AuCom MVS Series User manual

GUIDE

MVS SERIES SOFT STARTERS

PRODUCT

http://www.kontrolkalemi.com/forum/

CONTENTS

MVS SERIES 1 710-03261-00A

Section 1 Caution Statements

Section 2 General Description

2.1 Overview.......................................................................................................... 3

2.2 Feature List...................................................................................................... 3

2.3 Type Codes ..................................................................................................... 4

Section 3 Specifications

3.1 Current Ratings ............................................................................................... 5

3.2 Dimensions and Weights................................................................................. 6

3.3 General Technical Data................................................................................... 7

Section 4 Installation

4.1 Mounting Instructions – Power Assembly ....................................................... 9

4.2 Mounting Instructions – Controller ................................................................ 10

4.3 Power Terminations ...................................................................................... 11

4.4 Control Terminations ..................................................................................... 12

4.5 Electrical Schematic ...................................................................................... 12

4.6 Internal Wiring ............................................................................................... 13

Section 5 System Design

5.1 Overview........................................................................................................ 14

5.2 Main Contactor .............................................................................................. 14

5.3 Bypass Contactor .......................................................................................... 14

5.4 Main Isolator / Earth Switch .......................................................................... 16

5.5 "R Rated" Protection Fuses........................................................................... 16

5.6 Power Factor Correction Capacitor Contactor .............................................. 16

5.7 Line Inductors................................................................................................ 16

5.8 Transient / Overvoltage Protection................................................................ 16

5.9 Medium Voltage Control Supply Transformer ............................................... 16

Section 6 Application Examples

6.1 Installation into a Panel ................................................................................. 18

http://www.kontrolkalemi.com/forum/

CAUTION STATEMENTS

710-03261-00A 2 MVS SERIES

Section 1 Caution Statements

This symbol is used throughout this manual to draw attention to topics

of special importance to the installation and operation of the MVS soft

starter.

Caution Statements cannot cover every potential cause of equipment damage but

can highlight common causes of damage. It is therefore the installer’s

responsibility to adhere to all instructions in this manual, to follow good electrical

practice and to seek advice before operating this equipment in a manner other than

as detailed in this manual.

•Ensure that the MVS is completely isolated from the power supply before

attempting any work on the unit.

•Entry of metal swarf into the cabinet can cause equipment failure.

•Do not apply voltage to the control input terminals. These are active

24 VDC inputs and must be controlled with potential free circuits.

•Ensure contacts/switches operating the control inputs are suitable for low

voltage, low current switching (ie gold flash or similar).

•Ensure cables to the control inputs are segregated from AC power and

control wiring.

•Some electronic contactor coils are not suitable for direct switching with

PCB mount relays. Consult the contactor manufacturer/supplier to see if

this is advisable.

•Do not connect power factor correction capacitors to the output of the

MVS. If static power factor correction is employed, it must be connected to

the supply side of the MVS.

The examples and diagrams in this manual are included solely for illustrative

purposes. Users are cautioned that the information contained in this manual is

subject to change at any time and without prior notice. In no event will

responsibility or liability be accepted for direct or indirect or consequential damages

resulting from the use or application of this equipment.

WARNING – ELECTRICAL SHOCK HAZARD

The MVS contains dangerous voltages when connected to line

voltage. Only a competent electrician should carry out the electrical

installation. Improper installation of the motor or the MVS may cause

equipment failure, serious injury or death. Follow this manual, the

National Electrical Code (NEC®) and local safety codes.

GROUNDING AND BRANCH CIRCUIT PROTECTION

It is the responsibility of the user or person installing the MVS to

provide proper grounding and branch circuit protection according to

the National Electrical Code (NEC®) and local safety codes.

SHORT CIRCUIT

The MVS is not short circuit proof. Therefore, after severe overload

or short circuit, the operation of the starter should be fully tested.

