Aumuller EMB 7300 Guide

EMB 7300 Radio RWa SyStEM

Instructions for

installation and commissioning

2

Installation Instruction

Radio RWA System

Contents

08

07

06

05

04

03

02

01

Abbreviations

Warning and Safety symbols

Target groups, Intended use

Safety Instructions, Directives and Standards

Data Sheet for EMB 7300 Radio RWA System

Installation of the EMB 7300 Radio RWA System

Storage and Disassembly

Disposal

Warranty and Customer Service

Liability

Certicate

3 - 6

7

8 - 10

11 - 14

3

Installation Instruction

Radio RWA System

aBBREviationS

01

Preliminary remarks

Scale Units

°C Degree Celsius

A Ampere

Ah Ampere hour

kg Kilogramme

m Metre

min Minute

mm Millimetre

s Seconds

V Volt

VE (PU) Packaging Unit

Vpp Residual Ripple (Voltage peak-to-peak)

W Watts

Ω / k Ω Ohm / Kilo-Ohm

General Symbols

AC Alternating Current (50Hz / 60Hz)

DC Direct Current

I Electric Current

L Length

ME Module Space Unit (1 ME = 23 mm)

NC Contact „closed“ (normally closed)

NO Contact „opened“ (normally opened)

P Electric Power

R Electrical Resistance

U Electric voltage

Um Change-over switch

Colour Codes according to IEC 60757

BK black GY grey VT violet

BN brown OG orange WH white

BU blue PK pink YE yellow

GN green RD red

Index of abbreviations

The following abbreviations are used throughout these instructions.

All units of measurement in the instructions are in mm, unless otherwise

stated. General tolerances according to DIN ISO 2768-m.

aP Surface mounted

WxHxD Width x Height x Depth

CAN CAN-BUS

CM Control-Module

COM Common connection

DIN German Institute for Standardisation

DM Drive-Module

EN European Standard

IN Input

LON Local Operating Network

OUT Output

PG Price group

PM Power-Module

PS Power supply

RM6 Relay-Module

RWA Smoke and heat exhaust

SM Sensor-Module

uP Flush mounted

WM Weather-Module

WRG Wind direction transmitter

WaRning and SafEty SyMBolS in thESE inStRuctionS:

The symbols used in the instructions must be strictly observed and have the following meanings:

Failure to comply with these warnings may result

in permanent injury or death.

Failure to comply with these warnings may result

in permanent injury or death.

Failure to comply with these warnings may result

in minor or moderate (reversible) injuries.

Failure to comply with these notes may result in

property damage.

!

WaRning

!

dangER

!

caution

notE

Useful Note

for optimal installation.

Note regarding system conguration

setting options via the „Alpha“ conguration

software.

USB

Caution / Warning

Danger from electric current.

Attention / Warning

Risk of damage / destruction of Control Units, drives and

/ or windows.

!

4

Installation Instruction

Radio RWA System

These instructions are intended for qualied personnel

trained in electrical engineering and skilled operators

of systems for natural smoke ventilation (NRA / RWA)

(natural smoke exhaust / smoke and heat exhaust) and

for natural ventilation via windows, who have knowledge

of the operating modes and residual risks of the system.

This device is not intended for use by

persons (including children) with limited

physical, sensory or mental abilities or

lack of experience and/or knowledge.

taRgEt gRoup

!

WaRning

By connecting the window drives with a

control device and commissioning them,

the installer of the entire system becomes

the manufacturer of the electric window!

The installer may be required to carry out

a risk assessment of the entire system in

accordance with the Machinery Directive

2006 / 42 / EC if the use or operation of

the control unit or the connected window

drives deviates from the intended use!

notE

intEndEd uSE

Area of Application / Scope of Application

This control device is intended for the supply and cont-

rol of electrically operated windows in façade and roof

areas. The main task of this product, in combination

withtheelectromotivewindow,istoremovehotsmokeand

fumes in case of a re in order to save human lives and pro-

tect material assets. In addition, the electromotive window

ensures the supply of fresh air for natural ventilation

of the building.

Intended use according to the Declaration of Con-

formity

The control device is designed for xed installation and

electrical connection as part of a building.

