AUPURIT A+ Press User manual

Technical

Manual

A+ Press (Copper)

Copper press t connection

system for Water & Gas. Edition 1, December 2020

Technical Manual

www.aupurit.co.nz

Overview

Application

Copper Pipes & Fittings

Copper Pipes

Fittings – Gas

Fittings - Water

Primary Check Press Warning Indicator

Secondary Check Internal Leak Path Design (DN15-DN50)

Features & Benets

Installation Considerations

Copper Tube Cutting

Working Pressure

Protection of Sealing Element

Connection to Other Materials

Minimum Clearances

Protection from Physical Damage

Clipping

Chases, In-Slab, Under-oor

Underground

Testing

Jointing instructions

A+ Press (Copper) Fittings

A+ Press (Copper) Pipes

A+ Press (Copper) Tools

1

2

3

3

3

4

4

5

6

7

7

7

7

8

8

10

11

11

11

11

12

14

22

22

Contents

Edition 1, December 2020

Technical Manual

1www.aupurit.co.nz

The AUPURIT™ A+ Press (Copper) system provides a complete press t

system for copper tubes with size ranges from DN15 to DN100 and broad

range of ttings for water and gas applications.

• Traditional installation methods like brazing, soldering or aring are no longer

required. All joints are simply assembled with a pressing tool for a quick,

consistent, and secure result every single time

• Incorporates a dual indicator system to help minimise errors during installation:

• “Press Indicator Coating” which is applied to the outside of each ttings.

• “Leak Path Design O-ring” which allow tradesmen to detect un-pressed

joints during the pressure test phase.

• Black EPDM seals for water application

• Yellow HNBR seals for gas application

• Manufactured from high quality copper and DZR brass in compliance with AS

1432 and AS 3688

All installations are to be carried out by licensed tradesperson and in full

accordance with the AUPURIT™ A+ Press (Copper) installation guidelines, relevant

New Zealand standards, and any additional local authority requirements. When

installed subject to the above conditions the AUPURIT™ A+ Press (Copper) system

will provide years of trouble-free service.

Overview

Technical Manual

2www.aupurit.co.nz

The AUPURIT™ A+ Press (Copper) system uses pressing tool to produce a secure

joint in a minimal amount of time. The crimping method produces a consistent

level of compression around the full circumference of the crimp ring, guaranteeing

a perfect seal every time.

Gas ttings shall be installed in accordance with AS/NZS 5601 for gas

applications including:

• Natural Gas

• Liquid Propane Gas (L.P.G)

Water ttings shall be installed in accordance with AS/NZS 3500 for water

applications including:

• Hot and Cold Potable Water

• Grey Water

• Waste and Drainage

For optimum installation results, please take time to familiarise with the installation

considerations outlined on Pages 7-11 in this technical manual.

Application

Technical Manual

3www.aupurit.co.nz

AUPURIT™ A+ Press Type B copper

tubes are manufactured from high

quality copper and in compliance

with AS 1432.

AUPURIT™ A+ Press (Copper) gas

ttings are suitable for use on all

copper tube/pipe provided it complies

with AS 1432 (being either Type A or

B) and must be installed in accordance

with AS/NZS 5601 for pressure

applications not exceeding 200kPa.

AUPURIT™ A+ Press (Copper) Gas

ttings are manufactured from high

quality copper and/or DZR brass

material with a factory-tted high

performance yellow Hydrogenated

Nitrile Butadiene Rubber (HNBR)

sealing element.

HNBR is widely known for its physical

strength and retention of properties

after long-term exposure to heat, oil

and chemicals. HNBR is not suitable for

copper pipes

Fittings – Gas

Copper Pipes

& Fittings

Fittings are suitable for installation

using annealed copper tube.

AUPURIT™ A+ Press (Copper) water

ttings are suitable for use on all

copper tube/pipe which complies

with AS 1432 (being either Type A or

B) and must be installed in accordance

with AS/NZS 3500. Fittings are

suitable for installation using

annealed copper tube.

food contact applications and cannot

be used in drinking water applications.

All Gas ttings have a yellow external

indicator ring for easy identication.

All Gas ttings are manufactured to

comply with AS 3688. Installations

should be carried out in accordance

with AS/NZS 5601.

Technical Manual

4www.aupurit.co.nz

AUPURIT™ A+ Press (Copper)

Water ttings are manufactured

in high quality copper and/or DZR

brass material with a factory-tted

high-performance black Ethylene

Propylene Diene Monomer (EPDM)

sealing element.