http://www.kontrolkalemi.com/forum/

GENERAL DESCRIPTION

MVS SERIES 3 710-03261-00A

Section 2 General Description

2.1 Overview

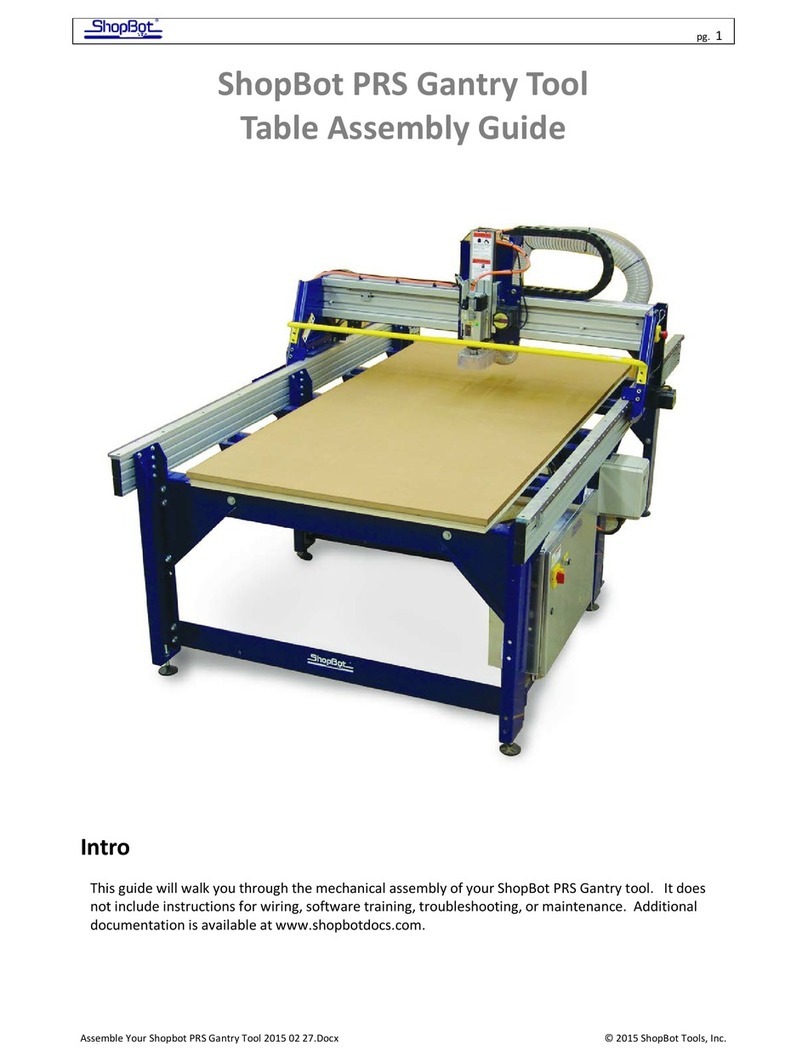

The MVS Series provides compact and robust soft start solutions for control of

medium voltage motors. MVS Series soft starters provide a complete range of

motor and system protection features and have been designed for reliable

performance in the most demanding installation situations.

The MVS soft starter comprises two elements:

•a power assembly, which varies between different models (depending on

mains voltage and current rating)

•a controller module, which is common to all models

The power assembly and controller module are supplied as a pair and share the

same serial number. Care should be taken during installation to ensure the correct

controller and power assembly are used together.

2.2 Feature List

Starting

•Constant Current

•Current Ramp

•Torque Control

Stopping

•Soft Stop

Protection

•Under/Overvoltage

•Supply Frequency

•Phase Sequence

•Shorted SCR

•Motor Overload (Thermal Model)

•Electronic Shearpin

•Ground Fault

•Undercurrent

•Phase Imbalance

•Motor Thermistor

•Excess Start Time

•Power Circuit

•Auxiliary Trip

Interface

•Remote Control Inputs

(3 x fixed, 2 x programmable)

•Relay Outputs

(3 fixed, 3 x programmable)

•Analogue Output (1 x programmable)

•Serial Output (1 x RS485)

Human Interface

•Multi-Language Display

•Starter Status LEDs

•Event Log (99 positions, date and

time stamped)

•Trip Log (8 positions, date and time

stamped)

•Counters (starts, hours-run, kWh)

•Metering (current, voltage, power

factor, kWh)

•User Programmable Metering

Screen

•Multi-Level Password Protection

Power Connection

•80 A to 321 A, nominal

•2300 VAC to 11000 VAC

Accessories (optional)

•RTD Interface

•Modbus RTU Interface

•Profibus Interface

•DeviceNet Interface

•Synchronous Motor Control

•PC Software

•Remote Operator

•Overvoltage Protection

•MV Control Supply Transformer

http://www.kontrolkalemi.com/forum/

GENERAL DESCRIPTION

710-03261-00A 4 MVS SERIES

2.3 Type Codes

Supply Voltage

V02 = 2300 VAC 50 / 60 Hz

V03 = 3300 VAC 50 / 60 Hz

V04 = 4160 VAC 50 / 60 Hz

V06 = 6600 VAC 50 / 60 Hz

V07 = 7200 VAC 50 / 60 Hz

V11 = 11000 VAC 50 / 60 Hz

Control Supply Voltage

C12 = 110 VAC & 230 VAC

MVS --

Current Rating

0080 = 80 A @ AC53b 4-20 : 1780

0159 = 159 A @ AC53b 4-20 : 1780

0230 = 230 A @ AC53b 4-20 : 1780

0321 = 321 A @ AC53b 4-20 : 1780

http://www.kontrolkalemi.com/forum/

SPECIFICATIONS

MVS SERIES 5 710-03261-00A

Section 3 Specifications

3.1 Current Ratings

Two starts per hour

3.5-15:1785 4.0-20:1780 4.0-30:1770 5.0-30:1770 5.0-60:1740

40 °C 50 °C 40 °C 50 °C 40 °C 50 °C 40 °C 50 °C 40 °C 50 °C

MVS-0080-xxx 96 91 80 74 72 66 59 55 46 42

MVS-0159-xxx 190 177 159 147 143 132 117 109 91 84

MVS-0230-xxx 282 261 230 213 201 185 165 152 121 111

MVS-0321-xxx 393 363 321 296 279 257 229 211 168 154

Three starts per hour

4.0-20:1180 4.0-30:1170 5.0-30:1170 5.0-60:1140

40 °C 50 °C 40 °C 50 °C 40 °C 50 °C 40 °C 50 °C

MVS-0080-xxx 73 68 65 60 53 49 40 37

MVS-0159-xxx 146 135 129 119 106 98 79 73

MVS-0230-xxx 207 190 175 162 144 132 101 93

MVS-0321-xxx 288 265 244 225 200 184 141 129

Four starts per hour

4.0-20:880 4.0-30:870 5.0-30:870 5.0-60:840

40 °C 50 °C 40 °C 50 °C 40 °C 50 °C 40 °C 50 °C

MVS-0080-xxx 68 63 59 54 48 45 35 33

MVS-0159-xxx 136 125 117 108 96 89 70 65

MVS-0230-xxx 188 173 157 144 129 118 88 81

MVS-0321-xxx 262 241 218 200 179 164 122 112

AC53b Utilisation Category Format

80 A: AC-53b 4-20 : 1780

Off Time (seconds)

Start Time (seconds)

Start Current (multiple of FLC)

Starter Current Rating (amperes)

Starter Current Rating: The full load current rating of the soft starter given the

parameters detailed in the remaining sections of the utilisation code.

Start Current: The maximum available start current given the parameters detailed

in the remaining sections of the utilisation code.

Start Time: The maximum available start time given the parameters detailed in the

remaining sections of the utilisation code.

