AU Tool DM303 User manual

www.autooltech.com

Auto Diagnostic Multimeter

AUTOOL DM303

User Manual

用户手册

COPYRIGHT INFORMATION

Copyright

Trademark Manual are either trademarks, registered trademarks, service

marks, domain names, logos, company names or are otherwise

the property of AUTOOL or its affiliates. In countries where any of

the AUTOOL trademarks, service marks, domain names, logos

and company names are not registered, AUTOOL claims other

rights associated with unregistered trademarks, service marks,

domain names, logos, and company names. Other products or

company names referred to in this manual may be trademarks of

their respective owners. You may not use any trademark, service

mark, domain name, logo, or company name of AUTOOL or any

third party without permission from the owner of the applicable

trademark, service mark, domain name, logo, or company name.

You may contact AUTOOL by visiting AUTOOL at https://www.au-

tooltech.com, or writing to aftersale@autooltech.com, to request

written permission to use materials on this manual for purposes or

for all other questions relating to this manual.

●

●

●

●

All rights reserved by AUTOOL TECH. CO., LTD. No part of this

publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical,

photocopying, recording or otherwise, without the prior written

permission of AUTOOL. The information contained herein is

designed only for the use of this unit. AUTOOL is not responsi-

ble for any use of this information as applied to other units.

Neither AUTOOL nor its affiliates shall be liable to the purchaser

of this unit or third parties for damages, losses, costs, or

expenses incurred by the purchaser or third parties as a result

of: accident, misuse, or abuse of this unit, or unauthorized modi-

fications, repairs, or alterations to this unit, or failure to strictly

comply with AUTOOL operating and maintenance instructions.

AUTOOL shall not be liable for any damages or problems

arising from the use of any options or any consumable products

other than those designated as original AUTOOL products or

AUTOOL approved products by AUTOOL.

Other product names used herein are for identification purpos-

es only and may be trademarks of their respective owners.

AUTOOL disclaims any and all rights in those marks.

TABLE OF CONTENTS

Cautions .............................................................................................................. 1

Safe operation guidelines................................................................................ 1

Product Introduction.......................................................................................... 3

Overview ......................................................................................................... 3

Composite indicator ........................................................................................ 3

Product Structure............................................................................................... 5

Structure diagram............................................................................................ 5

Button function ................................................................................................ 6

Cable Number................................................................................................. 7

Operations Instruction....................................................................................... 8

Functional operation guidelines ...................................................................... 8

Voltage measurement ..................................................................................... 8

Oscilloscope.................................................................................................... 9

Current measurement ..................................................................................... 11

Resistance test................................................................................................ 12

Automotive circuit test ..................................................................................... 13

Car start-up test .............................................................................................. 16

Injector test...................................................................................................... 17

Automobile relay test....................................................................................... 19

Analog signal test............................................................................................ 20

Ignition pulse signal test.................................................................................. 22

K line data ....................................................................................................... 23

CAN bus data.................................................................................................. 25

Frequency measurement ................................................................................ 26

Other Problems .................................................................................................. 27

Software upgrading ......................................................................................... 27

Equipment identification number..................................................................... 27

Maintenance Service.......................................................................................... 28

Maintenance.................................................................................................... 28

Warranty .............................................................................................................. 29

Warranty access.............................................................................................. 29

Disclaimer ....................................................................................................... 29

Return & Exchange Service .............................................................................. 30

Return & Exchange ......................................................................................... 30

CAUTIONS

Safe

operation

guidelines

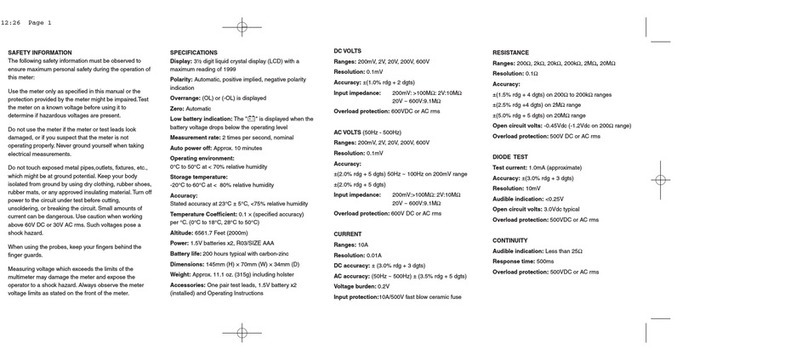

The automobile diagnostic multimeter is designed and

produced in strict accordance with GB4793.1 Safety Require-

ments for Electronic Measuring instruments and IEC61010

Safety Standard, and conforms to double insulation, overvolt-

age standards (CATII1000V, CATIII600V) and safety

standards of pollution level 2. Please operate the instrument

according to usage instructions in the Manual; otherwise, it

might weaken or lose protection function of the instrument.

