Auto Anchor 560 Instruction manual

IMPORTANT INFORMATION

READ BEFORE INSTALLING OR USING THE AUTOANCHOR

1

This User Guide is intended as a quick reference for day to day use of

the AA560. It must be read in conjunction with the Owner’s Manual. The

Owner’s Manual has installation, set up and testing instructions plus

information relating to troubleshooting and maintenance.

The AutoAnchor manufacturer and supplier accept no liability for personal injury or

property damage resulting from failure to follow the installation and operating instructions

or the use of the AutoAnchor in a way that may cause accidents or damage or that may

violate the law.

USER PRECAUTIONS

It is the owner’s sole responsibility to ensure the AutoAnchor is installed, used and

maintained in a manner that will not cause accidents, personal injury or property damage.

When using the AutoAnchor the operator must use safe boating practices and safe

windlass/winch and anchoring operation

• use the windlass/winch strictly according to the manufacturer’s instructions;

• only persons who are fully aware of the correct use of the windlass/winch

should be allowed to use the AutoAnchor to control this equipment;

• the user must personally control and supervise all anchoring operations;

• the user must know the location of the main breaker or battery switch to

disconnect the windlass/winch from all power sources in the event of an

emergency;

• the windlass/winch power supply must be turned off when the equipment is not in

use;

• there must be an alternative method available to operate the windlass/winch.

When Controlling a Windlass/Winch

• maintain a clear view of the windlass/winch, rode and/or anchor during operation;

• always ensure the anchor is fully docked and secured before moving the boat.

SET UP AND TESTING

Before use the AutoAnchor must be correctly set up for the equipment it is to control

and then tested in a safe environment. The AutoAnchor will not count correctly if the

windlass selection is wrong or the windlass is not standard (eg it is installed with a different

chainwheel or motor).

Required for all sensors other than a motor driven reed sensor. This screen automatically

displays on first use or if Factory Defaults are loaded, the sensor is reset or there has been

a loss of sensor signal. Refer to page 21 in the Owner’s Manual.