Off Time: The minimum allowable time between the end of one start and the

beginning of the next start given the parameters detailed in the remaining sections

of the utilisation code.

Contact your local supplier for ratings under operating conditions not covered by

the above charts.

http://www.kontrolkalemi.com/forum/

SPECIFICATIONS

710-03261-00A 6 MVS SERIES

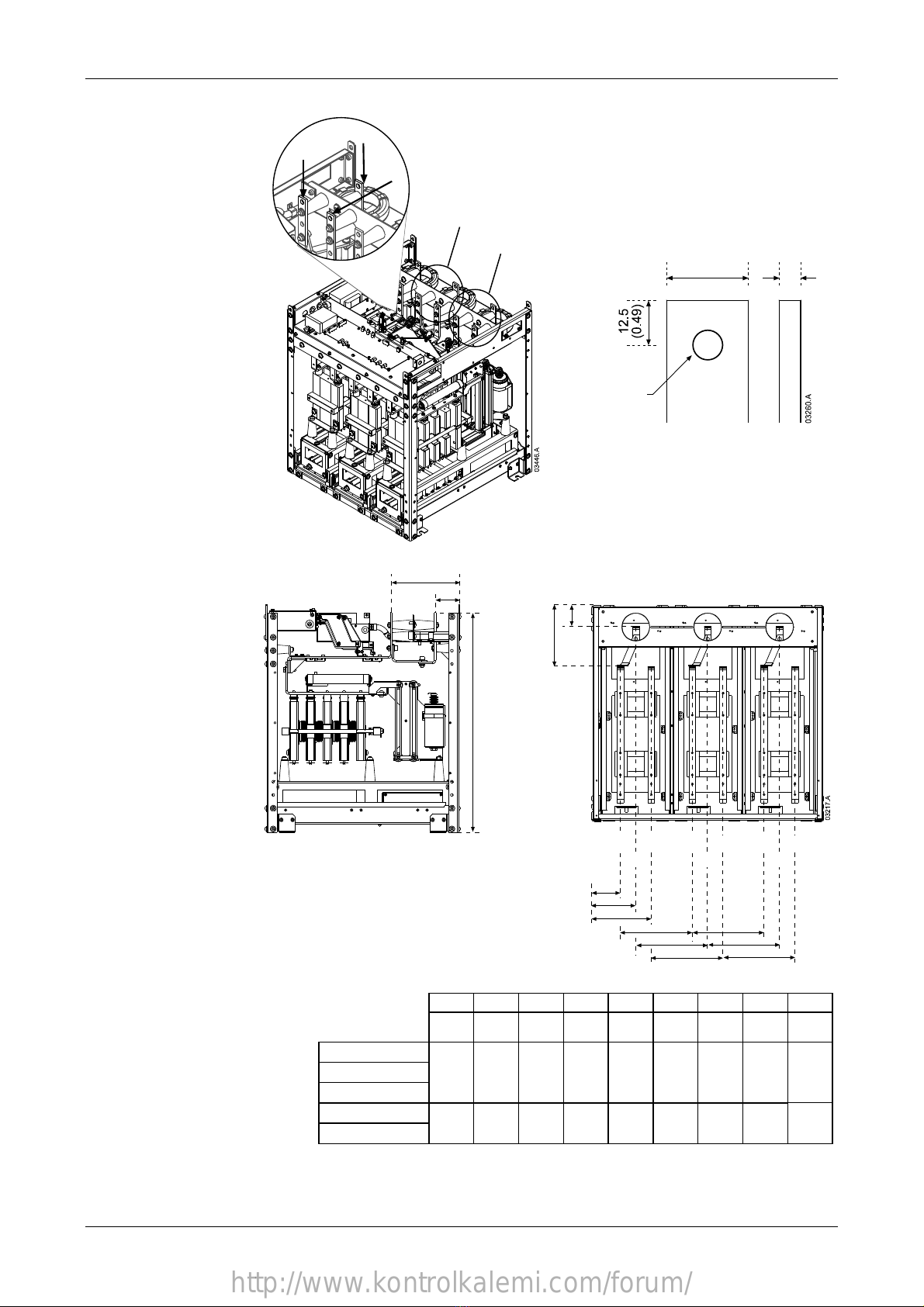

3.2 Dimensions and Weights

Power Assembly

Aa

b

B

c

C

d

e

Front View Side View

Extended

A

mm

(inch)

B

mm

(inch)

C

mm

(inch)

a

mm

(inch)

b

mm

(inch)

c

mm

(inch)

d

mm

(inch)

e

mm

(inch)

Weight

kg (lb)

MVS-

xxxx-V02

MVS-

xxxx-V03

MVS-

xxxx-V04

772

(30.39)

669

(26.34)

667

(26.26)

750

(29.53)

658

(25.91)

650

(25.59)

1302

(51.26)

531

(20.91)

165

(363.76)

MVS-

xxxx-V06

MVS-

xxxx-V07

832

(32.76)

875

(34.45)

817

(32.17)

810

(31.89)

864

(34.02)

800

(31.50)

1559

(61.38)

551

(21.69)

217

(478.40)

Please contact your local supplier for dimensions for MVS-xxxx-V11.

