Sifam Tinsley Gamma 10 User manual

Printed in India, Subject to change without Notice

User Manual

Analog-Digital Multimeter

Gamma 10

IC 2-60-006-00-00555/REV:A/15/05/2013

P R E C I S I O N I N S T R U M E N T A T I O N

Manufactured by:

Sifam Tinsley Instrumentation Inc

3105 Creekside Village Dr,

Unit 801, Kennesaw GA 30144

Distributed by:

Veracious Canada Inc

1101 Britannia Rd E,

Mississauga, ON L4W 3X1

Contact: +1 416-640-5364

Fax: +1 416-981-3933

E-mail: [email protected]

Web: www.veraciousinc.com

(12)

(11)

(13)

VA

DC

AC

-30

KW MW

kHz dB

nF

mF

mm

(8) (9) (10)

(16) (15) (14)

(20)

(19)

(18)

MIN

MAX t ON EVENTS

ON

-30.999

-10

0 -20

MAN

DATA

(17)

Zero

Zero

VA

MIN

MAX I ON EVENTS

DC

AC

ON

-8:8:8:8.8

-100

0 -200 -300

MAN

DATA

KW MW

kHz dB

nF

mF

mm

Gamma 10

(1)

(2)

(3)

(4)

(5)

(6)

mV

DC

-289.53

300 mA 10 A

(7)

100 200 300

ON

OFF

MAX

DATA

MIN/MAX

mA A

1000 V CAT II / 600 V CAT III

ON

V W

1000 V

fused

0

TRMS AC

TRMS AC+DC

MIN

AUTO

MAN

F0C

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

Scope of Supply:

1) Meter 2) Cable set

3) Spare Fuse 4) Safety Cover

5) Belt 6) Battery

7) User Manual 8) Warranty Card

9) Test Certificate

WARRANTY

Dear Customer,

You are now the privileged owner of Gamma 10 Digital Multimeter / Accessories, a

product that ranks the first of its kind in the world.

Company provides 36 months warranty from the original date of purchase against

defective material and workmanship.

In the unlikely event of failure of this meter / accessories within the warranty period,

Company will repair the meter / accessories free of charges. Please hand over the

meter / accessories to the dealer / Stockiest from whom you have purchased along

with this card and relevant cash memo / Invoice. This warranty entitles you to bring

the meter / accessories at your cost to the nearest stockiest / dealer and collect it

after repairs.

NO TRANSPORTATION CHARGES WILL BE REIMBURSED

The warranty is not valid in following cases:

1) Warranty card duly signed / stamped and original cash memo / invoice are

not sent along with the meter / accessories.

2) Complete warranty card is not presented to authorised person at the time of

repairs.

3) Meter / accessories not used as per the instruction in the user manual.

4) Defect caused by misuse, negligence, accidents, tampering and acts of

god.

5) Improper repairing by any person not authorised by the company.

6) Any sort of modification, alteration is made in electrical circuitry.

7) Seal provided inside is broken.

Warranty of Digital Multimeter / Clamp meter / Accessories does not cover fuses

and battery. Incase of dispute to the validity of warranty, the decision of Company’s

service center will be final.

If you brought this meter / accessories directly from the company, and if you notice

transit Damage, then you must obtain the insurance surveyors report and forward it

to Company.

Thank you.

Serial Number :

Date of Purchase :

Cash Memo / Invoice No. :

Dealer’s Signature :

Dealer’s Stamp :

(To be filled by authorized dealer)

Model No. :

