Auto Anchor 560 User manual

AutoAnchor 560 Owner’s Manual

Part 1 Important Information 1

Part 2 Installation 3

Part 3 Set Up 13

Part 4 Operation 20

Part 5 Maintenance 25

Part 6 Troubleshooting 25

Index

TABLE OF CONTENTS

To the best of our knowledge the information in this manual was correct at the time

of printing. However, the AutoAnchor products are continuously being reviewed

and improved and product specifications may be changed without notice. The

latest product specifications may not be reflected in this version of the manual. The

documentation relating to the AutoAnchor products is created in the English language

and may be translated from English to another language. In the event of any conflict

between translated documents, the English language version will be the official version.

• The AA560 should only be installed by a qualified marine electrician. Do not

attempt to install the AA560 unless you are suitably qualified.

• This manual supports the use of the AA560 only. The appropriate manufacturer’s

instructions must be followed for the installation and use of the windlass it is set

up to control.

• There must be an alternative method available to operate the windlass.

• The AA560 can be fitted to most vertical windlasses. A horizontal windlass may

require a sensor holder or a custom designed sensor which is not included in the

standard pack. Check with your supplier or the AutoAnchor manufacturer.

• The AA560 must be fitted to a windlass with a dual direction control box or

solenoid pack.

• Information for installation and operation of the AA560 is supplied, including

pre-set windlass profile lists, wiring diagrams, the Owner’s Manual and

the Quick User Guide. All documents must be left on board for the owner.

• Non compliance with the instructions could impair the windlass and the

AA560 operation, and could result in personal injury and/or damage to the boat.

• Non compliance with the instructions will negate the manufacturer’s warranty.

• The AA560 manufacturer and supplier accept no liability for personal injury or

property damage resulting from failure to follow the installation and operation

instructions or the use of the AA560 in a way that may cause accidents or

damage or that may violate the law.

• All the technical and cable specifications must be checked and adhered to.

• Wiring diagrams must be followed without modification.

• Before use the AA560 must be correctly set up for the windlass it is to control and

tested in a safe environment. The AA560 will not count correctly if the windlass

selection is wrong or the windlass is not standard (eg it is installed with a different

chainwheel or motor).

• All installations must be carried out in accordance with USCG, ABYC, NMMA and

BMEA requirements.

• When this product reaches the end of its useful life it must be disposed of in

accordance with local regulations.

PART 1 IMPORTANT INFORMATION

READ BEFORE INSTALLING OR USING THE AUTOANCHOR

ELECTROMAGNETIC COMPATIBILITY (EMC)

FCC Information:

This device complies with CFR47 Part 15 of FCC Rules for Class B equipment.

ESTI Information (CE):

This device meets the relevant standards set out in European Standard EN 60945:2002 for

maritime navigation and radio communication equipment and systems. These standards

are intended to provide reasonable protection against interference by other emission

generating products on the boat. Compliance with these standards is no guarantee that

interference will not occur in a particular installation. The installation instructions must be

followed to minimise the potential for interference.

Note: If shielded cable is not used for the sensor connections this will compromise the

EMC and may invalidate the warranty.

The AA560 console must be installed at least 3ft (1m) away from any transmission

equipment or cables carrying radio signals eg VHF radios, cables and antennas or radar

antennas; and at least 6ft (2m) away from any SSB equipment. AA560 cables must be

installed at least 1.5ft (500mm) away from such items.

Power Supply 12V/24V DC

Maximum Voltage 30V DC

Current Consumption 70mA

Output Maximum

Current Draw

12V DC: 4A

24V DC: 4A

Output Minimum

Current Draw

12V DC: 10mA

24V DC: 20mA

When connecting to a solid state switching or other low

current windlass drive eg a PLC or AC variable frequency drive

a dummy resistor load (Part #9515) may be required.

IP Rating IP67 from the front provided the unit is mounted so the back is

protected from moisture.

Operating Temperature

Range

23oF to 140oF (-5oC to 60oC)

Sensor Compatible with all AutoAnchor sensors, reed switches and

some proximity switches.

Rode - Chain Only Stainless or galvanised steel.

Rode - Rope and Chain Must have a minimum of 10ft (3 m) of chain. Chain must be

galvanised steel. Rope should be a good quality, nylon anchor

rope. Type 66 or equivalent.

DC windlasses require a dual direction solenoid

TECHNICAL SPECIFICATIONS AA560

PART 2 INSTALLATION

2.1 MAGNET AND SENSOR INSTALLATION

PLEASE READ BEFORE COMMENCING INSTALLATION

Correct magnet and sensor installation is critical for successful AutoAnchor

operation.

