AuCom PROFINET CARD User manual

INSTRUCTIONS

PROFINET CARD

RIGHT FROM

THE START

Profinet Card | Rev C 5/2021

Contents

1. Introduction ......................................................................................... 3

2. Installation........................................................................................... 5

3. Device configuration............................................................................ 6

4. Master configuration......................................................................... 11

5. Ground fault protection..................................................................... 11

6. Operation ........................................................................................... 12

7. Packet structures.............................................................................. 13

8. Network design ................................................................................. 21

9. Specifications .................................................................................... 23

Compatibility

This manual is suitable for:

•Profinet Card

•Profinet Card with Ground Fault

These cards are suitable for use with EMX4e and EMX4i soft starters.

The available features may vary according to the model and version of the starter.

This user manual is intended for use with version 3.x of the Profinet Card. Version 2.x

of the Profinet Card does not support custom users or IoT operation.

© 2021 AuCom Electronics Ltd. All Rights Reserved.

INSTRUCTIONS

2Profinet Card (710-16502-00C)

Disclaimer

The examples and diagrams in this manual are included solely for illustrative

purposes. The information contained in this manual is subject to change at any time

and without prior notice. In no event will responsibility or liability be accepted for

direct, indirect or consequential damages resulting from the use or application of this

equipment.

Failure to follow the information and instructions in this manual will void the warranty.

Warnings

It is the installer's responsibility to follow all instructions in this manual and to follow

correct electrical practice.

WARNING

For your safety, isolate the soft starter completely from mains voltage before

attaching or removing accessories.

WARNING

Inserting foreign objects or touching the inside of the starter while the

expansion port cover is open may endanger personnel, and can damage the

starter.

INSTRUCTIONS

Profinet Card (710-16502-00C) 3

1. Introduction

1.1 Product design

The Profinet Card allows the soft starter to connect to an Ethernet network and be

controlled or monitored using an Ethernet communication model.

Familiarity with Ethernet protocols and networks is required to operate the device

successfully. For difficulties using this device with third party products, including

PLCs, scanners and commissioning tools, contact the relevant supplier.

1.2 Connections

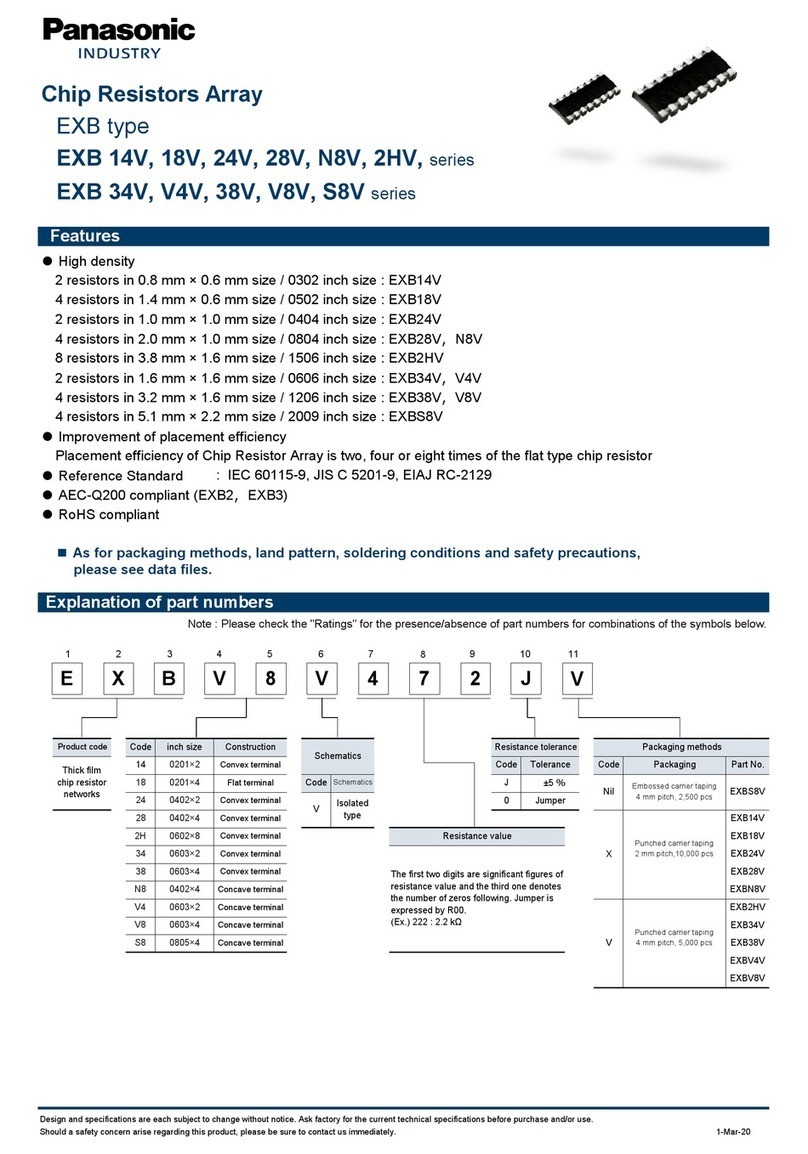

23081.A

2 31

1

2 x RJ45 ethernet ports, supporting line, star, ring and loop network topologies

2

2 pin connector for ground fault CT (selected models)

