18

Met

h

od

of

a l

ign

i

ng

hexagon

di

sc

with

wheel

using

~traight

edge

D,

and

to

"et

templete

line

to

stylus

E

using

a

square

F.

PIG

.

19

Styl\l~

Assembly.

47.

stylus

in

position

48.

Lock.crew

for

47

(locks

against

mille

d

flat

on

st,'lus

)

FIG .

ZO

Correc

t

stylus

se

t

ting

for

lef

t

and

ri¥ht

hand

she

s r

suppo

r

t$

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Pllga

8

Lock

the

template

in

position

.

Begin

...

ith

the

sty

l

us

in

its

mid_cro

••

_

traverse

po

s

ition

,

than

use

h,,"dwhe~l

(28)

for

final,

fine

setting

,

(after

ralessing

lock

29)

.

STYLUS Sf:Lr:CTION

AND

SETrING

Th,.ee

Ilre

provided,

coded

A,

C

and

E,

also

Il

plllin

stylus

.

Select

the

correct

stylus

according

to

the

holder

shear

angle

and

....

in

clell,.ance

angle

in

use

by

referring

to

the

chart.

Pit

the

~tylus

(47)

and

secure

ag

..

inst

the

fl

..t

using

lockscrev

(48),

Fig

19,

so

that

the

point

is

to

w

ards

th~

operator

an

d

at

the

s

am

~

side

as

the

high

point

of

the

knife

support,

see

Pig.

20

.

Note

that

each

s

ty

l

us

can

be

reversed

end

for

ond

for

use

vith

a

left

or

right

hand

shesr

holder

.

Th"

~ t

ylu"

(47)

is

used

to

cro

..

to

tho

ex

..

et

turning

profile

throughout

the

cutting

"idt

h

(See

'O

pera

ti

ng

Techniques'

for

method

of

use)

.

C"o"~-

..

dj

u.,

tmen

t

The

s t

ylus

can

be

cros8_a

(

ij

u

"ted

using

h

and"hoel

(28)

llnd

locked

by

(29).

Once

set

("h~n

aligning

c

ut

terhead

llnd

te

m

plate)

it

shou

l d

roma

in

undist

urhe

d

throughout

the

complete

cutterhe"d

grinding

.

It

c"n,

however,

be

used

to

regul"te

additional

side

grinding

clearance

on

non_cutting

section

s

of

eac

h

knife

where

this

is

thought

necessary

(

see

'

Ope,.ating

T

ec

h

nique

s

'.

Nor

m

ally

one

compl~to

rota

t

ion

of

the

h"nd"heel

"ill

torm

sufficient

extra

clear"

n

ce

...

here

needed

,

but

having

done

this

be

s

ur

e

to

re

t

urn

the

orig

i

nal

setting

before

commencing

furthor

work.

A

graduated

100so

indicator

ring

is

provi~ed

for

moro

accurate

off

and

re_setting,

having

a

2ero

lino

vhich

"

aligned

to

a

pointer

vhen

tha

setting

has

initially

been

made

.

Thi"

is

locked

hy

an

alIen

key

•

.£!>ttorhead

dia

m

eter

adjustm~nt

The

cutting

diameter

of

the

cutterhead

ia

regulated

by

front

to

rear

setting

of

the

s

tylUS

.

Fine

adjustmont

h

provided

by

h

andvheal

(30).

No

lock

iB

required.

H,wing

once

Bet

the

,tylus

,

the

adjustment

is

normally

l

eft

undisturbed

throug

hout

the

grinding

of

the

co

m

plete

cutte,.head

,

correction

for

"heel

vo

..r

boing

made

each

ti

..

e

the

"heel

is

dr

essed.

Stylus

adjustmen

t

can

be

made

,

for

ex

"",ple,

"'hen

rogrinding

damaged

kriives

or

vhen

blanking

,

but

s

uch

knives

t

hen

need

resetting

and

the

s

ty

l

us

re_set

to

its

original

position

.

FIT

T

TIlG

AND

US

I

NG

A

SAMPLE

TURNING

(Fig

.