The AutoAnchor can be installed on vertical windlasses, drum winches and most

horizontal windlasses. Installation differs depending on the windlass type and on the

rode (all-chain or rope and chain). Please follow the instructions for your windlass

and rode. If it is not possible to comply with these instructions please check with the

AutoAnchor manufacturer or your supplier for other options or if you are not sure how to

proceed.

2.1.1 MAGNET INSTALLATION OVERVIEW

Check before starting: Your chainwheel may be prefitted with a magnet or predrilled

ready for you to fit the magnet.

Magnet Polarity: Not relevant when using the grey AA sensor (#9067) or a reed switch

sensor. If retrofitting, using the black AA sensor (#9008) the south pole (marked side) of

the magnet must face the sensor.

Magnet Seal: Insert the magnet into the hole and cover it with a minimum of 1mm of epoxy

to protect it against corrosion. See Fig 1 on page 6.

Magnet Size and Position: Refer to the instructions for your specific windlass type.

2.1.2 SENSOR INSTALLATION OVERVIEW

Vertical Windlasses: The sensor is fitted in the deckplate. Some deckplates are predrilled

for the sensor. Others have a dimple or mark to show where the sensor should be fitted.

If the windlass is not factory drilled, drill a hole 10.3mm (13/32”) diameter through the

windlass deckplate. See the instructions for your specific windlass type.

+RUL]RQWDO:LQGODVVHV6RPHWLPHVLWLVQRWSRVVLEOHWR¿WWKHVHQVRUWRDKRUL]RQWDO

ZLQGODVVRULWPD\QHHGWREH¿WWHGE\WKHZLQGODVVPDQXIDFWXUHU%HIRUHVWDUWLQJ

FKHFNZLWKWKH$XWR$QFKRUPDQXIDFWXUHURUVXSSOLHUWKDWLWLVSRVVLEOHWR¿WWKH

VHQVRUWR\RXUZLQGODVV<RXPD\QHHGDVSHFLDO¿WWLQJ

Drilling the Deck: Before drilling into the deck, ensure there is nothing below the deck that

could be damaged and that any hole you drill will not weaken the boat’s structure. Drill a

hole 10.3mm (13/32”) diameter through the deck. Ensure this hole is directly in line with the

sensor hole in the deckplate.

Part #9507 Male Field Connector

Part #9508 Female Field Connector

If there is no plug on the sensor or console cable attach the AA field

connector to the wires and use the connecting cable as above.