3

DB9 connector for optional remote keypad

1.3 Communication protocols

The Profinet Card supports the following protocols:

Profinet

Industrial ethernet via Profinet

MQTT

Message Queue Telemetry Transport

OPC UA

Open Platform Communications Unified Architecture

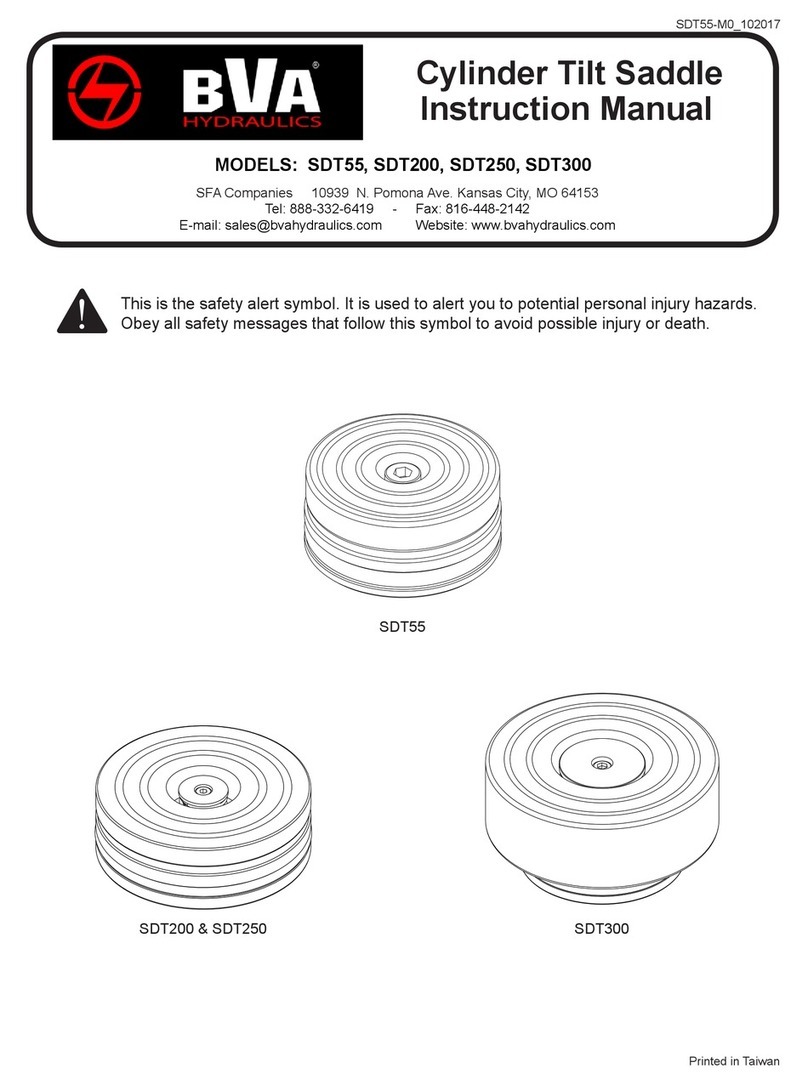

22542.A

1

23

4

INSTRUCTIONS

4Profinet Card (710-16502-00C)

1

Soft starter

2

Network switch

3

IoT connection (MQTT/OPC UA)