PLUG & PLAY SENSOR TUNING

2

OPERATION

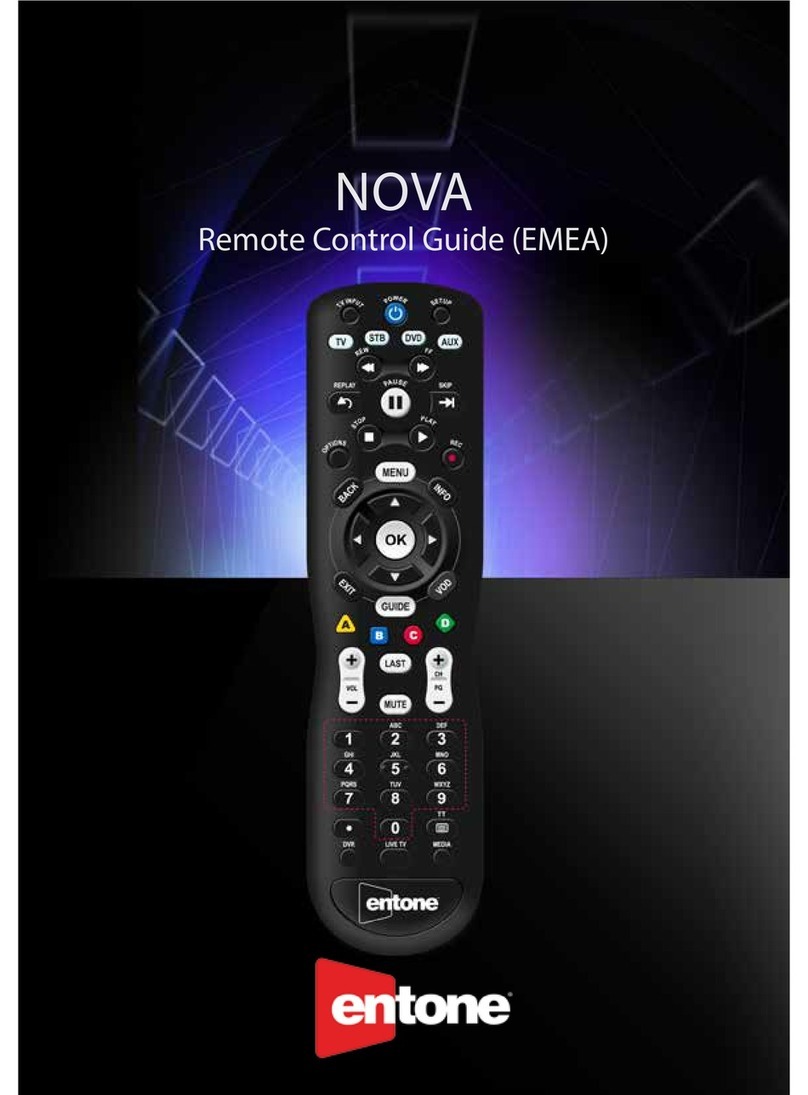

AA560 BUTTONS

Lock

The AutoAnchor is fitted with a lock to help protect against unintentional windlass

operation.

Hold the Mode button for 2 seconds to unlock.

Unlocked

Locked

The lock automatically resets 5 minutes after the AutoAnchor was last operated or when

the AutoAnchor is turned off. You can also reset the lock by holding down the button

until the key is displayed in the top right corner.

Note: Some operators prefer to swap the Up/Down buttons as follows:

Up = Out and Down = In. See the instructions on page 18 of the Owner’s Manual.

In an emergency shut off the

power to the windlass using

the isolating/breaker switch.

DownUp Auto ON/OFF

Sensor Pulse Indicator

& Windlass Direction

Standard AA

Operation

Functions

Hold 2 sec

to Turn Off

Hold 2 sec

to Unlock

Status bar

INFORMATION DISPLAYED DURING OPERATION

The length of rode deployed in feet, metres or fathoms.

The direction the anchor is moving.

The type of rode being deployed (chain or rope).

Windlass speed.

Settings and measurements are saved if the unit is turned off or the battery fails.

Counting continues if the windlass is operated by another control eg foot switches.

•

•

•

•15 u

u

3

AUTOMATIC AND MANUAL OPERATION

Keep your finger on the button to deploy the anchor manually or use the automatic function

for hands free anchor deployment and retrieval. See the instructions for both options below.

MANUAL OPERATION

Deploy and Retrieve the Anchor Using Manual Operation.

Turn the AutoAnchor on.

Clear the safety lock.

Hold down the up or down button to deploy or retrieve the anchor. Releasing the

button stops the windlass operation.

Ensure the anchor is fully docked and secured before moving the boat.

DOCKING ALARM: During retrieval the windlass will stop and the

AutoAnchor beeps to warn the operator the anchor is at the preset

docking distance. Press and hold the button to continue retrieval.

Extra care must be taken at this stage of retrieval.

Use the Automatic Function to:

Preset the length of rode for deployment.

Have hands-free operation of the windlass.

Retrieve the anchor automatically to the preset docking distance.

Note: For rope/chain counting, if the sensor or load sensing wires are

not installed correctly the automatic function will not operate. An

Installation warning message will display on the screen. The windlass

can still be operated using manual operation but on retrieval the displaybut on retrieval the display

may be incorrect because it cannot allow for the stretch in the rope.

•

•

•

AUTOMATIC OPERATION

WARNING: There is an inherent risk when using any automatic function

on a boat. If you choose to use the AutoAnchor automatic functions, you

must still control and supervise all windlass and anchoring operation.

For an accurate reading always ensure the AutoAnchor display reads 0.0 before

deploying the anchor.

4

Enable Automatic Operation

A “rode to be released” value must be entered to use automatic operation.

Safety Override

Press any button on the AutoAnchor to stop the windlass during automatic release or

retrieval. In an emergency shut off the power to the windlass using the isolating/

breaker switch.

Deploy the Anchor Using Automatic Operation

Turn the AutoAnchor on.

Clear the safety lock.

Press the Mode button to select Auto. The screen

displays the current length for Auto release.

If this setting is correct. Press and release the down button to

deploy the anchor.

To Change the setting:

Press the Mode button again to select Set auto.

Enter the value.

Save and return to Auto.

The windlass will stop and the AutoAnchor will beep when

the preset length of rode has been released. The screen

will display “Auto target reached”.

To Set A Rode to be Released Value

Turn the AutoAnchor on.

Clear the safety lock.

Press the Mode button twice to enter Set auto.

Scroll up or down to change the value.

Save ready to deploy. Press twice to return to start screen.

To disable the automatic operation: Set the rode to be released

value to Off.