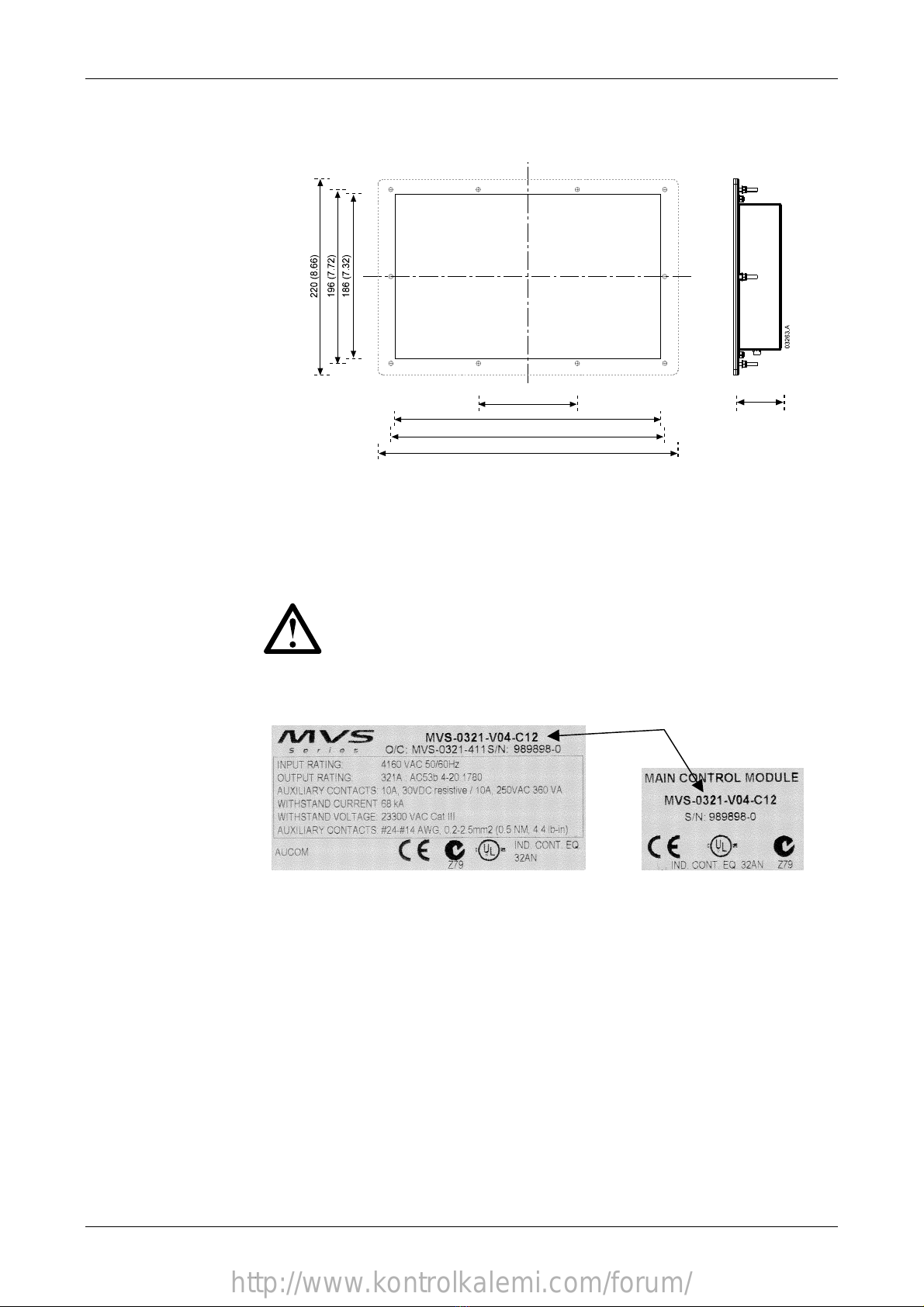

Controller

The MVS controller is suitable for use with all models in the MVS Series.

340.0

(13.39)

54.0

(2.13)

mm (inch)

Weight: 2.1 kg (4.63 lb)

http://www.kontrolkalemi.com/forum/

SPECIFICATIONS

MVS SERIES 7 710-03261-00A

3.3 General Technical Data

Supply

Mains Supply Voltage

MVSxxxx-V02-xxx ........................................................ 3 x 2300 VAC (± 10%)

MVSxxxx-V03-xxx ........................................................ 3 x 3300 VAC (± 10%)

MVSxxxx-V04-xxx ........................................................ 3 x 4160 VAC (± 10%)

MVSxxxx-V06-xxx ........................................................ 3 x 6600 VAC (± 10%)

MVSxxxx-V07-xxx ...................................................... 3 x 7200 VAC (± 10%)

MVSxxxx-V11-xxx ..................................................... 3 x 11000 VAC (± 10%)

Control Supply Voltage

MVSxxx-xxx-C12 ................................ 110 VAC to 130 VAC (+ 10% / - 15%)

or 220 VAC to 240 VAC (+ 10% / - 15%)

Supply Frequency .......................................................................... 45 Hz to 66 Hz

Rated Insulation Voltage

MVSxxxx-V02-xxx ........................................................................... 4200 VAC

MVSxxxx-V03-xxx ........................................................................... 4200 VAC

MVSxxxx-V04-xxx ........................................................................... 4200 VAC

MVSxxxx-V06-xxx ........................................................................... 6600 VAC

MVSxxxx-V07-xxx ........................................................................... 7200 VAC

MVSxxxx-V11-xxx ......................................................................... 11000 VAC

Rated Impulse Withstand Voltage (BIL)

MVSxxxx-V02-xxx .......................... 23300 VAC Cat III (1.2/ 50 µs at 2000 m)

MVSxxxx-V03-xxx .......................... 23300 VAC Cat III (1.2/ 50 µs at 2000 m)

MVSxxxx-V04-xxx .......................... 23300 VAC Cat III (1.2/ 50 µs at 2000 m)

MVSxxxx-V06-xxx .......................... 36700 VAC Cat III (1.2/ 50 µs at 2000 m)

MVSxxxx-V07-xxx .......................... 40000 VAC Cat III (1.2/ 50 µs at 2000 m)

MVSxxxx-V11-xxx ................................ xx VAC Cat III (1.2/ 50 µs at 2000 m)

Form Designation ......................... Bypassed semiconductor motor starter form 1

Control Inputs

Start (Terminals C23, C24) ..................................... Active 24 VDC, 8 mA approx

