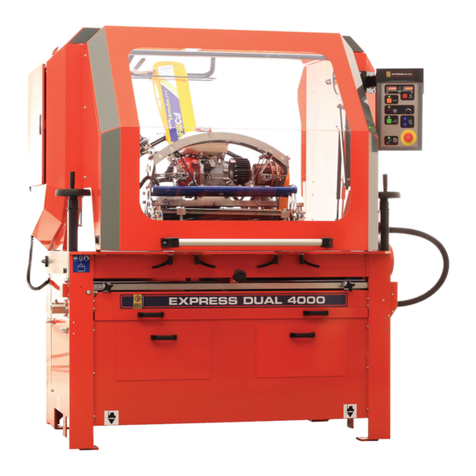

Bernhard BLADE RITE 1750 User manual

BLADE RITE 1750 MANUAL

BLADE RITE 1750

Please read this manual carefully before using the Blade Rite.

This manual should be kept in a safe place so that it can be used for future reference.

BR1750 Blade Relief Grinder

User’s Guide &

Instruction Manual

2

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

BLADE RITE

Contents

BERNHARD AND COMPANY LTD

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: info@bernhard.co.uk

USA Toll Free 1-888 GRIND IT (

1-888 474 6348)

BR1750 Blade Relief Grinder

You are now the owner/operator of a Bernhard’s Blade Rite 1750 which, if cared for

and operated correctly, will give you years of good service.

This manual will enable you to obtain the best results from your Blade RIte so

please read it thoroughly before using your machine.

If you have any service or operational problems contact your distributor,

or phone our

Technical Helpline (USA only) – 1-888 474 6348

or

Bernhard and Company Ltd, England – (+44) 1788 811600

or email

use the technical support feedback form on our web site

www.expressdual.com or www.bernhard.co.uk

Safety 3

Assembling the Blade Rite 4

Reel Grinding 5

Part Lists and Exploded Diagrams 10

BR1750_02/2007

3

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

1.1 This machine is designed to perform the operation of single blade/relief grinding on reel

mower cutting units.

The machine should not be used for any other purposes other than those for which it was

designed.

1.2 This machine should be installed, operated and maintained by only competent personnel.

1.3 Before carrying out any work on the machine, other than actual grinding, isolate the

electrical power supply.

1.4 Always operate the machine with the spark guard in place. Always wear adequate eye, ear

and breathing protection.

1.5 Only use recommended grinding wheels specically designed for this type of grinding unit.

1.6 Never leave rags or tools on the machine, or allow combustible materials to accumulate

around the machine.

1.7 Always ensure that the unit to be ground is securely mounted on the machine with no

loose components.

1.8 Always ensure that all electrical connections are sound, with cables safely routed.

Stay alert. Wear suitable clothing. Never operate the machine when tired or under the

inuence of alcohol or drugs.

