Auditronics 220 Digital Audio Console User manual

220 Digital Audio Console

TECHNICAL MANUAL

March 2000

R-16 / Dec 1997

220 Digital Audio Console Technical Manual - 1st Edition220 Digital Audio Console Technical Manual - 1st Edition

220 Digital Audio Console Technical Manual - 1st Edition220 Digital Audio Console Technical Manual - 1st Edition

220 Digital Audio Console Technical Manual - 1st Edition

©2000 Auditronics® *

AUDITRONICS

600 Industrial Drive

New Bern, North Carolina 28562

252-638-7000

*a division of Wheatstone Corporation

220/ March 2000

AA

AA

ATTENTIONTTENTION

TTENTIONTTENTION

TTENTION

RR

RR

READEAD

EADEAD

EAD MM

MM

MEE

EE

E!!

!!

!

220 / March 2000

Attention!

This console contains static sensitive devices:

Normal precautions against static discharge should be observed when

handlingindividualmodules.Inparticular, modulesbeingpackedforshipping

for return or repair must be packed in special static protection bags before

packaging. Damage caused by static discharge may not be covered under

warranty.

Replacing Modules in a Powered-up Console:

While in an emergency situation it is possible to remove and insert modules

on a powered-up console, Auditronics does not recommend this procedure.

Whenever possible it is best to power down the console first before removing

or replacing modules.

However, if you find you must proceed with this operation, then be sure to

take the following precaution:

When re-inserting a module, take care to replug it squarely into its

mainframe connector socket, so all edgecard fingers make contact

simultaneously. In other words, the gold-plated bus connector fingers on the

bottom edge of the module's printed circuit board must be inserted squarely

(i.e., perpendicular) to the mating socket on the bottom pan of the console

mainframe. The intent is to prevent a situation where one of the module's

power pins makes significant contact before the others. (Naturally, this

same precaution must be taken when using extenders.)

Iftheaboveinstructionsarefollowedtheprocedureshouldberoutine;ifthey

are not, you could run the risk of damaging the console's logic chips.

Again, to avoid ANY possibility of this damage, whenever possible we

stronglyrecommendpoweringdowntheconsolebeforereplacinganymodules.

!

AA

AA

ATTENTIONTTENTION

TTENTIONTTENTION

TTENTION

RR

RR

READEAD

EADEAD

EAD MM

MM

MEE

EE

E!!

!!

!

220 / March 2000

Console Clock Battery Backup

Console Clock Display Card

To activate battery backup of the console’s clock simply pull out the yellow

strip from the clock display card, that is mounted on the inside of console

meterbridge, as shown on the picture below.

page Contents – 1

220 / Sep 2000

CONTENTS

220 Technical Manual

Table of Contents

Chapter 1 – Installation and Power

CountertopMounting................................................................. 1-2

Clearances.............................................................................................................. 1-2

System Ground .......................................................................... 1-2

Power Supply ............................................................................. 1-4

The PSC-D340 Power Supply ................................................................................ 1-5

Power Connector Pinout......................................................................................... 1-5

PSC-D340 Power Supply Schematic ...................................................................1-5A

Energizing ............................................................................................................... 1-6

Audio and Control Wiring.......................................................... 1-7

ConnectionProcedures .......................................................................................... 1-7

Digital Connections................................................................................................. 1-7

Analog Insert Points................................................................................................ 1-7

Unbalanced Connections (analog audio) ............................................................... 1-8