EPDM is a synthetic rubber product

that is strong and exible, resists decay

and provides good resistance to aging,

ozone, sunlight, weathering and hot

water. This makes it ideal for seals in

a broad range of applications. It is

All AUPURIT™ A+ Press (Copper)

ttings have an external-coloured

press indicator ring. Once pressed, it

is shattered and stripped away from

the tting to give the contractor a

visual indication to ensure the tting

has been pressed.

Fittings – Water

Primary Check Press

Warning Indicator

also recommended for drinking water

applications.

All water ttings have a blue external

indicator ring for easy identication

In accordance with AS 3688, A+ Press

(Copper) Water ttings can operate

within temperature range of -20°C to

95°C.

All water ttings are manufactured

to comply with AS 3688. Installations

should be carried out in accordance

with AS/NZS 3500.

Technical Manual

5www.aupurit.co.nz

The AUPURIT™ A+ Press (Copper)

ttings have a water leak path

design on the sealing ring where the

water will leak from the tting until

the pressing operation is completed

adequately. Testing is suggested to

be at 200-300kPa to enable the leak

function to operate successfully.

Secondary Check

Internal Leak

Path Design

(DN15-DN50)

Technical Manual

6www.aupurit.co.nz

• Fast

• Secure

• Simple to use

• Reduced risk of installation errors

• Dual indicator system to identify

unpressed ttings

• Increased safety

• No need for gas cylinders or Hot

Works permits

• Reduced costs on welding

consumables

• Fittings available for most tasks

• In most cases ttings maintain full

bore size of tube

• Installed with special pressing

tools, which puts the product out

of reach of non-tradespeople,

preventing improper handling of

products

Press Jointing

Method

Flame-free Assembly

Size Range DN15 – DN100

Full Flow Fittings

Dedicated Tooling

Features and

benets

Technical Manual

7www.aupurit.co.nz

Features and

benets

Installation

Considerations

It is recommended that copper tube

should only be cut with a wheel-type

tube cutter. To prevent damage to the

sealing ring, it is essential to deburr

both the inside and outside of all

copper tube prior to insertion of any

AUPURIT™ A+ Press (Copper) tting.

AUPURIT™ A+ Press (Copper) Gas is

suitable for use in applications covered

by AS/NZS 5601, where all consumer

piping is restricted to 200kPa maximum

pressure.

All AUPURIT™ A+ Press (Copper) Water

and Gas ttings have been tested

to a maximum operating pressure of

1600kPa.

The sealing element is critical to the

integrity of the joint. Care should

be taken to protect it from damage.

Simple precautions include:

• Ensuring the seal ring is properly

located in the tting,

• Ensuring the ring is well

lubricated, and

• Ensuring the ring is not

contaminated by any foreign

material.

AUPURIT™ A+ Press (Copper) Gas should always be installed in compliance with

AS/NZS 5601. AUPURIT™ A+ Press (Copper) Water should always be installed in

compliance with AS/NZS 3500.

All installations should be carried out by appropriately licensed tradespeople, in full

accordance with the AUPURIT™ A+ Press (Copper) installation guidelines, the relevant

Australian standards and any additional local authority requirements. Most installation

requirements can be sourced from this document.

Copper Tube

Cutting

Working

Pressure

Protection of

Sealing Element

Technical Manual

8www.aupurit.co.nz

AUPURIT™ A+ Press (Copper) is

suitable for connection to most existing

pipe work systems by utilizing our

range of A+ Press (Copper) threaded

adaptors. When installing an A+

Press (Copper) threaded adaptor, it

is recommended that the threaded

connection be installed rst, before

performing the pressing operation. It is

important that the spanner ats on the

ttings are used rather than gripping

the tube section of the tting.

When installing two A+ Press (Copper)

ttings near one another, it is essential

that a minimum clearance should be

maintained between the two. This

ensures that the tube being pressed is

free of any deformities which might be

caused in the pressing process.

The table below provides the

minimum clearances required

between two ttings:

Connection to

Other Materials

Minimum

Clearances

Nom Size Minimum Clearance (mm)

DN15 5

DN20 5

DN25 5

DN32 15

DN40 20

DN50 20

DN65 20

DN80 20

DN100 20

Minimum clearance

Technical Manual

9www.aupurit.co.nz

When an A+ Press (Copper) tting is

being installed close to an existing

brazed tting, the clearances in the

following table need to be observed.

This will ensure that the press tting is

kept clear of tube that may have been

excessively annealed during the brazing

process.

Brazing close to A+ Press (Copper)

tting joints should be avoided as

the heat generated by the process

can damage the seals of the tting. To

ensure that damage is not caused, the

minimum clearances in the following

table should be observed. It’s also

recommended that additional heat

suppression methods are employed to

prevent damage to the joint.