Stop (Terminals C31, C32) ..................................... Active 24 VDC, 8 mA approx

Reset (Terminals C41, C42) ................................... Active 24 VDC, 8 mA approx

Programmable Input A (Terminals C53, C54) ........ Active 24 VDC, 8 mA approx

Programmable Input B (Terminals C63, C64) ........ Active 24 VDC, 8 mA approx

Motor Thermistor (Terminals B4, B5)

Outputs

Relay Outputs ............................................................. 10 A @ 250 VAC / 360 VA

10 A @ 30 VDC resistive

Main Contactor (Terminals 13, 14) ................................................ Normally Open

Bypass Contactor (Terminals 23, 24) ............................................. Normally Open

Run Output / PFC (Terminals 31, 32, 34) ............................................Changeover

Programmable Relay Output A (Terminals 43, 44) ....................... Normally Open

Programmable Relay Output B (Terminals 51, 52, 54) ...................... Changeover

Programmable Relay Output C (Terminals 61, 62, 64) ...................... Changeover

Analogue Output (Terminals B10, B11) .................................................. 4-20 mA

http://www.kontrolkalemi.com/forum/

SPECIFICATIONS

710-03261-00A 8 MVS SERIES

Environmental

Degree of Protection

Power Assembly ...................................................................................... IP00

Controller ............................................................................... IP54 / NEMA 12

Motor Controller Panel (optional) ........................... designed to IP54 / NEMA 12

Operating Temperature ............................................................. - 10 ˚C to + 60 ˚C

Storage Temperature ................................................................ - 25 ˚C to + 55 ˚C

Humidity ................................................................ 5% to 95% Relative Humidity

Pollution Degree ....................................................................... Pollution Degree 3

Vibration ..................................................................IEC 60068 Test Fc Sinusoidal

4 Hz to 13.2 Hz: ± 1 mm displacement

13.2 Hz to 200 Hz: ± 0.7 g

EMC Emission

Equipment Class (EMC) ............................................................................. Class A

Conducted Radio Frequency Emission ..... 10 kHz to 150 kHz: < 120 - 69 dB µV

0.15 MHz to 0.5 MHz: < 79 dB µV

0.5 MHz to 30 MHz: < 73 dB µV

Radiated Radio Frequency Emission .... 0.15 MHz to 30 MHz: < 80-50 dB µV/m

30 MHz to 100 MHz: < 60-54 dB µV/m

100 MHz to 2000 MHz: < 54 dB µV/m

This product has been designed for Class A equipment. Use of the product in

domestic environments may cause radio interference, in which case the user may

be required to employ additional mitigation methods.

EMC Immunity

Electrostatic Discharge ..................... 6 kV contact discharge, 8 kV air discharge

Radio Frequency Electromagnetic Field ............... 80 MHz to 1000 MHz: 10 V/m

Fast Transients 5/50 ns (main and control circuits) .................................................

2 kV line to earth, 1 kV line to line

Surges 1.2/50 µs (main and control circuits) ....2 kV line to earth, 1 kV line to line

Voltage dip and short time interruption ............ 5000 ms (at 0% nominal voltage)

(safe shutdown)

Short Circuit

Rated short-circuit current

MVSxxxx-V02-xxx .................................................................................. 68 kA

MVSxxxx-V03-xxx .................................................................................... 68 kA

MVSxxxx-V04-xxx .................................................................................. 68 kA

MVSxxxx-V06-xxx .................................................................................. XX kA

MVSxxxx-V07-xxx .................................................................................. XX kA

MVSxxxx-V11-xxx .................................................................................. XX kA

Heat Dissipation (Steady State)

Power Assembly (SCRs bypassed) ................................................. 20 W approx

Controller ........................................................................................... 10 W approx

Standards Approvals

C9.......................................................................................... EMC requirements

UL / C-UL ..................................................................................... UL 508, UL 347

CE ........................................................................................... EMC EU Directive

Marine ...................................................................................................... pending

http://www.kontrolkalemi.com/forum/

INSTALLATION

MVS SERIES 9 710-03261-00A

Section 4 Installation

4.1 Mounting Instructions – Power Assembly

All models in the MVS Series have an IP00 rating and must be installed inside an

enclosure. The power assembly should be installed with 100 mm clearance above

for isolation; no clearance is required below or at the sides.

min 100 mm (3.93 inch)

The MVS power assembly is mounted in place using four M12 bolts. One bolt is

required through each corner at the base of the unit, tightened to a torque of

40 Nm.

Front of Unit

A

To suit M12 mounting bolt

Horizontal Cross-section

A

mm (inch)

B

mm (inch)

C

mm (inch)

MVS-xxxx-V02

MVS-xxxx-V03

MVS-xxxx-V04

636

(25.04)

513

(20.20)

68.5

(2.70)

MVS-xxxx-V06

MVS-xxxx-V07

842

(33.15)

663

(26.10)

68.5

(2.70)

http://www.kontrolkalemi.com/forum/

INSTALLATION

710-03261-00A 10 MVS SERIES

4.2 Mounting Instructions – Controller

The MVS controller can be secured in place with ten M4 nuts, affixed to the bolts

on the back of the controller.

112 (4.41)

300 (11.81)

310 (12.20)

340 (13.39)

54.0 (2.13)

To mount the controller, make a 186 mm x 300 mm cutout at the desired mounting

location. Ensure adequate clearance (54 mm) is available behind the mounting

location.

Drill 5 mm holes to accommodate the bolts on the controller. Fit the controller

through the cutout and tighten the nuts onto the bolts.

NOTE

Before installation, always ensure that you are using the correct controller

for the starter. This can be checked by comparing the serial number on

the back of the controller with the serial number on the front of the power

assembly.

