AUROOM DICIA D User manual

IPx4 Technical changes reserved

INSTALLATION AND OPERATION MANUAL

Sauna control unit

DICIA D

DICIA H

www.auroom.ee

2

English

Contents

Scope of delivery .................................................................................................................................................... 4

Accessories ................................................................................................................................................................ 4

Technical data........................................................................................................................................................... 5

General information about sauna bathing .................................................................................................... 6

General safety precautions.................................................................................................................................. 7

Installation ................................................................................................................................................................. 9

Main electronic unit (relay box)............................................................................................................9-10

Control panel - location and cable connections ................................................................................11

Control panel - ush-mounted installation................................................................................... 12-13

Installation of the temperatur sensor.............................................................................................. 14-15

Electrical connections..........................................................................................................................................16

Connection of the sauna heater...............................................................................................................16

Connection of the sauna lighting............................................................................................................17

Connection of the power extension unit (LSG) ..................................................................................17

Installation diagram and terminal block overview..................................................................... 18-19

Temperature sensor......................................................................................................................................20

Humidity sensor.............................................................................................................................................20

2nd temperature sensor (bench sensor)...............................................................................................20

Connection scheme overview (Dicia D and H)......................................................................................21

Connection of the vaporizer .............................................................................................................................22

Installation and connection of the humidty sensor .................................................................................22

Installation and connection of the 2nd temperature sensor ................................................................23

Setup (commissioning / rst switching) .......................................................................................................24

Language setting...........................................................................................................................................24

Time and date setting..................................................................................................................................24

Basic setup (type of use, type of heater, safety)..................................................................................24

Operation.......................................................................................................................................................... 26-36

Overview...........................................................................................................................................................26

Symbol description (main navigation menu)......................................................................................27

Symbol description (additional settings)..............................................................................................28

Graphic user interface..................................................................................................................................29

Monitoring of climate conditions............................................................................................................29

Operation and settings (main functions)....................................................................................... 30-33

Operation and settings (additional functions)............................................................................. 34-36

Service-Level (setup and settings)........................................................................................................... 37-40

3

Setup level access and graphic user interface ....................................................................................37

Symbol description.......................................................................................................................................38

Description of settings.......................................................................................................................... 39-40

Troubleshooting (error messages)..................................................................................................................41

Main switch (Switch-o).....................................................................................................................................42

Service address ......................................................................................................................................................43

Warranty information ..........................................................................................................................................43

General Terms and Conditions of Service.....................................................................................................44

4

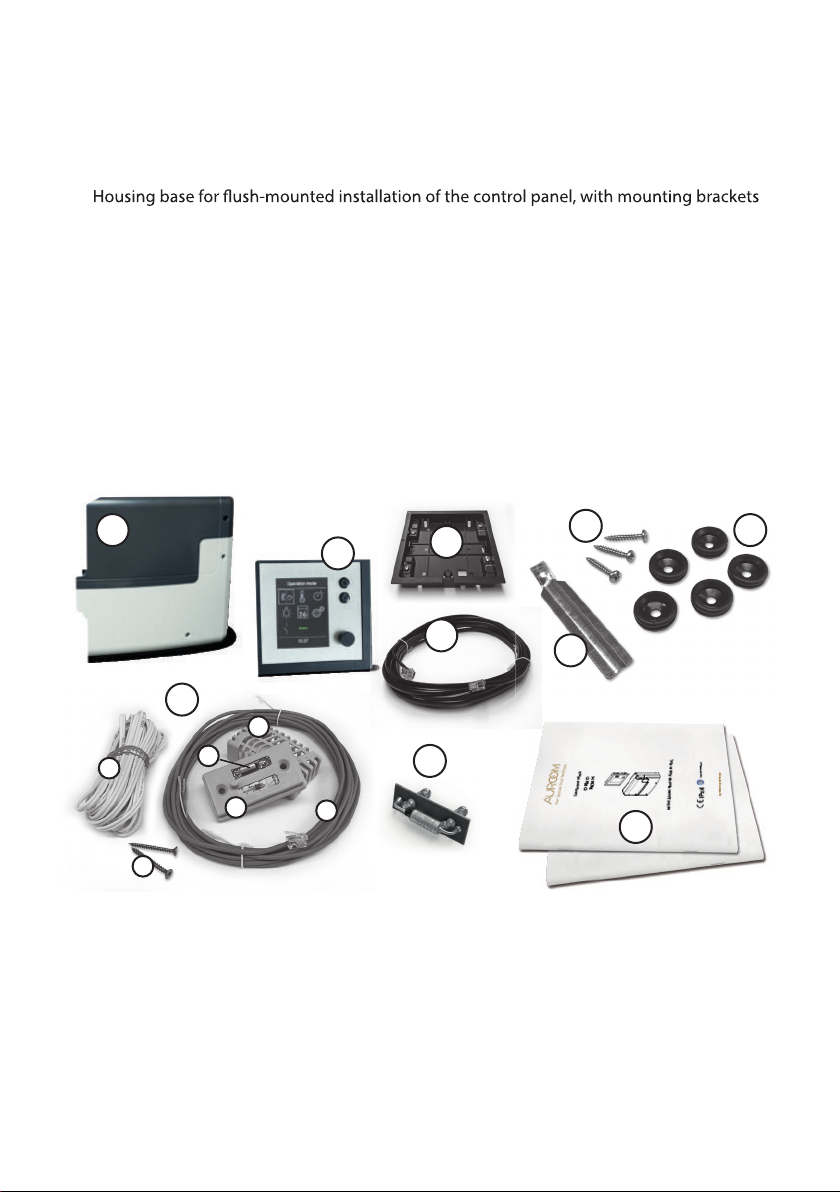

Scope of delivery

(changes are reserved)