4

Industrial ethernet connection to programmable logic controller

INSTRUCTIONS

Profinet Card (710-16502-00C) 5

2. Installation

2.1 Installing the expansion card

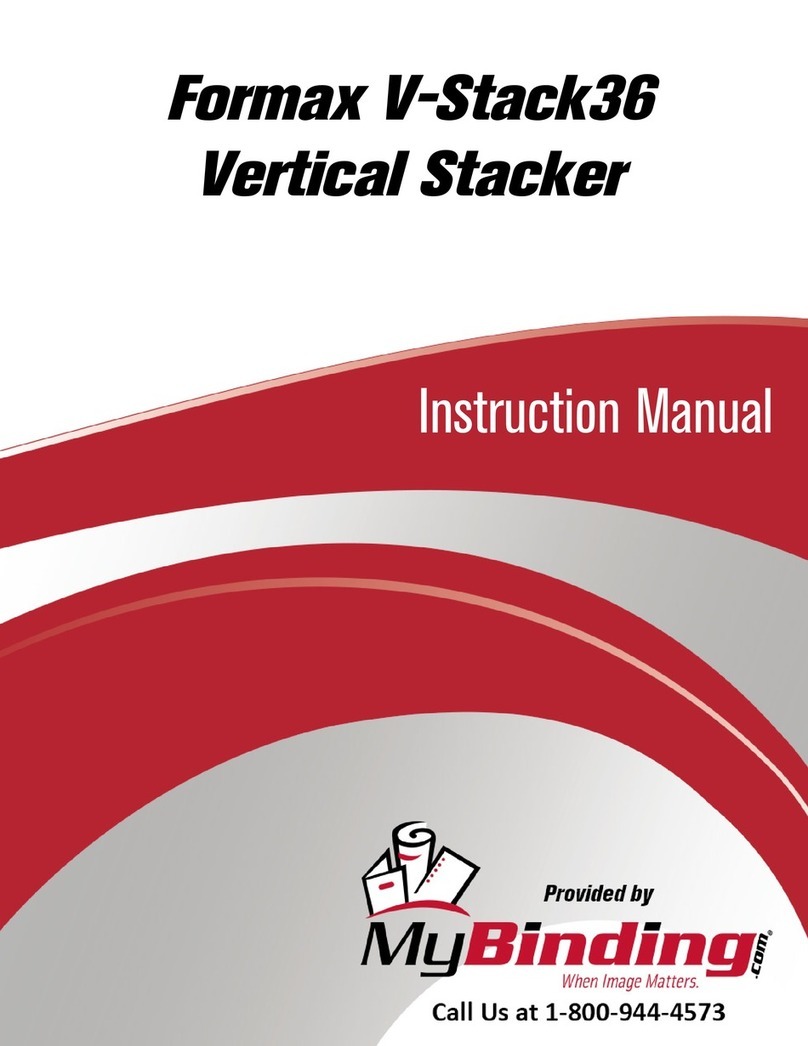

1. Push a small flat-bladed screwdriver into the slot in the centre of the expansion

port cover, and ease the cover away from the starter.

2. Line up the card with the expansion port. Gently push the card along the guide

rails until it clicks into the starter.

B4 B5 10

1112 13 14 15 21 22

33 34 41 42 44 53 54

B4 B5 10

1

1 12 13 14 15 21 22

33 34 41 42 44 53 54

1 2

17049.A

2.2 Network connection

Ethernet ports

The device has two Ethernet ports. If only one connection is required, either port can

be used.

Cables

Use Category 5, 5e, 6 or 6e cable to connect to the device.

EMC precautions

To minimise electromagnetic interference, Ethernet cables should be separated from

motor and mains cables by 200 mm.

If the Ethernet cable must cross motor or mains cables, the crossing should be at an

angle of 90°.

2.3 Network establishment

The controller must establish communications directly with each device before the

device can participate in the network.

2.4 Addressing

Each device in a network is addressed using a MAC address and a device name. The

MAC address is fixed within the device and is printed on a label on the front of the

device.

INSTRUCTIONS

6Profinet Card (710-16502-00C)

3. Device configuration

3.1 Configure the device name

Use the Ethernet Device Configuration Tool to configure the device. The Ethernet

Device Configuration Tool is available from your local supplier.

To identify the device using the Ethernet Device Configuration Tool:

1. Start the Ethernet Device Configuration Tool.

2. Click on Search Devices. The software will search for connected devices.

3. To configure a device name, click Configure then select Device Name.

NOTE

The Error LED is on if the device is not configured. If the device is configured

but is not passing I/O data, the Error LED will flash. The Error LED will be

active during the configuration process.

NOTE

If your PC has a firewall enabled, you must add the tool to the list of authorised

programs.

INSTRUCTIONS

Profinet Card (710-16502-00C) 7

3.2 Enabling network control

The soft starter will only accept commands from the Profinet Card if parameter 1A

Command Source

is set to 'Network'.

NOTE

If the reset input is active, the starter will not operate. If a reset switch is not

required, use parameter 7I to set the reset input to normally open or fit a link

across terminals 10, 11 on the soft starter.