Contents

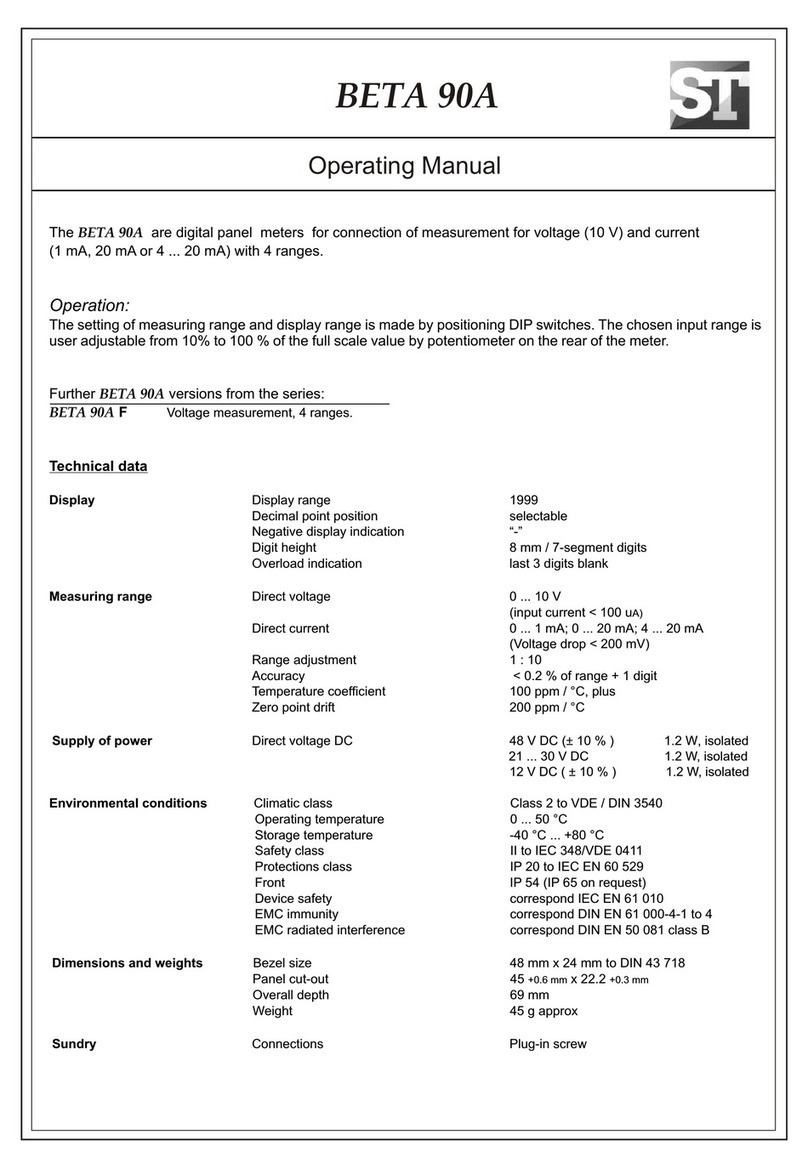

(1) Liquid crystal display

(2) ON / OFF pushbutton

(3) Pushbutton for data hold and

MIN/MAX storage functions

(4) Pushbutton for manual range

selection

(5) Multi-function pushbutton

(6) Function selector switch

(7) Terminal sockets with automatic

blocking system

(8) Symbol for “CONTINUOUSLY

ON”

(9) Digital display with indication of

decimal point and polarity

(10) Symbols for displaying

selected functions

(11) Display for selected function

(12) Display for the unit of

measured quantity

(13) Over range indication

(14) Pointer for analog indication

(15) Scale for analog indication

(16) Indication that negative analog

range is exceeded

(17) Activated stop watch indicator

(18) Zero adjust indicator

(19) Low battery indicator

(20) Buzzer indication

1. Safety features and safety precautions................................................. 4

2. Switching the meter on.......................................................................... 5

3. Function and range selection................................................................ 6

3.1 Autoranging........................................................................................... 6

3.2 Manual range selection......................................................................... 6

4. Liquid crystal display.............................................................................. 7

4.1 Digital display......................................................................................... 7

4.2 Analog indication................................................................................... 7

4.3 Backlit..................................................................................................... 7

5. “DATA” hold / compare facility .............................................................. 7

6. Minimum value and maximum value “MIN/MAX” storage facility

with time display..................................................................................... 8

7. Voltage measurement............................................................................ 8

7.1 Voltage measurement on electrical systems up to 1000 V

with the KS30 measuring adapter.......................................................... 9

7.2 AC level measurement (dB)................................................................... 9

8. Current measurement............................................................................ 11

AC Current measurement with (clip-on) current transformers............. 13

9. Resistance measurement and continuity test....................................... 13

10. Diode test and continuity test................................................................. 15

11. Capacitance measurement .................................................................... 15

12. Frequency measurement ....................................................................... 15

13. Temperature measurement ................................................................... 16

14. Event counter ......................................................................................... 17

15. Stop watch .............................................................................................. 17

16. RS 232C interface................................................................................... 18

17. Specifications.......................................................................................... 20

18. Maintenance .......................................................................................... 28

18.1 Battery ..................................................................................................... 28

18.2 Fuses ....................................................................................................... 28

18.3 Case ........................................................................................................ 29

19. Repair and replacement parts service .................................................... 29

20. Appendix .................................................................................................. 29

—The multimeter must be operated only by persons who understand the

danger of shock hazards and know how to apply safety precautions.

Shock hazards exist wherever voltages of more than 30 V (TRMS) can

appear.

—Do not work alone in shock hazardous environment while carrying out

measurement.

—The maximum permissible voltage between any of the terminal sockets

(7) and ground is 1000 V.

—Take into account that unexpected voltages can occur on devices under

test (e.g. defective instruments). Capacitors may be charged to a

dangerously high voltage, for instance.

—Verify that the test leads are in good condition, e.g. no cracked insulation,

no open circuits in the leads or connectors.

—This meter must not be used for measurements on circuits with corona

discharge (high voltage).

—Be particularly careful when measuring on HF circuits. Dangerous

composite voltages may exist there.

—Measurements under moist environmental conditions are not permitted.

—Do not exceed the permissible overload limits of the measuring ranges.

See Table “measuring ranges” under “17. Specifications”.

—All current measuring ranges, are fused. The maximum permissible

voltage of the measuring circuit (=nominal voltage of the fuse) is 1000 V

AC/DC on the “mA” ranges, “A” ranges.

—You must only use the meter in power systems, when the current circuit is

protected by a fuse or a circuit breaker of 20 A, and when the nominal

voltage of the system does not exceed 1000 V.