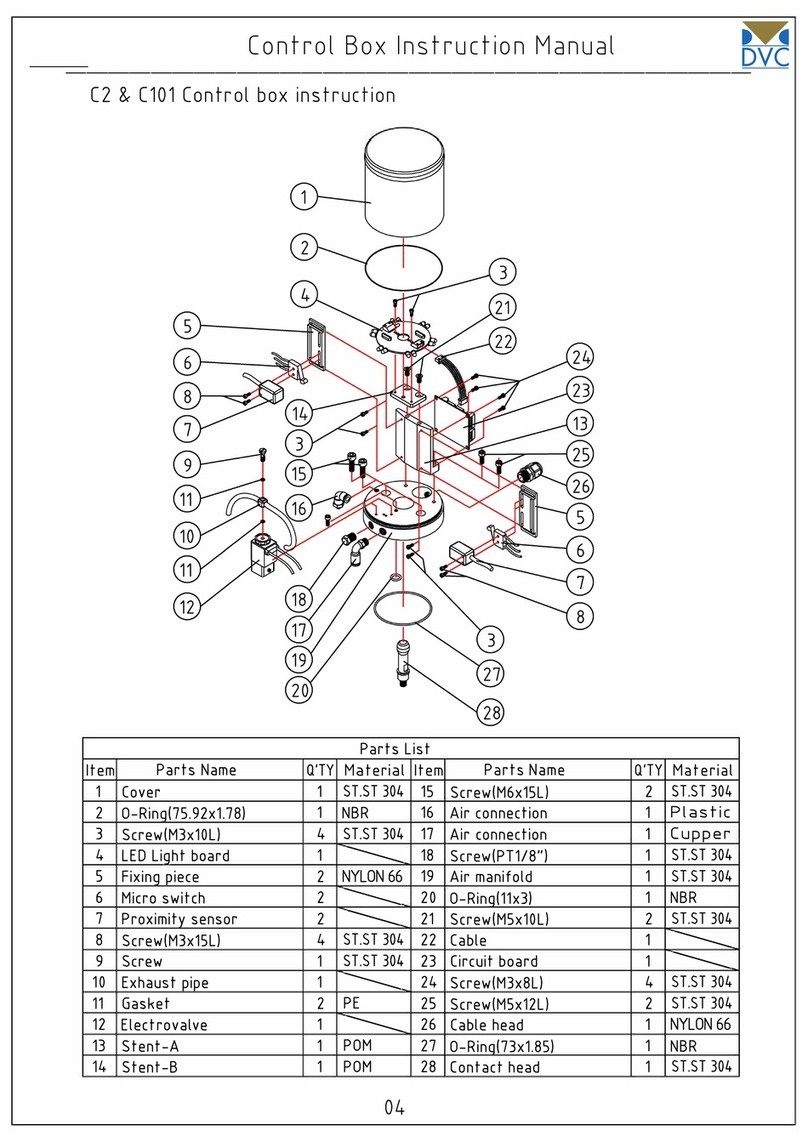

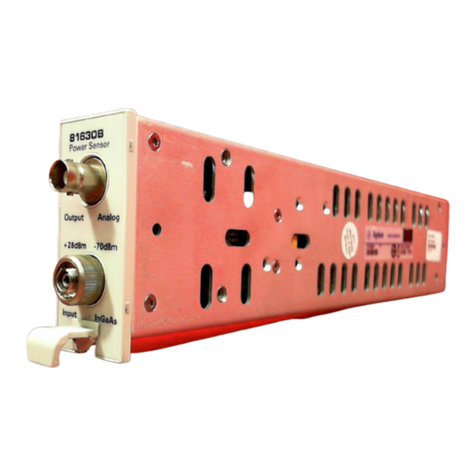

1. Main electronic unit (with two-part front cover)

2. Control panel with colour display

3.

4. De-installation tool (for control panel)

5. Temperature sensor: a) housing, b) sensor board, c) overheat protection fuse, d) 2 mounting

screws 4 x 40 mm, e) connection cable 5 m with RJ10 plug, f) 2-core white cable for overhea-

ting protection fuse 5 m

6. Connection cable (control panel - main block) with RJ14 / RJ10 plugs

7. Plastic bag with 3 mounting screws 4 x 25 mm (for main electronic unit)

8. 1 spare overheating protection fuse

9. 5 rubber cable glands

10. 1 installation & operation manual, 1 operation manual (for end users)

Accessories (optionally available):

2nd sensor........................................................item 94.5725 (only for Dicia D and H)

Humidity sensor...........................................item 94.5726 (only for Dicia H)

coloured light control module ...............item 94 5996, 94 6007

Sound module..............................................item 94 5920, 94 5921

Remote start module.................................item 94 5782

SBM-WCI-01 web app module................item 94 5987

4

10

79

5

f

e

d

a

b

c

1

23

6

8

5

Technical data

Voltage (power supply): 400 V 3 N AC 50 Hz

Switching capacity: max. 9 kW resistive load, may be extended with a power extension unit

(LSG)

Heating time limit: 6 h / 12 h / unlimited

Housing: plastic, shatter-resistant

Display: TFT colour display 55 x 74 mm (3,5“ size)

Operation: 2 direct buttons for On/O and light, jog-dial switch

Temperature control range: 30° - 115°C (dry sauna mode)

30° - 70°C (humid sauna mode - only Dicia H)

Humidity control: proportional to time or optionally as per rel. air humidity (%) with an

optional humidity sensor.

Sensor system: Digital sensor with oveheating protection fuse (STB) 142°C

Control characteristic: Digital two-point control

Connection for fan: min. 5 W, max.150 W (only fans without starting capacitor)

Please make sure to use only the fans compatible with the phase lead edge

control. Otherwise the fan or the sauna control unit may be damaged!

Connection for light: min. 5 W (20 mA),

resistive loads - max. 150 W,

dimmable energy saving lamps - max. 35 W

Lamps at conventional transformers - max. 60 VA.

Attention: only dimmable lamps may be used!

!Fan and light output share a common 5 A fuse.

Volt-free output: contact’s resistive load carrying capacity:

maximum current: 16 A

maximum voltage: 30 V DC / 250VAC

Start time pre-selection: up to 24 h in advance

Switching automation: Week timer with 4 switching programs per day

Error display: Clear text error indication on the display

Outputs: 3 x RJ10 jacks for sensor connections

2 x RJ14 jacks for control panel and extension modules

1 x potential free contact (2 terminals)

Output S1: maximal load 50 W / 50 VA, no capacitive loads allowed.

Terminal block area for power supply and steam generator connection:

0.5 – 2.5 mm² rigid or exible crimped wire, two cores with the same

cross section per terminal may be connected

Terminal block area WM, 3, 4, light, fan:

0.34 – 2.5 mm² rigid or exible crimped wire

Please observe the minimal cross section as per fuse protection of the line!

Card reader: Micro-SD card reader in control panel

Ambient temperatures: -10°C to +35°C

Storage temperatures: -20°C to +60°C

Sensors: may not be installed in corrosive or highly salty environment.

Control unit: may not be installed in corrosive environment or in an environment which

may cause water condensation.

Dimensions main block: H 270 x W 300 x D 100 mm

Dimensions control panel: H 127 x W 130 x D 25 mm (ush-mounting)

recessed part 20 mm deep

Dear customer

You have purchased a high-quality technical

device with which you will have years of sauna

fun. This sauna control unit was designed and

inspected according to the current European

safety standards and manufactured at the facto-

ry in accordance with the quality management

standard DIN EN ISO 9001:2000.

This detailed installation and operation manual

has been prepared for your information. Please

observe in particular the important notes and

the information on electrical connection.

We wish you exhilarating recreational experience

and lots of fun with your sauna!

Intended use

This sauna control unit is exclusively intended

for the control of the sauna heater in a sauna

cabin.

Any other use over and above the intended

purpose is not considered as appropriate use!

Compliance of the standard operation, mainte-

nance and repair conditions is also an element

of appropriate use.