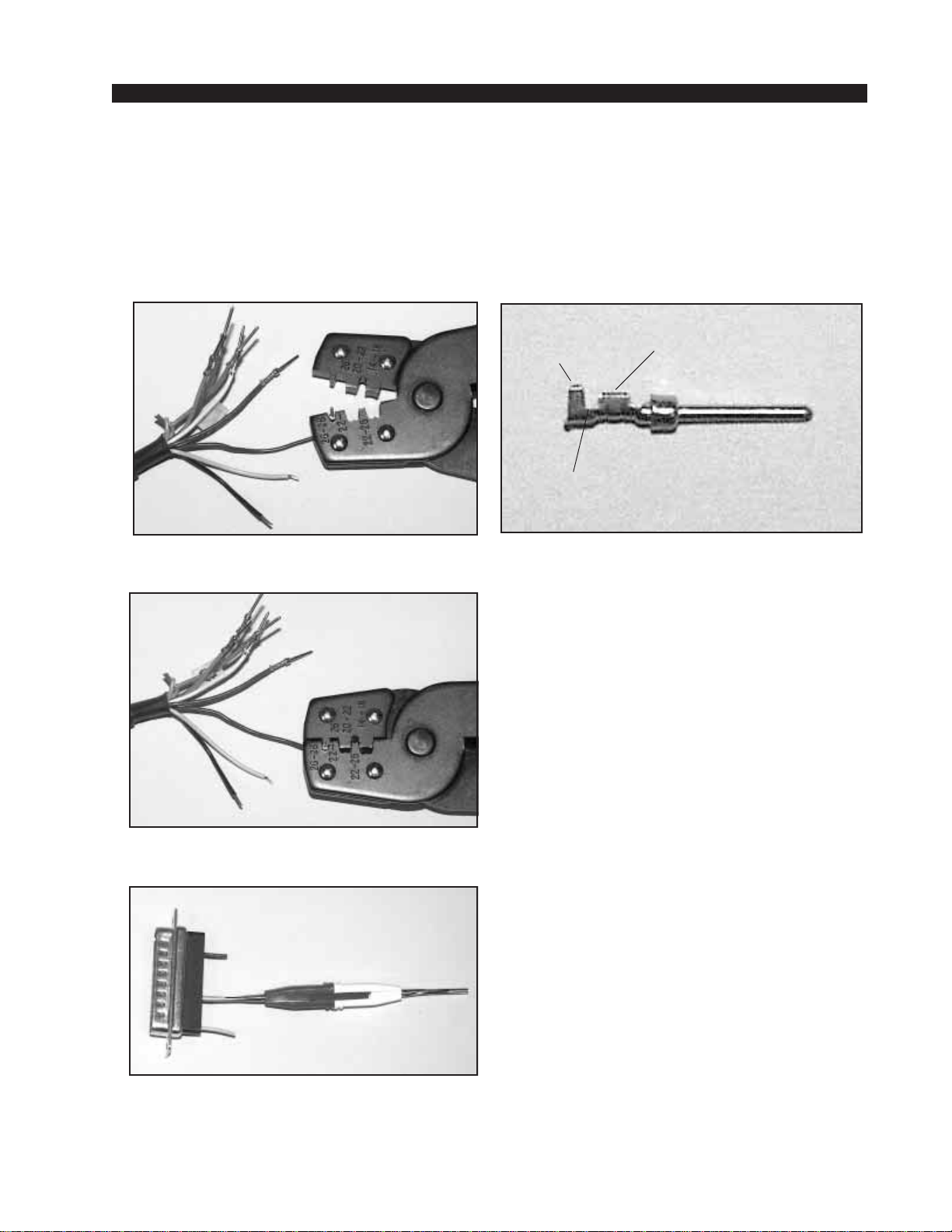

Hand Crimp Tool Wiring Instructions...................................................................... 1-9

Chapter 2 - Input Module

Module Overview........................................................................ 2-2

Internal Programming Options ................................................. 2-3

Insert Bypass .......................................................................................................... 2-3

Phantom Power ...................................................................................................... 2-3

Talkback.................................................................................................................. 2-3

VDT Programming Options ....................................................... 2-4

Hook-ups..................................................................................... 2-4

Microphone Inputs ..................................................................... 2-4

Audio Connections.................................................................................................. 2-4

Control Connections ............................................................................................... 2-4

Remote ON & OFF ................................................................................................. 2-5

Cough ..................................................................................................................... 2-5

Talkback to Control Room ...................................................................................... 2-5

On Tally................................................................................................................... 2-5

Off Tally................................................................................................................... 2-6

Tally B ..................................................................................................................... 2-6

Stereo Line Analog Inputs......................................................... 2-6

Audio Connections.................................................................................................. 2-6

Stereo Line Digital Inputs.......................................................... 2-6

Audio Connections.................................................................................................. 2-6

Control Connections ............................................................................................... 2-7

220 / Oct 2001

page Contents – 2

220 / Sep 2000

CONTENTS

Remote ON & OFF ................................................................................................... 2-7

External START & STOP ......................................................................................... 2-7

Ready........................................................................................................................ 2-8

Tally B ....................................................................................................................... 2-8

DB Connector Pinout Drawing

Mono Mic Inputs ....................................................................................................... 2-9

Stereo Line Analog Inputs ....................................................................................... 2-10

Stereo Line Digital Inputs ........................................................................................ 2-11

Mono-Mic Input Signal Flow Diagram ........................................2-12

Stereo Line Input Signal Flow Diagram .....................................2-13

Chapter 3 - Output Module

Module Overview...........................................................................3-2

CPU.................................................................................................3-3

DSP.................................................................................................3-4

Serial Interface ..............................................................................3-5

Using Serial Interface ............................................................................................... 3-5

Internal Programming Options ....................................................3-6

Global Settings ......................................................................................................... 3-6

RS-485/RS-232Select ............................................................................................. 3-7

RS-485 Termination.................................................................................................. 3-7

Hook-ups........................................................................................3-8

Analog Audio Outputs............................................................................................... 3-8

Digital Outputs .......................................................................................................... 3-8

Digital Control Ports.................................................................................................. 3-9

DB Connector Pinout Drawings

Analog and Digital Outputs...................................................................................... 3-10

Digital Control Ports................................................................................................. 3-11

Master Outputs Signal Flow Diagram ........................................3-12

CPU/DSP Signal Flow Diagram...................................................3-13

Chapter 4 - Control Room Module

Module Overview...........................................................................4-2

Internal Programming Options ....................................................4-3

Cue Interrupt............................................................................................................. 4-3

Cue Mute .................................................................................................................. 4-3

Hook-ups........................................................................................4-3

Upper DB-25 “A” Connector — Audio ...................................................................... 4-3

Upper DB-25 “A” Connector — Control.................................................................... 4-4

On-Air Tally......................................................................................................... 4-4

Lower DB-25 “B” Connector — Audio ...................................................................... 4-4

DB Connector Pinout Drawing.....................................................4-5

Control Room Monitor Signal Flow Diagram..............................4-6

page Contents – 3

220 / Sep 2000

CONTENTS

Chapter 5 - Studio Control Module

Module Overview...........................................................................5-2

Internal Programming Options ....................................................5-3

External Talkback Mute/Dim..................................................................................... 5-3

Studio Dim ................................................................................................................ 5-3

Hook-ups........................................................................................5-3

Upper DB-25 “A” Connector — Audio ...................................................................... 5-3

Upper DB-25 “A” Connector — Control.................................................................... 5-4

Tally 2 and Tally 3 ............................................................................................... 5-4

Lower DB-25 “B” Connector — Audio ...................................................................... 5-4

DB Connector Pinout Drawing.....................................................5-5

Studio Control Monitor Signal Flow Diagram.............................5-6

Chapter 6 - Virtual Dip Switch

Virtual Dip Switch Application Program .....................................6-2

Installation................................................................................................................. 6-2

Hooking up the computer ......................................................................................... 6-2