21)

A

s""'ple

t u

rning

c"n

he

fitted

as

a

guide

when

positioning

knife

bl"nks,

"hen

re_""tting

knives

during

""grinding,

wh

en

Checking

finished

knife

profiles

and

w

hen

adding

extrn

relief

a

ft

e,.

final

profile

grinding

.

(See

'O

p",.ating

Techniques'

).

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

"

,.

1":J--_57

PIG.2

1

Sa~ple

turning

fix

ture

47.

Stylus

.

49.

Template

12

.

Tem

pl

ate

Holder

50.

Template

~ecuring

scre"s

<adj

ust

screws

nellr

adg"

to

correct

for

diffar-nn

t

thickness

of

template)

.

51.

Fence

peg~

.

13

.

Carriage

handle.

52.

Adjust"ble

contre

for

~Il.mple.

53 .

Brncket

for

52

(can

be

reversed

or

placed

in ~i

de

or

outside

supports

to

suit

various

length

~

of

sample

).

1

4.

Elbow

rest

54.

Lock

leve

r

for

l

ocking

awnpl"

or

albo

"

re~t

in

position

.

15.

Swople

55 .

Bracket

for

controlling

p03ition

of

~wnple

turning

..

nd

elboW"

re3t.

56.

Arbor

collar.

57.

Cup

supports

collar

.md

"rbor

"hilst

being

centred.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Page 9

The

turning

il

held

bot~een

ad

justable

contres

(52)

whi

ch

ar

e

init

i

al

ly

lot

parallel

f.<)

the

arbor

~hen

thu

centru

,

swi

v

el

bar

and

arbor

are

.ll

level.

S~ing

the

centres

to

this

P08'

tion

on

the

swivol

bar

and

eec

ure

.

Vith

the

turning

between

the

centre8,

adjuet

both

centres

auch

that

an

appropriat

e

aection

of

the

turning

aligna

with

the

corrupond

ing

knife.

Lock

the

centree,

then,

for

final

tine

eetting.

uee

the

tabl

e

croaa

-

.owo.ent

.

(par

eho

rt

turninga

f

ix

th

.

centrel

within

th

e

traae,

r

eve

rs

ing

if

n

ec

auary

.

Por

long

turning

a

ule

an

.xtende

d

bllr)

.

U

se

adjus

ting

handwheel

(16) lIee

Fig

21

,

for

final

fin

e

lIetting

of

cutter

h

ead

to

patte

rn.

By

pus

hing

against

levor

knob

OH,

th

e

cu

tt

erhead

is

te~porarlly

ahifted

out

of

contact

with

the

tu

r

ning

_

.,

,ometi.ea

ne

ede

d

"h

en

rotating

a

cutte

rhead

contain

ing

aome

knive

a

inco~pl

e

tely

ground

_

but

then

return

.

automat

i

cal

ly

to

the

original

eetting.

Vh

en

reverting

f.<)

grinding

,

return

the

arm

rest

and

•

....,pl.

turning

to

their

original

position.

,"oving

the

work

table

for

"ard

as

required

. The

re

lit

and

operative

posi

ti

ons

of

the ..

rm

rest

ond

sa

mple

can

be

varied

by

adjusting

brad,et

(55).

(

Su

'

Opeuti

ng

Te

chnique,

'

for

off_

set

ccntru

) . Use

hand

w

heel

(16) t o

give

a

bsck

posit

i

on

of

the

cutterhead

80

that

the

knive

8

clear

the

erm r

est

when

rotated

.

OPERATING

THE

GR

I

Jil!l8R

CAUT

I

o.'1

no

NOT

fully

t i

ghten

either

a hol der

or

a

knife,

nor

looa

an them from

fully

tight

, w

hilst

mounted on

the

grinde

r.

Pre

_I

oosen

any

knife

Or

holder

befor

e

mounting

on

the

~ehine

( i f

.dju.~ent

~y

be

needed)

and

fully

tighten

i~ediately

after

r

emo

v~l

.