For safe voltage measurements on power systems, up to 1000 V we

recommend the KS30 measuring adapter, which is available as accessory. Its

internal resistance limits the measuring current in the case of overvoltage and

incorrect operation and safely suppresses sparking from spark gaps. Also

refer to Section “7.1 Voltage measurement on electrical systems upto 1000V

with the KS30 measuring adapter”.

1. Safety features and safety precautions

You have chosen a meter which offers you a very high degree of safety.

The analog/digital multimeter Gamma 10 is manufactured in compliance

with the safety standards IEC 61010-1:2001.

In case of incorrect use or careless handling, the safety of both user and

multimeter is not assured.

To maintain the safe and proper condition of the meters and to ensure

their safe operation, it is absolutely necessary to carefully and

completely read these operating instructions before using any meter.

These instruction must be followed in all respects.

For your safety and for protection of the meter, the Gamma 10 meter is

fitted with an automatic terminal blocking system. It is coupled with the

function selector switch, which blocks the terminal sockets not necessary

for measurement.

Please note the following safety precautions:

Fuse replacement

Open the meter same as for battery replacement.

Remove the blown fuse, e.g. with the aid of a probe, and replace it with

a new one.

permissible types

- for current measuring ranges up to 300mA:

Type FF(UR) 1.6A / 1000V AC/DC; (10kA); 6.3mm x 32mm

- for the 3A and 10A current measuring ranges :

Type FF(UR) 1.6A / 1000V AC/DC; (30kA); 10mm x 38 mm

Caution :

Absolutely verify that the specified fuse is installed!

If a fuse of other cut-out capacity, other nominal current or other switching

capacity is used, a dangerous situation exists for you, and there is danger of

damaging protective diodes, resistors or other components.

The use of mended fuses of shorting of the fuse holder is not permissible.

18.3 Case

Special maintenance of the case is not required. Take care that the surface

between the connection sockets is clean. For cleaning take a moist cloth.

Avoid scrabbing.

19 Repair and replacement parts service

When you need service, please contact :

20. Appendix

20.1 AC current measurement with (clip-on) current

transformers

20.1.1 Transformer output mA/A

Caution :

If current transformers are operated with an open circuit on the secondary side,

e.g. due to defective or disconnected leads, a blown fuse in the meter, or a wrong

connection, dangerously high voltages can occur at the connectors. Therefore,

verify that the current circuit of the meter and the secondary winding of the

transformer connected to the meter form an intact circuit. Connect the transformer

to the sockets ^ and mA and/or A.

The maximum permissible operating voltage is the nominal voltage of the current

transformer. When reading the measured value, take into account the transformer

ratio and the additional error in indication.

20.1.2 Transformer output mA/A

Several transformers are fitted with a voltage output (designation mV/A).

The secondary output must therefore be connected to the connection sockets ^

and V

Ambient conditions

0 0

Functional temperature range -20 C... + 50 C

0 0

Storage temperature range -25 C... + 70 C

Climatic class 2z/-20/50/70/75 % with reference to

VDI / VDE 3540

Altitude up to 2000 m

Mechanical configuration

Protection type IP 50 for the connection sockets IP 20

according to DIN VDE 0470 Part 1 / EN

60529

Dimensions 84 mm x 195 mm x 35 mm

Weight 350 g approx., including battery

18. Maintenance

Caution :

Disconnect the meter from the measuring circuit before you open

it to replace the battery or the fuse !

18.1 Battery

Prior to initial start-up, or after storage of your meter, verify that the battery of

your meter does not leak. Repeat this check in regular short intervals. If the

battery leaks, completely remove the battery electrolyte carefully with a moist

cloth and install a new battery before you operate your meter again.

When the symbol “ ” (17) appears on the LCD (1), replace the battery as

soon as possible. You can continue to measure, but a reduced measuring

accuracy must be taken into account.

The meter operates with a 9 V flat cell battery according to IEC 6F 22 or IEC 6

LR 61 or with a suitable NiCd storage battery.

Replacing the battery

êplace the meter on its face, loosen the two screws on the rear and

remove the lower part of the case, lifting it from the bottom. The lower and

the upper part of the case are fixed together at the top on the front by

means of detent hooks.

êRemove the battery from the battery compartment and carefully

disconnect the contacts from the battery.

êSnap the connection contacts to a new 9V battery and insert the battery

into the battery compartment.

êReplace the lower part of the case. Start at the top on the front and take

care that the detent hooks are properly engaged at this point.

êTighten the lower part with the two screws.

êPlease destroy the batteries in an environmental friendly way.

18.2 Fuses

A blown fuse is signaled on the LCD display the instant a measured quantity

having a voltage of more than 4V is applied to the corresponding connection

sockets. Then, the digital display (9) shows “FUSE”. The 16 A fuse interrupts

the 3 A and 10 A ranges, the 1.6 A fuse all other current measuring ranges.

All other measuring ranges continues to function. When a fuse blows, first

eliminate the cause of the overload before using the meter again!