1. Safety

4

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

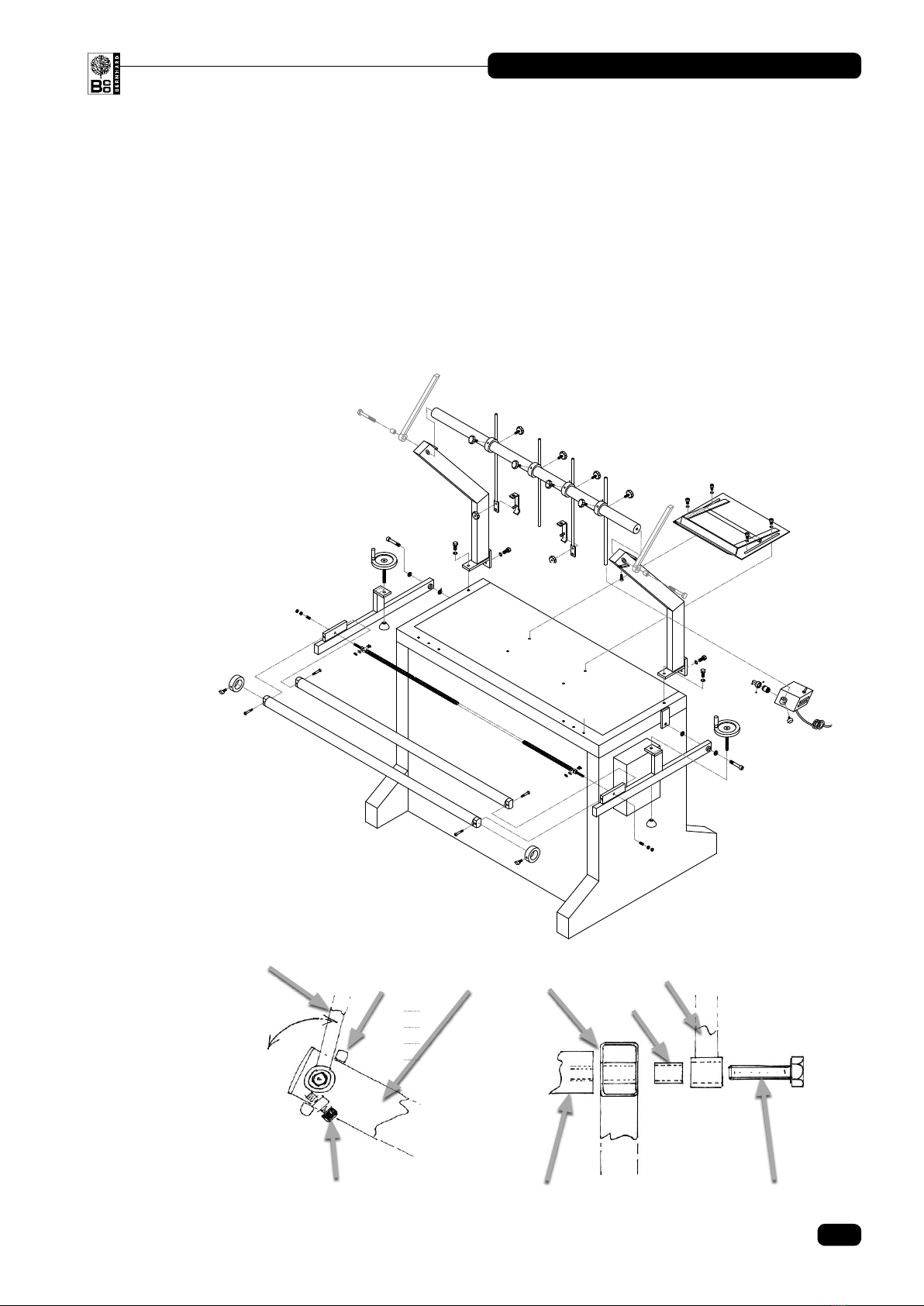

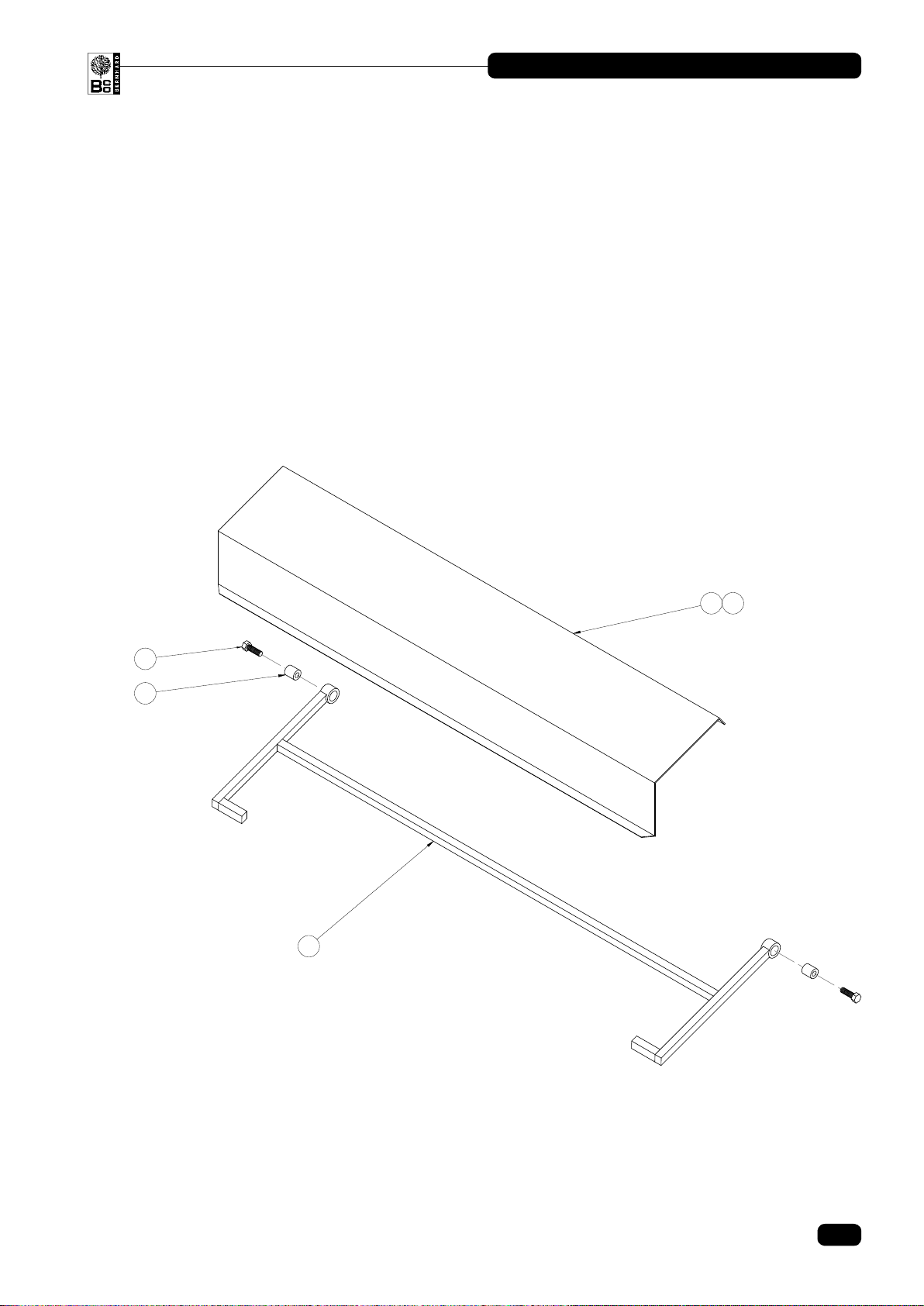

2. Assembling the Blade Rite 1750

2.1 You should receive this machine partly assembled.

2.2 Bolt the two support uprights to the top of the main chassis with the M12 hex bolts

provided. Do not fully tighten at this stage.

2.3 Slide the suspension and stop rod assemblies over the upper support rail.

Bolt the support bar between the support uprights tting the lift over guard at the same

time.

Guard Guard

Spacer

Support Upright

Upper Stop

Adjustable Lower Stop Upper Support Rail M12 Hex Bolt

5

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

3.1 Setting up for Blade Thinning (Relief grinding)

Note 1: Blade thinning (Relief grinding) is best carried out after the reel has been spun

ground to a perfect cylinder.

Note 2: Occasionally it may be necessary to remove the front roller and/or scraper from

some units to gain better access.

3.2 The mowing unit should sit with it’s rear roller in ‘vee’ support of the mower support

carriage [1] (g. 3.2.1.)

The hook/rope from the ratchet pulley block [2] should be attached to/around a convenient

point on the front of the mowing unit.

Raise the front of the unit whist simultaneously pulling the rope of the pulley block (g.

3.2.1.).

Slide the support carriage forward, complete with mowing unit, and set the unit into a

suitable position for grinding.

Tighten the 8mm Allen screws at the sides of the support carriage.

Rigidly secure the front of the mowing unit with the suspension rods by:

a) bolting directly to a convenient point on the mower frame, or (g.3.2.2.).

b) clamping to a suitable point with the suspension rod clamps.(g 3.2.3.).

1

3. Reel Grinding

Fig. 3.2

6

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

Note: The mounting system enables a wide range of

movement so that reels of all types and sizes

can be positioned to achieve the desired angle of

relief grind.

3.3 The grinding carriage should now be moved along the guide rails so that the grinding disc

can be adjusted close to the reel blades.

The grinding head can be adjusted up and down by loosening the locking ring [3] and

raising/rotating the head about its rear pivot by turning the adjuster knob [3A].

3. Reel Grinding (Continued)

Fig. 3.2.1

2

1

Fig. 3.2.2

Fig. 3.2.3

3A

3

Fig. 3.3

4

6

5

7

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

(Cont.) It can be adjusted in and out by means of the feed handwhee [4].

The blade rest (support nger) [5] should be positioned as close to the grinding wheel as

possible, then feed the grinding head in so that one end of one blade is supported by the

rest with the grinding wheel hardly touching the blade (Very light contact).

Traverse the grinding carriage to the other end of the blade, rotating the reel with the other

hand to keep the blade supported on the rest. Contact between blade and grinding wheel

should be even along the blade length. Adjustment to achieve this can be made using the

handwheels on the left and right hand guide rail side arms.

(Generally raising a side arm, turn handwheel clockwise, will bring the blade closer to the

grinding wheel at that end, whilst lowering a side arm, turn handwheel counter clockwise

will have the opposite result).