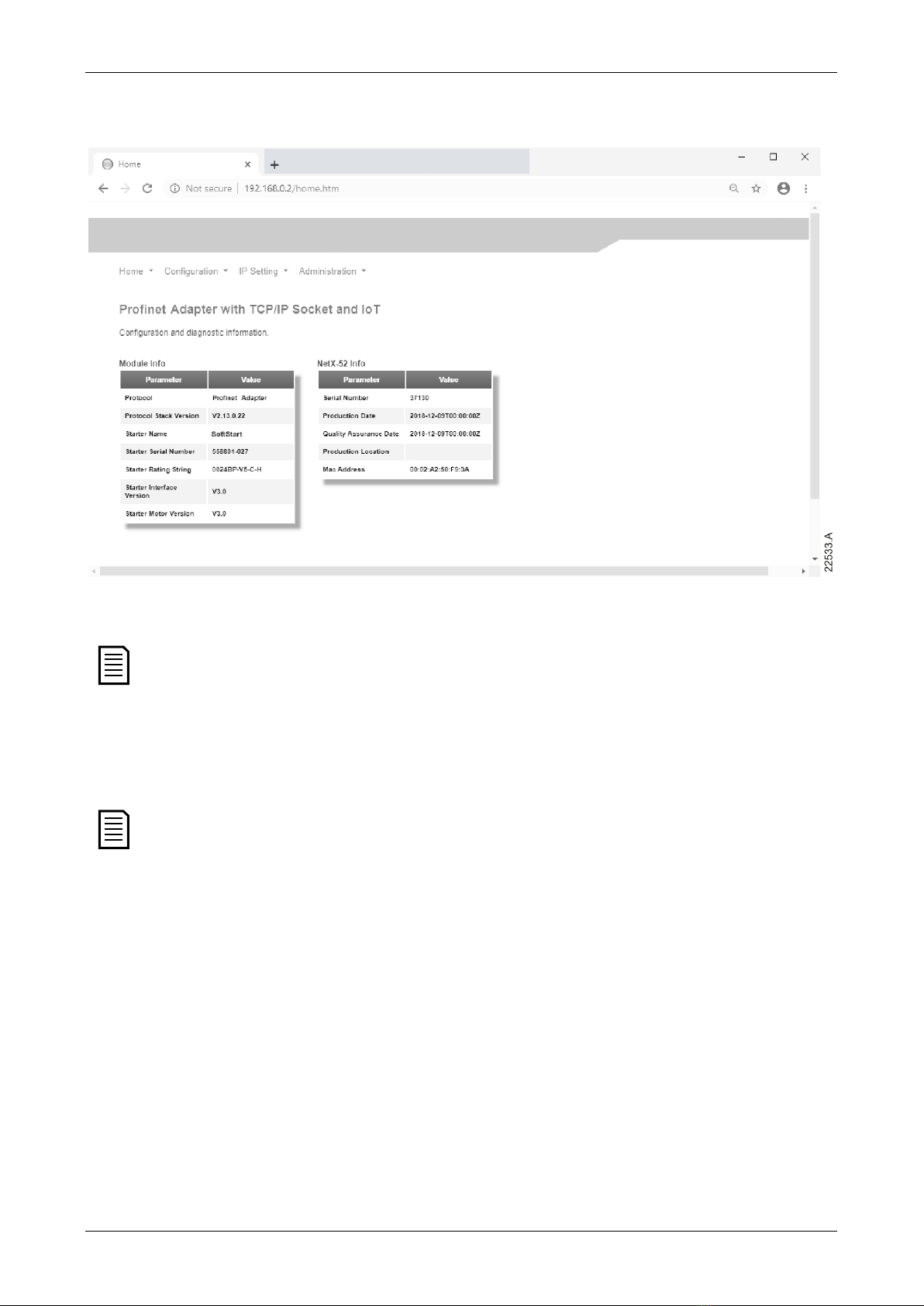

3.3 On-board web server

Settings in the Profinet Card can be configured via the card's web server.

Connect to the device

To configure settings using the on-board web server, the card must be installed in a

soft starter, control power must be available, and the card and computer must both be

connected to the Ethernet network.

The computer must use a fixed IP address (not DHCP) and the same subnet mask as

the card. The default IP address for the card is 192.168.0.2. The default subnet mask is

255.255.255.0.

INSTRUCTIONS

8Profinet Card (710-16502-00C)

Once connected, the web server reports basic information about the card and the soft

starter.

Manage users and passwords

NOTE

For security reasons, we recommend that you define a custom administrator

ID and password.

The default username and password are:

username: admin

password: 1978

NOTE

Version 2.x of the Profinet Card does not support custom users.

The Profinet Card supports multiple users and levels of privilege.

•Users can view the home screen and IP address settings

•Supervisors can view the home screen and IP settings and can change

configuration settings

•Administrators can view the home screen, change configuration settings and add or

delete users

To add a new user:

1. Connect to the web server then click Administration.

2. Click Create new user.

3. Enter the new username and password then click Create an account.

4. Set privileges (user, supervisor, administrator) as appropriate.

5. Click Save changes.

INSTRUCTIONS

Profinet Card (710-16502-00C) 9

To delete a user:

1. Connect to the web server then click Administration.

2. Click the required entry in the user list then click Delete user. Click Delete again to

confirm the action.

Configure IoT settings

The Profinet Card supports soft starter status monitoring over IoT. The card cannot

control or program the soft starter.

NOTE

Version 2.x of the Profinet Card does not support IoT operation.

•Configure MQTT settings

1. Connect to the web server then click Configuration > MQTT Client.

2. Tick the Enable checkbox to enable MQTT client operation. The MQTT client is

enabled by default.

3. Click Connection then configure the settings as required.

4. Use Connection > Actions to select which information the card will publish.

5. Click Submit to save all settings in the card.

INSTRUCTIONS

10 Profinet Card (710-16502-00C)

•Configure OPC UA settings

1. Connect to the web server then click Configuration > OPC UA Server.

2. Tick the Enable checkbox to enable OPC UA client operation. The OPC UA client is

enabled by default.

3. Click Server Configuration then configure the settings as required.

4. Use Actions to select the actions for different object instances.

5. Click Submit to save all settings in the card.

INSTRUCTIONS

Profinet Card (710-16502-00C) 11

4. Master configuration

Import the latest GSDML file into your Master configuration tool. This file is available

from your supplier.