In accordance with the attached Declaration of Con-

formity the control device, in combination with electromoti-

ve drives from Aumüller, is approved for proper use on a

power-operated window:

• Application for natural ventilation

installation height of the drive and the bottom side

of the sash at least 2.5m above the oor, or

opening width at the HSK of the operating unit

< 200 mm with a simultaneous speed of the HSK in

closing direction of < 15 mm/s.

• Application as NRWG (natural smoke and heat

exhaust ventilator) according to EN12101-2 without

dual function for natural ventilation.

notE

We recommend the exclusive use of

auMüllER system components, as their

compatibility is carefully checked at

the factory. auMüllER does not assume

any liability for the proper functioning

of third-party components. For applica-

tions and connections other than those

explicitly stated in these instructions,

the express written consent of auMüllER

is required. The use of applications and

components not expressly authorised by

auMüllER shall also be considered as not

in accordance with the regulations even

if their proper functioning can be proved

when they are put into operation (e.g. by

approval under building law).

Preliminary remarks

01

5

Installation Instruction

Radio RWA System

!

WaRning

Scope of application

The control device shall only be used according to its in-

tended use. For additional applications, please contact the

manufacturer or their authorised dealer.

Installation

These instructions are intended for competent and safety-

conscious electrical installers and/or qualied personnel

with knowledge of the electrical and mechanical installa-

tion of drives and control systems.

Mounting Material

The required mounting material must be modied to t the

applied load.

Routing cables and electrical connection

The laying or installation of electrical cables and

connections may only be carried out by approved

specialist companies. Never operate the drives, controls,

operating elements or sensors on operating voltages and

connections contrary to the manufacturer’s specications.

SafEty inStRuctionS

It is important to follow these instruc-

tions for the safety of persons. These

instructions must be kept in a safe place

for the entire life of the product.

The planning and calculation of the line

network is the responsibility of the building

owner, their agents or the commissioned in-

staller, and must be carried out in accordance

with the statutory regulations.

notE

All relevant regulations must be observed during instal-

lation, particularly:

• VDE 0100 Installation up high-voltage systems up to

1000 V

• VDE 0815 Installation cables and - / conductors

• Model Cable Systems Directive (MLAR).

The cable types, cable lengths and cross-sections must be

selected in accordance with the manufacturer’s technical

specications. If necessary, the cable types must be appro-

ved by the responsible local authorities and power supply

companies.

The mains supply line of the Control Unit must

be secured separately by the customer and

provided with an all-pole disconnecting de-

vice. After opening the system housing, live

parts are exposed. The system must be dis-

connected from the power supply and batte-

ries before any work can be carried out on the

Control Unit.

Clamping points must be checked for tightness of screw

connections and cable ends. The accessibility of junction

boxes, terminal points and external drive controls for main-

tenance work must be ensured.

Commissioning, operation and maintenance

After installation and after every change to the setup, all

functions must be checked by a test run. After completion

of the installation, the end user must be instructed in all im-

portant operating steps. If necessary, they must be informed

of any remaining risks / dangers.

The end user must be informed about the intended use of

the system and, if necessary, about the safety instructions.

Cables must be laid in such a way that they

are not sheared off, twisted or bent during

operation. It is recommended to carry out an

insulation measurement of the line network of

the system and to document it.

notE Put up warning signs!

Before working on the system, it must be com-

pletely disconnected from the power supply

and emergency power supply (e.g. batteries)

and secured against accidental reconnection.

When working in the Control Unit, the work-

place must be secured against unauthorised

access. It must be ensured that unauthorised

persons cannot open the Control Unit.

!

WaRning Carefully check all functions of the sys-

tem before releasing it for operation.

The installation instructions of system components (smo-

ke detector, natural smoke and heat exhaust ventilators,

drives, etc.) are part of the documentation of the overall

system and, like the installation and operating instructions

for the control unit, must be kept accessible to authorised

specialists throughout the service life of the system.

Software terms and conditions

The Control Unit is congured at the factory for its intended

use (standard conguration). With the software specially

developed for this Control Unit, the factory setting can be

quickly and easily adapted to suit specic requirements. In

addition, the system status can be saved, recalled and prin-

ted out.

01

Preliminary remarks

Changeable standard congurations are high-

lighted in these instructions. The range of

functions of the unlicensed version can be ex-

tended by license activation payment.