Serial number

http://www.kontrolkalemi.com/forum/

INSTALLATION

MVS SERIES 11 710-03261-00A

4.3 Power Terminations

T3, T3B, L3

T2, T2B, L2

L1

T1

T1B

6

(0.24)

25

(0.98)

13

(0.51)

Rear of Unit

ii

a

b

d

e

f

g

h

g

h

T1B T2B T3B

L3L2L1 T3T2T1

a

b

c

abcde f gh i

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

MVS-xxxx-V02

MVS-xxxx-V03

MVS-xxxx-V04

228

(8.98)

79

(3.11)

744

(29.29)

79

(3.11)

129

(5.08)

179

(7.05)

200

(7.87)

200

(7.87)

200

(7.87)

MVS-xxxx-V06

MVS-xxxx-V07

228

(8.98)

79

(3.11)

804

(31.65)

107

(4.19)

164

(6.46)

222

(8.72)

268

(10.55)

268

(10.55)

268

(10.55)

Please contact your local supplier for measurements for MVS-xxxx-V11.

http://www.kontrolkalemi.com/forum/

INSTALLATION

710-03261-00A 12 MVS SERIES

4.4 Control Terminations

Control wiring is secured in place by 3 mm spring terminals.

Control Wiring

3

(0.12)

mm (inch)

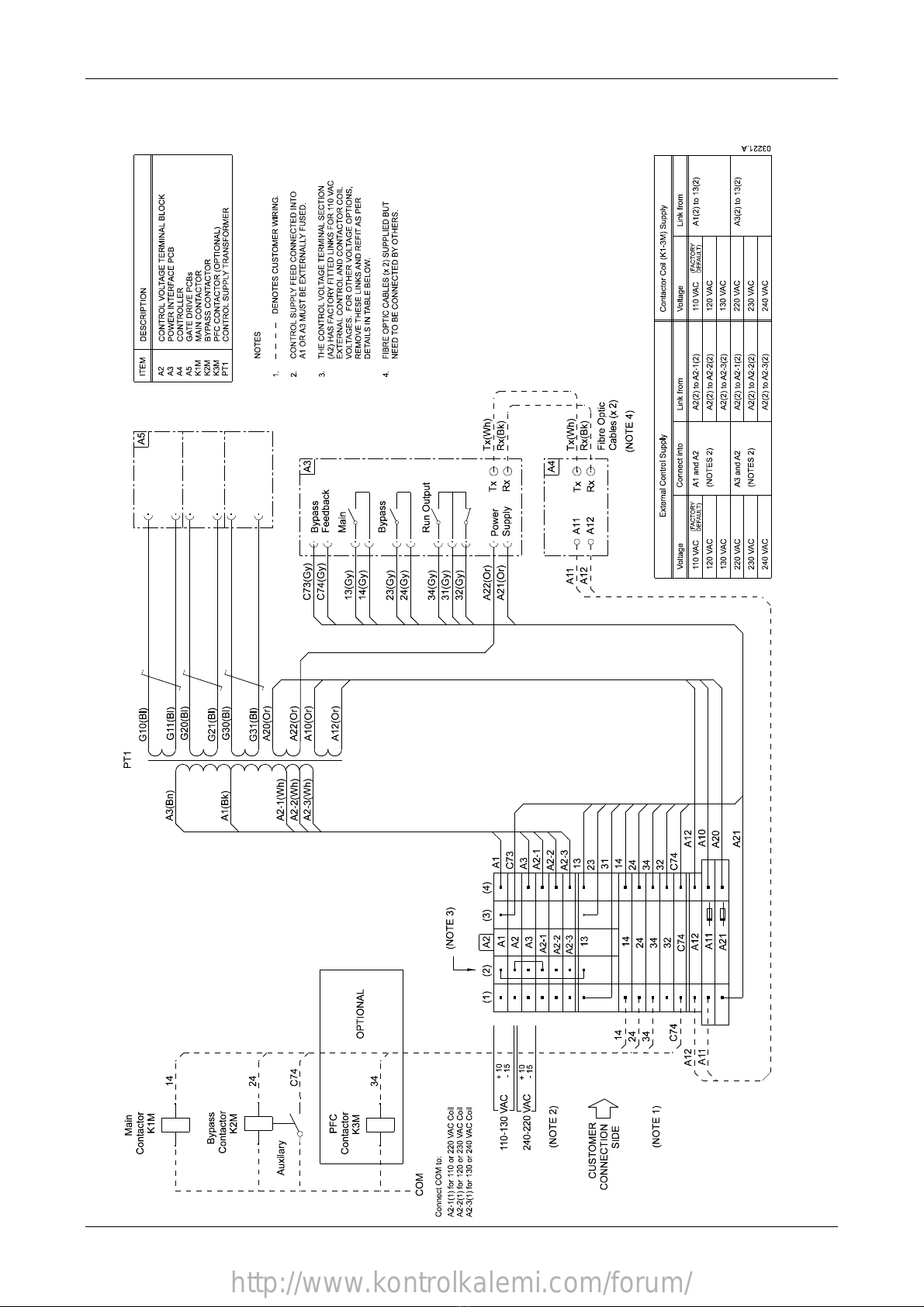

4.5 Electrical Schematic

Diagram 1: Electrical Schematic

K2M

BYPASS CONTACTOR

MAIN CONTACTOR

E

A3A2

TO MOTOR

SUPPLY

3 PHASE

ITEM

A1

A2

A3

A4

A6

K1M

K2M

DESCRIPTION

POWER ASSEMBLY

CONTROL VOLTAGE TERMINAL BLOCK

POWER INTERFACE PCB

CONTROLLER

COMMS MODULE (OPTIONAL)

MAIN CONTACTOR

BYPASS CONTACTOR

T3

T2

T1

L3

L2

L1

T3B

T2B

T1B

A1

K1M

K2M

110~130 VAC

220~240VAC - 15

+ 10

- 15

+ 10

TXRX

RXTX

A12A11

A12A11

-

+

34

31

32

RUN OUTPUT

(PFC)