Retrieve the Anchor Using Automatic Operation

Turn the AutoAnchor on.

Clear the safety lock.

Press the Mode button to Select Auto.

Press and release the Up button to retrieve the anchor.

The windlass will stop and the AutoAnchor will beep when the

docking distance is reached. The screen will display

Docking distance.

Press the Up button to complete retrieval of the anchor.

The AutoAnchor will beep during this process.

Ensure the anchor is fully docked and secured before moving the boat.

To Check Logs

The AutoAnchor must be turned on.

Press to access the Menu.

Select Logs.

Return to the menu.

Exit and return to start screen.

Logs are cleared using the Factory Default Settings. See page 14 in the Owner’s Manual.

Resetting the Factory Defaults clears all logs and calibrations.

To Adjust Backlight

The AutoAnchor must be turned on. It is best to change this setting in low light.

Press to access the Menu.

Select Backlight.

Change the Backlighting level.

Save and return to the menu.

Exit and return to start screen.

OTHER OPERATION SETTINGS

Press to access the menu when the AutoAnchor is turned on.

To Clear to Zero

The AutoAnchor must be turned on.

Press to access the Menu.

Select clear to zero.

Select No/Yes.

Yes - return to start screen.

No - return to the menu, then press again

to return to the start screen.

9

10742

112

Clear to zero

Logs

Backlight

Reset sensor

Reset sensor

To Reset Sensor

The AutoAnchor must be turned on.

Press to access the Menu.

Select Reset sensor.

Select No/Yes.

Save and return to the menu.

Exit and return to start screen.

Deploy the anchor to tune the sensor.

See page 21 in the Owner’s Manual.

Reset sensor

Reset sensor

5

$$7528%/(6+227,1**8,'(

The AutoAnchor is not faulty if these messages display. The diagnostics help with troubleshooting the sensor and wiring. These messages display briefly during opera-

tion and/or power up. A beep will sound and after 3 seconds the message will be cleared. The count will not be accurate until the cause of the error is fixed. After

the windlass is retrieved and the error is fixed reset the AA150 by holding down one of the buttons to zero the display.

Use the table below to help identify a problem and provide a possible solution. If you cannot resolve the problem, contact your supplier for further information.

Problem Possible Solution

Sn 1

Appears during operation.

The AA150 does not count and does

not display a sensor pulse.

Sn 2 (Rope/Chain Only)

Appears during operation. The AA150 will

count and will display a sensor pulse. The

count will not be accurate.

Sensor is too close to the magnet. Ensure the gap between the magnet and sensor is no less than 35 mm for a

10mm x 8 mm magnet and 30mm for an 8mm x 6 mm magnet). The count will not be accurate until the problem

is fixed. Fix the installation and reset the counter to zero.

Sn 3 (Rope/Chain Only)

Appears during retrieval when using a rope/

chain rode. The AA150 will count and will

display a sensor pulse. The count will not

be accurate.

The AA150 has failed to detect the change from rope to chain or there has been excessive rope slippage. Com-

plete retrieval and then reset the counter to zero. This message may also display if the chain is the wrong size for

the chainwheel.

Sn 4

Appears during AA150 power up.

AA150 will not count but it will

display a sensor pulse.

The orange wire to the Up solenoid is not connected. Fix the wire connection and reset the counter to zero.

Ld (Rope/Chain Only)

Appears during AA150 power up. The

AA150 will count and will display a

sensor pulse. The count will not be

accurate.

The load sensor wires are not connected to the motor. Fix the connection and reset the counter to zero.

Bottom Fit All-Chain Windlasses Top Fit Rope/Chain Windlasses

Magnet 6mm x 4mm Min 3mm Max 30mm N/A

Magnet 8mm x 6mm Min 3mm Max 44mm Min 30mm Max 44mm

Magnet 10mm x 8mm Min 3mm Max 50mm Min 35mm Max 50mm

If using a reed switch sensor, the gap must be between a minimum of 3mm and a maximum of 5mm.

Note: If the installation uses a black all-chain sensor (Part No: 9008) the gap must be between a minimum

of 3mm and a maximum of 8mm and the south pole of the magnet must face the sensor.

AA150 counts when the windlass is not

turning or counts erratically displaying a

large number eg 888.

The count pauses during retrieval. This is not a fault. The rode is changing from rope to chain.

