AUMA PF-M25 Series Manual

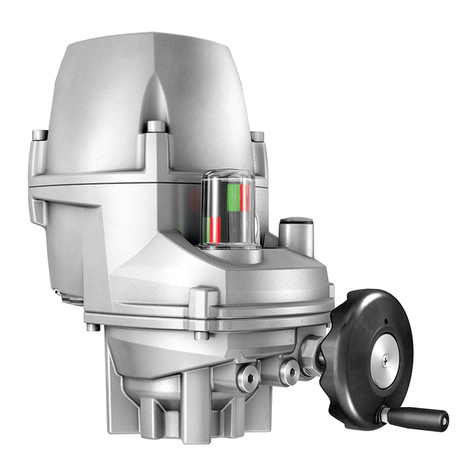

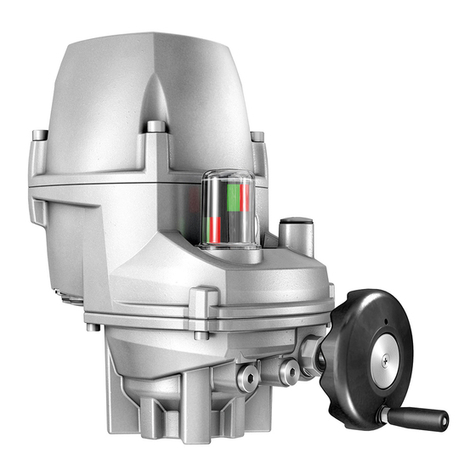

PROFOX actuators

PF-M25(X) –PF-M100(X)

PF-Q80(X) –PF-Q600(X)

Profibus DP

Use short instructions in combination with operation instructions only!

These short instructions are only complete with the respective operation instructions of the

actuator.Safety and warning instructions contained in the actuator operation instructions must

be heeded when performing work on the actuator!

Fieldbus connectionShort instructions

Table of contents Page

31. Basic information on fieldbus connection...........................................................................

42. Cable connection...................................................................................................................

73. Connect fieldbus cables........................................................................................................

94. Parameter (Profibus DP)........................................................................................................

105. Technical data......................................................................................................................... 105.1. PROFOX Profibus DP

2

Table of contents

1. Basic information on fieldbus connection

Electrical connection The actuator cover must be opened to allow connection of the fieldbus cables.

Refer to actuator operation instructions, “Electrical connection”chapter.

The “Electrical connection”chapter of the operation instructions fully applies

to the connection of the fieldbus cables.It is imperative to heed the safety and

warning instructions of this chapter in particular.

Fieldbus cable Table 1:

Cable recommendation

Only cables complying with IEC 61158 or IEC 61784, cable type A, may be used for Profibus DP wiring.

135to 165Ohm, ata measurementfrequency between3and 20MHzImpedance

< 30 pF per metreCable capacity

> 0.64 mmWire diameter

> 0.34 mm², corresponds to AWG 22Cross section

< 110 Ohm per kmLoop resistance

CU shielding braid or shielding braid and shielding foilScreening

Prior to installation, please note:

●Connect maximum 32 devices to one segment.

●If more devices are to be connected:

- Allot devices to different segments.

- Connect segments using repeaters.

●Install fieldbus cables at a distance of minimum 20 cm to other cables.

●If possible, fieldbus cables should be laid in a separate, conductive, and earthed

cable tray.

●Ensure absence of equipotential earth bonding differences between the indi-

vidual devices at fieldbus (perform an equipotential earth bonding).

1,500500187.5≥93.75Baud rate [kbit/s]

2004001,0001,200Maximum segment length [m]

3

Basic information on fieldbus connection

2. Cable connection

Cable arrangement

Cable arrangement depends on the number of cables connected in addition to the

mains cable.There are two options:

Figure 1: Cable arrangement

[1] Cable arrangement for one mains cable and one fieldbus cable

[2] Cable arrangement for a mains cable, a fieldbus cable and a signal cable

For better accessibility, we recommend heeding the following order.

1. If a signal cable is connected in addition to the fieldbus cable:Insert signal cable

into cable gland on the right and push upward until the cable is visible.

2. Insert fieldbus cables through middle cable gland and push upward until the

cable is visible.

3. Insert mains cable into cable gland on the left and also push upward until the

cable is visible.

4. Remove cable sheathing.

5. Strip wires.

→Controls approx. 6 mm, power supply unit approx. 10 mm

6. For flexible cables:Use wire end sleeves according to DIN 46228.

4

Cable connection

Protective earth connection

In case of a fault, electric shock due to presence of hazardous voltage if the

PE conductor is NOT connected!

Risk of death or serious injury!

→Connect all protective earth conductors.

→Connect PE connection to external protective earth conductor of connecting

cables.

→Start running the device only after having connected the protective earth con-

ductor.

7. Fasten PE using spade lugs or wire end sleeves at protective earth connection

( ) as shown.Do not completely loosen screw!