Meaning of the symbols on the device

Warning of a danger point

(Attention, refer to documentation)

Ground connector

Double or reinforced - insulation

CAT II/III/IV Instrument for a overvoltage catagory

II/III or IV

EU conformity mark

For US & Canada

Repair, replacement of parts and calibration

When opening the meter, live parts may be exposed. Therefore, the meter

must be disconnected from the measuring circuit prior to opening its case

for repair, replacement of parts or calibration. If repair or calibration cannot

be avoided unless the meter is open and live, this work must only be

performed by a qualified person who understands the danger involved.

Faults and extraordinary stress

When it must be assumed that safe operation is no longer possible, take

the meter out of service and secure it against accidental use. It is assumed

that safe operation is no longer possible.

—when the meter shows obvious signs of damage,

—When the meter no longer functions correctly,

—after prolonged storage under adverse conditions,

—Due to sever stress during transportation.

2. Switching the meter on Battery

Fit the meter with 9 volt flat cell battery provided along with the meter.

Before you use the meter for the first time or after storage,

absolutely refer to Section “18.1 Maintenance Battery”.

Switching the meter on

íPress the “ON/OFF” pushbutton (2).

Switch-on is acknowledged by a sound signal. As long as you keep the

push-button pressed, all segments of the liquid crystal display (LCD) will

appear. The LCD is shown on page 2.

After the pushbutton is released, the meter is ready for operation.

Note :

Electric discharge and high frequency interference may cause incorrect

information to be displayed and block the measuring process. Reset the

meter by switching it OFF and ON again. Otherwise, check the battery

connections.

Disconnect the meter from the measuring circuit before you open

it and see section “18. Maintenance”!

Automatic turn-off

Your meter turns off automatically, when the measured value remains

constant (variations of the measured value < ± 20 digits) for about 10

minutes and when neither a pushbutton nor the function selector switch is

operated during that time.

How to prevent automatic tun-off

Switch your meter to “CONTINUOUSLY ON” mode.

íTo do this, press the yellow multi-function pushbutton (5) and the

“ON/OFF” pushbutton (2) together. The function “CONTINUOUSLY ON”

is shown on the LCD (1) by the symbol (8).

(1 % of rdg. + 10 Digits)

1) With zero adjustment

2) With temperature : Error data apply per 10 K change in temperature.

With frequency : Error data apply to a display of 10% of the measuring

range.

3) With unknown waveform (crest factor CF>2), measure with manual

range selection.

4) With the exception of sinusoidal waveform.

5) After the “ ^ ” symbol is displayed.

4. Liquid crystal display

4.1 Digital display

The digital display (9) shows the measured value with correct location of decimal

point and sign. The selected measuring unit (12) and the function (11) are

simultaneously displayed. When measuring DC quantities, a minus sign appears

in front of the digits, when the positive pole of the measured quantity is applied to

the “ ^ ” input terminal. When exceeding the upper range limit 30999 [on the

range F:3099], “OL” is displayed.

With V, A and W measurements, the digital display is updated two times per

second.

Condition Meter reaction

4.2 Analog indication

The analog indicator with pointer presentation gives the dynamic response of a

moving coil movement and is updated 20 times per second. Analog indication

is of particular advantage when observing variations of measured values and

for calibration procedures.

The analog indicator has its own polarity indication.

When measuring DC quantities. the analog scale (15) has a negative range of

5 scale divisions. so that variations of the measured values around “zero” can

be observed exactly. When the measured value exceeds the range of

indication, the left triangle (16) is shown before the polarity of the analog

indicator switches over after approximately 0.7s. Exceeding of the measuring

range (>30999 digits, on the range F:>3099) is shown by the right triangle(13).

The graduation of the analogue scale is automatic which is helpful for the

manual range selection.

4.3 Backlit

The instrument is provided with user selectable Backlit for measurements in

poor light conditions or dark area.

Switching the Backlit ON and OFF:

By pressing “AUTO/MAN/MAX” keys simultaneously the Backlit can be switched

ON. And by pressing the same keys simultaneously Backlit can be switched

OFF.

5 “DATA” hold / compare facility

The DATA (hold) function allows you to automatically “hold” measured values

This is particularly useful, for instance, when applying the probes to the

measuring point requires full attention. When the measured value is applied

and the “condition” according to the table shown below is met, the meter holds

the measured value on the digital display and issues a sound signal. The

probes can now be removed from the measuring point and the measured

value on the digital display (9) can be read. When the measured value falls

below the limit specified in the table, the meter is reactivated for a new storage.

If the new stored value differs by less than 100 digits from the previous value

the sound signal is issued twice (DATA-Compare)

MIN/MAX MIN/MAX

300 A 3mA

0.15 +5

+ 3 % v. M

1) Reactivated by falling below the specified limits of the measured value .

2) Referring to AC values.

3) When storing a value for the first time twice a sound signal.

For following “holds” only twice if actual hold value differs from first stored value

by less than 100 digits.

The analog indication is not influenced by the DATA hold. You can still read the

actual measured value. Note that with a “held” digital display, the location of the

decimal point is also held.

As long as the DATA hold function is active, manual range selection is not

possible.

The DATA hold function is switched off, when the “DATA” pushbutton (3) is

pressed for approximately 1s, when the function selector switch (6) is operated,

or when the meter is turned OFF and ON again.

