2

Contents

1. Products Covered in This Manual..................................................3

2. Confidentiality Statement, Warranty, and Instructions

for Returning Materials.........................................................................3

2.1 Confidentiality Statement .....................................................................................3

2.2 Warranty...............................................................................................................3

2.3 Instructions for Returning Materials......................................................................4

3. Introduction to the Cee®1300CSX Thermal Debonder......5

3.1 Programmability ...................................................................................................5

3.2 Precision ..............................................................................................................5

3.3 Reliability..............................................................................................................5

3.4 Utilities..................................................................................................................6

3.5 Dimensions ..........................................................................................................6

4. Software.........................................................................................................7

4.1 Startup and Run Screen.......................................................................................7

4.1.1 Startup with Passwords Enabled...............................................................7

4.1.2 Home Slide Button ....................................................................................7

4.1.3 Run Screen ...............................................................................................8

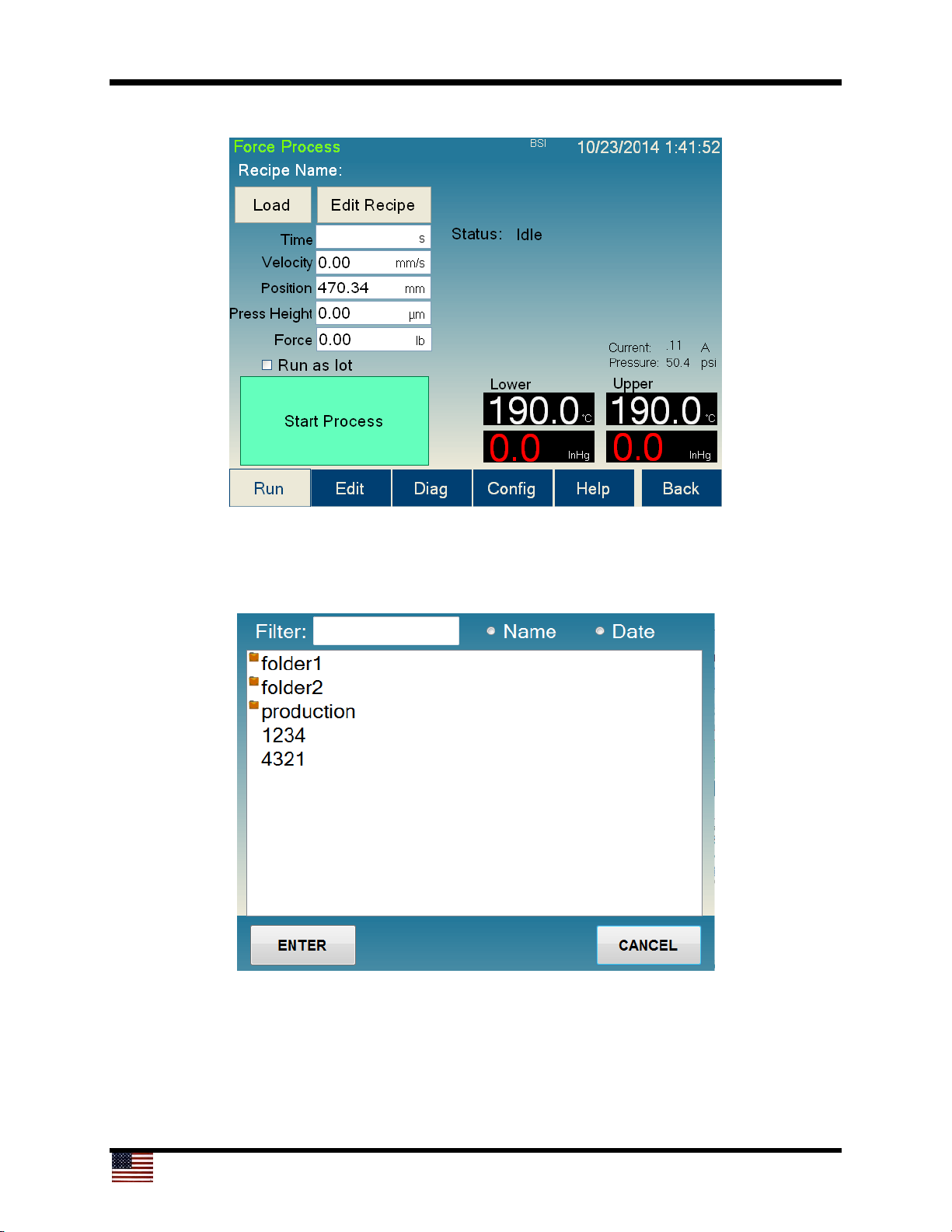

4.2 Debonding Process Screen..................................................................................9

4.2.1 Running a Debonding Process..................................................................11

4.2.2 Loading a Substrate..................................................................................12

4.2.3 Starting a Debonding Process...................................................................13

4.2.4 The Debonding Process Flow ...................................................................13

4.2.5 Aborting a Process....................................................................................15

4.2.6 Continuing a Process................................................................................15

4.3 Recipe Manager (Edit) Screen.............................................................................16

4.3.1 Writing a Recipe........................................................................................18

4.3.2 Entering Data ............................................................................................18

4.3.3 Recipe Management.................................................................................19

4.3.4 Recipe Backup..........................................................................................20

4.4 Diagnostics Screen ..............................................................................................21

4.4.1 Debonder Diagnostics Screen...................................................................22

4.5 User Configuration Screen...................................................................................30

4.5.1 Debonder User Configuration Screen .......................................................32

4.5.2 Password Configuration Screen................................................................34

4.5.3 User Level Access.....................................................................................34

4.6 Navigation Bar......................................................................................................35