Note: It may be necessary to re-adjust the position of the mower, to obtain the desired

relationship between grinding wheel and blade, in order to achieve the desired angle of

relief grind, but with experience this positioning becomes quick and easy.

3.4 Set the left-hand traverse stop collar on the guide rail so that the grinding wheel covers

the left-hand end of the reel blade. The reel blade stays on the blade rest whilst the index

nger [6] springs up above the blade ready for traverse towards the right.

3.5 Set the right hand traverse stop collar on the guide rail so that the grinding wheel and

blade rest (support nger just clear the end of the reel blade without coming into contact

with the mower’ side plate or frame). The reel rotates forwards and the next reel blade

pushes the index nger down aligning the blade so that it will run onto the blade rest when

traverse is to the left.

3.6 Adjust the “low” position of the index nger so that it leads the reel blades smoothly onto

the blade rest (support nger) The weight of the reel blade should not be at this index

nger during right to left traverse; Adjust the “high” position so that the index nger is just

clear (above) blades for r/h traverse AND is caught by the next blade when the reel rotates

at the index position (r/h traverse stop); If necessary the index nger can be adjusted in

and out of it’s mounting block (It is locked in place by a small grub screw).

3. Reel Grinding (Continued)

View from Operator Position Support Finger M6 Wing Knob

Index Finger

Support

Finger

Set Index Finger

“High” Position

Set Index Finger

“Low” Position

Support

Finger

Reel control motor

moves reel so

that blade collects

index nger

Index nger is set

‘Low’ position so

that blade is led

smoothly onto

support nger

View from Operator Position

At Left-hand Traverse

Reverse Position:

Index Finger springs up

Index Finger

Roller

(High position)

As grinding head

traverses left to right,

ideal position of index

‘High’ nger leaves a

small clearence above

reel blade

Stone stays on

end of reel blade

Index Finger

Roller

(Low position)

8

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

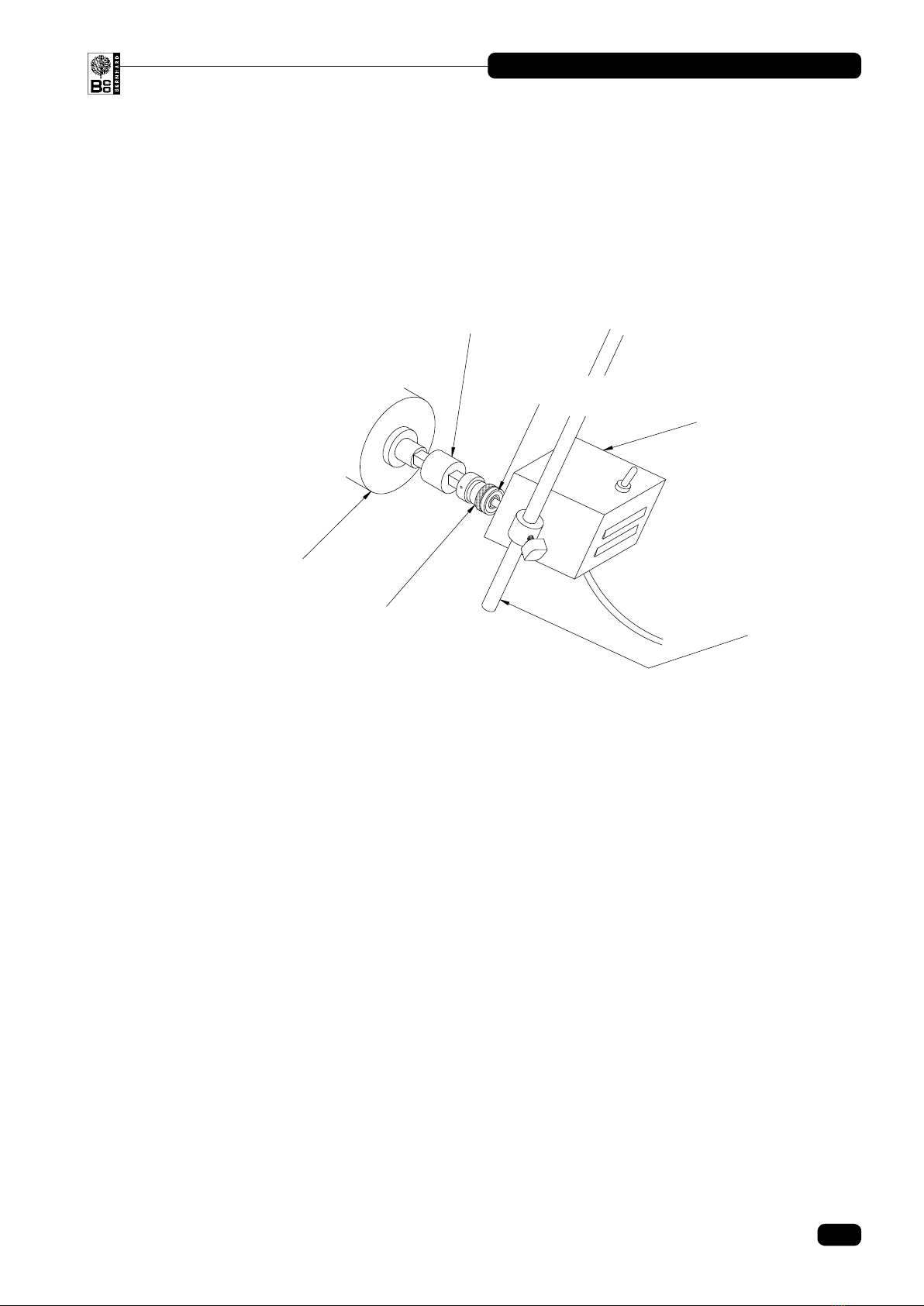

3.7 Connect reel drive motor. Loosen the locking lever clamping the support rod position

and the wing knob that locks the motor to the support rod; Rotate the support rod in it’s

mounting and slide the motor up and down until the output shaft aligns with the reel drive.

Connect the “slip clutch” output to the reel with a suitable coupling.

3.8 Select the direction to drive reel down onto blade rest (down from the top) and switch on

the motor.

3.9 Adjust the “slip clutch” so that it just keeps the reel blades onto the nger so that there is

sufcent torque for a smooth index between blades. This is achieved by loosening the

locking ring and by rotating the adjusting collar at the rear of the “slip clutch” (closest to

motor/gearbox) to increase spring compression; Clockwise rotation increases torque,

counter clockwise rotation reduces it.

3.10 Traverse the grinding head, by hand, to the left and right to check that the indexing is

working (remember to pause at the r/h traverse stop to give the reel time for the next blade

to reach the rest)

3.11 Switch on the traverse motor and engage with the lever, to conrm indexing works (The

traverse automatically pauses at each end, longer at the right-hand end to allow time for

indexing). If all is ok, disengage the traverse. Traverse speed may be adjusted by means of

the potentiometer knob on the control panel.