Nom Size Minimum Clearance (mm)

DN15 20

DN20 20

DN25 30

DN32 30

DN40 40

DN50 40

DN65 40

DN80 40

DN100 40

Nom Size Minimum Clearance (mm)

DN15 400

DN20 500

DN25 700

DN32 900

DN40 1000

DN50 1300

DN65 1700

DN80 2100

DN100 2600

Minimum clearance

Minimum clearance

Existing

Brazed

Fitting

Existing

Fitting

New Brazed

Fitting

Technical Manual

10 www.aupurit.co.nz

Due care should be taken to protect A+ Press (Copper) ttings from any mechanical

or chemical damage both prior to, during and after installation.

Where A+ Press (Copper) ttings and/or copper tube penetrate timber or metal

framework, appropriate precautions should be taken to protect it from damage.

Holes should be sized to allow for longitudinal movement, expansion and

contraction, whilst still securing the pipe adequately. Suitable grommets or sleeves

should be used in metal frames to protect the A+ Press (Copper) ttings and

copper tube from abrasion.

All A+ Press (Copper) ttings should be clipped by way of a recognized xing

which complies with the requirements of AS/NZS 5601 for gas applications or AS/

NZS 3500 for water applications.

Fixing spacing should be observed for both horizontal and vertical pipe runs

as outlined on the table below.

For pipe work being suspended on rod hangers the minimum diameter of the rod

hanger should be 9.5mm for all tube sizes up to and including 50mm and 12.7mm

up to 100mm.

Protection from Physical Damage

Clipping

Nom Size Vertical or Horizontal Run

Spacing (m)

DN15 1.5

DN20 1.5

DN25 2.0

DN32 2.5

DN40 2.5

DN50 3.0

DN65 3.0

DN80 3.0

DN100 3.0

Technical Manual

11www.aupurit.co.nz

Where A+ Press (Copper) ttings and

copper tube are installed in chases or

cast in slabs the installation must be in

accordance with AS/NZS 5601 for gas

applications and AS/NZS 3500 for water

applications and/or any other relevant

building regulations or standards.

A+ Press (Copper) Gas ttings can be

installed as an appliance connection

in accordance with AS/NZS 5601,

provided that an appropriate means of

disconnection is incorporated.

All testing should be undertaken

in accordance with AS/NZS 5601–

Appendix E (pressure testing for gas

installations) or AS/NZS 3500 for water

installations in addition to any other

local regulations or requirements.

During testing all joints should be

checked for leaks.

A+ Press (Copper) ttings and copper

tube should be buried with a minimum

cover of 300mm. Bedding/backll

material must be of a type that will not

have an adverse effect on the tube or

ttings. Sand is recommended. Marker

tape should be installed approximately

150mm above the tube. A+ Press

(Copper) ttings should be able to

be installed directly in the trench

without any form of coating. Additional

precautions should obviously be

taken in areas where aggressive soil

conditions are known to exist or where

it may be a requirement of the local

certifying authority.

Chases, In-Slab,

Under-oor

Appliance

Connection

TestingUnderground

Technical Manual

12 www.aupurit.co.nz

Jointing

Instructions

Cut tube at right angle with wheel-type

tube cutter.

Note: The cutter shall not have been used for other

ferrous metals to avoid corrosion.

Ensure to deburr both inside and

outside of tube to avoid damaging the

tting seal when inserting tube.

Note: The deburr tool shall not have been used for

other ferrous metals to avoid corrosion

Check the tting seal, ensure that it is

clean, sufciently lubricated & correctly

seated.

Mark the insertion depth on tube with

a waterproof marker pen to ensure the

tube is fully inserted.

1. Cut Copper Tube 2. Deburr Copper

Tube

3. Check the Seal

4. Mark

12

4

3

Technical Manual

13www.aupurit.co.nz

Jointing

Instructions

Insert the tube with a slight rotation

movement into the tting until it

reaches the full engagement depth

as marked.

Note: Extra care should be taken to ensure that the

tting seal is not dislodged or damaged.

Peel off coloured indicator ring after

pressing.

Ensure that the correctly sized jaw is

tted onto pressing tool. Position jaw

correctly over the tting, the tting

ring should be positioned in the jaw

groove. Start the process by pressing

and holding down onto the start button

for approximately 3-5 seconds until the

procedure nishes.

At completion, carry out pressure

testing in accordance with AS/NZS

5601 (Gas installations) or AS/NZS 3500

(Water installations) in addition to any

other local regulations or requirements.