The manufacturer cannot be held liable for

deviating, unauthorized alterations and any re-

sulting damages: the initiator of these changes

bears the full risk.

General information

Please check whether the unit has arrived in per-

fect condition. Any transport damages should be

immediately reported to the freight forwarder

delivering the goods or you should contact the

company that shipped the goods.

Please note that you will only be able to achieve

an optimum sauna climate if the cabin with its air

intake and ventilation, the sauna heater and the

control unit are aligned to each other.

Please observe the information and stipulations

made by your sauna supplier.

Sauna heaters heat up your sauna cabin using

heated convective air. Here, fresh air is drawn

in from the air intake which, when heated, rises

upwards (convection) and is then circulated

within the cabin. Part of the used air is pushed

out through the vent in the cabin.This creates a

typical sauna climate which can achieve temper-

atures of approx. 110°C measured directly under

the ceiling of your sauna, dropping in temper-

ature to approx. 30-40°C towards the oor. It is

therefore not unusual to measure temperatures

of 110°C on the temperature sensor hanging

over the heater, whilst the thermometer hanging

on the sauna wall, approx. 20-25 cm under the

cabin ceiling, only indicates 85°C. The bathing

temperature generally lies between 80°C and

90°C in the area of the upper bench when the

temperature is set to maximum.

Please note that the highest temperatures are

always generated over the sauna heater and that

the temperature sensor and the safety limiter

must be mounted there in accordance with the

control unit installation instructions.

When heating up for the first time, you may

notice a slight smell caused by evaporating

lubricants used in production processes. Please

ventilate your cabin before beginning your

sauna bath.

6

!

Attention!

If control units with remote control op-

tions* are used, protection against switch-

ing on if the heater is covered is required.

(e.g. cover protection rail type 1-5).

General safety precautions

• This device can be used by children aged

8 upwards and by persons with physical,

sensory, or mental disabilities, or who

have inadequate experience and knowl-

edge if they are supervised or if they have

received adequate instruction in how to

use the device safely and understand the

associated risks. Children may not play

with this device. Children may not clean

or carry out any user maintenance if un-

supervised.

• Children are to be supervised in order to

make sure that they do not play with this

device.

•

!

Attention: It is forbidden to install

the control box in a closed switch cabinet

or behind a wooden panelling!

• The electrical installation may be done

only by a qualied electrical technician.

• You must comply with the regulations of

your power supply company and applica-

ble VDE regulations (DIN VDE 0100).

•

!

WARNING: Never attempt repairs or

installations yourself, as this could result

in serious injury or death. Only a qualied

technician may remove the housing cover.

• Please note the dimensions in the assem-

bly instructions, especially when installing

the temperature sensor. The temperature

above the oven is critical for the temper-

ature setting. The temperature can be

held within operating parameters and

a minimal temperature gradient inside

the bench area of the sauna cabin can be

achieved only if unit is assembled correct-

ly.

• The device may only be used as intended

as a control unit for sauna ovens up to 9

kW (up to 36 kW when combined with a

contactor box).

• Completely disconnect the control unit

from the electrical circuit, i.e. ip all circuit

breakers or the main circuit breaker during

each installation or repair.

• Please note the safety and installation

information from the sauna oven manu-

facturer.

• Always heed the specications and in-

structions of the cabin manufacturer, too.

*Remote control = setting up, controlling or adjust-

ing a unit by a command that can be given out of

view of the unit by means of transfer media such as

telecommunication, audio technology or bus sys-

tems. (this also includes weekly timers)

7

!

Attention!

Dear customer,

according to the valid regulations, the

electrical connection of the sauna heater

and the control box has to be carried out

through the specialist of an authorized

electric shop

We would like to draw your attention that

in case of a warranty claim, you are kindly

requested to present a copy of the invoice

of the executive electric shop.

When designing the sauna cabin

ensure that the external exposed glass

surfaces only reach a maximum tempera-

ture of 76°C. If necessary, protective fea-

tures need to be tted.

!

Attention!

Only the original spare parts may be used.

Any modication of the cables included in

the delivery can lead to malfunctions and

is not permitted.

Any unauthorized technical alteration

makes the product warranty void.