USB

6

Installation Instruction

Radio RWA System

01

Preliminary remarks

Declaration of Conformity

The control device is manufactured and tested for its speci-

c intended use according to European guidelines. The res-

pective Declaration of Conformity is available. If the use or

operation of the control unit or the connected window dri-

ves deviates from this, a risk assessment must be carried out

for the entire power operated window system and a decla-

ration of conformity must be issued in accordance with the

Machinery Directive 2006/42/EC and the CE mark attached.

diREctivES and StandaRdS

During installation and electrical connection, the latest

country-specic laws, ordninances, regulations and stan-

dards must be adhered to without fail.

These are, for example:

State building code with special building regulations such

as:

- Industry Building Directive

- Ordninance on Places of Assembly etc.

MLAR - Model Piping Systems Directive

Regulations of the Fire Protection Authorities TAB

(technical connection conditions) of the Energy Sup-

ply Companies

Trade Association Regulations, such as:

- ASR A1.6 and 1.7(substitute for BGR 232)

Further standards and guidelines, such as:

EN 60335-2-103 Safety of electrical appliances

EN 60730-1 Automatic electrical controls

EN 12101-10 / prEN 12101-9 (ISO 21927-9/10)

Smoke and heat control systems

DIN 4102-12 Functional maintenance of electric

cable systems

VDE 0100 Installation of high-voltage systems up

to 1000 V

VDE 0298 Use of Cables

VDE 0815 Installation cables and lines

VDE 0833 Alarm systems

VdS-Guidelines: 2593, 2581, 2580, 2592

Accident Prevention Regulations, in particularly:

- VBG 1 „General Regulations“ and

- VBG 4 „Electrical Systems and Equipment“.

The relevant national laws, regulations, standards and safe-

ty provisions apply to the marketing, installation and com-

missioning outside of Germany.

The installer is responsible for the proper installation, ope-

ration and the issuing of a Declaration of Conformity accor-

ding to European Guidelines.

The system requirements (see chapter „SyStemS Configura-

tion of Software“) must be checked before installation. The

„Software clause for the provision of standard software as

part of deliveries“ of the ZVEI (Central Association of the

Electrical Engineering and Electronics Industry) is conside-

red to be legally binding upon installation. See our website:

(www.aumueller-gmbh.de)

Therefore, we recommend protecting the operating system

and the software from unauthorised access (e.g. by use of

a password) and attending the training provided by the

manufacturer.

Spare Parts

System components should only be replaced with spare

parts of the same manufacturer. The manufacturer’s liabi-

lity, warranty and customer service are considered void if

third-party products are used. Only original spare parts from

the manufacturer are to be used for system extensions.

Ambient Conditions

The product must not be exposed to impacts or falls,

vibrations, humidity, aggressive vapours or other harmful

environments unless approved by the manufacturer for one

or more of these environmental conditions.

• Operation:

Ambient Temperature: -5 °C … +40°C

Relative Humidity: < 90% up to 20°C;

< 50% up to 40°C;

no condensation

• Transport / Storage:

Storage Temperature: 0°C … +30°C

Relative Humidity: < 60%

Accident prevention regulations and employer‘s

liability insurance association guidelines

When working on, in or on top of a building or part of a

building, the specications and instructions of the respecti-

ve Accident Prevention Regulations (UVV) and Employers‘

Liability Insurance Associations (BGR / ASR) must be obser-

ved and complied with.

The conguration software of the control de-

vice largely excludes damage due to incorrect

settings. As a precaution, we would like to

emphasise that auMüllER, as manufacturer,

cannot be held liable for damages resulting

from the use of auMüllER software, because

auMüllER itself has no inuence on a per-

fect systems environment or object-specic

systems conguration.

USB

7

Installation Instruction

Radio RWA System

Radio HSE and Radio Receiver

The Radio HSE are connected to the Radio Receiver by

radio (ISM band) and exchange a data packet (Ping) every

96 seconds to signal the “life status”.

If a signal is generated on the Radio HSE (trigger button,

reset button or fault) an encrypted data packet is imme-

diately sent back to the Radio Receiver with a conr-

mation packet.

The radio system uses 6 frequencies for the Radio HSE. The

total number of all Radio HSE must not exceed 10 detec-

tors per system.