The sensor could be damaged, incorrect cable may be fitted, or the AA150 may have been subject to external

interference - RF or electrical. Check that the sensor cable is not damaged and that the cable fitted is as specified

in the instructions. Check for external interference on the boat eg damaged or loose RF cables or aerials or other

instruments that may not be working correctly or have been damaged by electrical interference including lightning.

No signal from the sensor to the AA150. Either there is no magnet, the gap between the magnet and sensor is too

big or the sensor signal is out of tune because of testing during installation. Try resetting the AA150 by running

the windlass up and down for 10-15 seconds. If the message still appears check the magnet and the gap and align-

ment between the magnet and sensor. Check sensor wiring and installation and check for damage to the sensor

and magnet. When fixed reset the AA150 as above. For manual reset, clear the counter to zero twice. To clear

to zero press and hold any key. The AA150 will beep and clear within 4 seconds. rE will be displayed during the

second clearing indicating the reset is okay.

AA500C TROUBLESHOOTING

Problem Possible Solution

1. AutoAnchor 500C will

not turn on.

Check battery is connected and has correct polarity. Check battery has sufficient voltage. See page 13 and note 3 below. Check fuses are working.

2. AutoAnchor 500C

does not operate the

windlass either up or

down.

Check Calibration Item 3 is not set to zero. Check the “Chain to be Released” is not set to zero (Refer to page 10). Check if the safety lock is on.

Check battery has sufficient voltage. See page 13 and also note 3 below.

The AutoAnchor 500C has built in diagnostics to help with troubleshooting. The diagnostics help identify problems with the battery, the solenoid, the sensor and windlass rota-

tion. The diagnostics appear briefly when the AutoAnchor 500C is first switched on. If you have a problem, check for the diagnostic messages by switching the AutoAnchor 500C

off and then on again.

Battery has dropped below 6 volts. Check battery connections and charge. See also note 3 above.4. AutoAnchor 500C

turns itself off.

ELECTRONIC DIAGNOSTICS

Battery low - check the voltage output. (See the notes on page 13). If the battery is fully charged check the wiring - for loose connections and check

the cable size. The cable from the battery to the console unit and/or the solenoids may not be heavy enough. See the Cable Specifications on page

15.

3. AutoAnchor 500C will

not operate the windlass

and the LCD shows

BATT when the UP

or DOWN buttons are

pressed.

6. Solenoids click on

and off when the UP

or DOWN buttons are

pressed but the windlass

does not operate.

Either the yellow (down) and orange (up) solenoid wires are shorted together or the AutoAnchor 500C has a poor ground connection. Check the

wiring and ensure the solenoid wires are separated.

The solenoids could be exceeding the maximum 2.6 Amps. The AutoAnchor 500C is designed to turn off if this occurs. Contact your supplier for

further information. Also see note 3 above.

7. Screen shows SOL. Solenoids are not connected. Check wiring to solenoids or control box.

5. The windlass operates

for a short period and then

stops. The AutoAnchor

500C may turn off.

Use the table below to help identify a problem and provide a possible solution. If you cannot resolve the problem, contact your supplier for further information.

Definitions SOL = Solenoid, SENS = Sensor, BATT = Battery

12. AutoAnchor 500C

display shows “Eror”

The Up or Down button has pressure on it at the time the the unit is turned on. Clear the pressure from the button. Then turn the unit off.

Turn it on again to operate normally.

8. AutoAnchor 500C

will not count or shows

SENS and the windlass

stops during automatic

operation.

The sensor is not working properly. Check the calibration settings are correct. Check if the sensor is disconnected or damaged. Check

wiring from console to sensor for loose connections and check that it is the correct specified cable.(See below). Check the magnet and

sensor are aligned and the gap between them is correct. (See Installation Instructions). Check the magnet is not corroded. Check the

magnet is installed with the white(south) end facing the sensor.

9. AutoAnchor 500C

counts when the

windlass is not turning

or counts too much per

revolution or displays

an unusually large

number.

The sensor may be damaged or the sensor cable is not the specified type. See the Cable Specifications below.

10. AutoAnchor 500C

does not stop exactly at

the preset point.

This is not a fault - Stopping is accurate to +1 chainwheel revolution. The chainwheel may run on slightly with momentum.

This will occur during automatic operation if you try to release more chain than is on board. Check the setting for chain on board.

(Calibration Item 3).