8

9

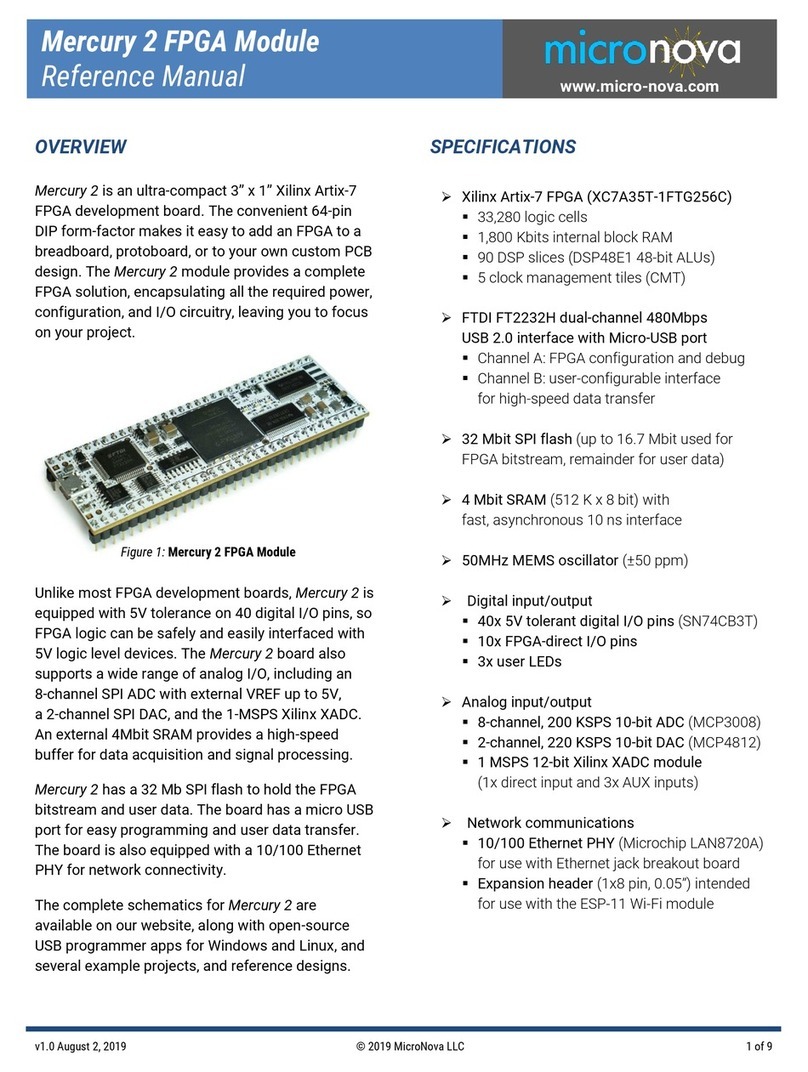

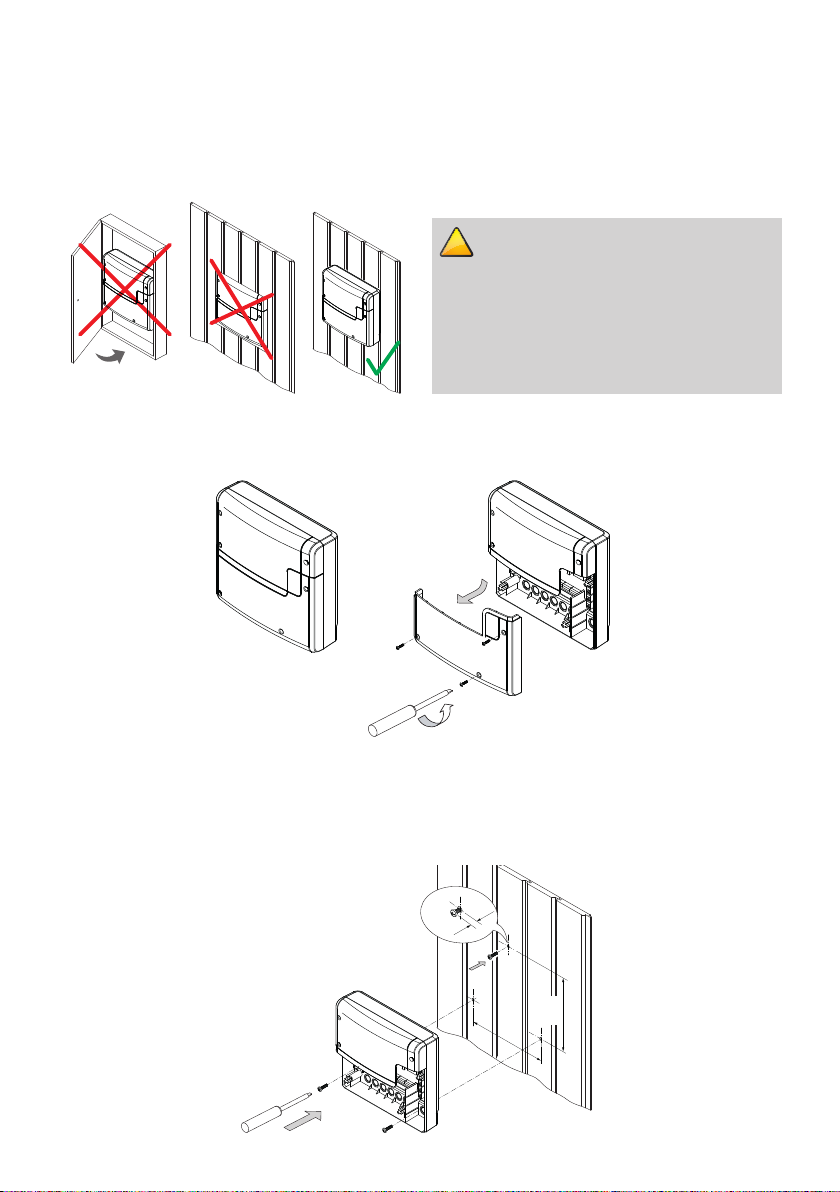

Installation of the main electronic unit

1. Take the lower part of the front cover o the relay box. For this undo 3 xation screws, then

pull the cover slightly downwards and take it o. See the g. 1 for details.

The main electronic unit (relay box) may be installed only outside sauna cabin. The recommended

places of installation are the outer sauna wall or a plant room (technical room). The installation

on the sauna roof is also possible. If empty ducts for connection cable are already available, then

they usually predetermine the installation position. The installation shall be carried out as follows:

1.

2.

210

180

3

!

Attention: The relay box may not be

installed in a closed switch cabinet or be-

hind a wooden panelling!

Risk of overheating! Fire hazard!

Fig. 1

Fig. 2

2. The relay box has three mounting holes on the rear side. Refer to g. 2 below for dimensions

in order to mark the position on the wall (template). The central upper screw shall be used to

hang the relay box onto it with the corresponding opening on its rear side. Two lower screws

shall be used to secure the housing to the wall after it is hanged on the upper screw.

10

180 mm

210 mm

Lower mounting holes

Fig. 3

3. Hang the housing on the central upper screw. Make sure that this screw stands out ap-

prox. 3 mm from the wall surface. If the connection cables shall be connected from the rear,

knock out the corresponding openings in the housing and insert the supplied cable glands

(rubber cable holders) into these openings. Pull the cables through them into the housing.

Secure the housing with two mounting screws 4x25 mm through the corresponding holes as

shown on g. 3 below.

Fig. 4

Knock-out openinigs for connection cables

for heater, vaporizer, fan, lamp.