Before use, check that the insulation layer of the probe is intact

without damage or breakage. If any obvious damage to insula-

tion of probe or instrument shell, or you believe that the instru-

ment cannot work normally, please do not use the instrument

any more.

While using a probe, put your fingers behind its finger protec-

tion ring.

Do not apply voltage above 1000Vrms between instrument

terminal and grounding terminal to prevent electric shock and

instrument damage.

In case of measured voltage higher than DC60V and 42Vrms,

be careful to prevent electric shock.

Before covering up the rear cover of the instrument, it is strictly

forbidden to use the instrument; otherwise there will be risks of

electric shock.

Measured signals are not allowed to exceed the regulated limit

value to prevent electric shock and instrument damage.

It is not allowed to use current to test terminals or voltage at

current gear.

A self-recovery fuse is used inside the instrument. Do not

change the internal wiring of the instrument to avoid damaging

the instrument and endangering safety.

When the battery symbol is shown in red on the LCD, the

battery should be replaced timely to ensure the measurement

For the correct use of the instrument, please read the full text

of this manual carefully before use, especially the “safety

precautions”.

1

accuracy.

Do not operate the instrument in the high temperature, high

humidity environment. Especially, do not store the instrument

in the wet environment, as the instrument performance may

deteriorate if being wetted.

Clean the instrument enclosure with a wet cloth and a gentle

detergent, and do not use abrasive agents or solvents.

2

3

The automobile diagnostic multimeter is a hand-held new

diagnostic oscillometric multimeter integrating digital oscillo-

scope, digital multimeter, automobile circuit and automobile

signal inspection, which is designed with the embedded digital

control technology.

The multimeter mode can measure the AC / DC voltage and

current, resistance, diode forward voltage drop, on-off and

frequency.

Oscilloscope mode is a complete intelligent measurement

system, which includes signal input, data sampling, data

processing and automatic search, with the waveform test

bandwidth of 500KHZ. With a variable sampling frequency, the

slowly varying signal amount can be measured. It is applicable

to measuring and observing various signals on the automobile

circuit during the car overhaul, including the motor drive signal

and motor power voltage of new energy vehicle, fuel car engine

ignition pulse signal, camshaft signal, crankshaft signal, wheel

speed sensor signal, oxygen sensor signal and so on;

Car circuit detection can online test the low voltage circuit,

prompt high voltage or line leakage and output the power

supply voltage. It can also output the power voltage to test the

parts of the car, or lower the voltage to drive the parts of the

car, such as lights; Test the battery voltage when the oil-fueled

vehicle starts, and judge whether the vehicle starting system

and the battery are in good condition;

The analog signal output can be applied to the car ECU detec-

tion and can simulate the square wave and sine wave output

and simulate the fuel injection signal to drive the fuel injection

nozzle; Check the data signal K line and CAN bus signal in the

vehicle.

PRODUCT INTRODUCTION

Overview ●

●

●

●

●

The multimeter function and the oscilloscope function are

integrated together on the instrument. When measuring the

voltage signal using a probe, switch to the oscilloscope function

with

[Fn]

key to facilitate the use and observation of signal wave-

form.