11. The windlass stops

before the length of chain

specified is deployed.

Note: When the sensor

is operating correctly

the sensor (feet/metres)

indicator flashes every

time the magnet passes

the sensor.

Message/Problem Possible Solution

TheAA550 is not faulty if these messages are displayed. The diagnostics help identify problems with installation, the battery, the solenoid

and the sensor and windlass rotation. Some of the messages appear when you try to operate the AA550 but others only appear briefly when

the AA550 is turned on. Always check for the diagnostic messages by switching the AA550 off and then on again. Use the table below to

help identify a problem and provide a possible solution. If you cannot resolve the problem, contact your supplier for further information.

ELECTRONIC DIAGNOSTICS

Definitions SoL = Solenoid, SEN = Sensor, Lo Pr = Low Power

3. Lo Pr + a number

Displayed when the Up or

Down button is pressed. The

AA550 will not operate the

windlass.

Low power to the AA550. To check the voltage received by the AA550, turn the AA550 off, and press

and hold the Down button. The voltage will display on the LCD. Check the battery voltage output.

Check wiring for loose connections. Check the cable size. If the cable is the wrong size there may be

voltage drop between the battery and the AA550. See the cable specifications on page 2 and the minimum

voltages on page 7.

SEN and LoAd messages: When these messages are displayed the AA550 will operate the windlass up and down manually but the Auto

function will not work and the count will not be accurate.

6. SEN 1

Displayed briefly when the

AA550 is turned on and

when it is operated manually.

Auto does not work. No sen-

sor pulse.

1. LoAd

Displayed briefly when the

AA550 is turned on and

when it is operated manually.

The Auto function does not

work.

2. LoC

Displayed when a button is

pressed. The AA550 will

not operate.

7. SEN 2

Displayed briefly when the

AA550 is turned on and when

it is operated manually. Auto

does not work. No sensor

pulse.

8. SEN 3

Displayed when the AA550 is

operated manually. Auto does

not work. No sensor pulse.

The sensor wires are disconnected or the red and black sensor wires are shorted together. AA550 will

operate the windlass up and down but there will be no count displayed on the LCD. Check sensor wiring

and installation. When fixed reset the AA550 to zero twice. The anchor must be docked. To reset to zero

- press and hold the ON/OFF button. Release when the display shows 0.0.

The load sensor wires are not connected to the motor. Use the AA550 manually and check the load wire

connections. If using an all-chain rode check that the AA550 is calibrated correctly for all-chain. When

fixed reset the AA550 to zero. The anchor must be docked. To reset to zero - press and hold the ON/OFF

button. Release when the display shows 0.0. The count will not be correct until the problem is fixed.

The safety lock is on. Hold down the Mode button to release the safety lock and then operate as normal.

5. SEN

Displayed when attempting

to use the Auto function.

Use the AA550 up and down manually and check for the specific sensor error. SEN1 - SEN5. Refer to the

notes 6-10 below.

4. OFF

Displayed when attempting

to use the Auto function.

No setting has been entered for the rode to be released so the Auto function cannot operate. Enter a length

of rode for release and the system will operate normally. (Refer page 10 Operation Manual).

The black sensor wire is shorted to ground. AA550 will operate the windlass up and down but there will

be no count displayed on the LCD. Check sensor wiring and installation. When fixed reset the AA550

to zero twice. The anchor must be docked. To reset to zero - press and hold the ON/OFF button. Release

when the display shows 0.0.

No signal from the sensor to the AA550. Either there is no magnet, the gap between the magnet and sen-

sor is too big or the sensor signal is out of tune because of testing during installation. AA550 will operate

the windlass up and down but there will be no count displayed on the LCD. Try resetting the AA550 by

running the windlass up and down for 10-15 seconds. If the message still appears check the magnet and

the gap and alignment between the magnet and sensor. Check sensor wiring and installation and check for

damage to the sensor and magnet. When fixed reset the AA550 as above. To reset manually the anchor

must be docked and the AA550 reset to zero twice. To reset to zero - press and hold the ON/OFF button.

Release when the display shows 0.0.

AA550&AA560 Troubleshooting

17. The windlass does not stop

exactly at the preset point.This is not a fault. Stopping is accurate to +1 chainwheel revolution. The chainwheel may run on slightly

with momentum.

18. AA550 counts when the

windlass is not turning or

counts erratically displaying a

large number eg 8888.