Knock-out openings

for sensor cables

upper central mounting hole

11

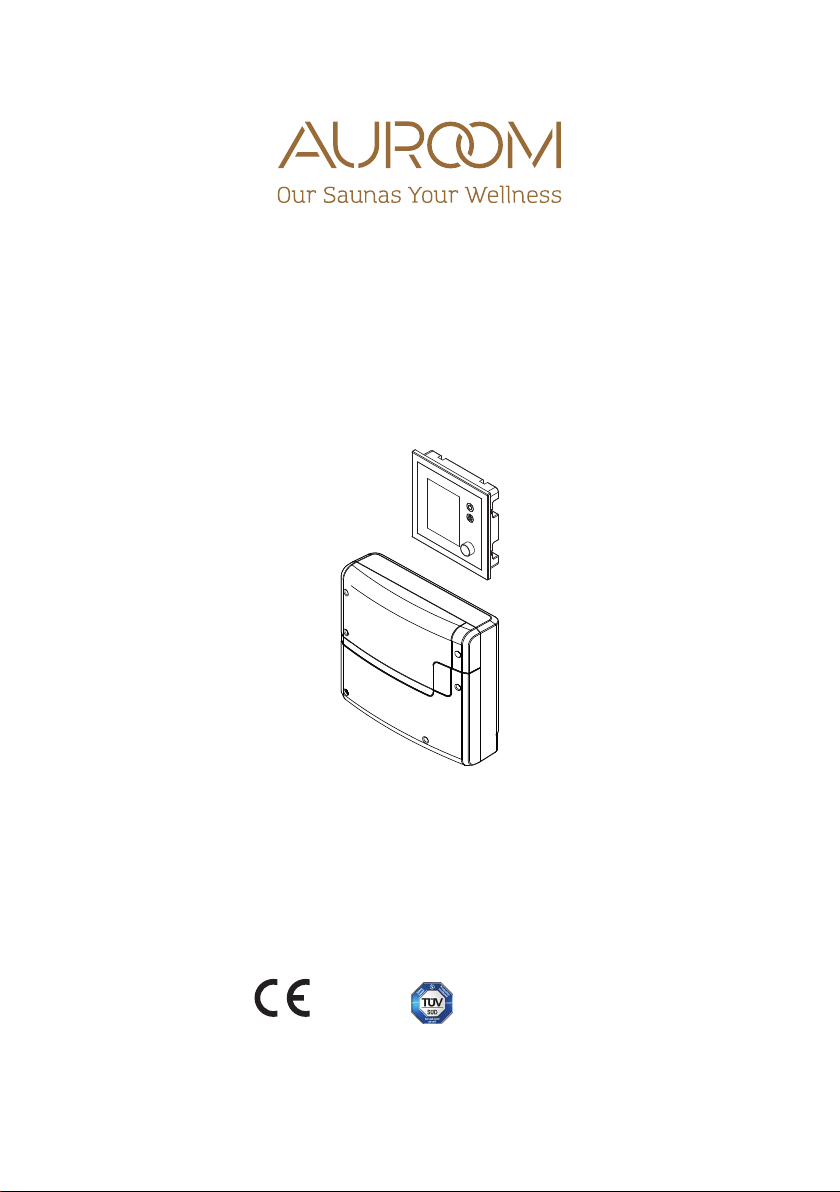

ca. 340 mm

120 mm

117 mm

ca. 340 mm

Cable connection

Use the supplied 5 m connection cable with

RJ10 plug (control panel side) and RJ14 plug

(relay box side).

If necessary this connection line may be ex-

tended to approx. 100 m length. For this you

will need to use a standard coupling RJ14/RJ14

and the extension cable with RJ14 plugs in re-

quired length. The coupling and extension ca-

ble may be purchased from specialist dealers.

Outer sauna

wall

insulation

connection cable

Inner sauna wall

Draw the connection cable from the relay box

to the control panel.

The connection cable may be laid only be-

tween the outer sauna wall and insulation layer

to prevent overheating (Fig. 7).

The insulation should ensure that the temper-

ature at the outer sauna wall may not exceed

75° C.

Pay attention to that the bigger plug (RJ14)

shall be oriented towards the relay box and the

smaller plug RJ10 towards control panel.

Fig. 5

Control panel

Installation place

The control panel may only be mounted out-

side the sauna cabin. If ductwork is already

provided for electrical installations then the

position of the control unit is predetermined

by that. The control panel is designed for

ush-mounted installation into the sauna wall

or a similar adjacent wall. The installation shall

be carried out as follows.

First of all determine the installation position.

Ideally it should be at the eye sight height, as

shown on g. 5

Fig.6

Make a cut-out in the wall with dimensions 117

mm height x 120 mm width.

Be careful not to make it too large, the ange of

the control panel has 5 mm.

eye hsight height

eye sight height

Fig. 7

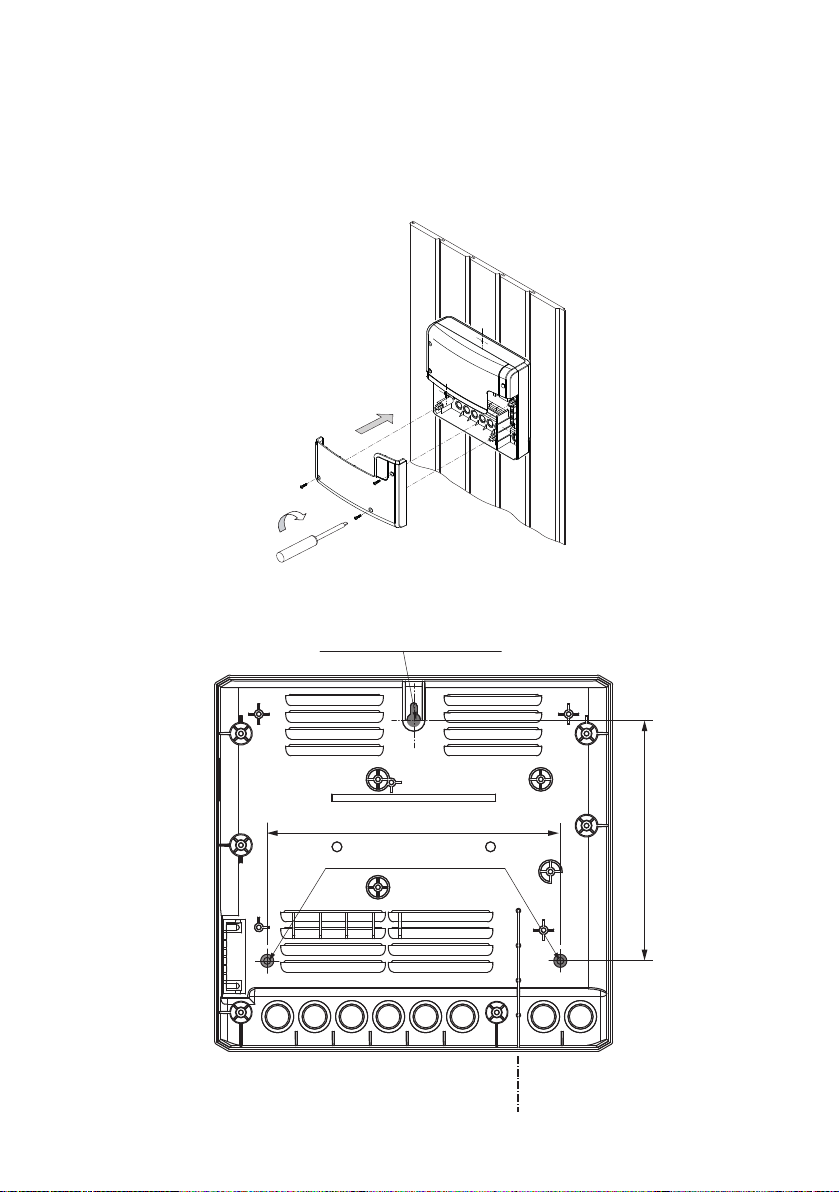

12

0,5

20

+

-

0,5

117

120

+

-

127

130

5

4x

4x

4x

1.

2.

3.

Fig. 9

By wall paneling < 15 mm (factory default)

First install the housing base (wall panelling up to 30 mm).

1. Loose 4 screws with mounting brackets on the base

2. Adjust the brackets to the designated wall panelling thickness (<15 mm or 15-30 mm)

3. Pull the connection cable through the opening in the housing base.

4. Insert the housing base into the wall opening.

5. Flip the brackets 90° to outside and tighten the screws - the housing base will be pulled to the

wall panelling from inside and fastened in the wall opening.