Figure 2: Protective earth connection (example)

Table 2:

Terminal cross sections and tightening torques of PE connection

Tightening torquesTerminal cross sectionsDesignation

3 –4 NmStandard version:1.0 –6 mm2(flexible)

via spade lug or wire end sleeve

Explosion-proof version:1.0 –2.5 mm2

(flexible) via spade lug or wire end sleeve

1.5 –2.5 mm2(flexible) directly

Standard version:1.5 –6 mm2(rigid)

directly

Explosion-proof version:1.5 –2.5 mm2

(rigid) directly

Protective earth connection (PE)

Connection of mains and signal cables

8. Connect mains cable according to order-related wiring diagram.

Table 3:

Terminal cross sections

Cross sectionWire typeDesignation

max [mm²]min [mm²]

2.50.08rigid/flexibleMains cable

AWG 12AWG 28AWG

5

Cable connection

9. Connect signal cables in push-in technology according to order-related wiring

diagram.

Information: Only required if a signal cable is to be connected in addition to

the fieldbus cable.

Damage to push-in terminals by jamming of wire end sleeves with the housing!

Replacement of the complete component is required.

→Use wire end sleeves with smooth surface.

→Always press the push-in terminals completely down using a screwdriver and

always carefully remove signal cables.

→It must be possible to pull out the signal cable without resistance when the push-

in terminal held down.

Information: To avoid unevenness at wire end sleeve, AUMA recommends

using the Crimpfox 6 model by Phoenix Contact as suitable crimping pliers.

Figure 3: Connect signal cables

Table 4:

Terminal cross sections

Cross sectionWire typeDesignation

max [mm²]min [mm²]

1.50.2solidI/O signal cable

1.50.2flexible

1.50.2flexible with wire end

sleeve without plastic

sleeve

AWG 16AWG 24AWG

10. Connect fieldbus cables.

Refer to subsequent chapter!

6

Cable connection

3. Connect fieldbus cables

If a PROFOX actuator is part of a complete line or loop topology,the connexion

remains continuous even if the actuator is without power or defective.

1. Observe characteristics of topology used.

Figure 4: Structure for line topology

further fieldbus devices will follow□

last fieldbus device, termination must be activ-

ated

■

from the previous device↑

to the next device↓

In case of a fault, electric shock due to presence of hazardous voltage if the

PE conductor is NOT connected!

Risk of death or serious injury!

→Connect all protective earth conductors.

→Connect PE connection to external protective earth conductor of connecting

cables.

→Start running the device only after having connected the protective earth con-

ductor.

2. Strip fieldbus cables.

7

Connect fieldbus cables

Shield connection 3. Remove fieldbus cable shield at a short section as shown and connect to shield

connection. Ensure absence of electrical contact to the terminal.

Information: If the cables are too thin to be clamped, fold over the shielding

and clamp it underneath.

Information: Strain relieve must always be made via cable glands.For this,

the shielding connection may not be used.

Figure 5: Shield connection

Fieldbus cables 4. Connect fieldbus cables:Connect green wires with green terminal and red wires

with red terminal.

Table 5:

Terminal cross sections

Cross sectionWire typeDesignation

max. [mm²]min. [mm²]

1.50.5solidFieldbus cables

1.50.5flexible

1.00.5flexible with wire end

sleeve without plastic

sleeve

AWG 16AWG 20AWG

Bus termination 5. If the actuator is the last fieldbus device within the fieldbus segment:Activate

parameteror functionPRM_5559 Bus termination channel 1 via AUMAAssistant

App or AUMA CDT software.

Information: As soon as the bus termination is active, the connection to the

next fieldbus device is automatically interrupted to avoid multiple terminations.

The bus termination is deactivated when leaving the factory.

6. If the PE conductor has been removed from the cover, it must be tightened

applying 2.2 Nm tightening torque prior to re-placing the cover.

7. Fasten cable glands with the torque as specified by the manufacturer to ensure

respect of required enclosure protection.

8. Connect power supply.

If the end position setting is carried out with the internal operation buttons

following the connection to the power supply: Do not close cover!

8

Connect fieldbus cables

4. Parameter (Profibus DP)

Signals

Feedback signals via fieldbus are defined by the GSD file.

Information If required, download the GSD file (General Station Description) from the Internet:

www.auma.com

Refer to Technical data of the actuator for the Profibus DP ident no.

Fieldbus address (Slave address)

Via AUMA Assistant App or AUMA CDT software:

DIS_53 Configuration

DIS_600 Profibus

PRM_1321 DP1 slave address

Default value: 126

Setting range: 0 ... 126

For information on the feedback signals via fieldbus and the configuration of the

parameters via fieldbus interface, refer to Manual “PROFOX Device integration

Profibus DP”.

Information Profibus DP address setting is carried out via parameter (AUMA CDT software or

AUMA Assistant App)

Change-over between fieldbus control and OPEN-CLOSE via I/O signals (for

actuators with fieldbus interface)

As standard, the actuator is supplied with fieldbus and binary signals.A digital input

is used to define which source is active, this means whether the actuator is controlled

via fieldbus or via I/O signals. It is not possible to use both sources to active

simultaneously.The PRM_926 Signal DIN 3 signal is assigned to PZD_275 I/O

interface as factory setting:

Not live (= 0V) means that control is made from REMOTE via fieldbus.