6. Minimum value and maximum value “MIN/MAX”

storage facility with time display

With the MIN/MAX function, you can “hold” the minimum and the maximum

measured value which was applied to the input of the meter after activating

MIN/MAX. The most important application is the determination of the

minimum and the maximum value for long-term monitoring of measured

quantities.

The function “MIN/MAX” can be activated in all ranges except for the diode

test. However, for frequency and capacitance measurement the relative

time display is not possible.

MIN/MAX does not influence the analog indication; you can still read the

actual measured value.

Apply the measured quantity to the meter and select the measuring range

prior to activating the MIN/MAX function.

With the function activated, you can only select the measuring ranges

manually. However, the stored MIN/MAX values are cleared.

The MIN/MAX function is switched off, when the MIN/MAX pushbutton (3) is

pressed for approximately 1s, when the function selector switch (6) is

operated or when the meter is turned OFF and ON again.

7. Voltage measurement

êAccording to the voltage to be measured, set the function selector switch

(6) to V~, V --- or V ---

Reference conditions

0

Ambient temperature : +23 C +2K

Relative humidity : 45% ... 55 % RH

Frequency of the measured quantity : 45 Hz... 65 Hz

Waveform of the measured quantity : sinusoidal

Battery voltage : 8V + 0, 1V

Display

Liquid crustal display section (65 mm x 30 mm) with analog indication and digital

display and with display of the unit of measured quantity, function and various

special functions.

Analog :

Indication LCD scale with pointer

Scale length 55 mm on V - - - and A - - - 47 mm on all other ranges

Graduation +5... 0 ... + 30 with 35 scale divisions on ,

0 ... 30 with 30 scale divisions on all other ranges

Polarity indication with automatic change-over

Overrange indication by triangle (13)

Sampling rate 20 reading/s

Digital :

Display / Height of numer. 7-segment numerals / 12 mm

Number of digits 4 3/4 digits 31000 counts

Overrange Indication “OL” is displayed

Polarity Indication “-” sign is displayed, when the positive pole is at “ ^ ”

Sampling rate 2 readings / sec

Connect the test leads as shown. The “ ^ ” socket should be connected to the

lowest potential ground available.

Notes :

On the 1000 V range, an intermittent sound signal warns you, when the measured

value exceeds the upper range limit.

Caution :

Ensure that a current measuring range (“mA” or “A”) is not selected, when you

connect your multimeter for voltage measurements! When the cut-out rating of

the fuses is exceeded because of incorrect operation, a dangerous situation

exists!

Zero adjustment on the 300 mV --- measuring range

You can adjust the zero on the 300 mV --- measuring range :

Connect the test leads to the meter and join the free ends.

After having selected the measuring range, briefly press the yellow multi

function pushbutton (5).

The meter acknowledges zero setting by a sound signal, the LCD shows

“000.00”(+1digit) and the symbol “ZERO” (18) is displayed. The voltage

displayed the instant the pushbutton is pressed is used as reference value

(max. + 2000 digits). It is automatically deducted from the values measured

thereafter you can clear the zero adjustment

®by pressing the yellow multi-function pushbutton (5) for a long time,

clearance is acknowledged by the buzzer sounding twice.

®by switching the instrument off.

7.1 Voltage measurement on electrical systems up to 1000 V with

the KS30 measuring adapter

On low-voltage systems, transient over voltages of several kilovolts can occur

due to switching function or lightning discharges. Direct connection of your

multimeter to such systems for voltage measurement can, therefore, be

dangerous. For voltage measurements on power systems with nominal

voltages up to 1000 V. use the KS30 measuring adapter. It is an adapter for

multimeters which eliminates danger caused by overvoltages and incorrect

operation of the multimeter. It provides the following protective functions :

—Protection of the input circuit to the voltage measuring range of multimeters.

The internal resistance of the KS30 limits the current in the case of

overvoltage.

—Overload capacity : continuously 1000Vms transient (rise 10ms/fall 1000ms)

6kV max

—Safe suppression of sparking from spark gaps after overvoltage.

—Current limitation in the case of incorrect operation (e.g applying a voltage

to a current input)

—Using the measuring adapter KS30 the additional measured fault is approx.

2%. Voltages above 1000 V can be measured with a high voltage probe,

provided the necessary safety precautions are taken!

7.2 AC level measurement (dB)

êSet the function selector switch (6) to V~.

Briefly press the multifunction button (5).

The function level measurement is activated now. The measured value is

calculated from the true rms value of the AC voltage (300 mV... 1000 V) and

displayed on the LCD display (9). The reference value is taken as dB=0.775V

(1mW on 600W). The corresponding AC voltage is displayed on the analog

scale.

+ ( - ) / ~

- ( + ) / ~

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

Voltage Measurement

+ / ~

- / ~

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

Voltage Measurement on electrical system up to

1000 V with the KS30 measuring adapter

1 min

continuou-

sly

1 min

7) Range/3V

30V

300V

: U= 1V ...10V

e eff/rms eff/rms

: U= 10V ...100V

e eff/rms eff/rms

: U= 100V ...1000V

e eff/rms eff/rms

8) Without sensor

8. Current measurement

êFirst disconnect the power supply to the circuit being measured and/or to

the load, and discharge all capacitors within that circuit.