If your Master uses on-screen icons, two graphic bitmap files are available from the

website. SSPM_N.bmp indicates normal mode. SSPM_D.bmp indicates diagnostic

mode.

5. Ground fault protection

NOTE

Ground fault protection is only available on ground fault enabled cards,

with soft starters running a compatible version of software. Contact your

supplier for assistance.

5.1 Overview

Ground fault protection

The Profinet Card can detect ground current and trip before the equipment is

damaged.

Ground fault protection requires a 1000:1 or 2000:1 5 VA current transformer (not

supplied). The soft starter can be configured to trip at 1 A~50 A. If ground fault current

rises above 50 A, the soft starter will trip immediately.

5.2 Connect the CT to the ground fault inputs

To use ground fault protection, a common mode current transformer (CT) must be

installed around all three phases. Use a 1000:1 or 2000:1 CT with rating of 5 VA and set

parameter 40E

Ground Fault CT Ratio

to match. Connect the CT to the ground fault

terminals (G1, G2, G3).

For maximum protection, the CT should be installed on the input side of the soft

starter.

5.3 Configure ground fault protection settings

Ground fault protection settings must be set in the soft starter.

Parameter

Parameter name

Description

40A

Ground fault trip

level

Sets the trip point for ground fault current

protection.

40B

Ground fault trip

delay

Slows the soft starter’s response to ground fault,

avoiding trips due to momentary fluctuations.

40C

Ground fault trip

active

Selects when a ground fault trip can occur.

INSTRUCTIONS

12 Profinet Card (710-16502-00C)

Parameter

Parameter name

Description

40D

Ground fault action

Selects the soft starter’s response to the

protection event.

40E

Ground fault CT ratio

Set to match the ratio of the ground current

measuring CT.

6. Operation

The device has been designed for use in a system complying with the Profinet

standard. For successful operation, the controller must also support all functions

and interfaces described in this document.

6.1 Device classification

The Profinet Card is a Profinet IO-Device and must be managed by an IO-Controller

over Ethernet.

6.2 Ensuring safe and successful control

Data written to the device will remain in its registers until the data is overwritten or

the device is reinitialised.

If the soft starter may be controlled via Command Override (parameter 7A) or may be

disabled via the reset input (terminals 10, 11) fieldbus commands should be cleared

from the registers. If a command is not cleared, it will be re-sent to the starter once

fieldbus control resumes.

