Gerd Eisenblätter GmbH Jeschkenstr. 10 DE-82538 Geretsried

CE Declaration of conformity for

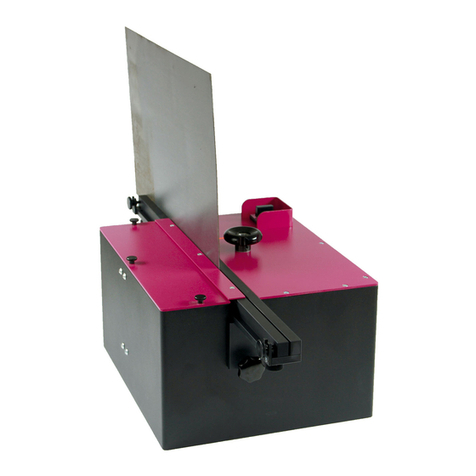

VARILEX

®

WSF 900

Operating instructions

ENGLISH NEDERLANDS

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is in conformity

with the following standards or standardi-

zation documents: EN 60745, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 according to the provisions of the reg-

ulations 2006/ 42/EG, 2004/108/EG.

EC-KONFORMITEITSVERKLARING

Wij verklaren op eigen verantwoording, dat dit produkt voldoet aan de

volgende normen of normatieve dokumenten: EN 60745, EN 55014-1,

EN 55014-2, EN 61000-3-2, EN 61000-3- 3 volgens de bepalingen van

de richtlijnen 2006/42/EG, 2004/108/EG.

DE TSCH DANSK

CE-KONFORMITÄTSERKLÄR NG

Wir erklären in alleiniger Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten übereinstimmt: EN

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000-3-3 gemäß

den Bestimmungen der Richtlinien 2006/42/EG, 2004/108/EG.

CE-KONFORMITETSERKLÆRING

Vi erklæerer under almindeligt ansvar, at dette produkt er i ove-

rensstemmelse med følgende normer eller normative dokumenter: EN

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000-3-3 i hen-

hold til bestemmelserne i direktiverne 2006/42/EG, 2004/108/EG.

FRANÇAIS NORGE

DÈCLARATION "CE" DE CONFORMITÉ

Nous déclarons sous notre propre responsabilité que ce produit est en

conformité avec les normes ou documents normalisés: EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3 conformément aux

termes des réglementations 2006/42/EG, 2004/108/EG.

CE-ERKLÆRING AV KONFORMITET

Vi overtar ansvaret for at dette produktet er i overenstem-

melse med følgende standarder eller standard-dokumenter: EN 60745,

EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3 i samsvar med

bestemmelsene i direktivene 2006/42/EG, 2004/108/EG.

ITALIANO SVENSKA

DICHIARAZIONE DI CONFORMITÀ CE

Assumendone la piena responsabilità, dichiariamo che il prodotto è con-

forme alle seguenti normative ed ai relativi documenti: EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3 in base alle prescrizi-

oni delle direttive 2006/42/EG, 2004/108/ EG.

CE-KONFORMITETSFÖRKLARINGEN

Vi intygar och ansvarar för att denna produkt överensstämmer med

följande norm och dokument: EN 60745, EN 55014-1, EN 55014-2, EN

61000-3-2, EN 61000- 3-3 enligt bestämmelserna i riktlinjerna 2006/42/

EG, 2004/108/ EG.

ESPAÑOL S OMI

DECLARACION DE CONFORMIDAD CE

Declaramos bajo neustra sola responsabilidad que este producto está en

conformidad con las normas o docu-mentos normalizados siguientes : EN

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000-3-3 de acuer-

do con las regulaciones 2006/42/EG, 2004/108/EG.

TODIST S CE-STANDARDINM KAIS DESTA

Todistamme täten ja vastaamme yksin siitä, että tämä tuote en allalue-

teltujen standardien ja standardoimisasiakirjojen vaatimusten mukai-

nen: EN 60745, EN 55014-1, EN 55014-2, EN 61000- 3-2, EN 61000-3-3

seuraavien ohjeiden määräysten mukaisesti: 2006/42/EG,

2004/108/EG.

PORT G ES GREEK

DECLARAÇÃ0 DE CONFORMIDADE CE

Declaramos sob nossa exclusiva responsabilidade que este producto

cumpre as seguintes normas ou documentos normativos : EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3 de acordo com as

disposições das directivas 2006/42/EG, 2004/108/EG.

∆΄HΛΩ∑Н ∑ΥМΒΑΤΙΚ΄ОΤΗΤОΣ

∆ηλώvoυµε υттεuθύvως óтı тo проїóv αuтó εіvαı καтασκεuασµέvo

ơúµφωvα µε тоuς εξής καvovισµοúς ή καтαơкεuασтıκές σuσтάσεıς: EN

60745, EN 55014-1, EN 55014- 2, EN 61000-3-2, EN 61000-3-3

σúµφωνα µε тıς

δıαтάξεıς тων Οδηуıών: 2006/42/EG, 2004/108/EG.

Gerd Eisenblätter GmbH