Running the program ................................................................................................ 6-3

Using the program .................................................................................................... 6-5

Input attenuation ....................................................................................................... 6-8

Advanced operation................................................................................................. 6-10

Ending the program ................................................................................................. 6-12

Serial Interface Cable DB Connectors Pinout Drawing ............6-13

Chapter 7 - Superphone Input Module

Module Overview...........................................................................7-2

Caller Set-Ups .......................................................................................................... 7-2

Automatic Features................................................................................................... 7-3

Inputs and Outputs ................................................................................................... 7-3

Internal Programming Options - Main PCB ................................7-4

External In................................................................................................................. 7-4

Cue Pre/Post ............................................................................................................ 7-4

Mutes ........................................................................................................................ 7-4

Timer Restart ............................................................................................................ 7-4

Tallies........................................................................................................................ 7-4

Cue Dropout.............................................................................................................. 7-5

Gain Trimpots ........................................................................................................... 7-5

Hook-ups........................................................................................7-5

Audio Connections (Upper DB-25 “A”) ..................................................................... 7-5

Audio and Control Connections (Lower DB-25 “B”) ................................................. 7-6

DB Connector Pinout Drawing.....................................................7-7

Superphone Module Signal Flow Diagram .................................7-8

page Contents – 4

220 / Sep 2000

CONTENTS

Chapter 8 - Line Preselector Module

Module Overview...........................................................................8-2

Internal Programming Options ....................................................8-2

Hook-ups........................................................................................8-3

Audio Inputs .............................................................................................................. 8-3

Outputs ..................................................................................................................... 8-3

DB Connector Pinout Drawing.....................................................8-4

Line Preselector Signal Flow Diagram........................................8-5

Chapter 9 - Tape Remote Module

Module Overview...........................................................................9-2

DB Connector Pinout Drawing

START/STOP Function Control I/O.......................................................................... 9-3

Full-Function Control I/O .......................................................................................... 9-4

Chapter 10 - Meterbridge

Overview .......................................................................................10-2

Replacement Parts.......................................................................10-2

Digital Timer .................................................................................10-3

Console Clock ..............................................................................10-3

Controls.................................................................................................................... 10-3

Setting the time........................................................................................................ 10-4

Battery Backup ........................................................................................................ 10-4

Operational Modes .................................................................................................. 10-4

Clock/Timer(CLK-220)

Schematic ................................................................................................................ 10-5

Load Sheet............................................................................................................... 10-6

Clock/Timer Display (CLD-220)

Schematic ................................................................................................................ 10-7

Load Sheet............................................................................................................... 10-8

Chapter 11 - I/O Schematic Drawings

Mono Mic ADC I/O Card Schematic (MMADC-220) .............................................. 11-2

Analog Stereo Line ADC I/O Card Schematic (SLADC-220)................................. 11-3

Digital Stereo Line SRC I/O Card Schematic (SRC-220) ...................................... 11-4

Output Module I/O Schematic (OMD-220) ............................................................. 11-5

Control Room Module I/O Schematic (CRD-220) .................................................. 11-7

Studio Control Module I/O Schematic (SCD-220).................................................. 11-9

Superphone Module I/O Schematic (SPD-220) .................................................... 11-11

Line Select Module I/O Schematic (LS-220) ......................................................... 11-13

Appendix

Replacement Parts List ............................................................... A-2

220 / Jun 2002

INSTALLATION and POWER

page 1 – 1

220 / March 2000

Installation and Power

Chapter Contents

CountertopMounting................................................................. 1-2

Clearances.......................................................................................................... 1-2

System Ground .......................................................................... 1-2

Power Supply ............................................................................. 1-4

The PSC-D340 Power Supply ............................................................................ 1-5

Power Connector Pinout..................................................................................... 1-5

PSC-D340 Power Supply Schematic ...............................................................1-5A

Failsafe Dual Redundant Supply........................................................................ 1-6

Energizing........................................................................................................... 1-6

Audio and Control Wiring.......................................................... 1-7

ConnectionProcedures ...................................................................................... 1-7

Digital Connections............................................................................................. 1-7

Analog Insert Points ........................................................................................... 1-7

Unbalanced Connections (analog audio) ........................................................... 1-8

Hand Crimp Tool Wiring Instructions.................................................................. 1-9

220 / Oct 2001

INSTALLATION and POWER

page 1 – 2

220 / March 2000

Installation and Power

CountertopMounting

The 220 digital audio console is designed for countertop drop-in

mounting. Console placement should avoid proximity to any electro-

magneticfields,suchaslargepowertransformers,motors,andfluores-

centlightingfixtures.Therequiredcut-outwidthis371/4”andcut-out

front-to-back dimension is 19”. The front of the console will extend

approximatelyoneinchforward ofthe cut-out.The console’swooden

sidepieces will extend about 7/8” on either side of the cut-out width.

Clearances

Note the two module extractor tools (black thumbwheel screws)

mounted in the front surface of console’s lower mainframe pan (just

above and to the left of the righthand headphone jack). These must be

removed before lowering the console into its cutout!

Once in place the console mainframe pan will extend approxi-

mately 5/8 inches below the countertop surface. Note the hinged

meterbridge will require 15” above the countertop surface to open

freely. When fully open the meterbridge will extend 5 1/2” behind the

rear line of the cut-out. When closed, the meterbridge will extend

2 1/4” behind this rear cut-out line and 8 1/8” above the countertop

surface.

Do not connect the 220 console to its power supply (and do not

connect the power supply to the AC power line) until instructed to do

so.

System Ground

The first step is to ground the console.