Composite

indicator

4

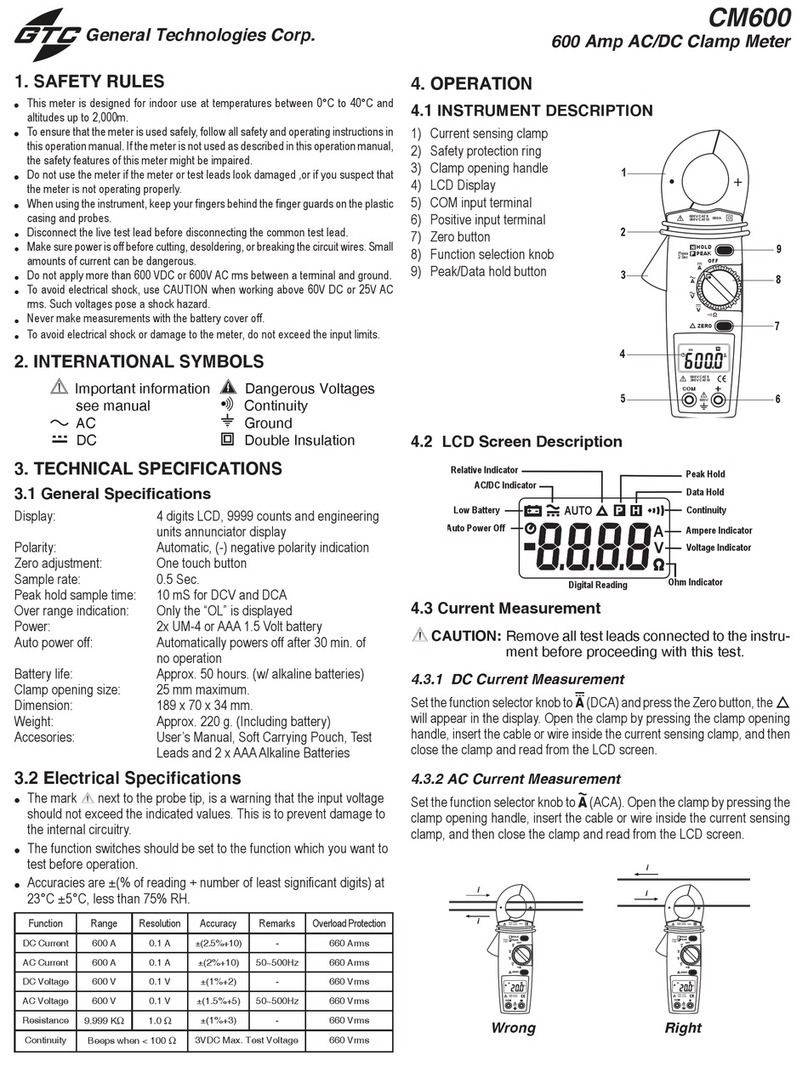

LCD is a 2.8-inch color screen, with a resolution of 320*240;

Input impedance for the voltage measurement: it is 2~3MΩ

when the voltage is lower than 160V; it is 10MΩ when the

voltage is higher than 160V. The maximum input voltage is

1000Vpp; The analog bandwidth is 500KHz; The voltage

range is converted automatically;

The 10A terminal fuse for current measurement is 15A self-re-

covery fuse, and the maximum measurable current is 20A; The

current measurement mA/uA terminal fuse is 0.5A self-recov-

ery fuse, and the maximum measurable current is 200mA;

Working temperature: 0~40°C(32~104°F) Humidity: ≤75%;

Storage temperature: 10~50°C(14~122°F) Humidity: ≤70%;

Altitude: 2000m.

●

●

●

●

●

●

5

PRODUCT STRUCTURE

Structure

diagram

Display screen Power supply indicatorA B

Button 10A current input

C D

mA/uA measurement

input COM measurement input

E F

Diode, voltage,

resistance, frequency

measurement input

Lighting lamp

G H

DB15 interface

I

A

B

I

C

D

E F

H

G

6

Button

function

Power key

A

HOLD Pause Hold / Measurement key.B

Direction

button Select the functional items.

C

ESC Return key.D

Fn Measurement mode switch key.

EOK Enter key.

F

F2 Function keys, defined by the test function.G

ZERO / F1 Function key, quick reset setting, or

defined by test function.

H

Lighting key Press the light on / off.

I

A

B

C

D

E

H

I

G

F

Press for power-on, press for about 0.3

seconds to turn off the power when it is

on, and long press 3 seconds to reset the

instrument.

7

Cable

number Cable Number

NO. Distribution

Head No.