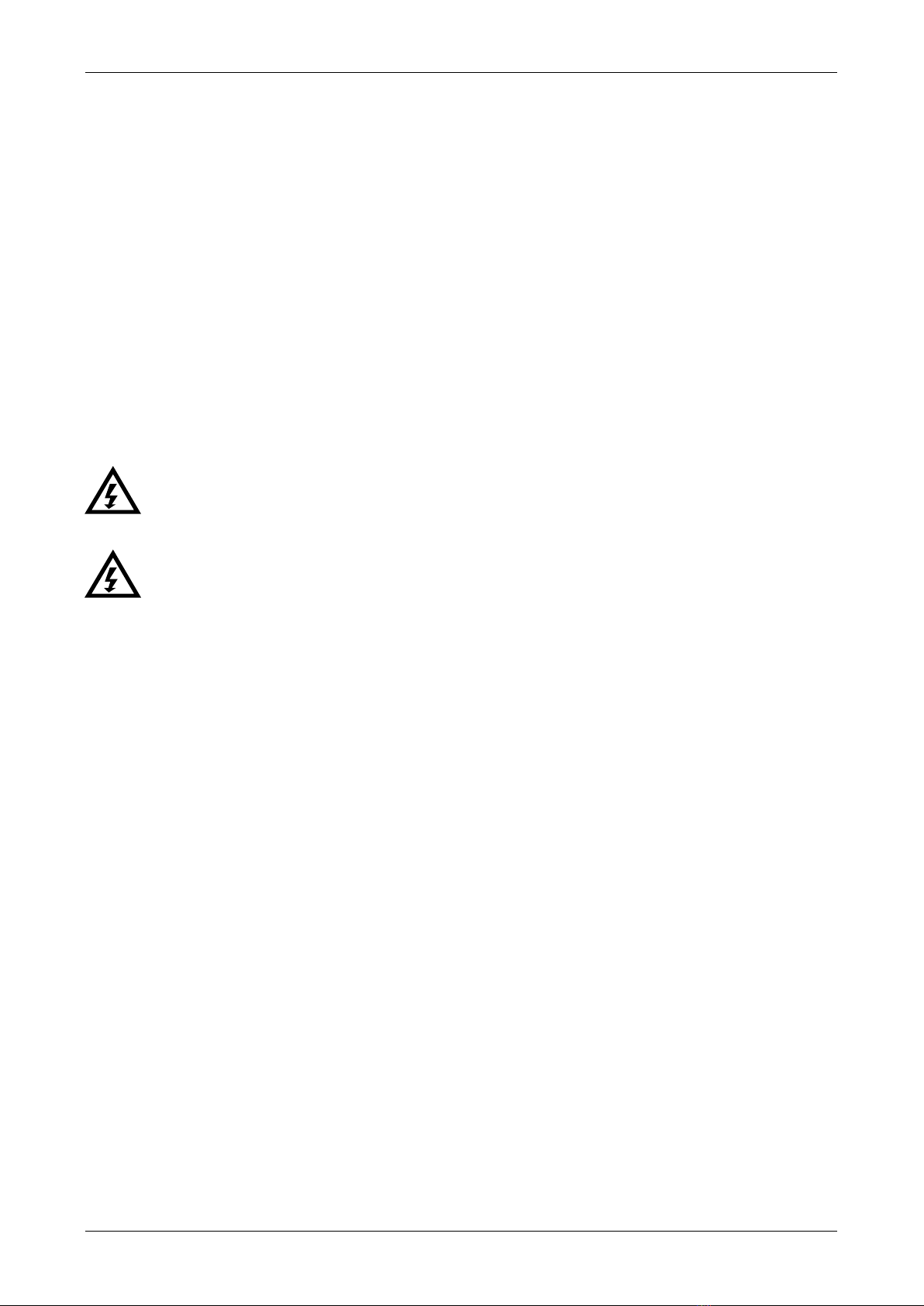

6.3 Feedback LEDs

Port 1 Port 2 Keypad

LINK 2

TX/RX2

LINK 1

TX/RX1

ERROR

STATUS

17821.A

LED name

LED state

Description

Power

Off

Device is not powered up.

On

Device is receiving power.

Error Off No error.

Flashing

Connection not established.

On No physical link or slow physical link.

No configuration.

Status

Off

No error.

Flashing DCP signal service initiated via the bus.

Link x

Off

No network connection.

On Connected to a network.

TX/RX x

Flashing

Transmitting or receiving data.

INSTRUCTIONS

Profinet Card (710-16502-00C) 13

7. Packet structures

NOTE

The available features and parameter details may vary according to the model

and software version of the starter. Refer to the soft starter user manual for

details of parameters and supported features.

7.1 Control commands (controller to device)

Use output bytes 0-1 to send a control command to the soft starter.

Byte

Bits

Details

0

0 to 1

Reserved

2 to 3 0 = Use soft starter remote input to select motor set

1 = Use primary motor set when starting

2 = Use secondary motor set when starting

3 =

Reserved

4

0 = stop action will be as selected in the soft starter

1 = stop action will be a coast to stop

5 to 7

Reserved

1

0

0 = Stop

1 = Start

1 to 2

Reserved

3 1 = Reset

4 to 7

Reserved

2 to 5

Parameter management (refer to

Parameter management

on

page 17)

7.2 Status information (device to controller)

Starter status information is always available when the device is active.

Bytes 0-1: Control status

Bits

Details

0 to 5 Current (% motor FLC)

6

Command source

0 = Network, Timer

1 = Remote Keypad, Digital Input, Clock

7

1 = Ramping (starting or stopping)

8 1 = Ready

9

1 = Starting, running or stopping

10 1 = Tripped

11

1 = Warning

12 to 15

Reserved

INSTRUCTIONS

14 Profinet Card (710-16502-00C)

Bytes 2-3: Starter state

Bits

Details

0 to 3 The decimal value of bits 0~3 indicates the starter's state:

0 = Communication error between device and soft starter

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart temperature check, run simulation,

reset input is open)

6 = Tripped

7 = Menu open (cannot start)

8 = Jog forward

9 = Jog reverse

4

0 = Negative phase sequence

1 = Positive phase sequence

5

1 = Current exceeds FLC

6 0 = Uninitialised

1 = Initialised

7

1 = Communication error between device and soft starter

8 to 15

Reserved

Bytes 4-5: Trip code

Bits

Details

0 to 15

Refer to Trip codes on page 18

Bytes 6-7: Motor current

Bits

Details

0 to 15

Average rms current across all three phases

Bytes 8-9: Motor temperature

Bits

Details

0 to 15

Motor thermal model (%)

INSTRUCTIONS

Profinet Card (710-16502-00C) 15

Bytes 10-63: Extended information

Bytes 10~63 report information from the soft starter's internal registers.