Note that as supplied from the factory, console rackmount power

supply common, audio ground, and the 220 mainframe are connected

togetherattheconsole,butareNOTconnectedtoelectricalgroundand

the chassis of the power supply. Safety requirements dictate that a

positiveconnectionfromtheconsolemainframetoelectricalgroundbe

!

I N S T A L L A T I O N a nd P OWER

page 1 – 3

220 / March 2000

CONSOLE

2-TRACK

MULTI-TRACK

AC BREAKER

BOX

DEVICE 1

DEVICE 2

DEVICE N

CONSOLE POWER SUPPLY

CONTROL ROOM POWER AMP

STUDIO POWER AMP

OTHER

POWER COMPANY

EARTH GROUND

HEAVY

(#4 or #6)

COPPER

WIRE

HIGH POWER

EQUIPMENT RACK

COPPER ROD

SOIL 3-wire ground or separate wire run from chassis

EFFECTS RACK

MIC PANEL

GND

TYPICAL SYSTEM

GROUNDING SCHEME

etc.

3–5 ft.

Tie the console ground lug

terminal strip to the system

earth ground. Tie every piece

of equipment in the entire

audio system to the console

ground lug terminal strip.

made in the completed installation. Use one of the grounding lugs on

the rear of the mainframe to establish your system ground. The

grounding lug terminal strip may be found at the rear of the console,

along the bottom edge of the mainframe pan directly under the

rightmost mainframe slots (to the lower left if you are looking at the rear

of the console).

The system ground serves two important purposes:

(1) It provides a zero signal reference point for the entire audio system;

(2) It assures safety from electrical shock.

There exist two terms that one encounters in a discussion of ground:

(A) EARTH GROUND, which is usually a heavy copper rod driven into the

soil adjacent to the building (around 6 feet down) or a connection to the copper

water pipes leading into the building. Either is acceptable (unless, of course,

the water pipe is made of plastic).

(B) THE POWER COMPANY EARTH CONDUCTOR that enters the

building at the power line breaker box; this conductor should be (and is often

by code) tied to the above-mentioned earth ground at one point. This point is

the SYSTEM EARTH GROUND.

INSTALLATION and POWER

page 1 – 4

220 / March 2000

TIE THE CONSOLE GROUND LUG TERMINAL STRIP TO THE

SYSTEMEARTHGROUND. TIEEVERYPIECEOFEQUIPMENTIN

THE ENTIRE AUDIO SYSTEM TO THE CONSOLE GROUND LUG

TERMINAL STRIP. If the system earth ground point is inaccessible, tie

the console ground terminal strip to the power company earth conductor

at the main breaker box (see drawing "Typical Grounding Scheme" on

previous page).

Each piece of equipment should be connected by its own ground wire

(usually the round third pin on the AC cord). This means that every AC

outlet must have a separate conductor run to the console ground lug

terminal strip; the outlets cannot be daisy-chained as is normally encoun-

tered in commercial and residential AC systems. Any equipment not

supplied with 3-wire AC cables must have individual ground wires (16

gauge or larger) connected to their chassis grounds and then run to the

console ground lug terminal strip.

Further Grounding Details

Check all equipment to be absolutely certain that each unit is power

transformer isolated from the AC mains to prevent safety hazards.

It is assumed that in each piece of audio equipment the audio ground

and the chassis are tied together at some point. Any piece of equipment

lacking a grounded chassis is likely to be prone to interference problems.

Locateallunbalancedaudio equipment inthesamerack if possible,to

minimize chassis ground potential differences. It may also be helpful to

insulateeachpieceofunbalancedequipmentfromitsmountingrailsinthe

rackbymeansofnylon10-32screwsandinsulatingwashersbetweenrails

and faceplates.

Once the system is properly grounded, proceed with the console

power supply installation and connection (next section).

Power Supply

The 220 console is powered by a Wheatstone Model PSC-D340

rackmount power supply. This heavy duty unit occupies three 19” wide

rack spaces (total height 5-1/4”). Convection cooled, it requires ample

ventilation space above and below it. Do not mount heat generating

devices in the same rack cabinet.

Notethepowersupplyshouldbemountedinanequipmentrackwithin

fifteen feet of the console (but no closer than 3 feet). Avoid locating any

highgainequipment(suchasphonopreamps,taperecorders,etc.)toonear

the rackmount supplies, to avoid magnetic interference into that equip-

ment.

220 / June 2001

Iffailsaferedundantsup-

plieshavebeenordered,

you will be installing two

units and an additional

rackmount panel.

INSTALLATION and POWER

page 1 – 5

220 / March 2000

Oncethesupplyis rackmounted, itshouldbeconnected to theconsole

usingthefactorysuppliedcable.Theconsole’spowersupplyconnectoris

locatedattherearoftheconsole,attherightendofthemeterbridgebottom

pan.Ifyouareusingonesupply,connectittotheconsoleconnector.Ifyou

are using two supplies (failsafe option), connect the long power supply

cabletothecenterconnectoroftherackmountfailsafepanel.Thenconnect

onesupplywithashort cabletoeitherofthe two remainingconnectorson

the failsafe panel and connect the second supply with a short cable to the

lastconnector.Notethatthepowersupplycable’s10-pinfemaleconnector

has to be rotated until its locating pins match the male connector on the

console. Do not force a connector on; it attaches easily when properly

aligned. Connect the cable first to the console, then to the rear of the

rackmount power supply.

Note each power supply is fitted with a 3-wire grounded AC cord that

shouldbe plugged intoa "clean"AC power source. Thatis, anAC source

that feeds only the control room audio gear. This source should be a

separatefeedfromthosepoweringlighting,air-conditioning,oranyother

non-audiomachinery. Thethird pin groundwire of theACsource should

be tied to the central system ground point. Note that while the AC power

cord ground wire terminates at the power supply chassis, it does NOT

connect to the 220 console common; the console itself must be grounded

separately. (See previous section, "System Ground".)