Name Functions

C01

C01 - 1

Multi-functional

detection line

DC connector,

connected to the

battery clip line

C02

Battery clip line

C03

Ignition pulse

signal detection

line

Sensing high-voltage

line signal

C05Jumper(Black)

C06Jumper(Green)

C07Jumper(Yellow)

C04

C04 - 1

Automotive

circuit detection

line

DC connector,

connected to the

battery clip line

C04 - 2 Probe terminal

C01 - 2 Terminals for

injector test and

Automobile relay test

C01 - K K line signal line

C01 - CAN+ CAN+ signal line

C01 - CAN- CAN- signal line

C01 - GND Ground wire

C01 - SIN Sine wave signal line

C01 - S1 5V signal line

C01 - S2 Square signal line

RedBlack

8

OPERATIONS INSTRUCTION

The instrument is equipped with a power switch and the

automatic sleep function. The automatic sleep time can be set

to 1-30 minutes. The key tone of the instrument can be set to

turn on and off, but the warning tone cannot be turned off. The

brightness of the screen can be set. The brightness can be set

according to the actual operation environment, and the battery

time can be extended by appropriately lowering the brightness.

The help function of the instrument provides a brief operation

description.

The instrument is configured in one or more languages

according to the sales area. Please contact your local dealer

for different languages.

After turning on the power supply, according to the displayed

icon, use the [up / down / left / right] direction keys to move the

current option, and press [OK] to enter the function item.

●

●

●

●

Functional

operation

guidelines

Insert the red probe into the “V” jack and the black probe into

the “COM” jack;

●

Voltage

measurement

Voltage(DC)

<HOLD>Hold

<Fn>Function Mode

<F1>Zero

<F2>PULL DOWN

0.00V

9

Insert the red probe into the “V” jack and the black probe into

the “COM” jack. The instrument does not have a dedicated

BNC interface. The oscilloscope is used as an expanded

function of voltage signal detection, which greatly facilitates

user operation and is particularly suitable for vehicle mainte-

nance.

●

The current measured value is displayed. If the voltage fluctu-

ates, press the [HOLD]key to maintain the display status. If

there is no voltage signal, the displayed value is non-zero, the

red and black probe can be shorted, and press the [F1]key at

the same time to perform the quick zeroing operation. [F2]key

is used to remove the induction power at the measurement

point. Press [F2]key during the measurement, which is equiv-

alent to a 10K resistance connected the red and black probe.

This function is suitable for detecting the induction voltage of

the new energy vehicle. Press [Fn]key to switch to the AC

voltage measurement and the oscilloscope mode to observe

the signal waveform; In the voltage measurement or oscillo-

scope mode, the range is automatically converted, and the

maximum measurable voltage signal is 1000V;

In the voltage measurement mode, the probe only inputs

signal, but no pulse signal, without interference to the

measured point.

●

●

Oscilloscope

Enter the function item, displayed as shown below:

●

5V/di v 1mS

0V

U: 0.00V MIN: 0.00V MAX: 0.00V

Trig. +00

10

Display the current signal waveform, 5V/grid - display the

voltage scale value, and press the [up]and [down]keys to

change during measurement; 1ms-scan time scale value;

during measurement, press the [left]and [right]keys to

change; Trigger+01 - displays the correction value of the

trigger level, which can be changed by pressing [F1 / F2]. The

trigger level is the average value of the current waveform

automatically calculated. The positive value of trigger correc-

tion indicates the increase value of trigger level correction, and

the negative value of trigger correction indicates the decrease

value of trigger level correction;

Press the [HOLD]button to pause the display of the waveform.

When the waveform is suspended, the [up / down / left / right]

keys can be used for the left and right movement control of the

waveform, so as to facilitate the comparison and observation

of the waveform.

●

●

Enter the function item, displayed as shown below:

●

RedBlack

Ampere(DC) mA(Green)

<HOLD>Hold

<Fn>Function Mode

<F1>Zero

<F2>20A/mA

0.0mA

Below 200mA Above 200mA

Red Black Red Black

11

In the process of voltage signal measurement, the instrument

automatically changes the range and the maximum measur-

able voltage signal is 1000V;

●

Enter the function item, displayed as shown below:

●

Measure the current below 200mA, insert the red probe into

the green “mAuA” jack, and insert the black probe into the

“COM” jack;

Measure the current above 200mA, insert the red probe into

the yellow “A” jack, and insert the black probe into the “COM”

jack;

●

The current measured value is displayed. If the current fluctu-

ates, press the [HOLD]key to maintain the display status. If

there is no current signal, the displayed value is non-zero, the

red and black probe can be shorted, and press the [F1]key at

the same time to perform the quick zeroing operation. [F2]key

is used to switch the large current measurement, [Fn]key is

used to convert measurements of DC current and AC current.