êWith the function selector switch (6), select A for currents > 300 mA, and

mA - - - for currents < 300 mA. When measuring currents of unknown

magnitude, select the highest measuring range first.

êSelect the function corresponding to the measured quantity by briefly

pressing the yellow multi-funciton pushbutton (5). Each time the

pushbutton is pressed, alternate switching takes place between DC and

(DC + AC) and the change-over is acknowledged by a sound signal. The

symbols DC and AC (11) show the selected function on the LCD.

When selecting a range with the function selector switch (6), the DC

function is always set initially. When pressing the yellow multi-funciton

pushbutton (5) for a long time, the meter always switches back to DC and

acknowledges this by the buzzer sounding twice.

êConnect the meter in series with the load, as shown. Make the

connections tight (without contact resistance).

Notes on current measurement :

êThe meter must be used only in power systems, when the current

circuit is protected by a fuse or a circuit breaker of 20 A, and when the

nominal

Note :

The multimeter does not contain termination resistors. The input impedance is

5 MΩ respectively. In order to measure correctly on unterminated objects, you

have to connect the termination resistor to the terminals. Please take the power

dissipated by the termination resistor into consideration.

Reference measurements

êBriefly press the multifunction button (5) again.

The terminal input AC voltage is displayed and the “ZERO” indicator (18)

flashes.

êBriefly press the multifunction button (5) again. The displayed AC voltage

is taken as the reference value. The “ZERO” indicator (18) does not flash

anymore, but remains continued on.

You can now perform level measurements over several voltage ranges

relation to the stored reference value. Note, however, that the maximally

allowed measuring voltage is 1000 V. The following table shows the

display range.

êBy briefly pressing the multifunction button (5) again you return to the

voltage measurement with the flashing “ZERO” indicator (18).

The funciton “dB-measurement” is deactivated by pressing the

multifunction button for a long period (about 1s), or by changing the

function selector switch getting or by turning the multimeter OFF and then

ON again.

1,0 + 30(>600 Digit)

6) Specified accuracy is valid for > 3% of measuring range.

6

1+30

6

1+30

6

1+30

6

1+30

6

1+30

6

1.5+30

6

1.5+30

6

1.5+30

6

1.5+30

6

1.5+50

6

1.5+30

+ ( - ) / ~

- ( + ) / ~

+ ( - ) / ~

- ( + ) / ~

~

~

A (20.1.1)

mA (20.1.1)

V (20.1.2)

Transformer output

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

A

Voltage of the system does not exceed 1000 V.

—Make the measuring circuit connections mechanically strong and secure so

that they do not accidently open. The conductor cross sections and

connection points should be designed to avoid excessive heating.

—On the 300mA and 10A ranges, an intermittent sound signal warns you,

when the measured value exceeds the upper range limit.

—The current measuring ranges upto 300 mA are protected to a short circuit

current of 25 A by a fuse FF 1.6/1000V in conjunction with power diodes.

The cutout capacity of the fuse is 10 kA at a rated voltage of 1000 V and

ohmic load.

—The current measuring ranges up to 10A are protected by a 16A/1000 V

fuse. The cut-out capacity of the fuse is 30kA at a nominal voltage of 1000

V and ohmic load.

—A blown fuse is signaled on the LCD the instant a measured quantity having

a voltage of more than 4V is applied to the corresponding connection

sockets. Then, the digital display (9) shows the word “FUSE”.

—After a fuse has blown, eliminate the cause of the overload before using the

meter again!

—Replacement of the fuses is described in section “18. Maintenance”.

AC current measurement with (clip-on) current transformers

See appendix section 20.1.

9. Resistance measurement and continuity test

îVerify that the device under test is electrically dead. External voltages

would falsify the measured result !

îSet the function selector switch (6) to “ W ”.

îConnect the device under test as shown.

îZero adjustment on the measuring ranges 300 W to 3 kW

When measuring small resistance values on the 300W and 3kW range, you

can eliminate the resistance of the leads and transient resistances by zero

adjustment:

îConnect the test leads to the meter and join the free ends.

îBriefly press the yellow multi-function pushbutton (5).

The meter acknowledges zero adjustment by sound signal, the LCD

shows “000,00” (+1 digit) and the symbol “ZERO” (18) is displayed. The

resistance measured the instant the pushbutton is pressed is used as

reference value (max. 2000 digits). It is automatically deducted from the values

measured thereafter.

You can clear the zero adjustment

- by pressing the yellow multifunction pushbutton (5) for a long time,

clearance is acknowledged by the buzzer sounding twice,

- by switching the instrument off.

Continuity test with buzzer

With “buzzer” function activated, the meter issues a continuous sound signal

below 100.00 on the 300.00 range only.

íTo switch buzzer ON:

Select range 30kW, 300kW, 3MW, or 30MW, through manual mode and briefly

press the yellow multi function key(5). The meter will show “cont.n” on display.