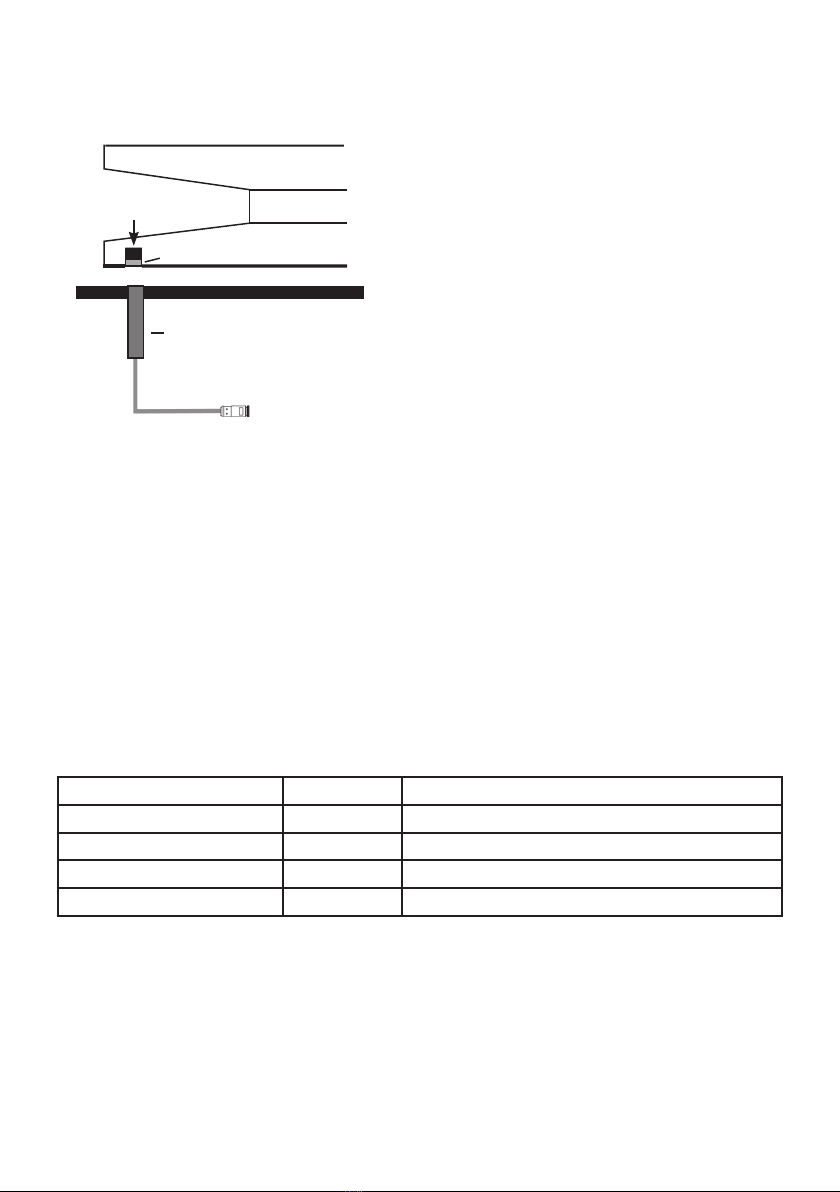

2.1.3 PLUG AND PLAY SENSOR CABLE

The AutoAnchor plug and play sensor extension cable is 2 core tinned shielded cable. It

must be used to connect the sensor to the console unit. This cable is shielded and ensures

the product meets the EMC requirements.

Ensure the connectors are firmly screwed together.

The warranty does not apply if the sensor cable plugs are removed.

The sensor cable and the console sensor cable are fitted with female plugs.

Sensor connecting cable with a male plug at each end is available in the following lengths:

6.5 m (21.33 ft) Part #9500

10 m (32.81 ft) Part #9501

15 m (49.21 ft) Part #9502

20 m (66.62 ft) Part #9503

25 m (82 ft) Part #9504

35 m (114.83 ft) Part #9514

AutoAnchor

AA560

Console

Up Down

Sensor

Chainwheel

Sensor Connecting Cable

Fitting the Sensor: Do not force the sensor into the hole. Hammering the sensor head

can damage the internal electronics. Ensure the sensor head is positioned so that it will not

be hit by the chainwheel during windlass operation and that it is at least 300mm (1ft) away

from the battery and motor cables. Secure the sensor using a good quality neutral cure

silicone or a strong adhesive eg. Sikaflex 291 or 3M 5200.

Field Connectors

Connecting 2 cables together:

If you need to extend the cable length - 2 cables can be joined

together using Part #9510 Gender changer.

Dual Installation

Use the T junction connector Part #9506 and the 2m (Male/Female) extension cable Part

#9505.

2.1.4 REED SWITCH SENSORS

Some windlasses are supplied pre-fitted with a reed switch sensor. Reed switch sensors

must have a 10mm x 8mm magnet (#9061) and the gap between the reed switch sensor

and the magnet must be a minimum of 3mm and a maximum of 5mm. This sensor requires

a field connector.

The AutoAnchor will operate with a reed switch sensor for all-chain rode. If using rope/

chain rode the reed switch sensor provides a reasonably accurate count of rode deployed

but on retrieval the display may be incorrect because it cannot allow for the stretch in the

rope.

For an accurate rope and chain count, the reed switch sensor should be replaced with the

AA grey sensor (#9067).

2.1.5 PLUG AND PLAY SENSOR TUNING

When the AutoAnchor is completely installed the sensor must be tuned. See the

instructions on page 21.

Part

#9506

AutoAnchor

AA560

Console

Up Down

AutoAnchor

AA560

Console

Up Down

Chainwheel

Sensor

Part

#9505

Magnet Fit: Drill a hole 10.3mm (13/32”) diameter and 9.5mm (3/8”) deep to fit the magnet

in the underside of a spoke in the bottom of the chainwheel. Cover the magnet with a

minimum of 1 mm epoxy. The magnet must be aligned with the sensor. See Fig 1.

2.1.6 INSTALLATION VERTICAL WINDLASS - CHAIN ONLY

Magnet Size: Standard size is 10mm x 8mmm (#9061). This may be replaced with the

smaller 6mm x 4mm (#9009) magnet if required for your windlass.

Gap Between the Sensor and Magnet:

Sensor Magnet Size Gap

AA Grey Sensor #9067 6mm x 4mm Minimum 3mm - Maximum 30mm

AA Grey Sensor #9067 10mm x 8mm Minimum 3mm - Maximum 50mm

AA Black Sensor #9008 All Magnets Minimum 3mm - Maximum 8mm

Reed Switch Sensor 10mm x 8mm Minimum 3mm - Maximum 5mm

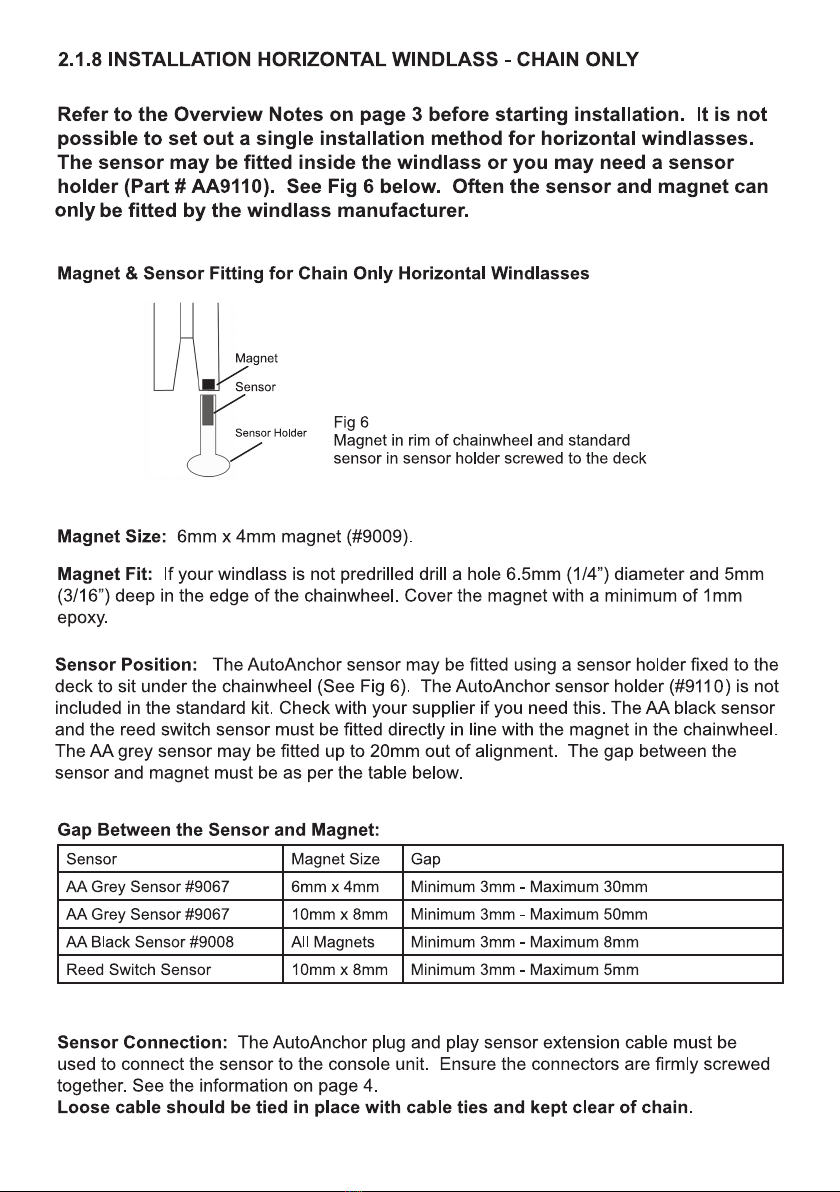

Refer to the Overview Notes on page 3 before starting installation.

Sensor Connection: The AutoAnchor plug and play sensor extension cable must be

used to connect the sensor to the console unit. Ensure the connectors are firmly screwed

together. See the information on page 4.

Loose cable should be tied in place with cable ties and kept clear of chain.

Sensor Position: The AA black sensor and the reed switch sensor must be fitted direclty

in line with the magnet in the chainwheel. See Fig 1 above. The AA grey sensor may be

fitted up to 20mm out of alignment. The gap between the sensor and magnet must be as

per the table below.

Fig 1 - All sensors

Seal with minimum 1mm epoxy.

Magnet

Sensor

Chainwheel

Deckplate

Note: If it is not possible to

align the sensor and magnet

exactly the AA grey sensor may

be fitted up to 20mm out of

alignment. The AA black sensor

and the reed switch sensor must

be directly aligned.

Magnet Fit: Some windlasses are predrilled and others need a special fit. Please check

with your supplier. The usual fit is as follows: Drill a hole 10.3mm (13/32”) diameter and

9.5mm (3/8”) deep into a spoke in the top of the chainwheel. Cover the magnet with a

minimum of 1mm epoxy. The magnet and sensor must be aligned so that the anchor rode

passes between them.(See Figs 2 & 3).

Sensor

Magnet

Fig 2 Fig 4

Seal with minimum 1mm epoxy.

Magnet

2.1.7 INSTALLATION VERTICAL WINDLASS - ROPE & CHAIN

For an accurate rope and chain count, the rode must run between the sensor and

magnet. If your windlass is prefitted with a magnet in the bottom of the chainwheel you

need to remove it and fit a new magnet in the top of the chainwheel. Refer to Figs 2-4.