Byte

Description

Bits

Details

10-11 Version 0 to 8

Reserved

9 to 15

Product type code:

12 = EMX4e

13 = EMX4i

12-13

Model number

0 to 7

Reserved

8 to 15 Soft starter model ID

14-15

Reserved

16-17

Reserved

18-19 Starter state 0 to 4 0 =

Reserved

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart

temperature check, run simulation, reset

input is open)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

5

1 = Warning

6 0 = Uninitialised

1 = Initialised

7

Command source

0 = Network, Timer

1 = Remote Keypad, Digital Input, Clock

8

Reserved

9 0 = Negative phase sequence

1 = Positive phase sequence

10 to 15

Reserved

20-21

Current

0 to 13

Average rms current across all three phases

14 to 15

Reserved

22-23

Current

0 to 9

Current (% motor FLC)

10 to 15

Reserved

24-25 Motor temperature 0 to 7 Motor thermal model (%)

8 to 15

Reserved

INSTRUCTIONS

16 Profinet Card (710-16502-00C)

Byte

Description

Bits

Details

26-27 Power

0 to 11 Power

12 to 13

Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

14 to 15

Reserved

28-29

% Power factor

0 to 7

100% = power factor of 1

8 to 15

Reserved

30-31

Voltage

0 to 13

Average rms voltage across all three phases

14 to 15

Reserved

32-33

Current

0 to 13

Phase 1 current (rms)

14 to 15

Reserved

34-35

Current

0 to 13

Phase 2 current (rms)

14 to 15

Reserved

36-37 Current 0 to 13 Phase 3 current (rms)

14 to 15

Reserved

38-39 Voltage 0 to 13 Phase 1 voltage (rms)

14 to 15

Reserved

40-41

Voltage

0 to 13

Phase 2 voltage (rms)

14 to 15

Reserved

42-43

Voltage

0 to 13

Phase 3 voltage (rms)

14 to 15

Reserved

44-45

Parameter list

0 to 7

Parameter list minor revision

version number 8 to 15 Parameter list major version

46-47

Digital input state

For all inputs, 0 = open, 1 = closed (shorted)

0

Start/Stop

1

Reserved

2

Reset (Refer to note)

3 Input A

4

Input B

5 to 15

Reserved

48-49

Trip code

0 to 15

Refer to Trip codes on page 18

50-51

Reserved

52-53

Frequency

Frequency (Hz)

54-55

Ground current

Ground current (A)

56-59

Reserved

60-63

Parameter

management

Refer to Parameter management on page 17

INSTRUCTIONS

Profinet Card (710-16502-00C) 17

NOTE

The reset input is normally closed by default. If parameter 7I

Reset/Enable

Logic

is set to normally open, the reported state will be inverted (0 = closed, 1 =

open).

NOTE

For models EMX4x-

0064B and smaller, current reported via communications is

10 times greater than the actual value (displayed on the keypad).

NOTE

Frequency reported via communications is 10 times greater than the actual

value.

7.3 Parameter management

The Profinet Card can read parameter values from and write parameter values to the

soft starter. The card handles one parameter at a time.

The device references parameters according to their position in the starter's

parameter list.

NOTE

Parameter lists vary according to the model and version of soft starter. Refer

to the relevant soft starter literature for a complete parameter list.

CAUTION

Changing the values of the Advanced parameters (parameter group 20) may

cause unpredictable behaviour in the soft starter. Consult your local supplier

before adjusting the Advanced parameters.

Output

Use output bytes 2-5 to read or write a parameter to the soft starter.

Controller > device output bytes are structured as follows.

Byte

Bits

Details

2

0 to 7

Parameter number to read/write

3

0

Reserved

1 1 = Read parameter

2

1 = Write parameter

3 to 7

Reserved

4

0 to 7

Low byte parameter value to write to soft starter/ zero data

values for read

5

0 to 7

High byte parameter value to write to soft starter/ zero data

values for read

INSTRUCTIONS

18 Profinet Card (710-16502-00C)

Input

Parameter data from the starter is reported in input bytes 60-63.

Device > controller input bytes are structured as follows.

Byte

Bits

Details

60

0 to 7

Echo parameter number

61 0 1 = Invalid parameter number

1

1 = Invalid parameter value

2 to 7

Reserved

62

0 to 7

Low byte parameter value read from soft starter

63

0 to 7

High byte parameter value read from soft starter

7.4 Trip codes

Trip code

Description

255

No trip

1

Excess start time

2

Motor overload

3 Motor thermistor

4 Current imbalance

5

Frequency

6

Phase sequence

7

Overcurrent

8

Power loss

9 Undercurrent

10

Heatsink overtemperature

11

Motor connection

12

Input A trip

13

FLC too high

14

Unsupported option (function not available in inside delta)

15 Communications card fault

16 Network communication

18

Overvoltage

19

Undervoltage

23

Parameter out of range

24 Input B trip

26 L1 phase loss

27

L2 phase loss

28

L3 phase loss

29

L1-T1 shorted

30

L2-T2 shorted

INSTRUCTIONS

Profinet Card (710-16502-00C) 19

Trip code

Description

31

L3-T3 shorted

33 Time-overcurrent (Bypass overload)

34

SCR overtemperature

35

Battery/clock

36

Thermistor circuit

47

Overpower

48 Underpower

56 Keypad disconnected

57

Zero Speed Detect

58

SCR Itsm

59

Instantaneous overcurrent

60

Rating Capacity

70 Current Read Err L1

71

Current Read Err L2

72

Current Read Err L3

74

Motor Connection T1

75

Motor Connection T2

76

Motor Connection T3

77 Firing Fail P1

78

Firing Fail P2

79

Firing Fail P3

80

VZC Fail P1

81

VZC Fail P2

82 VZC Fail P3

83 Low Control Volts

84~96

Internal fault x. Contact your local supplier with the fault code (X).