The power feed recom-

mended in the text is of-

teninstalledandreferred

to in studios as an “iso-

lated AC ground” outlet.

It is usually orange in

color.

220 / June 2001

The PSC-D340 Power Supply

HA

ED

I

JB

C

G

F

TYPICAL POWER

CONNECTOR

(10-pin)

A :

B :

C :

D :

E :

F :

G :

H :

I :

J :

audio/phantom common

+V audio

-V audio

digital common

phantom power

digital common

+digital

+digital

n/c

n/c

ON

OFF

+VD1

PHANT

Model PSC-D340 Power Supply

D2

–

V

220 / June 2001

R1

330

.05

R2

.05

R7

Q1

1

23

LM1085

VIN

ADJ

OUT

3

2

1

Q3

LM1085

VIN

ADJ

OUT

1uF

C1

6A4

D1

C7

1uF

1uF

C2

C6

1uF

620

R6

R5

100

1N4002

D3

6A4

D2

R20

1.0K

R14

.05

R19

.05

LM1085

3

2

1

Q5

VIN

ADJ

OUT

1uF

C12

6A4

D14

1uF

C18

1uF

C13

1uF

C17

R15

620

R16

470

1N4002

D12

D13

6A4

R4

47

47

R17

1uF

C4

1uF

C15

WP1

=14V

DC

+

WP17

+7.5V

OUTPUT

TP4 -

WP18

TP2

WP15

WP12

TP4

+

7.5V

TEST

POINT

-

TP3

WP5

=23V

DC

+

WP24

-16V

OUTPUT

WP8 -

WP25

TP8

+

16V

TEST

POINT

-

TP7

NOT

INSTALLED DS5

+16V

LED

DS6

+7.5V

LED

DS3

NOT

INSTALLED

-16V

LED

DS4

+7.5V

LED

2200uF

C26

2200uF

C28

WP19

WP9

WP22

WP20

WP21

WP16

WP26

WP3

WP2

WP7

WP6

R1

1.0K

R2

.05

R7

.05

LM1085

3

2

1

Q1

VIN

ADJ

OUT

LM1085

Q3

1

23

VIN

ADJ

OUT

C1

1uF

D1

6A4

1uF

C7

50V

10000uF

C19

C2

1uF

1uF

C6

R6

620

R5

470

D3

1N4002

6A4

D2

R20

330

.05

R14

.05

R19

Q5

1

23

LM1085

VIN

ADJ

OUT

C12

1uF

D14

6A4

C18

1uF

C13

1uF

C17

1uF

R15

330

R16

100

D13

6A4

47

R4

C4

1uF

C15

1uF CR3 1

2

3

500

+7.5V

TRIM

WP1

=23V

DC

WP17

+

+16V

OUTPUT

TP4

WP18

-

TP1

TP2

WP15

WP12

TP4

+

16V

TEST

POINT

-

TP3

WP5

=14V

DC

WP24

+

+7.5V

OUTPUT

WP8

WP25

-

TP8

+

7.5V

TEST

POINT

-

TP7

DS5

+16V

LED

DS3

-16V

LED

DS4

+7.5V

LED

2200uF

C26

2200uF

C28

WP19

WP9

WP22

WP20

WP21

WP16

WP26

WP3

WP2

WP7

WP10

WP11

82V

82ZA2

V1

100V

470uF

C21

D4

1N4002

D7

1N4002

D5

1N4002

D6

1N4002

D10

1N4002

10K

CR2

3

2

1

+40V

TRIM

63V

10uF

C22 C11

10uF

63V

0.0047uF

C8

0.0047uF

C10

D8

1N4002

LM317

Q4

1

23

VIN

ADJ

OUT

220

R10

R9

470

R8

100K

D9

1N4002

SW1

PHANTOM

POWER ON

DIP SWITCH

1

2

3

4

D11

1N4002

WP23

+

+40V

OUTPUT

WP14

-

WP13

R11

10K

R12

10K

R13

10K

TP6

+

4OV

TEST

POINT

-

TP5

DS1

+40V

LED

DS2

NOT

INSTALLED

+40V

LED

TP1

F1

.4A

POLYSW

10uF

63V

C9

WP6

50V

10000uF

C23

Q7

3

2

1LM1085

VIN

ADJ

OUT

R17

47

D12

1N4002

NOT

INSTALLED

DS6

+7.5V

LED

500

CR1

3

2

1

+16V

TRIM

LM1085

1

23

Q7

VIN

ADJ

OUT

C19

10000uF

50V

C23

10000uF

50V

500 3

2

1

CR3

CR1 1

2

3

500

600 Industrial Drive

New Bern, NC 28562

C27

0.47uF

GRAY

BLACK

WHT/BLK

WHT/BLK

BRN FDIGITAL

COMMON-2

ORG G+DIG-2

PHANTOM

E

VIO

-V AUDIO

BLU C

+V AUDIO

RED B

Z15L390

GRN

N/C

J

IN/C

BLACK

Z15L390

RED

BLUE

RED

ORANGE

VIOLET

ORANGE

WHITE

BROWN

BROWN

Z15L390Z15L390Z15L390Z15L390Z15L390

MB3510

+

-

~

~

MB3510

+

-

~

~

MB3510

+

-

~

~

D

GRN DIGITAL

COMMON-1

YLW H+DIG-1

AGND

AGND

AGND

GND

GND

LM1085/LM317

IC PINOUT

VIEWED FROM BOTTOM

(SOLDER SIDE)

12

3

IN

ADJ

OUT

CASE

Z15L390

MB3510

+

-

~

~

AUDIO

COMMON

BLK A

H) +DIGITAL-1

G) +DIGITAL-2

F) DIGITAL COMMON-2

D) DIGITAL COMMON-1

J) N/C

C) -V AUDIO

B) +V AUDIO

E) +PHANTOM

I) N/C

POWER SUPPLY CONNECTOR

A) AUDIO/PHANTOM COMMON

J

I

H

G

F

ED

C

B

A

.0047uF

115 OR 230 VAC

50-60Hz INPUT

A.C.