5. Insert

7. Peel Off

Coloured Press

Indicator Ring

6. Press

8. Pressure Test

5

7

6

8

Technical Manual

14 www.aupurit.co.nz

A+ Press

(Copper) Fittings

Product description Size Part number

(water)

Part number

(gas)

#1 COUPLING DN15 A10000015000 A11000015000

DN20 A10000020000 A11000020000

DN25 A10000025000 A11000025000

DN32 A10000032000 A11000032000

DN40 A10000040000 A11000040000

DN50 A10000050000 A11000050000

DN65 A10000065000 A11000065000

DN80 A10000080000 A11000080000

DN100 A10000100000 A11000100000

Product description Size Part number

(water)

Part number

(gas)

DN15 A10002015000 A11002015000

DN20 A10002020000 A11002020000

DN25 A10002025000 A11002025000

DN32 A10002032000 A11002032000

DN40 A10002040000 A11002040000

DN50 A10002050000 A11002050000

DN65 A10002065000 A11002065000

DN80 A10002080000 A11002080000

DN100 A10002100000 A11002100000

SLIP REPAIR COUPLING

Technical Manual

15www.aupurit.co.nz

Product description Size Part number

(water)

Part number

(gas)

DN20 X DN15 A10003020015 A11003020015

DN25 X DN15 A10003025015 A11003025015

DN25 X DN20 A10003025020 A11003025020

DN32 X DN15 A10003032015 A11003032015

DN32 X DN20 A10003032020 A11003032020

DN32 X DN25 A10003032025 A11003032025

DN40 X DN20 A10003040020 A11003040020

DN40 X DN25 A10003040025 A11003040025

DN40 X DN32 A10003040032 A11003040032

DN50 X DN20 A10003050020 A11003050020

DN50 X DN25 A10003050025 A11003050025

DN50 X DN32 A10003050032 A11003050032

DN50 X DN40 A10003050040 A11003050040

DN65 X DN25 A10003065025 A11003065025

DN65 X DN32 A10003065032 A11003065032

DN65 X DN40 A10003065040 A11003065040

DN65 X DN50 A10003065050 A11003065050

DN80 X DN40 A10003080040 A11003080040

DN80 X DN50 A10003080050 A11003080050

DN80 X DN65 A10003080065 A11003080065

DN100 X DN50 A10003100050 A11003100050

DN100 X DN65 A10003100065 A11003100065

DN100 X DN80 A10003100080 A11003100080

#1R REDUCING COUPLING -

SOCKET X SOCKET

Technical Manual

16 www.aupurit.co.nz

Product description Size Part number

(water)

Part number

(gas)

DN15 A10005015000 A11005015000

DN20 A10005020000 A11005020000

DN25 A10005025000 A11005025000

DN32 A10005032000 A11005032000

DN40 A10005040000 A11005040000

DN50 A10005050000 A11005050000

DN65 A10005065000 A11005065000

DN80 A10005080000 A11005080000

DN100 A10005100000 A11005100000

#3 MALE ADAPTOR

#3 MALE ADAPTOR

#12 ELBOW 90° -

SOCKET x SOCKET

Product description Size Part number

(water)

Part number

(gas)

DN15 X DN15 A10014015012 A11014015012

DN20 X DN15 A10014020012 A11014020012

DN20 X DN20 A10014020034 A11014020034

DN25 X DN25 A10014025001 A11014025001

DN32 X DN32 A10014032114 A11014032114

DN40 X DN40 A10014040112 A11014040112

DN50 X DN50 A10014050002 A11014050002

Product description Size Part number

(water)

Part number

(gas)

DN15 X DN15 A10015015012 A11015015012

DN20 X DN20 A10015020034 A11015020034

DN25 x DN25 A10015025001 A11015025001

DN32 X DN32 A10015032114 A11015032114

DN40 X DN40 A10015040112 A11015040112

DN50 X DN50 A10015050002 A11015050002

Technical Manual

17www.aupurit.co.nz

Product description Size Part number

(water)

Part number

(gas)

DN15 A10006015000 A11006015000

DN20 A10006020000 A11006020000

DN25 A10006025000 A11006025000

DN32 A10006032000 A11006032000

DN40 A10006040000 A11006040000

DN50 A10006050000 A11006050000

Product description Size Part number

(water)

Part number

(gas)

DN15 X DN15 A10022015012 A11022015012

DN20 X DN20 A10022020034 A11022020034

Product description Size Part number

(water)

Part number

(gas)