7.5 Examples

Control commands (controller to device)

Start the motor using parameter set 1

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

4

1

Start the motor, select via remote input

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0

1

Stop the motor using the programmed soft stop for motor set 2

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

8

0

INSTRUCTIONS

20 Profinet Card (710-16502-00C)

Quick stop the motor

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

16

0

Reset a trip

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

≤ 28

8

Status information (device to controller)

Read control status - Ready

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0

1

Read control status - Running

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

3

0

Read control status - Tripped, trip code 4 (Current imbalance)

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

6

0

4

0

Parameter management

Write parameter to starter: parameter number 2, 1B

Motor Full Load Current

= 55

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

2

4

55

0

Parameter write response

Byte 56

Byte 57

Byte 58

Byte 59

Byte 60

Byte 61

Byte 62

Byte 63

2

0

55

0

EMX4e: Read parameter number 12, 2I

Stop Mode

Byte 0

Byte 1

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

12

2

0

0

Parameter read response: parameter 2I

Stop Mode

= 1 (TVR Soft Stop)

Byte 56

Byte 57

Byte 58

Byte 59

Byte 60

Byte 61

Byte 62

Byte 63

12

0

1

0

Table of contents

Other AuCom Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

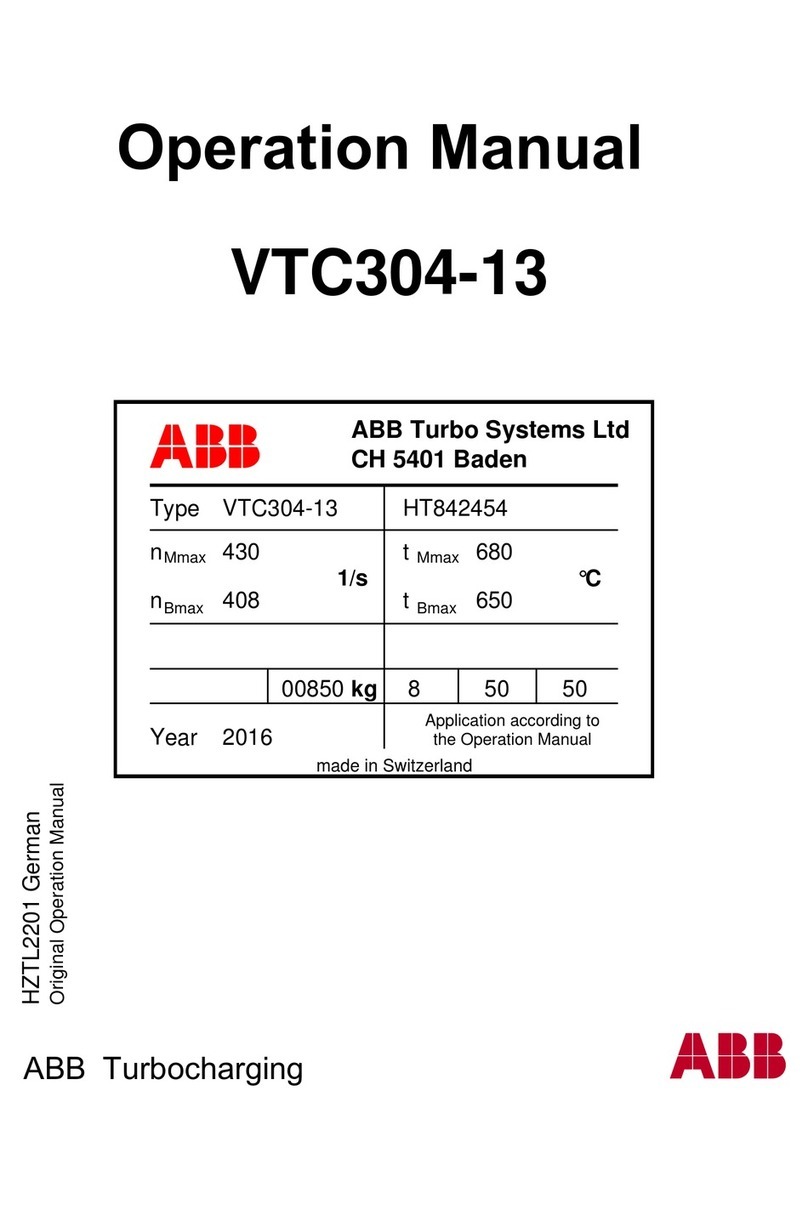

ABB

ABB HT842454 Operation manual

HMS

HMS Anybus Wireless Bolt SP2554 Series Startup guide

Wilo

Wilo Wilo-Helix V FIRST V 2.0-VE 2 Installation and operating instructions

Graco

Graco EcoQuip 300 Operation, repair, and parts

MICRO-EPSILON

MICRO-EPSILON thicknessSENSOR 10/200 operating instructions

ABB

ABB HT567437 Operation manual