Press “AUTO/MAN” key. The meter will show “cont.y” on display.

Now press the yellow key(5) again. The symbol (20) appears on the display

when 300.00W range is selected.

íTo switch buzzer OFF:

Select range 30kW, 300kW, 3MW, or 30MW , through manual mode and

briefly press the yellow multi function key(5). The meter will show “cont.y”

on display. Press “AUTO/MAN” key. The meter will show “cont.n” on display.

Now press the yellow key(5) again. The symbol (20) disappears on the

display when 300.00W range is selected.

+

-

2.1058

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

Hardware : You need

wAn IBM AT - compatible PC with 640kB main memory for the DOS version

A WINDOWS-executing, IBM compatible PC with 2 MB main memory for

the WINDOWS version.

wA VGA or EGA monitor; a Hercules monitor can also be used for the DOS

version

wA hard disk with 3 MB free storage space

wA 3.5” disk driver fas disks with 1.4 MB storage capacity

wA MICROSOFT-compatible mouse.

If you wish to make hard copies

wan EPSON compatible printer when using the DOS version,

wa printer supported by WINDOWS when using WINDOWS.

-

+

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

00000

-

+

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

-

+

0.6000

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

-

+

A

F

---

W

Hz

dB

V

---

V~

V

---

mA

---

0C

---

êBriefly press the yellow multi- function pushbutton (5). “00:00:00” and the

stop watch symbol (17) are displayed on the LCD.

êThe stop watch is started and stopped by pressing the “ AUTO/MAN”

pushbutton (4). The display is in minutes, seconds and tenth of seconds .

êThe time can be cleared by pressing the “DATA-MIN/MAX” pushbutton(3).

êBriefly press the multi- function pushbutton (5) in order to return to voltage

measurement.

Software

The software package consists of a DOS version and a WINDOWS version.

With Gamma 10 you can simultaneously acquire, store, display and document

the measured data of several Multi multimeters.

The measured values can be presented in the WINDOWS version:

¬As digital display and analog indication similar to that of the multimeter (up to 4

multimeters)

¬In traces (XY and Yt) as on a 4-channel recorder

¬In tabular form (data logger: up to 10 channels).

The DOS version only allows the recorder presentation Yt.

The measured data is stored in ASCll format for further processing.

For the use of software the following requirements must be met:

Software: You need

¬MS DOS or PC DOS, version 5.0 or higher

¬MS WINDOWS 3.1 or higher, if you wish to work the WINDOWS version

16. RS-232C interface

The Gamma 10 multimeter is fitted with a serial RS-232C interface for

transmission of measured data to electronic data precessing systems. The

measured values are optically transmitted through the case with infrared light

to an interface adapter which is attached to the multimeter. The

measured data is passed to the computer via a cable.

Switching the interface ON

When switching on the instrument press the “ON/OFF” pushbutton (2) and the

“DATA-MIN/MAX” pushbutton (3) together. With the interface switched on,

automatic turn-off of the meter is inactive. This is shown on the LCD (1) by

flashing of the (8) symbol. The “DATA” function cannot be activated.

Interface packs as accessories

interface adapters without memory permit a transmission of measured data

up to 4 meters to the computer ( One-channel interface pack or our channel

interface pack.)

With a memory adapter it is also possible to store the measured data without

computer for a later transmission of the memorized data to the computer. For

establishing a powerful meter system you can connect up to ten meters offline.

In online a connection up to six meters to the computer is possible via memory

adapter. (One - channel memory pack or four-channer memory pack)

All interface packs include the adapters, the necessary connection cables and

the Gamma 10 data acquisition and evaluation software with

operating instructions.

software /

10. Diode test and continuity test

êVerify that the device under test is electrically dead. External voltages would

falsify the measured result!

êSet the function selector switch (6) to

êConnect the device under test as shown.

Forward direction and/or short circuit :

The meter displays the forward voltage in Volts. As long as the voltage drop does

not exceed the maximum display value of 3.0999 V, you can also test several

series-connected elements or reference diodes with small reference voltage.

Reverse direction or interruption :

The meter indicates overrange “ OL ”

11. Capacitance measurement

êVerify that the device under test is electrically dead. External voltages

would falsify the measured result !

êSet the function selector switch (6) to “ F ”.

êConnect the (discharged) device under test on the “ ^ ” and “ F ” sockets

via test leads.

Notes

Connect polarized capacitors with the “-” pole to the “ ^ ” socket.

Resistors and semiconductor junctions in parallel with the capacitor falsify the

measured result !

Zero adjustment on the measuring ranges 3nF to 30 nF

When measuring small capacitance values on the 3 nF and 30 nF range, you

can eliminate the internal resistance of the meter and the capacitance of the

leads by zero adjustment:

Note :

Resistros and semiconductor junctions in parallel with the diode falsify the

measured result!

Diode test and continuity test with buzzer

With the “buzzer” function selected, the meter issues a continuous sound signal

on the range 0...approx 0.2V.

To switch the buzzer ON:

êBriefly press the yellow multi-function pushbutton (5)

The meter acknowledges turn-on with a sound signal. At the same time, the

symbol (20) appears on the LCD.