SUPPLY

CABLE

.0047uF

GRN

ORAGEBLACK

8-31-01

RD-12/Aug 2001

PS-410E PCB

00S0023E

Page 85

Power Supply Schematic - Sheet 1 of 1

W# 700259

SA

PSC-D340

7 OF 7

ISSUED

CHECKED

DRAWN

APPROVALS DATE

CONTRACT NO.

SCALE

FSCM NO. DWG. NO.

SHEET

SIZE REV

D

2

1

2

3

4

5

6

7

88

7

6

5

4

3

1

ABCD

DC

B

A

WHITEYELLOW

NOT

INSTALLED

NOT

INSTALLED

+48V

~

~

+

-

+

-

+

-

-

+

~19V

~19V

~19V

~19V

~11V

~11V

~22VAC CT

~11V

~11V

~42VAC

~115VAC

~36VAC CT

~36VAC CT

STATIC

SHIELD

10 PIN

OUTPUT

CONNECTOR

~22VAC CT

5A 1

2

3

4

For 220-240 V operatin:

Disconnect 1 & 3, 2 & 4;

Connect 2 & 3.

-16V

TRIM

PS-410 PCB

(LEFT)

PS-410 PCB

(RIGHT)

INSTALLATION and POWER

page 1 – 6

220 / March 2000

Failsafe Dual Redundant Supply

Wheatstone failsafe power supply systems use two separate rack-

mount power supplies for each piece of powered equipment. Though

either is capable of running a full load on its own, in failsafe operation

both units run in tandem: if one fails, the other takes over, assuring

uninterrupted operation.

NOTEdual failsafesupplieshavetheiroutputstrimmedtoentirely

different settings than stand-alone single units, and are MEANT to be

run in tandem.

In order for failsafe systems to perform as designed, always have

BOTH rackmount supplies powered up and connected to their associ-

ated equipment.

Energizing

Assuming the 220 console mainframe is properly placed and

grounded,anditsPSC-D340powersupplycorrectlyrackmountedand

connected to the console, you may now energize the PSC-D340

rackmountpowersupply by pluggingitinto theACmains and turning

iton,usingitsfrontpanelcircuitbreaker/switch. ThefiveLEDsonthe

power supply front panel should light up to indicate the presence of

theirrespectivevoltages.Theconsole'sVU meters willilluminateand

individual module switches will assume factory default settings.

Once you have verified proper power-up, turn off the rackmountOnce you have verified proper power-up, turn off the rackmount

Once you have verified proper power-up, turn off the rackmountOnce you have verified proper power-up, turn off the rackmount

Once you have verified proper power-up, turn off the rackmount

power supply to de-energize the console. You may now proceed topower supply to de-energize the console. You may now proceed to

power supply to de-energize the console. You may now proceed topower supply to de-energize the console. You may now proceed to

power supply to de-energize the console. You may now proceed to

wire up audio and control connections.wire up audio and control connections.

wire up audio and control connections.wire up audio and control connections.

wire up audio and control connections.

220 / June 2001

INSTALLATION and POWER

page 1 – 7

220 / March 2000

Audio and Control Wiring

Allaudioandcontrol I/O connectionstothe 220 consolearemade through

multipin DB-25 (or in the case of the OMD-220 Digital Control Ports, a DB-

15) connectors located on the top of the each module.

ConnectionProcedures

As supplied from the factory, the console requires no logic connections to

function. Therefore an orderly installation begins with the audio wiring. Note

this manual is organized by module type (inputs, outputs, monitor modules,

etc.); each chapter contains detailed wiring instructions for its module type.

Proceed through the manual, chapter by chapter, until all modules have been

wired to suit your particular installation requirements. Once proper audio

operation is verified, go back to each individual chapter and proceed with

control wiring.

Digital Audio Connections

CABLE - All AES/EBU input and output digital audio connections are

balanced and should be made using a high quality digital audio cable. Be sure

toselectadigitalaudiocablewithanintegraldrainwireofthesamewiregauge

(AWG) as the twisted pair. Typical AES/EBU digital audio cable has a very

lowcharacteristiccapacitanceperft(pF/ft),andanominalimpedanceof110Ω.

Highquality digital audiocable offersbetter signaltransmission performance

versus typical analog audio cable, especially over long cable runs. Check the

cablemanufactures data sheet to be sure the cableyou plan touse will work in

your application.

CONNECTORS - All AES/EBU connections are made with the supplied

DB-25 male mating connectors. These crimp style connectors are the insula-

tion displacement type and will accept wire gauge 24 - 28AWG.

SPDIF INPUTS - The SPDIF (Sony/Philips Digital Interface) or “con-

sumer” digital audio interface is a two wire unbalanced signal typically on a

single RCA style connector. To connect SPDIF devices to the 220 console

simplywiretheSPDIFcenterconductor(HOT)totheIND-220“HI”inputpin

and SPDIF shell (ground) to the IND-220 “LO” input. Connect the IND-220

“SHIELD” at the console end only.

Analog Insert Points

Certain module signals have insert patch points in their signal chains to

allowoutboard audioprocessing. These include MONO MIC INPUTS (IND-

220).

Normally these points are internally bridged at the factory (via PCB-

mounted programming jumpers) prior to shipment. If you intend to use

outboard signal loops at these points, you must reprogram these jumpers. See

pages 2-3 (mic inputs).