3.12 Mark one blade as a “datum” so that it can be returned to each time.

3.13 Lower the safety guard.

Note: Before actual grinding takes place, ensure that appropriate safety wear is used (see safety

notes in section 1).

3. Reel Grinding (Continued)

Reel Drive Motor

Reel Cutting Unit

Coupling

Slip Clutch

Torque Adjusting Collar

Suspension Rod

9

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

4.1 Switch on the grinding motor and apply a light cut. Traverse the length of the blade

manually without touching the l/h stop or allowing the blade to index. Check that the

width/angle of cut is constant along the blade length. Adjust the side arm handwheels, if

necessary, to achieve this.

4.2 Apply a reasonable cut and engage the traverse.

4.3 Increase the feed as necessary to keep the cut on each blade constant.

4.4 Finish the nal rotation of the reel with a light cut so that grindstone wear does not effect

the relative amount of metal removed from each blade.

4.5 Disengage the traverse and switch off vacuum and grinder, traverse and reel drive motors.

4. Relief Grinding (Blade Thinning)

10

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

5. Parts List

Page

BASE _________________________________________________ 11

CARRIAGE _____________________________________________ 13

MOTOR PLATE AND TRANSMISSION ______________________ 15

ELECTRICAL CABINET __________________________________ 17

CONTROL BOX _________________________________________ 18

GUARD ________________________________________________ 19

11

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

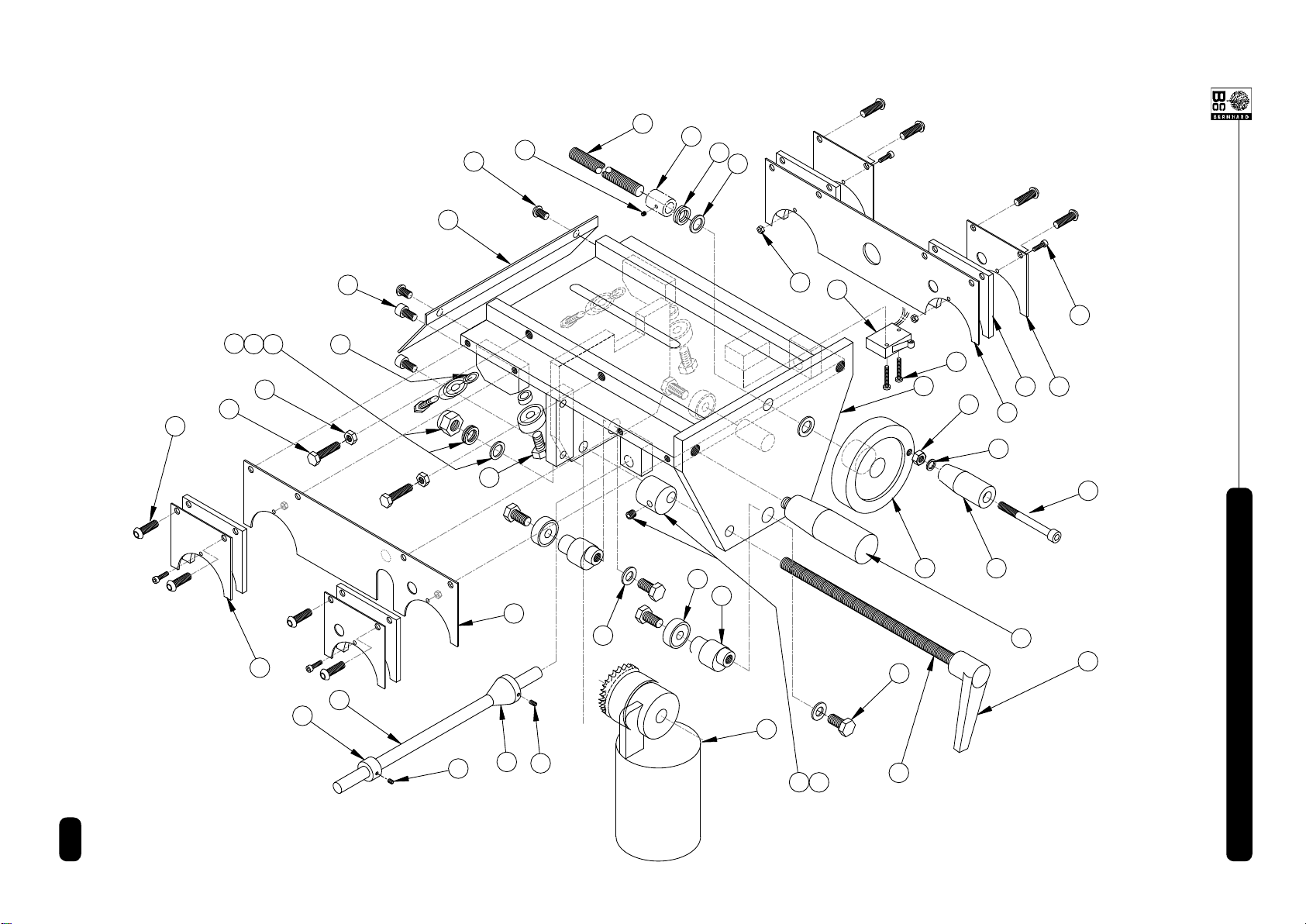

BASE ________________________________________________________________________

1 Base Frame ............................................................................. 1 A4216

2 R.H. Top Rail Support Arm ..................................................... 1 A4232

3 L.H. Top Rail Support Arm ......................................................1 A4233

4 R.H. Sidearm...........................................................................1 A4218

5 L.H. Sidearm ........................................................................... 1 A4219

6 Roller Cradle ...........................................................................1 A4239

7 Suspension Clamp ..................................................................2 A4237

8 Suspension Clamp Cradle ......................................................2 A4238

9 Top Rail ...................................................................................1 A6152

10 Front Rail .................................................................................2 A9134

11 Traverse Collar Stop................................................................ 2 A9136

12 ” Drive for Clutch ..................................................................1 A9140