Wall aperture:

Width 120 mm

Height 117 mm

Depth min. 20 mm

Installation of the housing base

Flush-mounted installation

Fig. 8

pull the connection cable here

Advice:

Pay attention to the correct

orientation of the housing

base, the opening for con-

necting cable should be at

the bottom side as shown on

g. 8

13

4x

4x

4x

2.

1.

3.

4x

4x

Fig. 10

Fig. 11

By wall paneling 15 - 30 mm

turn the brackets around

By wall thickness > 30 mm

Leave the brackets in original position and mount

the housing through the mounting holes

in the bottom using 4 screws.

Use 4 screws appropriate to

the wall material.

Installation of the housing upper part (control panel with display)

Place the control panel directly in front of the housing base and pay attention to the correct orien-

tation (jog-dial switch shall be at the bottom right). Plug in the connection cable with RJ10 plug

which you pulled through the housing base.

Now press the control panel carefully into the housing base until you hear a click sound (hooks of

the upper part should snap into the holders in the base). Make sure the control panel sits reliably

in the base part.

Installation hint: When you lay the connection cable do not pull it too tight, allow some extra

length around the base, so that later you can take the control panel out of the base easily while

still having it connected.

Taking the control panel out

To remove (detach) the control panel use the included deinstallation tool or a suitable athead

screwdriver. Insert the tool or screwdriver into the groove located in the middle of the bottom

side (between housing upper part and housing base) and carefully pull it away from the wall until

control panel is released from the base and may be taken out. Do not apply excessive force as this

may damage the inner holders.

14

20 cm

19 cm

< 2 x 2 m

35 cm

> 2 x 2 m

Connection of sensor cables

Do not lay sensor and power supply lines together, or lead them through the same duct. This can

lead to interferences in the electronics, such as“uttering” in the relays. Connect the cable shield-

ing (if present) to ground in the control unit.

Please observe that the following dimensions relate to the values stipulated during the unit in-

spection acc. EN 60335-2-53. The heater sensor must always be installed at the point where the

highest temperatures are to be expected. Fig. 12-14 provide you an overview of the mounting

point of the sensor.

1. Mount the heater sensor in cabins up to 2 x 2 m according to g. 13, in larger cabins according

to g. 14.

2. Drill a hole to lead the cable through, preferably through the middle of one of the wooden

planks.

Fig. 12

Fig. 13 Fig. 14

Installation of the temperature sensor

Make sure that there is no deviating mounting position of the sensor, specic to

the sauna heater (check the installation guide of the sauna heater).

sensor line

heater heater

sensor line

Sauna control

unit. Display

panel design

may vary.

Sauna control

unit. Display

panel design

may vary.

15

Drilled hole in the ceiling

Sauna ceiling

Sensor, mounted in

the middle of a plank

Sensor cables

Sensor connector

RJ10 in relay box

Connector for the overheating pro-

tection fuse line STB (white cable)

Fig. 15

Fig. 16

3. Lead the sensor cable (red) and the limiter cable (white) through the drilled hole and connect

both cables to the main relay box as advised on pages 18-19.

4. Connect the sensor cable to the sensor board according to g. Make sure the connections are

correct. Connect the limiter cable (2-core white cable) to the limiter board (STB).

5. Mount the sensor to the ceiling plank using two supplied screws and attach the housing

cover.

6. After completed installation and correct commissioning of the control unit, the sensor line for

overheating protection must be tested for proper functioning. Disconnect one of the wires

of the white cable at the STB board in the sensor housing - the respective error message shall

appear on the display. Re-connect the wire to make the error message disappear.

Temperature sensor - connections:

Temperature sensor - installation overview:

Attention! Make sure to observe the correct

wire connecton order on the temperature sensor

board as shown on g. 15

connection pins on the sensor board

Attention:

Please pay attention that by the installation of the

cable lines for sensors and display panel it is not

permitted to pull the cable by the modular plug.

If you use a help to draw the cable through the

ducts it must not be attached to the plug but to

the cable only!

Pulling the cable by the plug may damage it and

cause loose contacts resulting in malfunction of

the control unit. In such case the warranty will be

void and the cable should be replaced.

Temperature sensor

board

white

green

brown

Overheating protec-

tion board (STB)

white

16

Electrical connection

The electrical connections may only be car-

ried out by a certied electrician in compli-

ance with the guidelines of the local power

supply company and applicable legal regu-

lations (e.g. VDE norms for Germany).

In general, there may be only one permanent

connection line to the network. Furthermore

equipment should be provided that makes it

possible to disconnect the system on all phases

from the power supply with a contact gap of

minimum 3 mm.

All electrical installations and all connection

lines that are installed inside the sauna cabin

must be suitable for an ambient temperature

of at least 170 °C.

The power supply line shall be laid to the con-

trol unit and connected to the power input ter-

minals.

The power supply cable shall be laid to the

main relay box and connected to the power

input terminal as per connection diagram (see

wiring diagrams, page 18-19).

Install the sauna heater and the vaporizer in

front of the air intake according to the manu-

facturer’s installation instructions.

Draw the silicone cable through the ductwork

to the relay box and connect it to the appropri-

ate terminals as directed in the wiring diagram.

Make sure to observe the wiring diagrams on

pages 18 - 19 with the corresponding terminal

connection scheme.

Notice:In case there is no ductwork available

drill a hole next to the air intake opening and

run the heater line through this hole to the

outside and to the appropriate terminals in the

control unit. The silicone line must be covered

to protect it from outside inuences. There-

fore, use a suitable cable-duct or a PVC-pipe

through which you can run the line up to the

power unit.

Special advice for connection of

Bi-O sauna heaters to control unit.

Sauna heater connection

Relay box, lower front cover opened

!

Attention!

By working vaporizer the power output

line„W“ will be diverted to the„Wb“ line

of the vaporizer.

The sauna heater section will then oper-

ate with 2/3 of the total power.

(if no LSG 18 H or LSG 36 H is used)

If a vaporizer is connected and the operation

mode is set to humid operation, then upon

switching the unit on the vaporizer will be

energized for a short time. This allows you to

prove that the vaporizer is functional and op-

erates correctly. It will then switch o until the

temperature reaches 10°C below the target lev-

el and then switch on. This ensures faster heat

up times and prevents that the steam is sup-

plied into a still too cool sauna cabin.

Fig. 17

17

Sauna lamp connection Heating time limitation

LSG

Connection of the power

extension unit

The switching capacity may be extended with

an external power extension unit (LSG), in or-

der to connect and operate the sauna heaters

above 9 kW power.

For connection details please refer to the instal-

lation and operation manual for the respective

LSG model.

The maximal heating time may be limited with

the jumper #5 on the main board of the relay

box. The limitation may be set to 6 hours, 12

hours or to unlimited.

If the control unit has been set to private (do-

mestic) use, then the heating time will be auto-

matically limited to 6 hours.

The jumper setting will override the software

settings.