Magnet Size: 10mm X 8mm magnet (#9061). An 8mm x 6mm magnet (#9052) may be

used on smaller windlasses. Check with your supplier.

Sensor Position: The sensor must be fitted into the deckplate within the sensor position

range at the stern end of the windlass (See Fig 5). It must also be aligned with the magnet

so that the rode passes between the sensor and the magnet. The centre of the magnet

and the centre of the sensor may be up to 10mm out of direct alignment. (See Fig 3). The

gap between the sensor and magnet must be as per the table below.

Chainwheel

Deckplate

Fig 3

Sensor & Magnet may be up to

10mm out of direct alignment

10mm

Sensor

Magnet

Sensor

Magnet

Sensor Position

Range

Fig 5

90o

Bow

Stern

Rode

Anchor

Locker

Chainwheel

Sensor Position Rope & Chain Vertical Windlasses

Gap Between the Sensor and Magnet

Sensor Magnet Size Gap

AA Grey Sensor #9067 8mm x 6mm Minimum 30mm - Maximum 44mm

AA Grey Sensor #9067 10mm x 8mm Minimum 35mm - Maximum 50mm

Refer to the Overview Notes on page 3 before starting installation.

Sensor Connection: The AutoAnchor

plug and play sensor extension cable

must be used to connect the sensor

to the console unit. Ensure the

connectors are firmly screwed together.

See the information on page 4.

Loose cable should be tied in place

with cable ties and kept clear of

chain.

Before starting check with the AutoAnchor manufacturer, or supplier, that it is

SRVVLEOHWR¿WWKHVHQVRUDQGPDJQHWWR\RXUKRUL]RQWDOZLQGODVV

For an accurate rope count the rode must run between the sensor and magnet. On a

horizontal windlass the magnet and sensor must be fitted by the windlass manufacturer.

If it is not possible to have the sensor and magnet fitted to achieve this you can use the

chain only horizontal windlass installation above. This provides an accurate count of

rode deployed but during retrieval the display may be incorrect because it cannot

allow for the stretch in the rope.

2.1.9 INSTALLATION HORIZONTAL WINDLASS - ROPE & CHAIN

Gap Between the Sensor and Magnet:

Minimum 5mm and maximum 40mm.

7KHPDJQHWDQGVHQVRUPXVWEH¿WWHd so that the gap remains consistent as the

winch turns.

Magnet Installation:

Size: 10mm x 8mm magnet (#).

The magnet can be mounted on the main shaft or on the side of the drum. See Figs 8 and

9. If mounted on the side of the drum, position it close to the inside to reduce the

peripheral speed of the magnet. Fix the magnet into position with epoxy ensuring it is

completely sealed to prevent corrosion.

Sensor Installation

The Grey 3 wire AutoAnchor sensor (#9067) is recommended but a proximity sensor may

be used. Every installation is different so this manual can provide guidelines only. The AA

sensor holder #, or a customised sensor holder, will be required to ensure the

sensor remains in position and the gap is consistent between the sensor and magnet

during operation.

2.1.10 INSTALLATION DRUM WINCHES

Sensor Connection: The AutoAnchor plug and play sensor extension cable must be

used to connect the sensor to the console unit. Ensure the connectors are firmly screwed

together. See the information on page 4.

Loose cable should be tied in place with cable ties and kept clear of chain.

For drum winch set up and operation, refer to page 19.

Magnet

on side of

drum

Magnet

on shaft

Sensor

Sensor

Fig 8 Fig 9

Magnet

Sensor

Fig 7

OD

ID

2.2 CONSOLE INSTALLATION

Choose a position where the operator will be able to see the anchor and windlass when

using the AA560.

Mount on a flat surface at least 3ft (1m) away from any equipment or cables carrying

radio signals eg VHF radios, cables and antennas or radar antenna and at least 6ft (2m)

away from any SSB equipment. The front of the console is waterproof but the cable boot

on the back is designed to breathe. Mount the console so that the back is protected from

moisture. Refer to the drilling template to drill the 4 holes to mount the console. Do not

use sealer or glue. The rubber grommets will seal the unit. Do not use metal studs, nylon

bolts are supplied. These should be hand tightened only.