13 Top Rail Clamp Block (large) .............................................3 (4) A4235

14 Setting Rod/Reel Motor Support....................................... 1 (2)

15 Cylinder Drive Motor ...............................................................1 A6028

16 Clutch ...................................................................................... 1 A9727

17 Handwheel 100 dia .................................................................2 A6148

18 Lobed Knob M8 x 20 ......................................................... 6 (8) A6146

19 Lobed Female Knob M8..........................................................2 A6166

20 Foot 50 dia............................................................................... 2 A6147

21 Wing Knob M6 x 15 .................................................................1 A6129

22 Lobed Knob M8 x 20 ............................................................... 2 A6146

23 Shoulder Screw 16 dia x 40 x M12.......................................... 2 A5178

24 Shoulder Screw 12 dia x 50 x M10.......................................... 4 A5177

25 Hex. Set Screw M12 x 30 ........................................................ 4 A5713

26 Washer M16 ............................................................................4 A6808

27 Cap Head Screw M10 x 20 .....................................................4 A5180

28 Washer M12 ............................................................................4 A5315

29 M16 Double Coil Spring Washer ............................................. 2 A5493

30 Grub Screw M4 x 6.................................................................. 3 A5190

31 Cap Head Screw M10 x 25......................................................1 A5116

32 Washer M10 ............................................................................4 A5310

33 Side Arm Plastic Cap .............................................................. 4 A6150

34 Top Rail Support Arm Plastic Cap ..........................................2 A6153

35 12” Scale (not shown) .............................................................2 A6629

36 Traverse Chain ........................................................................ 1 A7408

37 Chain Tension Bolt ..................................................................2 A5420

38 Chain Link................................................................................ 2 A7502

39 Tension Spring ........................................................................2 A6739

40 Nut M10 ...................................................................................4 A5504

41 Chain Link................................................................................ 2 A7502

42 Tension Spring ........................................................................2 A6739

43 Nut M10 ...................................................................................4 A5504

44 Diamond Dresser (Not shown)................................................1 A6737

9. Parts List (Continued)

Ref # Name of Part Qty. Part #

12

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

9. Parts List

(Continued)

1

2

3

4

5

6

9

10

11

14

16

17

18

19

20

21

23

24

25

26

28

27

29

30

31

32

34

33

35

36

37

39 40

41

42

43

20

8

15

7

BASE

13

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

Ref # Name of Part Qty. Part #

CARRIAGE __________________________________________________________________

1 Carriage Base ......................................................................... 1 A4241

2 Carriage Deector Front.......................................................... 1 A6367

3 R.H. Inner Wiper Plate ............................................................ 1 A6368

4 Outer Front Wiper Plate ..........................................................2 A6369

5 Wiper Felt ................................................................................4 A6811

6 Eccentric Adjuster ................................................................... 2 A4223

7 Feedscrew ............................................................................... 1 A9150

8 Feedscrew Locking Bush ........................................................1 A9151

9 Bearing Spacer ....................................................................... 4 A9147

10 Bearing 628zz ......................................................................... 7 A7723

11 Feed Screw Handle 80mm......................................................1 A6154

12 Handle M6 x 20 dia ................................................................. 1

13 Handle M10 x 20 .....................................................................1 A6170

14 Hex Head Bolt M8 x 18 ..........................................................2 A5731

15 Hex Head Bolt M8 x 20 .......................................................... 4 A5726

16 Button Head Screw M6 x 16 .................................................. 8 A5148

17 Button Head Screw M6 x 10 ..................................................2 A5142

18 Brass Hex Set Screw M6 x 25 ................................................2 A5750

19 Brass Full Nut M6....................................................................2 A5528

20 Cap Head Socket Screw M3 x 12 ........................................... 4 A5181

21 Nut M3 ..................................................................................... 4 A5510

22 Cap Head Screw M6 x 60 ....................................................... 1 A5157

23 Washer M8 ..............................................................................2 A5321

24 D’Coil Spring Washer M10 ...................................................... 1 A5309

25 Washer M10 ............................................................................2 A5310

26 Washer M6 ..............................................................................1 A5320

27 Grub Screw M3 x 4.................................................................. 1 A5207

28 Traverse Motor 24v DC ...........................................................1 A3396

29 Cap Head Screw M6 x 12 ....................................................... 2 A5171

30 Microswitch.............................................................................. 1 A8163

31 Slotted Pan Head Screw M3 x 20 .......................................... 2 A5430

32 Traverse Actuator Rod ............................................................ 1 A9148

33 Traverse Actuator Cone .......................................................... 1 A9149

34 Traverse Rod Stop Collar ........................................................ 1 A9163

35 Socket Screw M5 x 6............................................................... 1 A5137

36 Socket Screw M6 x 6............................................................... 1 A5156

37 Clutch Shaft (Long) ................................................................. 1 A3391

38 Clutch Lever M10..................................................................... 1 A6157

39 Clutch Eccentric ...................................................................... 1 A9159

40 Socket Screw M5 x 5............................................................... 1 A5137

41 Washer M10 ............................................................................1 A5310

42 D’Coil Spring Washer M10 ...................................................... 1 A5309

43 Nyloc Nut M10 ......................................................................... 1 A5505

44 Outer Rear Wiper Plate ........................................................... 2 A6370

45 L.H. Inner Wiper Plate.............................................................1 A6371

46 Nut M6 ..................................................................................... 1 A5516

47 Traverse Motor Bracket/Adaptor Plate (Not shown) ............... 1 A3394

9. Parts List (Continued)

14

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

12

43 42 41

40

39

38

37

36 35

34

33

32

31

30

29

28

15

23

6

10

14

13

11

22

5 4

3

26

1

21

25

24

8

7

27

17

2

9

19

18

20

16

BR1750 CARRIAGE

46

44

45

9. Parts List

(Continued)

