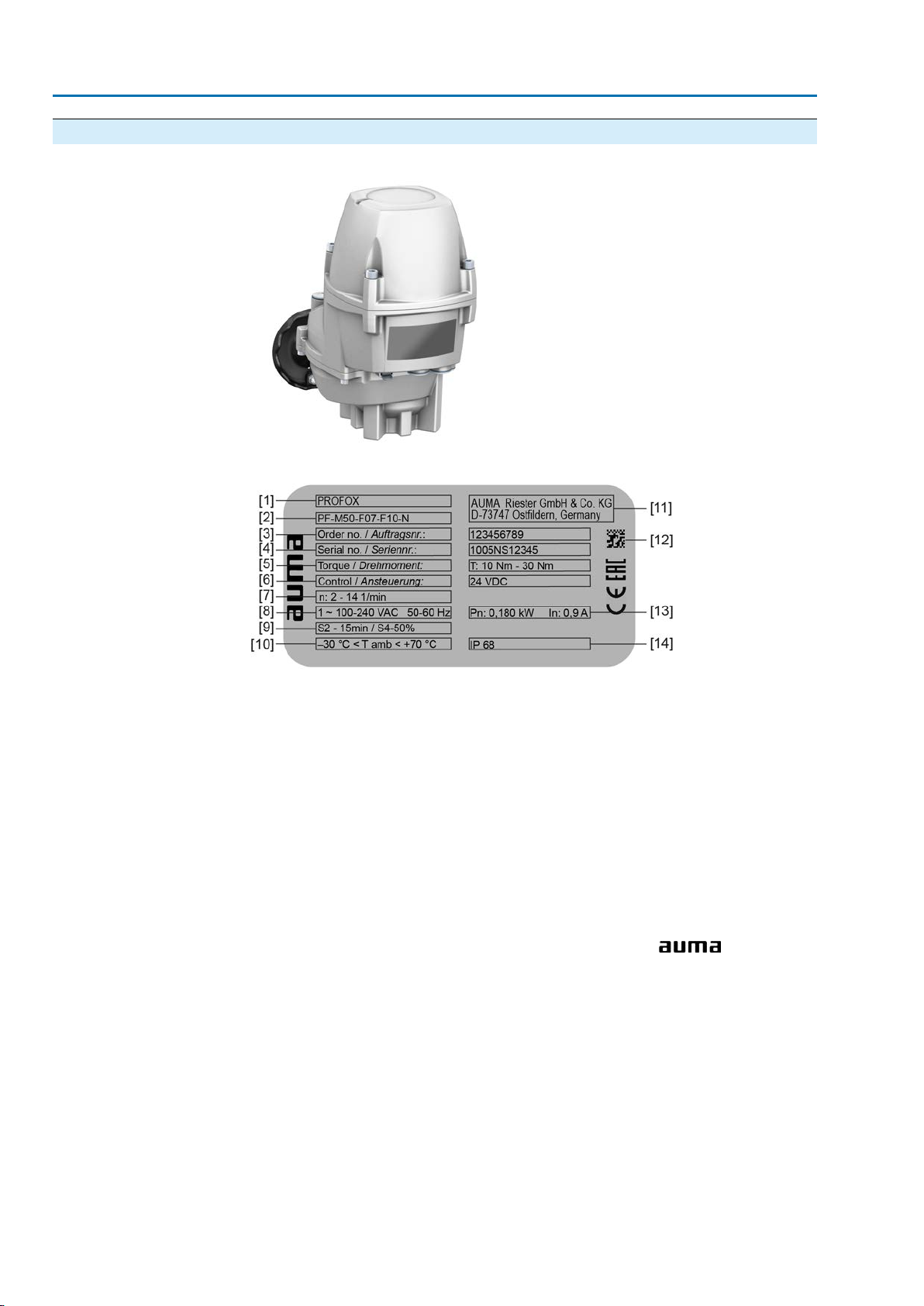

AUMA PROFOX PF-M25 User manual

Other manuals for PROFOX PF-M25

2

This manual suits for next models

3

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SEVEN 2SA7 Instruction manual

AUMA

AUMA SG 03.3 Series User manual

AUMA

AUMA NORM Series User manual

AUMA

AUMA SAEx 25.1 User manual

AUMA

AUMA PF-M25 Series Manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA VARIOMATIC SARV 10.1 User manual

AUMA

AUMA TIGRON TR-M30X Manual

AUMA

AUMA SQVEx 05.2 User manual

AUMA

AUMA SAEx 07.2-UW User manual

AUMA

AUMA SAE 07.2 Series Training manual

AUMA

AUMA PROFOX PF-M25X User manual

AUMA

AUMA AMB 01.1 User manual

AUMA

AUMA SA-UW User manual

AUMA

AUMA AUMATIC AC 01.2 User manual

AUMA

AUMA SVCR 05.1 User manual

AUMA

AUMA SAN 07.1 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA TIGRON TR-M30X User manual

Popular Controllers manuals by other brands

BFT

BFT deimos ultra bt a 400 Installation and user manual

Brooks Instrument

Brooks Instrument GF100 Series Installation & operation manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO HC-KF Series instruction manual

GSI Group

GSI Group PNEG-1405 installation manual

Zamel

Zamel Extra Free RZB-02 manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA CON 100 - REV 1.1 instruction manual

Murphy

Murphy Automatic Engine Controller AS3000 Specification sheet

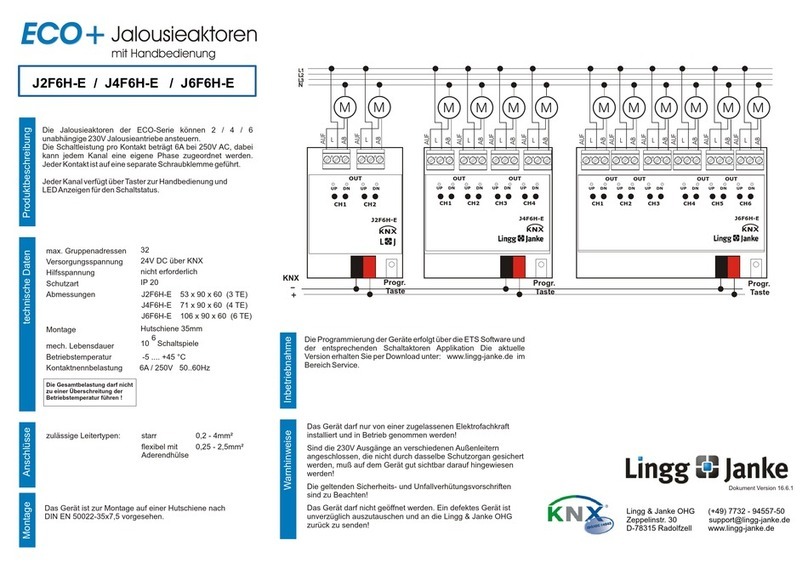

Lingg & Janke

Lingg & Janke ECO+ J2F6H-E manual

RadioMaster

RadioMaster BOXER quick start guide

TRACK STAR

TRACK STAR 1/5 Brushless Sensorless Car ESC instruction manual

Flex-a-Lite

Flex-a-Lite 31165 installation instructions

Johnson Controls

Johnson Controls F4-CG Series installation guide