• Long service life of the battery-powered Radio HSE

• High security for all transmission channels

- AES encrypted packets in the event of triggering

- Hand-shake for radio and serial data

- Distribution on 6 frequencies against jamming

transmitters

• High range in buildings

- VNA optimised Radio HSE antennas for horizontal

and vertical radio alignment

- 433MHz ISM narrow bandwidth with 1.2kbps

EMB 7300 Radio RWA System: Radio HSE (Transmitter) and Radio Receiver

For comissioning the licensed version of the

conguration software EMB Compact is

absolutely necessary!

!

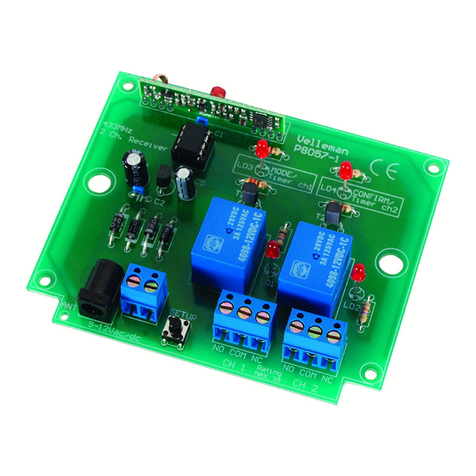

Connection: Radio Receiver on EMB 7300

1

7 1

1

7 2

Slot for radio module

Plug-in direction:

Antenna connection

towards main board

Data sheet EMB 7300 Radio RWa SyStEM

02

Application: The Radio HSE is used to control the EMER-

GENCY OPEN and EMERGENCY CLOSE functions

via a Radio Receiver in the detector line of the

EMB 7300 RWA Control Unit.

Radio: FM narrow bandwidth

Frequency: 433.100 to 434.600

For the use of Radio RWA, an EMB 7300

rmware V0.1.9 or higher is required.

!

Additional Equipment

Radio Receiver 528738

Radio Antenna including holder 528737

Radio HSE VARIANTS

Radio HSE Plastic red (similar to RAL 3000) 528731

Radio HSE Plastic yellow (similar to RAL 1018) 528732

Radio HSE Plastic grey (similar to RAL 7035) 528733

Radio HSE Plastic blue (similar to RAL 5015) 528734

Radio HSE Plastic orange (similar to RAL 2011) 528735

Inclusive: 3,6 V Lithium-Battery, > 2000mAh, Typ: 14500

8

Installation Instruction

Radio RWA System

installing EMB 7300 Radio RWa SyStEM

InstAllIng step 1:

Select frequency group:

A predened frequency group can be selected for the radio

link of the EMB 7300 Radio RWA via the 4 selection elds

under Frequency Group:

InstAllIng step 2:

Preparing the push-button:

• Remove the battery.

• Hold down the reset key.

• Insert the battery.

• The red LED ashes.

• When the red LED stops ashing, release the reset key.

• The push-button is reset.

InstAllIng step 3:

Set the freqency group on the RWA buttons:

• Remove the battery.

• Press and hold the reset key and the release key

simulatenously.

• Insert the battery.

• All LEDs light up until the keys are released.

• The red LED now ashes for the group number (1 x for

Group A, 2 x for Group B, etc.).

Press the reset key to select the next group and the

release key to accept the currently selected group.

Group A

EMB7300-0102A

Basic Features Frequency Group

Radio RWA

File System Configuration Language Help Absolut ...

Features

Firmware Update

System Features

Drive line 1

Drive line 2

Radio RWA

Frequency Groups (MHz)

Group A 433.100, 433.700, 434.450,

433.300, 434.225, 433.500, 434.000

Group B 433.150, 433.750, 434.500,

433.350, 434.275, 433.550, 434.050

Group C 433.200, 433.800, 434.550,

433.400, 434.325, 433.600, 434.100

Group D 433.250, 433.850, 434.600,

433.450, 434.375, 433.650, 434.150

03

If the network option Radio SHEVs is selected under System

Properites, the following tab appears in the left-hand menu:

„Radio RWA“.

EMB 7300 Radio RWa SyStEM

The licensed version of the „EMB Kompakt“

software is required in order to change the

network options and to programme and con-

gure the radio RWA buttons.