!The sauna lamp must have the protection

class of at least IPx4 and should be resistant to

the ambient sauna temperatures. The sauna

lamp may be installed at any location but never

close to the rising hot air of the heater.

Only dimmable lamps may be used.The control

unit will detect strongly inductive loads and

will adjust the phase edge control accordingly.

Make sure to observe the specications of the

light output of the control unit for each light

type.

!Notice: By connection of not dimma-

ble lamps there is a risk of damaging either

the illuminant or the control unit. No war-

ranty claims may be accepted in this case.

The terminals „3“ and „4“ on the main board of

the relay box are the terminals of the normal-

ly open (NO) contact of a relay. Both terminals

have no further connection and are therefore

potential-free (voltage free). You can inte-

grate this NO contact into any circuit, in order

to switch an external power load or to relay a

switching signal.The max. load on the potential

free contact, depending on whether AC or DC

shall be switched, is given in the specications

on the page 5.

!

Attention! If you use the terminals L1,

L2 or L3 to power the circuit connected to the

potential free contact, then the connection

line should not be overloaded. If necessary,

the load (consumer) connected to the poten-

tial free contact should be additionally pro-

tected and provided with a separate power

supply.

Potential-free contact

Only use fans whose speed can be control-

led via phase control. The fan must have the

splashwater protection class (IPx4) and must

be resistant to the ambient temperature. The

fan can be mounted anywhere, however never

close to the rising ow of hot air from the stove

and must be positioned as far away as possible

from the IR spot (it may not be in the light path

of the spot).

Lüfter

18

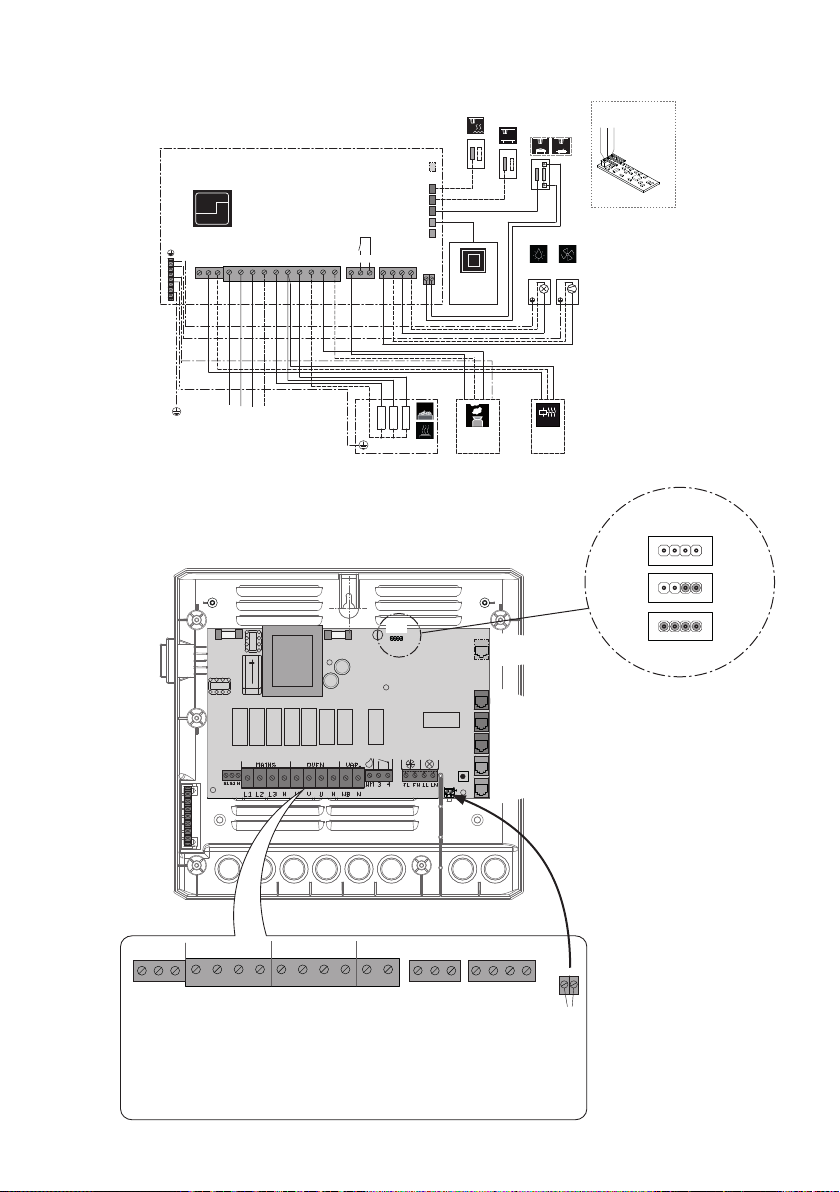

Jumpers are supplied

with the default

setting to 6 hours

LSG

Contactor box

STB

PE

P max. 9 kW

STB

fan light

L N L N

NL1 L2 L3

L1 L2 L3 N W V U N N

WB

WM

potentialfreier

Kontakt

3 4

S1

S1 N

Saunaofen

Sauna heater

Sensorbus

Saunabus

reserviert

Leuchte/light Lüfter/fan

Bankfühler/2nd Sensor

humidity sensor

Feuchtefühler

Ofenfühler/Sensor

Leistungsteil

Main unit (relay box)

Relais box

Силовой блок

B

Steckeranschluß Fühler

Sensor plug connector

weiß/white

grün/green

braun/brown

Bedienteil

Control panel

Tableau de commande

Панель управления

LSG

}

}

STB

}

I

II

fan light

FL FN LL LN

L1 L2 L3 N W V U N N

WB

WM

3 4

S1

S1 N

MAINS OVEN VA P.

JP5

Jumper 5

6 h

12 h

∞

Terminal layout on the main board

(relay box)