Take

care

that

no

furth

er

ahift

tak

es

place

on

final

tighte

ning

•

•

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

GmERAL

OPEIL\T

I

CtI

A l"ay

~

grir><l

"et.

The

d i

rection

and

no"

of

coolant

frOll

both

the

overhead

jot

and

e i

de

je

t

..

are

con

t

rollable

by

shif

t

inc

th

e

jets

and

by

regu

l

ating

tap

s

(2)

/lnd

(24

).

Do

not

run

c"obnt

agsinat

...

s

tat

ionary

vheel

.

GR

I

NDING

BUNKS

Method

nf

blank

ins

Set

the

"hoel

vertical.

Yi

th

t

he

knit

e r

elting

on

the

approp

r

iAte

sup

port

make a

.er

i

ee

nf

straight

cnU

a t

"bout

5

1Ml

.

pitch

until

th

e

rough

profile

is

tormed

. (To fortll

cut,

o!

clo~or

pitch

"n"ld

re.u

it

in

applying

side

pressure

to

the

vheel

vhich

could

cauUl

tra

c

tur

e

in

~"tre

..

e

circlIOlshnco8)

.

In

tha

atome

vay

grind

&vay

al

l

the

unev

an

projec

t

ion"

r&maining

betore

f i

nelly

traversing

the

knit

e

tully

acrou

(aee

later

notes

on

tinal

end

regrindins

knives)

.

Regular

Stylus

Sattinn

Knitll

s.lLtt

.

ina

.i

..

eut

..

ide

.t.ha...soo

pe

ot

Lb.ia in.a.t.r_

ue-tioll

book-but

.

ne"

.....

tbal.

...... .

aftect

s

the

grinding

_othod

.

a)

A~sw

,

'ing

that

.hor

t

holder.

""d

ahor

t

knives

are

"s

ed

for

the

l a

rge

s t

dlo.meter

of

turning.

set

the

stylus

vhiht

grinding

ono

of

the80

knives

.

Adju.t

the

stylus

progre.sively

toward

s

the

rear

until

the

tull

vidth

ot

knite

i s

fully

for.ed

.

Uso

this

sty

lU

8

8ettlng

vhen

grinding

th

e

ra-aining

blanks.

b)

Alternatively.

adjust

the

~ty

lu

a

ror

..

ach

knife

individually

a.

needed

to

r

oughly

form

the

profile

acrou

the

full

width

.

Check

the

knivu

a

gnin

s t

the

sMlpla

pattorn

and

either

re-set

or

further

grind

the

..

(

at

the

dhcretion

of

the

operator}

unt

il

th

oya

ll

align

.

Fino.lly

rough

grind

a t

tho

average

sty

l

us

setting

so

e8t

..

bli

.h~d

.

Strlug

Setting

vhen

uaing

Support

Sugments

Roughly

grilld

all

knive8

as

st

b).

Check

them

against

the

s

...

ple

turning

and

note

those

needing

further

griooing

or

re_etting.

Select

and

fit

suitable

seRDent.

to

give

.i

ni

mal

grinding

and/or

re_

setting

of

the

kniv

es

.

Set

the

stylus

t,o

the

ugment

(aee

full

notea

in

"Final

end

Regrinding

or

Knives")

.

Re_set

..

nd

re

_

grind

all

knives

t o

this

nev

stylus

aetting

.

Frequoncv

ot

vlo

nol

'Iro~sinS

Regular

wh

eel

dreSSing

is

not

essen

tial

wh

en

rough

grinding

except

imae

dlately

betnTe

a

final

light

grind

vh

en

sett

ing

th

e

atylus

or

vh

en

ca-p

leting

knive

s •

• e

vheel

vear

takea

place

it

ia

an

advantage

to

periodically

advance

the

..

heel

to

..

intoin

slightly

_nre

tha

n

normal

c l

earence

between

wh

eel

and

support.

To

Qven

out

vhoel

vear,

wh

i

ch

is

unbalanced

..

nd

uneven,

rnugh

grind

right

and

left

hand

s h

ear

kn;vos

al

t

ernativoly.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Table of contents