FEEDBACK SIGNAL

BYPASS CONTACTOR

C74

C73

C42

C41

ANALOGUE OUTPUT

PROGRAMMABLE

B11

B10

OUTPUT C

PROGRAMMABLE

OUTPUT B

PROGRAMMABLE

OUTPUT A

PROGRAMMABLE

61

62

64

51

52

54

44

43

24

23

14

13

B5

B4

(OPTIONAL)

COMMS MODULE

THERMISTOR

MOTOR

C64

C63

C54

C53

INPUT B

RESET

STOP

START

C32

C31

C24

C23

A3

A2

A1

PROGRAMMABLE

INPUT A

PROGRAMMABLE

A4

A6

(Wh) (Bk)

(Bk) (Wh)

http://www.kontrolkalemi.com/forum/

INSTALLATION

MVS SERIES 13 710-03261-00A

4.6 Internal Wiring

Diagram 2: Internal Wiring

http://www.kontrolkalemi.com/forum/

POWER CIRCUITS

710-03261-00A 14 MVS SERIES

Section 5 Power Circuits

5.1 Overview

MVS starters are designed to operate as part of a system including other

components. A main contactor and bypass contactor are required in all

installations. The following additional components may also be required:

•main isolator/earth switch

•"R Rated" protection fuses

•power factor correction capacitor contactor

•line inductors

•transient / overvoltage protection

•medium voltage control supply transformer

Please refer to the schematic drawings on pages 12, 13, 15 and 17 for details.

5.2 Main Contactor

A main contactor is required in all MVS Series installations. The contactor should

be selected such that the contactor's AC3 rating is greater than or equal to the full

load current rating of the connected motor.

The main contactor is associated with terminals L1, L2, L3 on the input side of the

soft starter and the coil is associated with output terminals 13, 14 of the MVS (refer

to Diagram 3).

To ensure that the potentially dangerous medium voltage area is isolated from the

low voltage control area, power is supplied to the main contactor coil from the

control voltage terminal block (refer to Diagram 2).

5.3 Bypass Contactor

A bypass contactor is required in all MVS Series installations. The contactor should

be selected such that the contactor's AC1 rating is greater than or equal to the full

load current rating of the connected motor.

The bypass contactor is associated with bypass terminals T1B, T2B, T3B on the

starter. The coil is associated with output terminals 23, 24, and the auxiliary

Normally Open contact is associated with input terminals C73, C74 of the MVS

(refer to Diagram 3).

To ensure that the potentially dangerous medium voltage area is isolated from the

low voltage control area, power is supplied to the bypass contactor coil from the

control voltage terminal block (refer to Diagram 2).

http://www.kontrolkalemi.com/forum/

POWER CIRCUITS

MVS SERIES 15 710-03261-00A

Diagram 3: Standard Power Circuit Configuration

MVS starter installation with main and bypass contactors.

T3B

BYPASS CONTACTOR

MAIN CONTACTOR

POWER INTERFACE PCB

CONTROL VOLTAGE TERMINAL BLOCK

POWER ASSEMBLY

DESCRIPTION

K2M

K1M

A3

A2

A1

ITEM

A3

A2

A1

K2M

T1B

T2B

E

L1

L2

L3

T1

T2

T3

A1

A2

A3

CONTROL

SUPPLY

13

14

23

24

C73

C74 BYPASS CONTACTOR

FEEDBACK SIGNAL

(PFC)

RUN OUTPUT

32

31

34

K2M

K1M

K2M BYPASS CONTACTOR

K1M MAIN CONTACTOR

3

M

MOTOR

http://www.kontrolkalemi.com/forum/

POWER CIRCUITS

710-03261-00A 16 MVS SERIES

5.4 Main Isolator / Earth Switch

If specified, a main isolator/ earth switch can be connected upstream of the main

contactor as shown in Diagram 4. The isolator interlocks the panel door to ensure

personnel safety.

5.5 "R Rated" Protection Fuses

If specified, "R Rated" protection fuses can be installed on the input side of the

starter to provide Type 2 coordination and short circuit protection for the motor

branch circuit. The appropriate fuse should be selected from the table below,

based on the motor's rated full load current.

Motor Rated FLC System Voltage

2.3 kV

System Voltage

3.3 ~ 4.2 kV

System Voltage

6 ~ 7.2 kV

70 A 2R

100 A 3R

130 A 4R

150 A 5R

170 A 6R

200 A 9R

230 A 12R

390 A 18R

Ferraz type code A240Rrr A480Rrr-1 A072xxDxRO-rr

Bussmann type code JCK JCL JCR-A, JCR-B

5.6 Power Factor Correction Capacitor Contactor

If power correction factor capacitors are being used, a contactor can be selected

according to the required kVAr, and should be connected upstream of the MVS soft

starter. The power factor correction capacitor contactor coil is associated with

output terminals 31, 34 of the MVS (refer to Diagram 4).

To ensure that the potentially dangerous medium voltage area is isolated from the

low voltage control area, power is supplied to the power factor correction capacitor

contactor coil from the control voltage terminal block (refer to Diagram 2).

NOTE

The capacitor bank must be connected to the input side of the MVS soft

starter.

5.7 Line Inductors

Line inductors are required if the cable run between the soft starter and the motor

is more than 200 m. Line inductors should be installed outside the panel, and

connected between terminals T1, T2, T3 of the soft starter and the motor.

5.8 Transient / Overvoltage Protection

Overvoltage protection should be installed if there is a risk of high transients at the

installation. If required, use the optional Overvoltage Protection Kit.