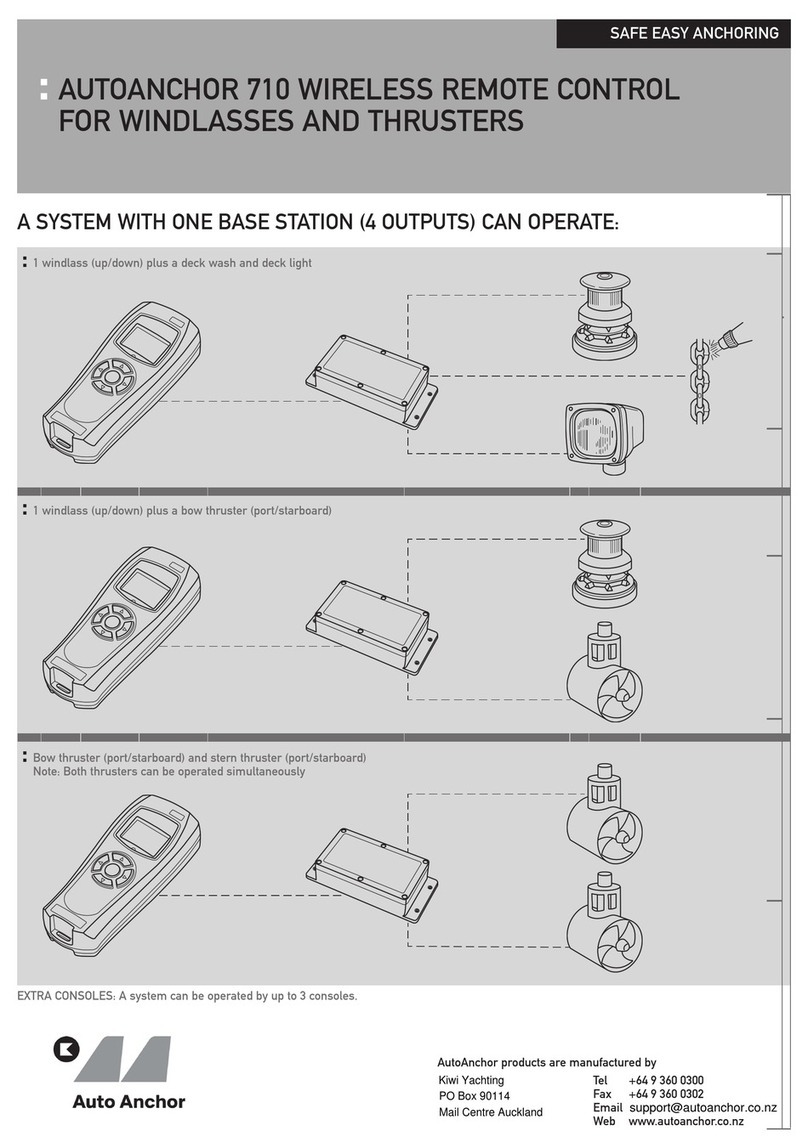

2.2.1 MULTIPLE CONSOLE INSTALLATION

Up to 3 AA560 consoles can be installed to provide multiple control stations. The AA560

can also be installed with other windlass control stations eg foot switches, remote controls

and other AutoAnchor products. T-adapters and 2m extension cables are available for

multiple installations. Refer to the wiring diagrams and pages 4 and 5 for details. If you

are uncertain how to proceed contact your supplier.

Multiple battery bank negative terminals must be permanently connected together to

become the common negative return (ground).

Power supply to the AA560 must be from the windlass control circuit, along with all other

windlass controls eg. toggle switch, remote switches, deck switches, other AutoAnchor

devices. Power supply must not be from the motor positive near the windlass.

12V or 24V DC power supply is required.

Check battery polarity before connecting power.

5HIHUWRWKHZLQGODVVPDQXIDFWXUHU¶VVSHFL¿FDWLRQV for fuse/breaker, isolator and main

power cable specifications. Ensure any fuse/breaker on the control circuit has a rating

applicable to the current loads connected to the outputs. (AA560 Output maximum is 4

Amps). An additional isolating switch should be installed for controls if the main breaker or

isolator is not readily acessible from the helm.

THE POWER SUPPLY MUST BE DISCONNECTED WHEN INSTALLING,

CONNECTING OR CHANGING THE WIRING

2.3 POWER SUPPLY

2.4 VOLTAGE LEVELS

Neither the windlass nor the AutoAnchor will operate with insufficient power. (See minimum

voltages below). Batteries must be properly maintained and charged and all connections

and wires must be of good quality and the correct gauge to prevent voltage drop.

Minimum Voltage Required 12V DC System 24V DC System

Minimum voltage required to start windlass

operation.

10V DC 20V DC

If the windlass is already operating, this is the

minimum voltage required to continue operating.

6V DC 12V DC

CABLE SPECIFICATIONS

All battery and motor cables must be ring type, insulated to prevent short circuits and

installed no closer than 1ft (300mm) away from the sensor head.