INSTALLATION and POWER

page 1 – 8

220 / March 2000

Unbalanced Connections (analog audio)

ANALOG INPUTS — Wire to the console with typical shielded

twoconductorcable(likeBelden9451),justasifyouwereconnecting

abalancedsource.Attheunbalancedsourcemachine’soutput,connect

theblackwire(LOW)totheshield.Ifthemachinehasa-10dBuoutput,

don’t hesitate to turn module input gain as high as is needed.

ANALOG OUTPUTS — 220 consoles use a balanced output

circuit which behaves exactly like the secondary of a high-quality

transformer, with no center tap—this output is both balanced and

floating.EithertheHIGHorLOWsideoftheoutputshouldbestrapped

to ground, with the output taken from the other side. (Normally you’d

strap LOW to ground, and take HIGH to feed your unbalanced

equipment.)

INSTALLATION and POWER

page 1 – 9

220 / March 2000

(2) The terminal conductor tabs with stripped wire

are placed in anvil 26-28.

HAND CRIMP TOOL WIRING INSTRUCTIONS

The supplied hand crimping tool (W/S#850068) is used for all I/O wiring

connections to and from the console. It is to be used with the supplied pin

(figure 1) intended for 24"-28" gauge wire.

1) Strip wire approximately 3/16" (insert in

proper wire stripper, rotate one half turn, and

pull insulation off wire).

2) Insert wire into terminal until wire

insulation is stopped by conductor tabs, and

place the conductor tabs on the anvil marked

as 26-28 (figure 2).

3) CRIMP by squeezing handles until jaws

are fully closed to secure wire in the terminal

(figure 3).

4) If there is an insertion error or if a

circuit change is needed, you'll need to use

the supplied pin extractor tool (W/S#850069)

to remove terminals, and correct your mistake

without having to sacrifice a connector. Place

extractor tip (red side) over pin terminal to be

removed (figure 4), and press it downwards

motion until tip rests upon Housing. Then

pull out the pin terminal from Housing. It

should never be necessary to discard a con-

nector due to a wiring error.

Note that metallized plastic hoods for

each connector are also supplied with the

console.

(3) Jaws fully closed; the insulation tabs have

been crimped.

(1) Pin crimp terminal

CONDUCTOR

TABS

INSULATION

TABS

INSULATION

STOPS HERE

(4) Place extractor tip over pin terminal to be

removed.

page 2 – 1

220 / March 2000

INPUT MODULE

Input Module (IND-220)

Chapter Contents

Module Overview........................................................................ 2-2

Internal Programming Options ................................................. 2-3

Insert Bypass .......................................................................................................... 2-3

Phantom Power ...................................................................................................... 2-3

Talkback.................................................................................................................. 2-3

VDT Programming Options ....................................................... 2-4

Hook-ups..................................................................................... 2-4

Microphone Inputs ................................................................... 2-4

AUDIO CONNECTIONS..................................................................................... 2-4

CONTROL CONNECTIONS .............................................................................. 2-4

Remote ON & OFF ........................................................................................... 2-5

Cough ............................................................................................................... 2-5

Talkback to Control Room................................................................................ 2-5

On Tally ............................................................................................................ 2-5

Off Tally ............................................................................................................ 2-6

Tally B ............................................................................................................... 2-6

Stereo Line Analog Inputs....................................................... 2-6

AUDIO CONNECTIONS..................................................................................... 2-6

Stereo Line Digital Inputs........................................................ 2-6

AUDIO CONNECTIONS..................................................................................... 2-6

CONTROL CONNECTIONS .............................................................................. 2-7

Remote ON & OFF ........................................................................................... 2-7

External START & STOP ................................................................................. 2-7

Ready ............................................................................................................... 2-8

Tally B ............................................................................................................... 2-8

DB Connector Pinout Drawings

Mono Mic Inputs ..................................................................................................... 2-9

Stereo Line Analog Inputs .................................................................................... 2-10

Stereo Line Digital Inputs ..................................................................................... 2-11

Mono Mic Input Signal Flow Diagram .................................... 2-12

Stereo Line Input Signal Flow Diagram ................................. 2-13

220 / Sep 2000

page 2 – 2

220 / March 2000

INPUT MODULE

Input Module (IND-220)