The sensor could be damaged, incorrect cable may be fitted, or the AA550 may have been subject to ex-

ternal interference - RF or electrical. Check that the sensor cable is not damaged and that the cable fitted

is Beldon 9501 or equivalent, 2 core, tinned, copper, screened, as specified in the instructions. Check for

external interference on the boat eg damaged or loose RF cables or aerials or other instruments that may

not be working correctly or have been damaged by electrical interference including lightning.

19. AA550 beeps when it is

turned off or locked.

Anchor rode is running through the windlass. Check if the windlass is being operated using the deck

switches or a remote control. If not, check the windlass and anchor is secured.

20. The count pauses

during retrieval.

If the sensor indicator is pulsing this is not a fault. The rode is changing from rope to chain.

13. AA550 will not turn

on or turns off.

Check if the safety lock is on - the LCD will display LoC. Refer note 2 above.

Check voltages at the battery and the AA550. The LCD will display Lo Pr. Refer note 3 above.

Check wiring for loose connections to the solenoids. The LCD will display SoL Up or SoL dn if the

wires are disconnected. Refer note 12 above.

Check that the windlass is not already in operation using the deck switch or remote control.

Check the total rode on board (Calibration 3 - Operation Manual Pg 4) is not set to OFF.

14. AA550 will not

operate the windlass.

Check battery connections, polarity and voltage. The voltage to the AA550 can be checked by turning it

off and holding the Down button. The voltage is displayed on the LCD. See page 7 for minimum volt-

ages. Check fuses and wiring and for the Lo Pr diagnostic message. Refer note 3 above.

15. AA550 will operate the

windlass manually but Auto

function does not work

16. Windlass rotates down

when the Up button is

pressed and up when the

Down button is pressed.

Check the rode to be released is not set to zero. The LCD will display OFF. See note 4 above. Use the

AA550 manually and check for specific diagnostic messages SEN or LoAd (See notes 1 and 5-10 above).

The motor or solenoid wiring is reversed. Change the wiring and check the direction of the windlass

rotation.

12. SoL uP or SoL dn

Displayed briefly when the

AA550 is turned on. The

AA550 will not operate the

windlass.

SoL uP - The Up (orange) wire is not connected to the solenoid. SoL dn - The Down (yellow) wire is not

connected to the solenoid. These messages also appear if the up or down button is pressed on the AA550

when the windlass is already in operation using a deck switch. Diodes or interlock devices between the

AA550 and the solenoid will also cause these messages. The AA550 has internal diode protection. Exter-

nal diodes will cause the system to fail.

11. SoL oL

Displayed when the Up or

Down button is pressed. The

windlass may operate for a

short period and then stop.

The solenoids could be exceeding the maximum 4 Amps or a solenoid wire is shorted to ground. The

AA550 is designed to turn the solenoids off if these events occur. Check the solenoids and the wiring and

fix as necessary.

9. SEN 4

Displayed when the AA550

is operated manually. The

sensor indicator does pulse.

Auto does not work.

The sensor is too close if running rope/chain or the windlass has been run without rode.AA550 will oper-

ate the windlass up and down but the count will not be accurate. Try resetting the AA550 by running

the windlass up and down for 10-15 seconds. If the message still appears make sure you have the correct

calibration setting for the windlass and rode. Check the magnet and sensor are aligned, the sensor is in

the correct quartile and the gap between the sensor and magnet is correct. Check for loose wiring from

the sensor to the AA550. When fixed reset the AA550 as above. To reset manually, the anchor must be

docked and the AA550 reset to zero twice. To reset to zero - press and hold the ON/OFF button. Release

when the display shows 0.0. the display shows 0.0.

10. SEN 5

Displayed during retrieval.

The sensor indicator does

pulse. Auto does not work.

The AA550 has not detected the change from rope to chain. Use Manual Up to complete retrieval. The

count displayed will not be accurate. Check for rope slippage and that the rope and chain are the correct

size for the chainwheel. Check that the sensor is in the correct quartile. When fixed reset the AA550 to

zero. The anchor must be docked. To reset to zero - press and hold the ON/OFF button. Release when the

display shows 0.0.

&KHFNRXWWKHFROOHFWLRQRIDQFKRUVDQGGRFNLQJZHRIIHU

Other manuals for 560

2

Table of contents

Other Auto Anchor Remote Control manuals