After selecting the network option

„Radio RWA“ and the desired frequency

group (this is set on the system and the

push-button), the change must be saved in

the control panel. No push-buttons can be

programmed before this.

notE

9

Installation Instruction

Radio RWA System

InstAllIng step 4:

Startup Phase on the SHE button:

• After inserting the battery in the RWA button, the

startup phase of the button (boot) begins.

This lasts approx. 20 seconds and is completed as soon

as the green und yellow LED ash simultaneously.

• The button is now ready to be programmed.

InstAllIng step 5:

Programming push-buttons in the system

• When Step 3 is completed, the push-buttons can be pro-

grammed on a Control Unit.

• Start the software and select the tab “Radio RWA”.

There is a „Plus“ button under the selection of

frequency groups.

• When the „Plus“ button is pressed, the system

switches to search mode and sends a “Search Signal” to

all manual call points.

• The signal lasts for 3 minutes.

• On all manual call points

- that do not have an assigned address

- are in the correct frequency group and

- are within reach

the „Triggered LED“ (red LED on the push button)

now starts to ash.

• To complete the programming process, the

„EMERGENCY OPEN“ button in the RWA button must

be pressed. After a few seconds the button is program-

med and appears in the congurator.

Group A

EMB7300-0102A

Basic Features Frequency Group

Radio RWA

File System Configuration Language Help Absolut ...

Features

Firmware Update

System Features

Drive line 1

Drive line 2

Radio RWA

button

„Plus“

EMB7300-0102A

Group B

Wait for manual alarms

2 : 59

File System Configuration Language Help Absolut ...

Basic Features

Features

Firmware Update

System Features

Drive line 1

Drive line 2

Radio RWA

Group AFrequency Group

Radio RWA

EMB7300-0102A

Group B

File System Configuration Language Help Absolut ...

Basic Features

Features

Firmware Update

System Features

Drive line 1

Drive line 2

Radio RWA

Group AFrequency Group

Radio RWA

installing EMB 7300 Radio RWa SyStEM

03

10

Installation Instruction

Radio RWA System

Additional Displays

LED´s Show the current status which the respective

key reports back to.

Battery Indicates the current battery charge level.

Reception Displays the current signal strength of the

button.

Blue

Points

Shows which motor lines (1 or 2 or both) the

button currently triggers.

11-61-04-00

resettIng AButton

To delete the addressing of a push-button (e.g. for pro-

gramming to another installation), the following steps are

necessary.

• Remove the battery.

• Press and hold down„EMERGENCY CLOSE“.

• Insert the battery.

• Red LED ashes.

• When the LED stops ashing, release the push-button.

InstAllIng step 6:

Edit Push-button

To edit a programmed push-button, simply left-click with

the mouse on the desired push-button – the push-button’s

editing menu opens:

Edit manual call point

Name:

Adress:

Drive Line:

Status: Pink ok

AL1

11-61-04-00

AL2

11-61-04-00

Adjustable functions

Name Here you can assign a name for each

push button as free text.

Adress Hardware-bound –

nothing can be changed here.

Drive Lines

Here you can set which drive lines

(1 or 2 depending on the Control Unit

variant) the RWA button should trigger.

Status

Info eld, here the push-button reports

its status (e.g. missing, if it is no longer

recognised).

Colour selec-

tion push

button

Here you can select the colour of the

button for better orientation.

All changes must be saved via the disk in the

editing menu.

Battery Change

The battery of the manual call point must be

changed at least every 2 years (in standard

operation).

In case of frequent malfunctions / tripping,

an annual change may also be necessary. The

exact battery status can be monitored via the

central software.

Normal Operation:

If all push-buttons have been properly pro-

grammed and the system is in normal opera-

tion (no fault is present), the green LED on

the HSE push-button ashes, therefore signal-

ling normal operation.

For energy-saving reasons, the LED on the

radio HSE push-button ashes (on wired

push-buttons, it is permanently lit)

If you want to delete a key which has already

been programmed, you can use the „Trash“

icon in the software.

!

!

!

The respective indicators can be displayed

with a delay of up to 30 seconds depending

on the situation.

!

installing EMB 7300 Radio RWa SyStEM

03

11

Installation Instruction

Radio RWA System

WaRRanty and cuStoMER SERvicEStoRagE and diSMantling

!