15

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

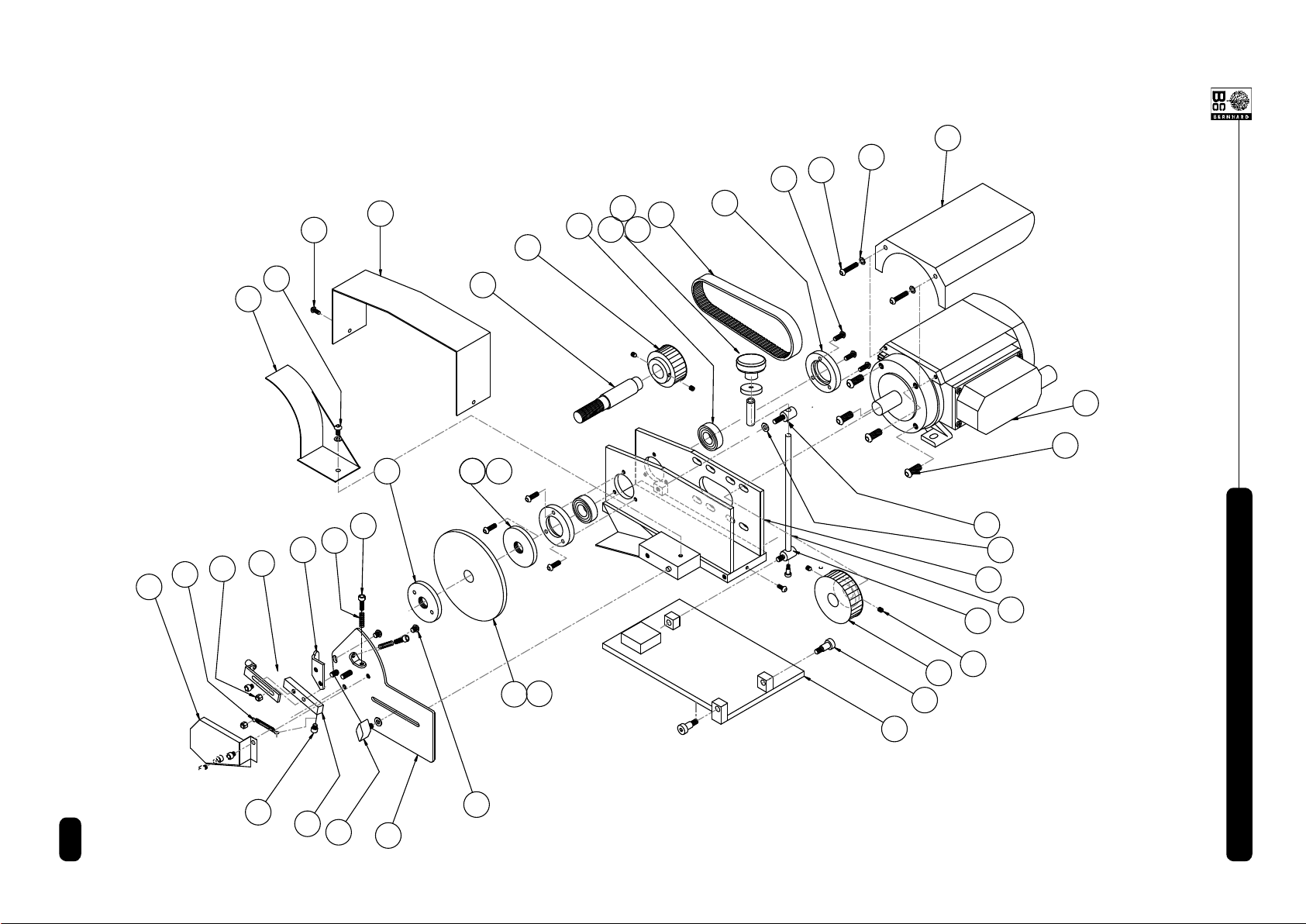

MOTOR PLATE AND TRANSMISSION __________________________________

1 90 Degree Rotating Base........................................................1 A4245

2 Motor Transmission Housing................................................... 1 A4147

3 Index Mounting Plate............................................................... 1 A4151

4 Index Finger Block................................................................... 1 A4152

5 Index Finger c/w Roller ........................................................... 1 A3397

6 Blade Rest ............................................................................... 1 A4154

7 Cover for Index Mechanism .................................................... 1 A6373

8 Pin Lock Plate ......................................................................... 2

9 Stone Guard ............................................................................1 A6374

10 Stone Spacer for 6mm Stone..................................................1 A3387

10A Stone Spacer for 9.5mm Stone...............................................1 A3386

11 Grinding Wheel Spindle .......................................................... 1 A9152

12 Lobed Knob .............................................................................1

12A Locking Ring............................................................................ 1

12B Spacer .....................................................................................1

13 Bearing Housing......................................................................2 A9153

14 30 tooth Pulley 60Hz (Driven) ................................................. 1 A7214

15 40 toothed Pulley (Drive) ........................................................1 A7210

16 Drive Belt 5mm x 16mm x 420mm ..........................................1 A7108

17 Bearing 6003 2RS................................................................... 2 A7726

18 Main Motor 60Hz single phase ...............................................1 A6006

Main Motor 50Hz single phase ...............................................1 A6004

Main Motor 50 / 60Hz 3 phase................................................1 A6005

19 Motor Cover Plate ...................................................................1 A6446

20 125 x 6mm Stone ....................................................................1 A3382

20A 125 x 9.5mm Stone ................................................................. 1 A3383