5.9 Medium Voltage Control Supply Transformer

The control supply for the MVS soft starter should usually be provided as a low

voltage supply (110~130 VAC or 220~240 VAC). If this is not possible, a control

supply transformer will be required. A transformer should be selected with primary

voltage matching the mains voltage and secondary voltage of 110 VAC. Use a

single phase ~ 500 VA transformer with protection fuses on both primary and

secondary side (refer to Diagram 4).

http://www.kontrolkalemi.com/forum/

POWER CIRCUITS

MVS SERIES 17 710-03261-00A

Diagram 4: Complete Power Circuit Configuration

MVS Starter installation with main contactor, bypass contactor, isolator/earth switch, fuses and medium

voltage control supply transformer. Configured for two-wire start/stop control.

http://www.kontrolkalemi.com/forum/

APPLICATION EXAMPLES

710-03261-00A 18 MVS SERIES

Section 6 Application Examples

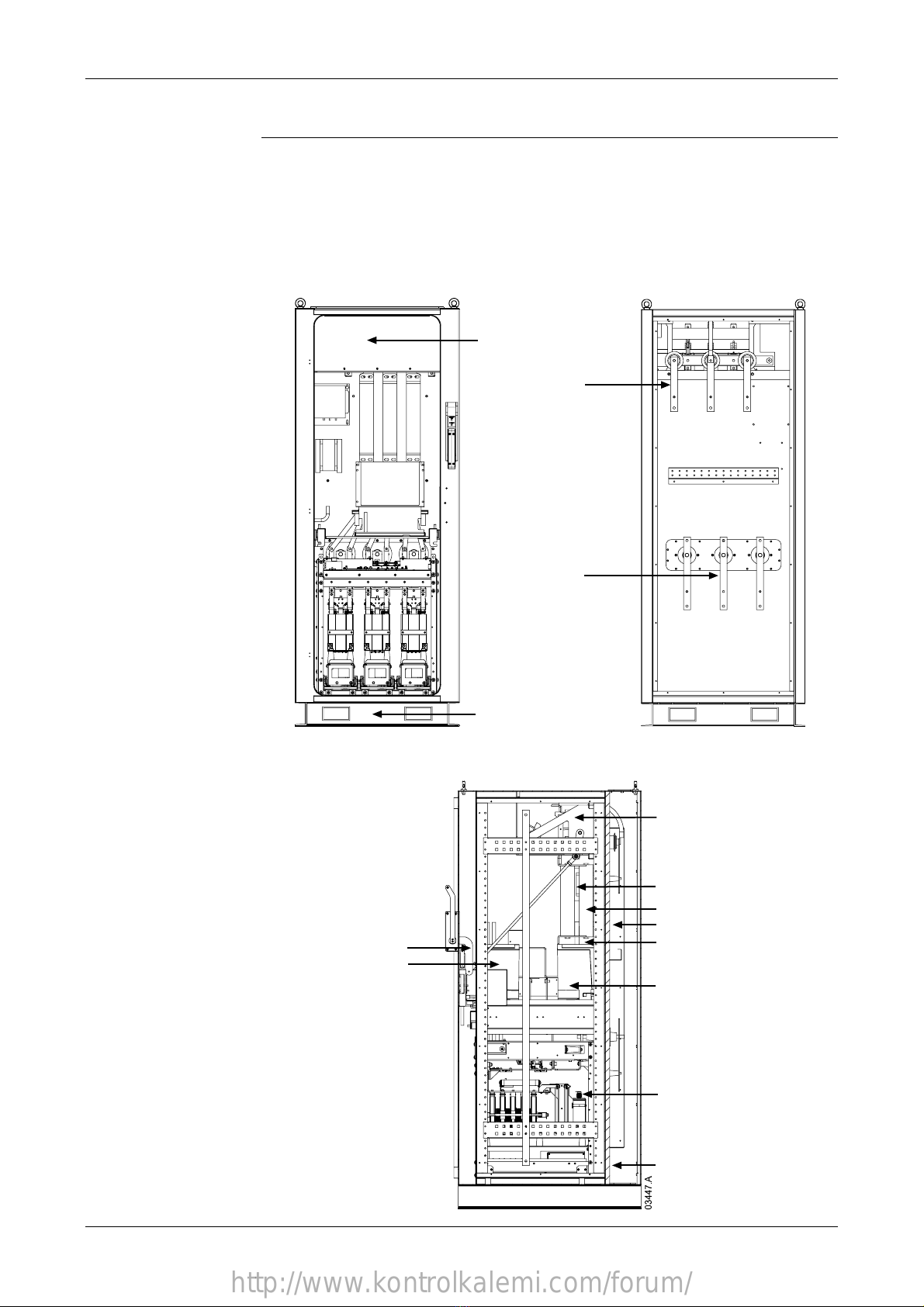

6.1 Installation into a Panel

The MVS panel permits a wide range of installation configurations. Power input

and output can be top or bottom entry and power input can be provided from either

cables or top horizontal bus bars.

The diagrams below illustrate one possible configuration for installation.

Front View

Welded steel plinth

Earth switch viewing window

Rear View

Line bus bars

Motor bus bars

Side View

Interlock mechanism

Fuses

Main contactor

Rear cabling cavity

Power assembly

Bypass contactor

Low voltage trunking

Single phase MV transformer

Three phase MV transformer

Earth / line switch

http://www.kontrolkalemi.com/forum/

NOTES

MVS SERIES 19 710-03261-00A

http://www.kontrolkalemi.com/forum/

This manual suits for next models

11

Table of contents

Other AuCom Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

GFA

GFA ELEKTROMAT KE 40.24-40,00 installation instructions

Unitary products group

Unitary products group PT8 installation manual

Hubbell

Hubbell CHANCE PSC3090323CE manual

Condair

Condair Defensor OptiSorp Installation and operating instructions

ABB

ABB HT614359 Operation manual

ABB

ABB A130-M Series Operation manual