Total Length Cable Size

Cable from AA560 to the Power Supply and Solenoids

Less than 10m (33ft) 1.5mm2 (AWG16)

10m (33ft) - 20m (66ft) 2.0mm2 (AWG14)

20m (66ft) - 40m (132ft) 3.0mm2 (AWG12)

Cable from Motor Load Wires

Up to 30.5m (100ft) 1.0mm2 (AWG18)

2.5 WIRING

Interlock protection is included in the system. Do not fit diodes or interlock devices to

windlass outputs as these will prevent the system from operating correctly.

All main power conductors and terminations are to be installed according to the windlass

manufacturer’s specifications. Seal terminals against moisture by spraying with CRC

[3013] Soft Seal or CRC [2043] Plasticoat 70. Insulation must be used to protect all

terminals.

To reduce the potential for interference all cables must be located at least 1.5ft (500mm)

away from any equipment or cables carrying radio signals eg VHF or SSB radios, cables

and antennas or radar antennas.

Do not leave cables hanging loose, they must be tied in place with cable ties.

9083

3.1 USING THE AUTOANCHOR BUTTONS

Scroll: Menu/Numbers/Up/Down.

Mode/Select/Enter/Save.

On/Off/Escape or Back.

Hold together to access the Set up menu.

Hold for 2 seconds to disable the lock.

Hold for 2 seconds to return the AutoAnchor to the idle state.

PART 3 SET UP

DownUp

3.2 SET UP MENU OVERVIEW

Use to scroll through the menu.

Hold together to display the Set up menu.

The AutoAnchor must be turned off to access the Set up menu.

General

Diagnostics

Sensor

Up Solenoid

Down Solenoid

Load Wires

Battery

Windlass

Diagnostics

About

Windlass Set Up

Docking distance

Total rode length

Rode

Chain only

Chain per turn

Rope and chain

Preset

Chain per turn

Rope per turn

Drum Winch

Inside diameter

Outside diameter

Sensor

Standard

Motor Driven Reed

Gearbox ratio

Swap controls

General Set Up

Language

Units

Feet

Meters

Fathoms

Key Beep

Lock

Factory Defaults

2.0

V2

3.3 GENERAL SET UP

To Access General Set Up

Turn the AutoAnchor Off.

Hold together to display the Set Up menu.

Select General.

To Exit General Set Up

Exit to the Set up menu or hold for 2 seconds to exit

to the start screen.

Set Units

Select units.

Scroll to meters, feet or fathoms.

Save.

Return to General Menu.

Set Key Beep

Scroll to key beep.

Save key beep on or off.

Set Lock - For safety we recommend the lock be left on.

Scroll to lock.

Save lock on or off.

3.4 FACTORY DEFAULTS

Resetting the Factory Defaults clears all programmed

settings and logs.

To Reset Factory Defaults:

Turn the AutoAnchor off.

Hold together to access the Set up menu.

Select General.

Select Factory defaults.

Select No/Yes.

Yes - Apply the factory reset. The AutoAnchor will turn off.

Re-enter all your Settings.

No - Return to the General menu.

Hold the On/Off button down for 2 seconds to return the

AutoAnchor to the start screen.

Set Language

Select Language.

Scroll to the preferred language.

Save.

Return to General Menu.

3.5.1 To Access Windlass Set up

Turn the AutoAnchor Off.

Hold together to access the Set up menu.

Scroll to Windlass.

Select Windlass.

3.5 WINDLASS SET UP

For accurate counting you must set up the AutoAnchor with information for your windlass.

Record the settings for future reference.

3.5.2 Set Docking Distance

Defaut = 1.5m or 4ft. Minimum setting = 1m or 3.3ft.

Note: During retrieval the windlass stops at the docking distance.

Scroll to Docking distance.

Select docking distance.

Increase or decrease the docking distance.

Save and return to Windlass Setup.

Setting:

3.5.3 Set Total Rode Length

Add total length of chain plus total length of rope.

Defaut = 60m or 196ft. Minimum setting = 10m (33ft).

or OFF to operate as a counter only.

Scroll to Total rode length.

Select Total rode length.

Increase or decrease the value in meters or feet.

Save and return to Windlass Set up.

Setting:

3.5.4 Set Rode

Scroll to Rode.

Select Rode.

Select Chain only or Rope and chain and follow the

instructions below to enter the settings for the rode selected.

This is the length of chain that is released during one complete turn of the chainwheel.

The information for some windlasses is listed in Appendix 1. If your windlass is not listed

follow the instructions below to calculate the chain per turn.

3.6.1 Chain Per Turn

3.6 CHAIN ONLY RODE SET UP

Setting:

3.6.3 Calculating the Chain Per Turn

Step 1 Use adhesive tape to place a mark on the

chainwheel.

Step 2 Use adhesive tape to place a mark on the chain

coming out of the chain wheel.

Step 3 Use adhesive tape to place a mark on the deck

below the mark on the chain.