21 Shoulder Screw M8 x M6 x 12 ................................................ 3 A5165

22 Upper Height Adjust Boss .......................................................1 A3393

23 Wing Knob M6 x 15 .................................................................1 A6129

24 Height Adjust Stud................................................................... 1 A3390

25 Lower Height Adjust Stud........................................................1 A3389

26 Button Head Screw M5 x 25 ...................................................2 A5169

27 Button Head Screw M5 x 16 ...................................................6 A5133

28 Button Head Screw M8 x 16 ...................................................4 A5813

29 Cap Head Socket Screw M6 x 12 ........................................... 2 A5171

30 Cap Head Socket Screw M5 x 6 ............................................. 4 A5139

31 Nylock Nut M5 .........................................................................2 A5513

32 Index Finger Spring .................................................................1 A6814

33 Spring .....................................................................................2 A6908

34 Button Head Screw M5 x 6 .....................................................2 A5139

35 Socket Grub Screw M4 x 6 .....................................................4 A5190

36 Washer M6 ..............................................................................2 A5320

37 Washer M5 ..............................................................................3 A5318

38 Button Head Screw M5 x 10 ...................................................1 A5129

39 Transmission Cover Guard .....................................................1 A6372

40 Button Head Screw M3 x 10 ...................................................2 A5187

Junction Box Assembly (Not shown) ...................................... 1 A3403

9. Parts List (Continued)

Ref # Name of Part Qty. Part #

16

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

2

3

4

56

7

8

11

12 13

14

15

16

17

18

19

20 21

22

23

25

26

27

28

29

30

31 32

33

34

35

36

37

38

40

1

24

39

MOTOR PLATE

& TRANSMISSION

12A 12B

20A

9

10 10A

9. Parts List (Continued)

17

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

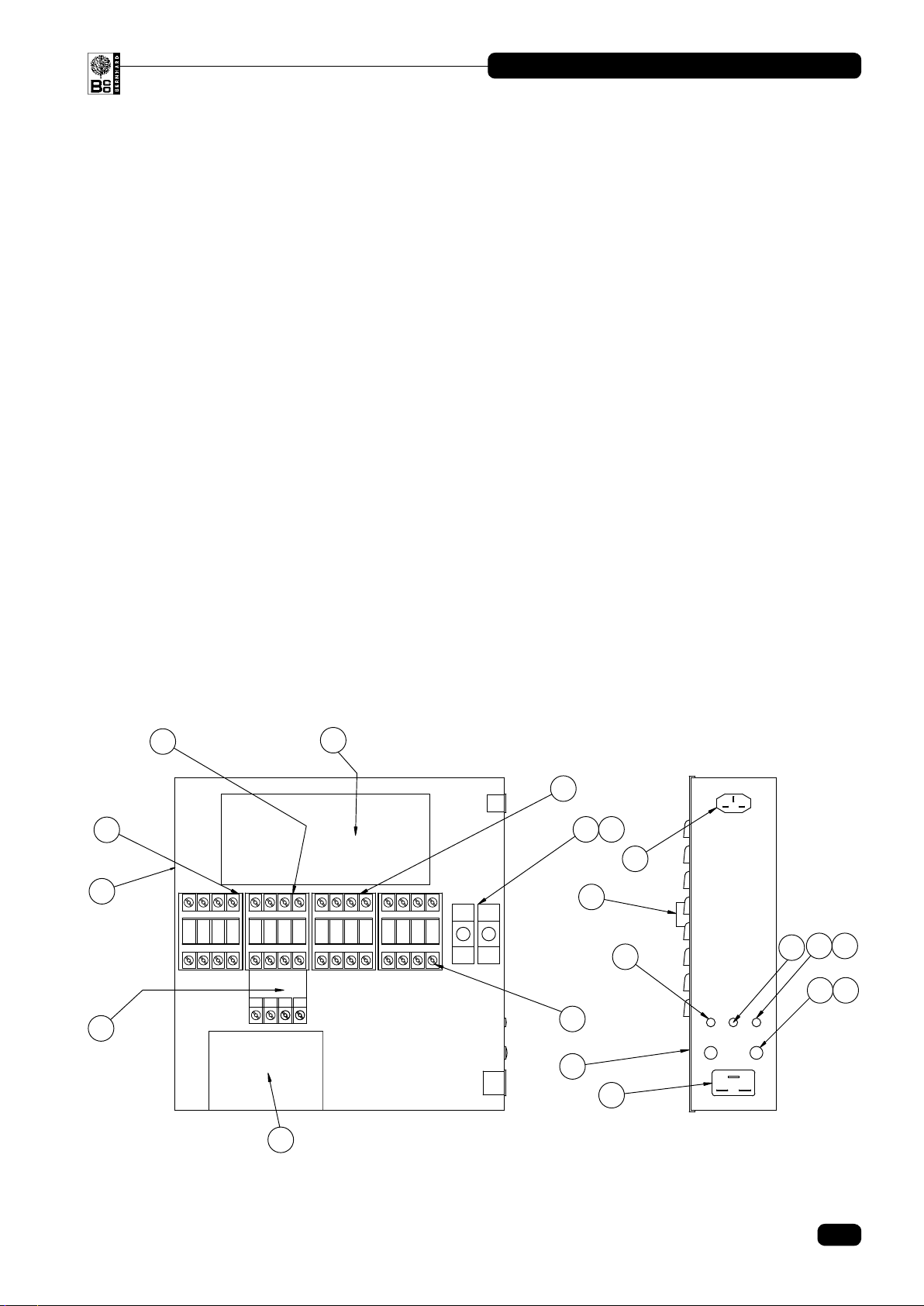

ELECTRICAL CABINET ___________________________________________________

1 Electrical Box .......................................................................... 1 A6379

2 Cover .......................................................................................1

3 Main Motor Contactor..............................................................1 A8063

4 Thermal Overload ...................................................................1 A8116

5 Traverse Motor Contactor .......................................................1 A8063

6 Reversing Contactor ............................................................... 1 A8062

7 Reel Drive Motor Contactor ....................................................1 A8063

8 Transformer 24v ......................................................................1 A8928

9 Timer Base ....................................................................... 1 (2) A8176

10 Timer ................................................................................. 1 (2) A8175

11 10 amp 3 pin Plug.................................................................... 1 A8172

12 10 amp 3 pin Socket................................................................ 1 A8171