DN20 A10007020000 A11007020000

DN25 A10007025000 A11007025000

DN32 A10007032000 A11007032000

DN40 A10007040000 A11007040000

DN50 A10007050000 A11007050000

DN65 A10007065000 A11007065000

DN80 A10007080000 A11007080000

DN100 A10007100000 A11007100000

ELBOW 45° -

SOCKET X SOCKET

ELBOW 90° -

SOCKET X SOCKET

#13 MALE ELBOW

Technical Manual

18 www.aupurit.co.nz

Product description Size Part number

(water)

Part number

(gas)

DN15 X DN15 A10023015012 A11023015012

DN20 X DN20 A10023020034 A11023020034

DN25 X DN20 A10023025034 A11023025034

Product description Size Part number

(water)

Part number

(gas)

DN15 X DN15 A10022015012 -

DN20 X DN20 A10022020034 -

Product description Size Part number

(water)

Part number

(gas)

DN15 A10010015000 A11010015000

DN20 A10010020000 A11010020000

DN25 A10010025000 A11010025000

DN32 A10010032000 A11010032000

DN40 A10010040000 A11010040000

DN50 A10010050000 A11010050000

DN65 A10010065000 A11010065000

DN80 A10010080000 A11010080000

DN100 A10010100000 A11010100000

#14 FEMALE ELBOW

#62 UNION

#24 EQUAL TEE

Table of contents

Popular Industrial Equipment manuals by other brands

INOXPA

INOXPA BCI Series Installation, service and maintenance instructions

Siemens

Siemens ASZ7.5 Series Mounting instructions

Danfoss

Danfoss S19 INSTALLATION, COMMISSIONING AND MAINTENANCE

Sonny's

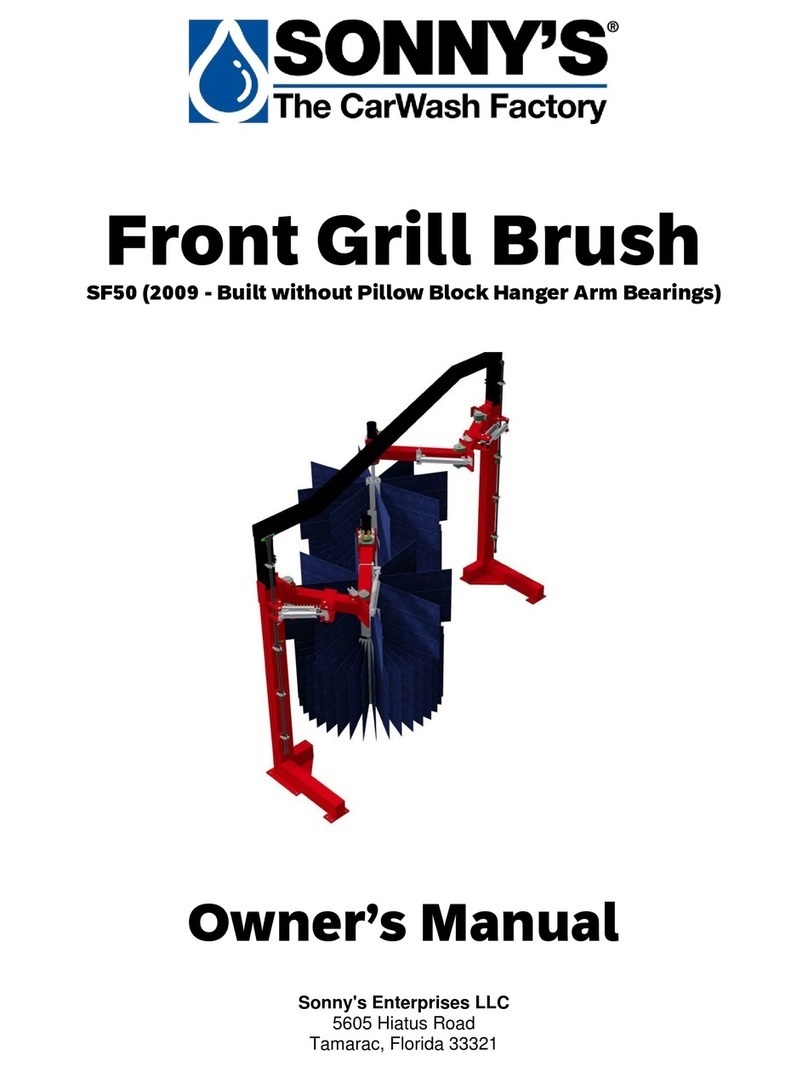

Sonny's SF50 owner's manual

Fontaine

Fontaine 3000 series ASSEMBLY, DISASSEMBLY AND TROUBLESHOOTING INSTRUCTIONS

Mitsubishi Electric

Mitsubishi Electric MR-JET-G user manual