The Control Unit should only be stored in places protected from mois-

ture, heavy contamination and high temperatures (not above 30 °C). Do

not remove the packaging until the control unit is ready to be installed.

Disconnect the batteries and store them separately if the control unit has

already been used.

When storing rechargeable batteries it is essential to observe the

following:

If the Control Unit is to be permanently decommissioned, the legal

regulations for destruction, recycling and disposal must be adhered to.

The control unit contains plastic, metal and electrical components as well

as batteries. Replaced batteries contain highly toxic pollutants and must

therefore only be disposed of at the collection points stipulated by law.

Keep the storage time of the lead acid batteries as

short as possible, as the batteries discharge over time.

The batteries must be recharged after seven months

of storage at the latest. For recharging, either use a

suitable charger or connect the batteries to an

EMB Control Unit and supply it with mains voltage.

In both cases the charging time is at least 8 hours

(depending on discharge).

In principle, the following applies:

„General Terms of Delivery for Products and Services of the

Electrical Industry (ZVEI)“.

„Terms of Delivery for the software used“.

The warranty complies with the legal requirements and applies to the

country in which the product was purchased.

The warranty extends to material and manufacturing defects that occur

under normal use.

The warranty period for material delivery is twelve month.

Warranty and liability claims for personal injury and damage to

property are excluded if they are attributable to one or more of the

following cause:

• Improper use of the product.

• Improper installation, commissioning, operation, maintenance or

repair of the product.

• Operating the product with defective, incorrectly installed or non-

functional safety and protective devices .

• Failure to observe the instructions and installation requirements in

these instructions.

• Unauthorised structural changes to the product or accessories.

• Catastrophes caused by foreign bodies and Acts of God.

• Wear and tear.

The contact person for possible warranties or for spare parts or accesso-

ries is the branch ofce responsible for you or your responsible clerk at:

.

The contact details are available on our website

(www.aumueller-gmbh.de)

liaBility

Product changes and product adjustments can be made without prior

notice. Illustrations are not binding. Despite the greatest possible care, no

liability can be accepted for the content of these instructions.

diSpoSal

Do not throw electrical appliances in the household waste! According to

the European Directive 2012 / 19 / EU on Waste Electrical and Electro-

nic Equipment (WEEE) and its implementation in national law, electrical

equipment that is no longer usable must be collected separately and sent

for environmentally friendly recycling.

storage / Warranty anD Customer serviCe / liability

04

Before removing the Control Unit, it must be dis-

connected from the mains at all poles!

12

Installation Instruction

Radio RWA System

04

13

Installation Instruction

Radio RWA System

04

14

Installation Instruction

Radio RWA System

04

15

Installation Instruction

Radio RWA System

This is aTranslaTion of The original german insTrucTions for insTallaTion and commissioning

Important Note:

We are aware of our responsibility to act with the greatest possible care in the presentation of products that save lives and preserve value.

Although we make every effort to keep all data and information as up-to-date as possible, we cannot guarantee that it is free of errors.

The information and data contained in this document are subject to change without notice.

The distribution and reproduction of this document, as well as the use and communication of its contents are not permitted unless specically authorised.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the granting of a patent or registration of a utility model.

For offers, deliveries and services the terms of business and delivery of Aumüller AutomAtIc gMBhshall exclusively apply.

With publication of these instructions all previous editions become invalid.

cERtificatE and

dEclaRation of confoRMity

We declare that the product described under “Data

Sheet” is in compliance with the following guidelines

under our sole responsibility:

• 2014/30/EU

Directive relating to Electro-Magnetic Compatibility

• 2014/35/EU

Low voltage Directive

We further declare that the drive is a partly permanent

machine according to the European machinery directiv

(2006/45/EG).

Technical documents and explanations at company:

Aumüller AumAtIc GmbH

Gemeindewald 11

D-86672 Thierhaupten

Ramona Meinzer

Managing Director (Chairwoman)

The proof of the application of a quality management

system is for company:

Aumüller AumAtIc GmbH

according to the certication basis DIN EN 9001 as well

as the installation and conformity declaration are avai-

lable via the QR code below or directly on our website:

(www.aumueller-gmbh.de)

notE:

04

90000029201_V0.3_KW51/20

Other manuals for EMB 7300

1

Table of contents