13 Control/Traverse Fuse 2 amp .................................................1 A8085

14 Fuse Holder ............................................................................. 2 A8173

15 Transformer Fuse 5 amp ......................................................... 1 A8086

16 Mains Supply Fuse 10 amp.....................................................2 A8083

17 Fuse Holder ............................................................................. 2 A8174

18 Reset Button............................................................................ 1 A8130

19 Reel Control with Motor Fuse 2 amp....................................... 1 A8085

20 DC Control Card (Traverse Motor)..........................................1 A8187

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

1

2

4

5

6

7

8

9 10

11

13 14

15

16 17

18

19

IMO

TY4

SIDE VIEW

INTERNAL VIEW OF ELECTRICAL CABINET

3

12

ELECTRICAL CABINET

TY4

IMO

20

18

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

Ref # Name of Part Qty. Part #

CONTROL BOX ____________________________________________________________

1 Control Box.............................................................................. 1 A6452

2 Control Box Lid........................................................................1 A6454

3 Emergency Stop......................................................................1 A8073

4 Push Button.............................................................................3 A8040

5 Contact Block N/O .................................................................. 3 A8235

6 Contact Block N/C...................................................................1 A8236

7 Traverse Speed Potentiometer ...............................................1

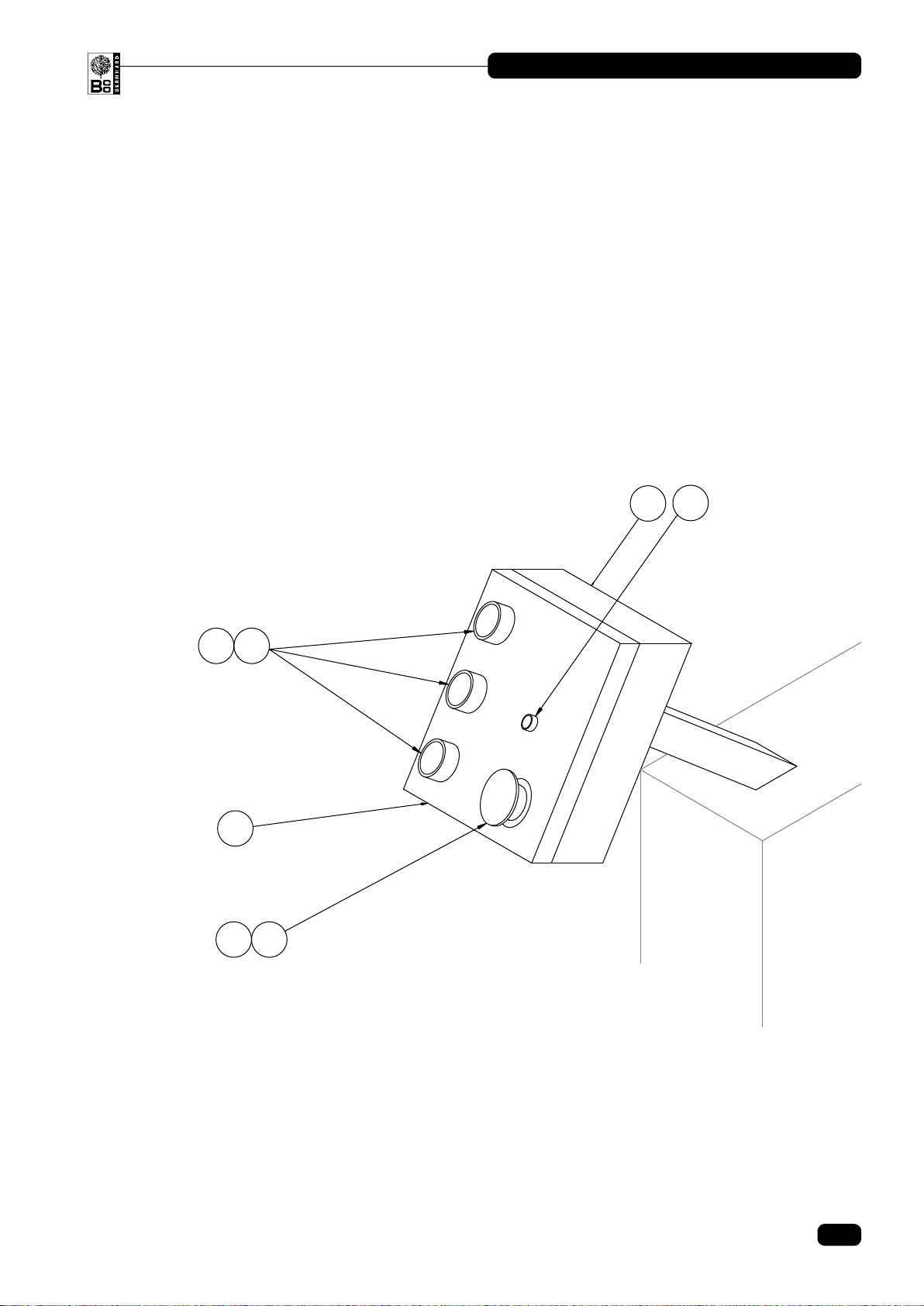

9. Parts List (Continued)

1

2

3

4

CONTROL BOX

5

6

7

19

BLADE RITE 1750 MANUAL

© Bernhard and Company Limited

GUARD ______________________________________________________________________

1 Main Frame .............................................................................1 A4234

2 Makralon Guard ...................................................................... 1 A6800

3 Plastic Rivets...........................................................................7 A5427

4 Hex Head Bolt M12 x 40.......................................................... 2 A5728

5 Guard Spacer / Bush...............................................................2 A9142

Ref # Name of Part Qty. Part #

9. Parts List (Continued)

BERNHARD AND COMPANY LTD / ATTERTON AND ELLIS LTD

Declare that the product:

Machine Name

Type

Serial No.

To which this declaration relates complies with the relevant Health &

Safety requirements of EC Directive:

89/392/EEC

as amended by:

91/368/EEC

93/44/EEC

93/68/EEC

and that for the implementation of the Health & Safety requirements the

following standards and/or technical specifications have been

consulted:-

ISO 7000 1989

BS.EN 292 Pt. 1 1991

BS.EN 292 Pt. 2 1991

BS.EN 418 1992

Stephen Bernhard (Managing Director)

Date:

BERNHARD AND COMPANY LIMITED • BILTON ROAD • RUGBY • ENGLAND CV22 7DT

EC DECLARATION OF CONFORMITY

Table of contents

Other Bernhard Grinder manuals

Popular Grinder manuals by other brands

EINHELL Bavaria

EINHELL Bavaria BWS 115/850-2 operating instructions

Maktec

Maktec GD0600 instruction manual

Toolla

Toolla TM 76010 instruction manual

Bosch

Bosch GBG 35-15 Professional Original instructions

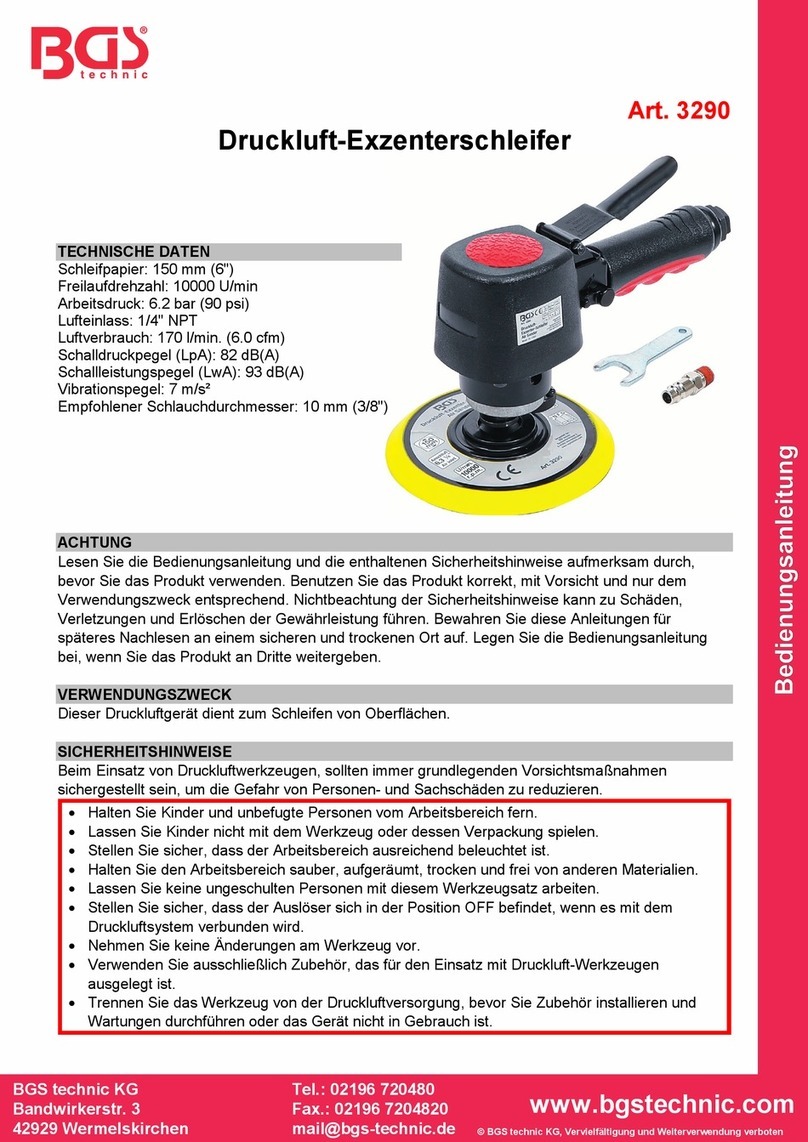

BGS technic

BGS technic BGS 3290 instruction manual

EINHELL

EINHELL TP-AG 1212 E operating instructions