Live (= 24V) means that control is made from REMOTE via binary I/O signals.

Commands for the operation function:

OPEN-CLOSE operation commands can be issued via fieldbus or a setpoint can be

sent for any position.Change-over is made via the PZD_332 Fieldbus SETPOINT

command.

●Setpoint control:

Fieldbus SETPOINT command bit = 1 = REMOTE SETPOINT

The actuator reacts to the setpoint E1 transmitted via the fieldbus.

●OPEN-CLOSE control:

Fieldbus SETPOINT command bit = 0 = REMOTE OPEN-CLOSE

Actuator can be operated via Fieldbus OPEN/Fieldbus CLOSE command bits

in direction OPEN or CLOSE.

For further information on these parameters as well as on other settings,refer

to the Manual PROFOX “Parameters and functions”.

9

Parameter (Profibus DP)

5. Technical data

Information The following tables include standard and optional features.For detailed information

on the customer-specific version, refer to the order-related data sheet.The technical

data sheet can be downloaded from the Internet in both German and English at ht-

tp://www.auma.com (please state the order number).

5.1. PROFOX Profibus DP

Setting/programming the Profibus DP interface

Automatic baud rate recognitionBaud rate setting

The setting of the Profibus DP address is made via parameters using the AUMA Software CDT or AUMA

Assistant App.

Setting the Profibus DP interface

Commands and signals of the Profibus DP interface

OPEN, STOP, CLOSE, position setpoint, RESET, EMERGENCY operation commandProcess representation output

(command signals)

●End positions OPEN, CLOSED

●Actual position value

●Selector in position LOCAL/REMOTE/OFF

●Torque switches OPEN, CLOSED

●Limit switches OPEN, CLOSE

Process representation input

(feedback signals)

●Torque switch tripped in mid-travelProcess representation input

(fault signal)

The behaviour of the actuator is programmable:

●Stop at current position

●Execute operation to end positions OPEN and CLOSED

●Travel to any intermediate position

●Execute last received operation command

Behaviouron lossof communication

General Profibus DP interface data

Profibus DP according to IEC 61158 and IEC 61784-1Communication protocol

Line (fieldbus) structure.When using repeaters, tree structures can also be implemented. If a unit fails,

communication in the line is still maintained.

Network topology

Twisted, screened copper cable according to IEC 61158Transmission medium

EIA-485 (RS485)Fieldbus interface

●Baud rate and maximum cable length (segment length) without repeater:

-between 9.6 and 93.75 kbit/s: 1,200 m

-for 187.5 kbit/s:1,000 m

-for 500 kbit/s:400 m

-for 1,500 kbit/s:200 m

●Baud rate and possible cable length with repeater (total network cable length):

-between 9.6 and 93.75 kbit/s: approx. 10 km

-for 187.5 kbit/s:approx.10 km

-for 500 kbit/s:approx.4 km

-for 1,500 kbit/s:approx.2 km

Transmission rate/cable length

●DP master class 1, e.g.central controllers such as PLC, PC,.

●DP master class 2, e.g.parts programming/configuration tools

●DP slave, e.g. devices with digital and/or analogue inputs/outputs such as actuators, sensors

Device type

32 devices without repeater, with repeater expandable to 126Number of devices

●Token-passing between masters and polling for slaves

●Mono-master or multi-master systems are possible.

Bus access

Cyclic data exchange, sync mode, freeze mode, fail safe modeSupported fieldbus functions

0x1146. Standard applications with Profibus DP-V0 and DP-V1Profibus DP ident no.

10

Technical data

11

AUMA Riester GmbH & Co. KG

P.O. Box 1362

DE 79373 Muellheim

Tel +49 7631 809 - 0

Fax +49 7631 809 - 1250

www.auma.com

Y009.651/003/en/1.22

For detailed information on AUMA products, refer to the Internet: www.auma.com

This manual suits for next models

11

Table of contents

Other AUMA Controllers manuals

AUMA

AUMA SG 05.1-FA07 User manual

AUMA

AUMA SA 25.1 User manual

AUMA

AUMA SAN 07.1 User manual

AUMA

AUMA SAI 07.2 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SGM Series User manual

AUMA

AUMA SQ 05.2 User manual

AUMA

AUMA PROFOX PF-Q80 User manual

AUMA

AUMA AMB 01.1 User manual

AUMA

AUMA SAExC Series User manual

AUMA

AUMA NORM SQ 05.2 Administrator Guide

AUMA

AUMA PROFOX PF-M25 User manual

AUMA

AUMA SAVEx 07.2 User manual

AUMA

AUMA AM 01.1 Manual

AUMA

AUMA SQVEx 05.2 User manual

AUMA

AUMA SAVEx Series User manual

AUMA

AUMA SA 48.1 User manual

AUMA

AUMA SAEx 07.2 User manual

AUMA

AUMA SG 03.3 User manual

AUMA

AUMA SG 05.1-F05 User manual