Module Overview

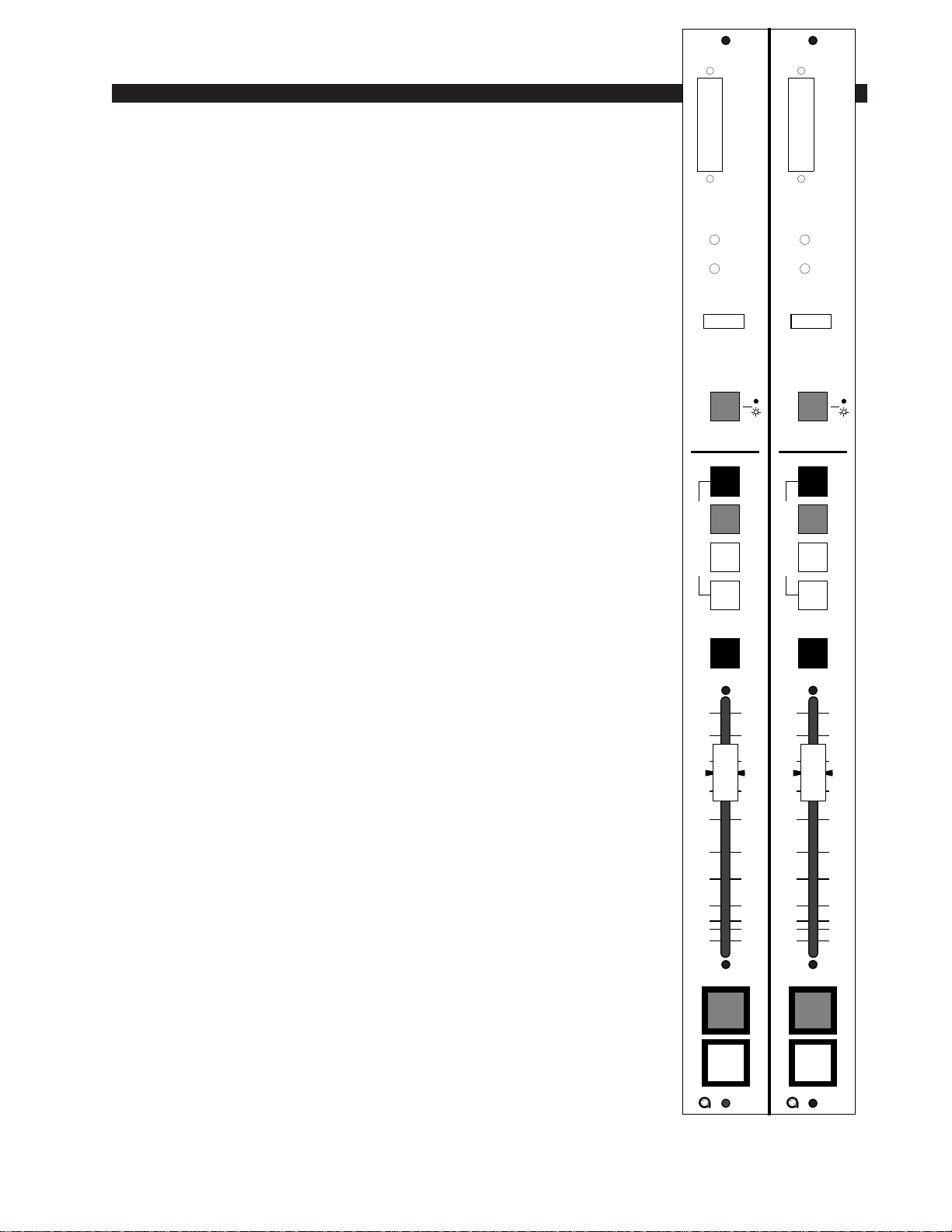

The IND-220 is a dual input module with double wide faceplate,

and having one main PCB card. Depending on the type of input

signals the module will handle, it will also have any combination of

twopiggybackcardsformonomicrophone(-50dBunominal),stereo

line analog, or stereo line digital inputs. Each section of the dual

module accepts two sources, A and B, switched at the top of the

module.

IND-220 modules are for microphone input signals (-50dBu

nominal) and for stereo line input signals. Each module accepts two

mono/stereo sources: A and B, switched at the top of the module.

They are available in three different versions: mono microphone

inputs, analog stereo line inputs and digital stereo line inputs.

The mono version uses an MMADC-220 piggyback card at the

input stage of the module. Phantom power is available at both input

ports; it may be selectively activated by an internal jumper (the

factory default is OFF). Recessed front panel multi-turn trimpots

(range 38dB) adjust the level of the A and B inputs independently.

Example: with a microphone input of –60dBm @150Ωat the port,

gain trim can set levels from -22dBu to +16dBu (note maximum preamp

gain is +76dB).

An insert point (+4dBu balanced) is provided: it is post-trim and

may be internally bypassed, which is the factory default setting.

TheADC(analog-to-digitalconverter)versionusesanSLADC-

220 piggyback card at the input stage of the module, and accepts

+4dBu balanced analog input signals. Recessed front panel multi-

turn trimpots adjust the left and right levels..

The SRC (sample rate converter) version uses an SRC-220

piggyback card at the input stage of the module, and accepts digital

(AES is factory default) input signals.

Output switches assign the selected source signal to any combi-

nation of the console’s four stereo outputs: PGM (program), AUD

(audition), AUX (auxiliary) and/or UTL (utility).

Level is set by a long-throw fader.

The channel ON and OFF switches are at the bottom of the

module. In addition to being controlled remotely, these can also be

programmed (via VDIP program) to perform a variety of console

control functions, including activating control room and studio

mutes, talkbacks, external tallies, and timer restart.

All audio and control input and output signals are made via a

multi-pin DB-25 connector mounted on the top of each individual

module and located underneath the hinged meterbridge.

0

5

10

15

20

30

40

50

70

60

00

0

5

10

15

20

30

40

50

70

60

00

IND IND

CUE CUE

P

G

M

A

U

D

U

T

L

A

U

X

A

S

S

I

G

N

A

S

S

I

G

N

P

G

M

A

U

D

U

T

L

A

U

X

START

A

B

A

B

O

N

O

F

F

O

N

O

F

F

MIC IN

LINE IN

DIG IN

MIC IN

LINE IN

DIG IN

I/O I/O

MIC / LINE TRIM

M1 / LT

M2 / RT

MIC / LINE TRIM

M1 / LT

M2 / RT

W# 026000AW# 026000A

MODULE TYPE MODULE TYPE

Table of contents

Other Auditronics Recording Equipment manuals

Popular Recording Equipment manuals by other brands

Behringer

Behringer POWERPLAY 16 P16-D quick start guide

Harman Kardon

Harman Kardon CDR 25 Preliminary service manual

ESD

ESD CPCI-CAN/331 Hardware installation and technical data

Monacor

Monacor DMR-1608A instruction manual

Klein Tools

Klein Tools VDV500-063 Toner-Pro instruction manual

Singular Sound

Singular Sound MIDI Maestro manual