Installation diagram %JDJB D / *NQFSB D/Di

reserved

Fan / Phase

Fan / Neutral

Light / Phase

Light / Neutral

volt-free contact 16 A

Neutral heater

Neutral mains

Power supply phase 1

Power supply phase 2

Power supply phase 3

Output heater phase 1

Output heater phase 2

Output heater phase 3

Power

extension LSG

Schaltlasterweiterung

LSG, optional

Power extension,

optional

Sensor Bus

RJ 10

Sauna Bus

RJ 12

overheating

limiter fuse

19

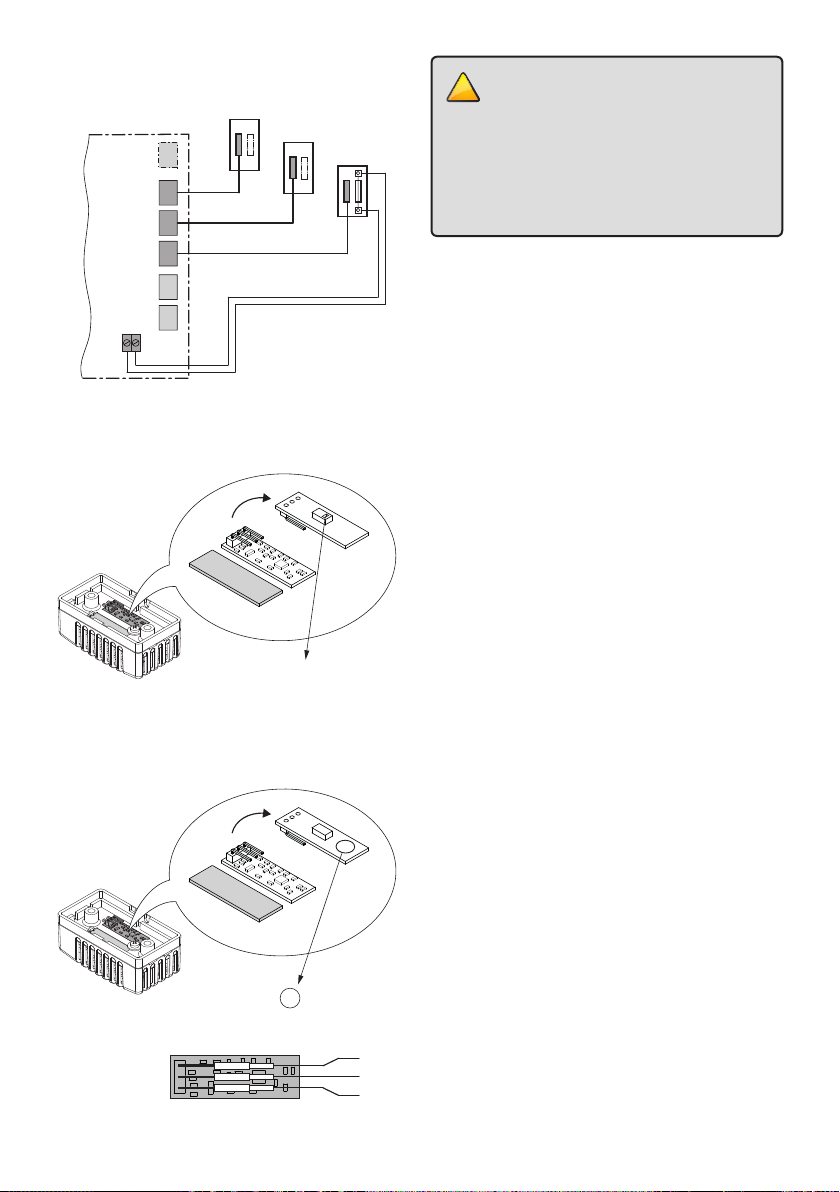

Jumpers are supplied

with the default

setting to 6 hours

STB

PE

P max. 9 kW

Wb PEWm N

LSG

STB

fan light

L N L N

NL1 L2 L3

L1 L2 L3 N W V U N N

WB

WM

potentialfreier

Kontakt

3 4

S1

S1 N

LSG

Contactor box

Saunaofen

Sauna heater

Verdampfer

Vaporizer

Sensorbus

Saunabus

reserviert

Leuchte/light Lüfter/fan

Bankfühler/2nd Sensor

humidity sensor

Feuchtefühler

Ofenfühler/Sensor

Leistungsteil

Main unit (relay box)

Relais box

Силовой блок

B

Steckeranschluß Fühler

Sensor plug connector

weiß/white

grün/green

braun/brown

Bedienteil

Control panel

Tableau de commande

Панель управления

}

}

STB

}

I

II

fan light

FL FN LL LN

L1 L2 L3 N W V U N N

WB

WM

3 4

S1

S1 N

MAINS OVEN VA P.

JP5

Jumper 5

6 h

12 h

∞

Terminal layout on the main board

(relay box)

Installation diagram %JDJB H / *NQFSB H/Hi

Sensor Bus

RJ 10

Sauna Bus

RJ 12

reserved

Vaporizer

Water shortage alarm

Schaltlasterweiterung

LSG, optional

Power extension,

optional

Neutral heater

Neutral mains

Power supply phase 1

Power supply phase 2

Power supply phase 3

Output heater phase 1

Output heater phase 2

Output heater phase 3

Fan / Phase

Fan / Neutral

Light / Phase

Light / Neutral

Potential free contact 16 A

Neutral

overheating

limiter fuse

Power

extension LSG

20

!

ATTENTION!

Connecting a sensor to the sauna bus

connector (RJ12) may damage the sensor

and the main board of the control unit!

Sensorbus

RJ 10

reserviert

Bankfühler

2nd sensor

Feuchtefühler

Humidity sensor

Ofenfühler

Main sensor

STB

B

}

Saunabus

RJ 14

}

RJ

10

RJ

14

RJ

10

RJ

10

RJ

14

B

B

For further details please refer to page 22.

Pin-type connec-

tors in sensor

2nd sensor (bench sensor)

Opening in chip

white

green

brown

How to set / change the cabin address

1. Press the programming button > 4-5 sec to

launch the programming mode. The green sta-

tus LED will go out. The red status LED will start

to ash.

2. Press now briey on the button - the ca-

bin address will move to the next va-

lue. The green LED will ash accordin-

gly to indicate the new address number.

For instance, the address has changed from 1 to

2 - green LED ashes two times.

3. Press again on the button to move the address

to the next value as required. In this manner you

can set the addresses 1 to 8.

4. The factory default address is always 1. The rst

press on the button will therefore set the cabin

address 2. The green LED will ash two times

accordingly.

5. After 8 the address wil return back to 1.

6. The programming mode will automatically exit

if you do not press the button for >10 seconds.

The new set address will be saved. The red LED

will go out, the green LED will start to ash

again.

Temperature sensor

Humidity sensor (optional, for H series)

2nd sensor (optional)

The sensors are connected via RJ10 modular

plugs to one of the corresponding sensor bus

RJ10 jacks on the main board of the relay box

as shown on the left. The connection order

may be chosen freely. The sensor bus supports

hot-plugging, sensors may be re-connected

while the control unit is switched on and will be

detected and congured within 2-3 seconds.

The white cable from the overheat protection

fuse in the sensor should be connected to the

2-pin STB connector on the main board.

Do not try to plug the sensors into the sauna

bus connectors (two lower RJ12 jacks), this will

damage the sensor and the main board.

reserved

Sauna = address 1

(Basic setting)

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

NI

NI 9350 Getting started guide

hexinverter

hexinverter Mutant Hihats user guide

LOVATO ELECTRIC

LOVATO ELECTRIC FF128EP Series Installation, operation and maintenance manual

Woodward

Woodward easYgen-2000 Series manual

Comau Robotics

Comau Robotics C5G Instruction handbook

LOVATO ELECTRIC

LOVATO ELECTRIC EXP10 30 quick start guide