●

●

Current

measurement

Ampere(DC) 10A(Yellow)

<HOLD>Hold

<Fn>Function Mode

<F1>Zero

<F2>20A/mA

0.00A

RedBlack

12

●

Enter the function item, displayed as shown below:

●

Insert the red probe into the “Ω” jack and the black probe into

the “COM” jack;

●

Press [F2]key and switch to detect high current mode as

shown below:

●In the high current mode, the maximum measurable current is

20A and the maximum measurable continuous current is 10A.

There is 15A 30V self-recovery fuse inside, which can protect

the instrument from damage due to excessive current in the

use of vehicle detection. However, the detection of current in

220V / 380V strong current circuit cannot prevent damage

caused by excessive current, and cannot exceed the measur-

able current range during use.

Resistance

test

Resistance

<HOLD>Hold

<Fn>Function Mode

<F1>Zero

Diode: . V

0.00Ω

Diode/Short

<HOLD>Hold

<Fn>Function Mode

<F1>Zero

Resistance: . Ω

0.00V

13

●

Insert the special wire for automobile circuit into the multi-func-

tional interface (top of the machine), connect the battery clip

line, clamp the red clip on the positive plate of the automobile

battery, clamp the black clip on the negative plate of the

automobile battery, and use the probe to detect the automobile

circuit. During the detection process, the probe will send a test

signal to detect the electric leakage of the circuit.

●

The instrument detection resistance and the diode are

two-in-one function display. Press [Fn]key to switch the

display mode. When measuring the resistance, the resistance

can be set as the main display; when measuring the diode, the

diode can be set as the main display; As shown in the following

figure:

●The resistance value displayed is the resistance value when

measuring the resistance, and the voltage value displayed is

the pressure drop value when measuring the diode. Connect

the red and black probe, and press [F1]key for zeroing. If the

resistance is excessive low, the instrument will give a sound

prompt.

Automotive

circuit test

Voltage(DC)

<HOLD>Hold

Supply voltage: 12.50V

<UP>SHORT TO B+

<F1>Zero

<DOWN>SHORT TO B-

0.00V

Red

Red

Black

C04 - 1C04 - 2

C04

C02

14

Enter the function item, displayed as shown below:

●

●

●

●

●

Connecting the battery for power supply, the instrument will

obtain the external power;

The instrument displays the current probe voltage value and

the voltage value of the power clip;

Insert the probe into the COM port of the instrument, showing

the voltage is zero; if not zero, press [F1]key to zero;

Detect the circuit on the automobile using a probe, showing the

current detection voltage. If the voltage is a constantly chang-

ing signal, press [Fn]key to enter the oscilloscope for observa-

tion; if the detected voltage is lower than 0.7V, the instrument

will automatically detect the leakage; if the figure with blue

background is displayed and there is a sound prompt, it

indicates that the circuit resistance to ground is lower than

Test signal

12.40V

Voltage(DC)

<HOLD>Hold

Supply voltage: 12.50V

<UP>SHORT TO B+

<F1>Zero

<DOWN>SHORT TO B-

0.00V

Voltage(DC)

<HOLD>Hold

Supply voltage: 12.50V

<UP>SHORT TO B+

<F1>Zero

<DOWN>SHORT TO B-

15

If the detected voltage is very high and close to the power

supply voltage, the instrument will display a number on the red

background with a sound prompt, indicating that the circuit

voltage is high, which may be a power supply line. If it is an

insulated line, it indicates that the line is leaking to the power

supply, as shown in the following figure:

Probe power supply function on instrument line: Press the [up]

function key, and the probe outputs the power supply voltage;

Probe grounding function on instrument line: Press the [down]

function key, and the probe is short circuited to the negative

pole of the power supply;

Test function of automotive electrical appliances: The instru-

ment outputs a power supply voltage value through the probe

to drive the automobile electrical appliances to work. It judges

whether the electrical appliances are damaged by observing

whether the electrical appliances are working, or drive the

automobile electrical appliance through short connecting the

special probe to the negative pole, and then judge whether the

electrical appliance is damaged by observing whether the

electrical appliance is working. For example, check whether

the turn signal is intact and use the probe to detect the current

voltage value of the two leads of the lamp. If both lines are

●

●

●

●

10K. If the circuit is insulated to ground, it indicates that the

circuit has leakage, as shown in the following figure:

Table of contents