To switch the buzzer OFF:

êBriefly press the yellow multi-function pushbutton (5) again.

The meter acknowledges turn-off with a sound signal. The symbol (20)

disappears on the LCD.

When selecting the function “Diode test and continuity test” with the function

selector switch (6), the buzzer is always switched off. Repeated brief pressing of

the multifunction pushbutton (5) alternately switches the buzzer on and off.

When pressing the pushbutton for a long time, the buzzer is always switched

off, this is acknowledged by the buzzer sounding twice.

êConnect the test lead to the meter without the device under test

êBriefly press the yellow multi-function pushbutton (5).

The meter acknowledges zero adjustment by a sound signal, by displaying

“0.000 resp. “00.00” (+1 digit) and the symbol “ZERO” (18) on the LCD. The

capacitance measured the instant the pushbutton is pressed is used as reference

value (max. 500 digits). It is automatically deducted from the values measured

thereafter.

You can clear the zero adjustment

wby pressing the yellow multi-function pushbutton (5) for a long time, clearance

is acknowledged by the buzzer sounding twice,

wby switching the instrument off.

12. Frequency measurement

Frequency measurement is only possible with a voltage measurement in the

(DC+AC) mode.

15. Stop watch

This function allows you to measure elapsed times up to one hour.

êRun the function selector switch (6) to “V - - - ”

êUse the pushbutton “AUTO/MAN” (4) to select a measuring range between 3 V

and 1000 V.

êThe function stop watch cannot be activated in the range 300 mV - - -.

14. Event counter

Event counter is only possible with a voltage measurement in(DC+AC) mode.

With this function it is possible to measure and indicate the number of elapsed

time of the events and the total of the function activation. Voltage signals are

indicated with an amplitude of >2 500 digits, with a maximum, repetition rate of

0.25 Hz (minimum, duration of 4 seconds) and a minimum, event time of 2

seconds.

wby pressing the yellow multi- function pushbutton (5) longer, this

is Confirmed

wby the buzzer sounding twice, by switching the meter off.

Note:

The correction value for the lead resistance remains stored when exiting the

function and when switching off the multimeter.

To determine the lead resistance, only use the multimeter you use to measure the

temperatures. Only this way, it is assured that the measuring error is within the

specified range.

êSet the function switch (6) to V - - -.

êSwitch the signal on as for voltage measurement.

For other functions see the following table.

With this function the meter is not switched off automatically.

It is possible to return directly from event counter to voltage measurement

wby pressing the yellow multi- function pushbutton (5) longer. This is confirmed

by the buzzer sounding twice. The voltage measuring range which was set the

last time, keeps switched on.

wby actuating the function switch (6).

êSet the function selector switch (6) to V

êConnections are made the same way as for voltage measurement. See foot

note 6) on page 22.

êBriefly press the yellow multi-function pushbutton (5).

The meter switches to frequency measurement. The frequency is displayed

on the LCD.

See Section “17. Specifications” for the lowest measurable frequencies and

the maximum permissible voltages.

êFrom frequency measurement, you can directly switch back to voltage

measurement

wby pressing the yellow multi-function pushbutton (5) for a long time. The meter

acknowledges this with the buzzer sounding twice. The voltage measuring

range last selected is maintained.

wby operating the function selector switch (6).

13. Temperature measurement

With Pt 100 and Pt 1000 temperature sensors you can measure temperatures on

0 0

the range from-200 (-100) C ...+850 C

0

êSet the function switch (6) to “ C ”.

êConnect the sensor to the two sockets for which access is allowed.

The meter automatically detects the connected sensor( Pt 100 or Pt 1000)

0

and shows the measured temperature in C on the digital display.

Notes:

This measurement automatically considers the lead resistance of the Company

temperature sensors which are available as accessory.

Temperature measurement

considering sensor lead resistances up to 50W

Lead resistance of sensors having a value differing from that of Company sensors

can be considered up to a value of 50W as follows:

êBriefly press the yellow multi-function pushbutton (5).

The temperature measurement range is now selected which considers a

changed lead resistance of the sensor. This is indicated on the LCD by the

“ZERO” symbol.

êBriefly press the yellow multi- function pushbutton (5) again.

The LCD now displays the resistance value which the meter automatically

considers. So that you can recognize that is the resistance correction value

0

on the temperature measuring range, the “ C” character is simultaneously

shown.

êYou can set the line resistance correction value as follows:

Press the DATA-MIN/MAX pushbutton (3) to increment the value, or the

AUTO/MAN pushbutton (4) to decrement the value. Each time the

pushbutton is briefly pressed, the value changes by one digit. You pass

through fast, when you press the pushbutton longer.

êBriefly press the yellow multi- function pushbutton (5) again.

The LCD displays the measured temperature in consideration of the changed

lead resistance. The symbol “ZERO” (18) in the LCD shows you this.

êEach following time the yellow multi- function pushbutton (5) is briefly

pressed, the display changes between measured temperature with changed

lead resistance and correction value of the lead resistance. You can exit the

function “temperature measurement with changed lead resistance”

Table of contents

Other Sifam Tinsley Multimeter manuals