MI00362-4-EN INSTALLATION MANUAL 3/4

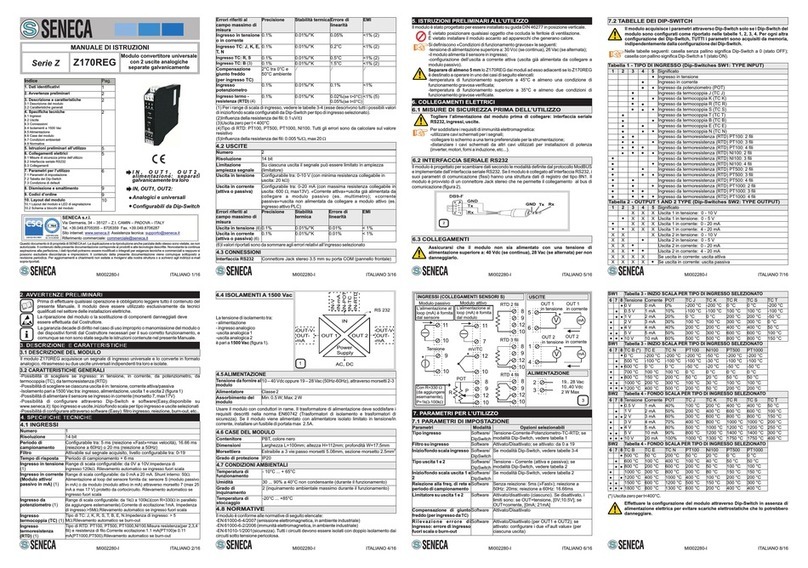

INPUTS

Voltage input:Bipolar with F.S. programmable at +2Vdc and +10Vdc Input impedance >100kOhm

Current input:Bipolar with F.S. Programmable at +20mA with 50Ohm internal shunt selectable via DIP-

switch. Available power supply: 90 + 90mA at 13Vdc.

Number of chan-

nels: 8

Input resolution: 15 bit + sign.

Input protection: ± 30Vdc or 25mA

Precision

voltage and

current:

Starting: 0.1 of full scale

Linearity : 0.03% of scale.

Zero: 0.05% of scale.

TC: 100 ppm, EMI: <1 %

Sampling time 120 ms/channel or 60 ms/channel

CONFIGURATION OF FACTORY SETTINGS

All DIP-switches in OFF position

Communication parameters of ModBUS protocol: 38400 8, N, 1 Address 1

Communication parameters of micro USB front port 2400 8, N, 1 Address 1

Channel input from 1 to 8: VOLTAGE ± 10Vdc

Numerical representation of the input measurement: ± 10000mV

Sampling time: 120ms

Note: When DIP switches 1 to 8 are OFF, the communication settings are taken from programming (EEPROM).

Note 2: The RS485 line must be terminated only at the ends of the communication line.

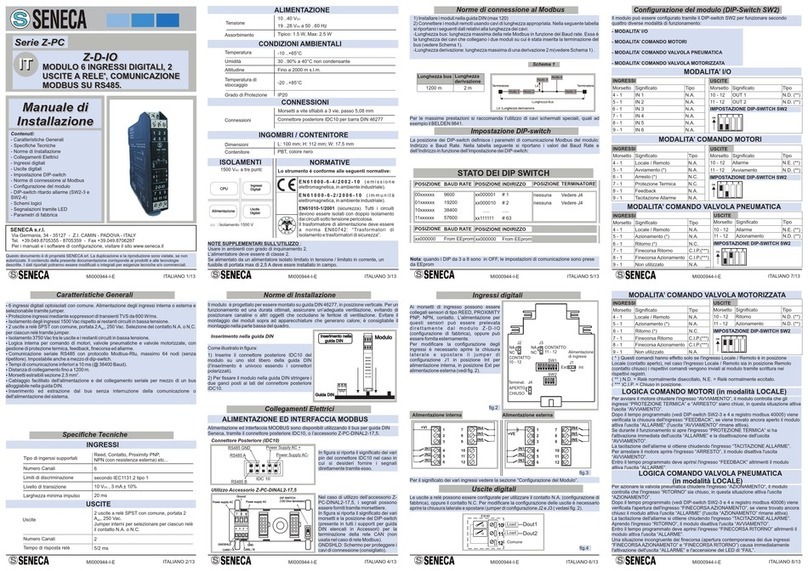

SETTING THE DIP-SWITCHES

The position of the DIP-switches denes the Modbus communication parameters of the module: Address and Baud Rate

The following table shows the Baud Rate and Address values according to the

DIP-switch

setting:

DIP-Switch status

SW1 POSITION BAUD

RATE

SW1 POSITION ADDRESS POSITION TERMINATOR

1 2 3 4 5 6 7 8 3 4 5 6 7 8 10

9600 #1 Disabled

19200 #2 Enabled

38400 #...

57600 #63

From

EEPROM

From

EEPROM

LEGEND

ON

OFF

SW2 INGRESSI ANALOGICI

12345678 CHANNEL

CURRENT INPUT

VOLTAGE INPUT

The settings of the dip-switches must be compatible with the settings on the registers. The description of the registers is

available in the USER MANUAL.