Step 4 Carefully release the chainwheel so that it can be

turned by hand to feed the chain out.

Step 5 Using the mark on the chainwheel as a guide, turn the

chainwheel one turn, causing the chain to be

released on to the deck.

Step 6 Measure the length of chain from the mark on the

deck to the mark on the chain.

Step 7 Enter this measurement (See below).

Chainwheel Mark

Chain Mark

Deck Mark

Distance to Measure

Select Chain per turn.

Enter the measurement. In mm or in metric inches

(depending on units selected). See the table

below for metric inch calculations.

Save and return to Rode Set up.

Exit to Windlass Set up.

3.6.2 To Enter the Chain per Turn for Chain Only Rode

Setting:

3.7 ROPE AND CHAIN RODE SET UP

Some rope and chain windlasses have the settings already entered in the AutoAnchor.

Refer to the Preset Windlass Profile List in Appendix 1. If your windlass is on the list

select “Use preset” to enter the Windlass profile.

If your windlass is not on the list:

You will need to enter information for the chain and rope per turn.

(See instructions on page 17).

Inches Metric Inches AutoAnchor Setting

(to 1 decimal point)

1/8 0.125 0.1

1/4 0.25 0.3

3/8 0.375 0.4

1/2 0.5 0.5

5/8 0.625 0.6

3/4 0.75 0.8

7/8 0.875 0.9

Metric Inches Conversion Table

3.7.1 Selecting Use Preset

Refer to the Preset Windlass Profile List list in Appendix 1.

Select Use Preset.

Select Windlass profile.

Scroll to the correct Windlass profile for your windlass.

Save and return to Windlass Set up. There are no

further settings.

Exit to Set up menu or hold for 2 seconds to return

to the start screen.

Setting:

This is the length of chain that is released during one complete turn of the chainwheel.

The chain per turn for some windlasses is listed in Appendix 1. If your windlass is not

listed, follow the instructions on page 16 to calculate it.

3.7.2 Chain per Turn for Rope and Chain Rode

Select Chain per turn.

Enter the measurement in mm or metric feet

(depending on the units selected). See the

table for metric inch calculations.

Save and return to Rode Set up.

3.7.3 To Enter the Chain per Turn

Setting:

3.7.4 Rope per Turn for Rope and Chain Rode

This is the length of rope that is released during one complete turn of the chainwheel. You

need to measure the length of rope pulled through for 10 turns and divide the result by 10.

See instructions below to calculate the rope per turn.

3.7.5 Calculating the Rope Per Turn

Step 1 Carefully release the chainwheel so that it can be

turned by hand to feed the rode out until you have

rope.

Step 2 As you did for the chain, use adhesive tape to mark

the chainwheel, the deck and the rope. (See the

instructions for the chain per turn above).

Step 3 Using the mark on the chainwheel as a guide, pull the

rope out by hand until the chainwheel has completed

10 turns.

Step 4 Measure the length of rope pulled, divide it by 10.

Step 5 Enter this measurement (See page 18).

Chainwheel Mark Chain Mark

Deck Mark

Distance to Measure

Select Rope per turn.

Enter the measurement in mm or metric inches

(depending on the units selected).

Save and return to Rode Set up. There are no further

settings.

Exit to Windlass Set up. Press twice to exit to the Set Up

menu or hold for 2 seconds to return to the start screen.

3.7.6 To Enter the Rope per Turn

Setting:

3.8.1 Motor Driven Sensors

To select the motor driven sensor:

Scroll to Sensor.

Select Sensor.

Scroll to Motor driven reed.

Select.

Scroll to Gearbox ratio.

Select Gearbox ratio.

Increase or decrease the Gearbox ratio.

Save and exit to the Sensor set up menu.

Exit to the Windlass set up menu or hold for

2 seconds to return to start screen.

3.8 SENSOR SET UP

Default setting: Standard - Applies to all AA sensors, reed switch

baseplate sensors and proximity sensors. The default setting

should only be changed if you are using a motor driven sensor. (See

below).

Note: The sensor is tuned to the system on first use. See page 21.

3.9 SWAP CONTROLS

Default setting: = Up and = Down

Some operators prefer to use the buttons so that

= Out and = In

Access the swap controls feature via the Windlass Set up Menu.

Turn the AutoAnchor Off.

Hold together to access the Set up menu.

Scroll to Windlass.

Select Windlass.

Scroll to Swap Controls.

Select Swap Controls.

Exit to the Windlass Set Up or hold for 2 seconds

to return to start screen.

Note: This feature can not be used to correct wiring errors.

Other manuals for 560

2

This manual suits for next models

1

Table of contents

Other Auto Anchor Remote Control manuals