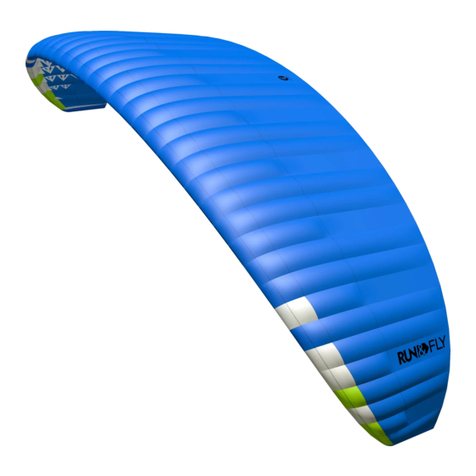

DESIGN

Canopy was designed in our CSG (Canopy Shape Guard)

system, comprising a number of elements resulting in

exceptional coherence and stability of the shape. Below

you will find a short description of CSG subsystems.

Nemo XX has an elliptic shape with slightly back-swept wingtips. The canopy

is made of doubled cells, with ribs supported by VSS (V-Shaped Supports)

system. Such design guarantees that the canopy stays rigid, the upper

surface is smooth with correctly reproduced aerofoil, and what is most

important we have fewer suspension points (thus reducing overall lines'

length and drag).

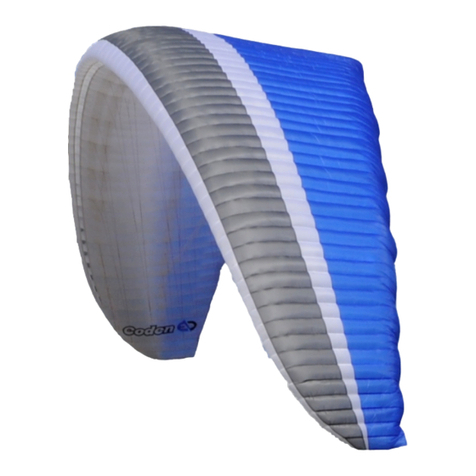

Inside the canopy there is RSS (Reinforcing Strap System) applied on the

lower surface. RSS is a ballooning-independent reinforcement system made

entirely of paragliding fabric, stiffening and stabilizing the canopy.

The aerofoil was perfected with DOA technology (Dudek

Optimized Airfoil). It merges all our experiences stemming

from previous designs and as a special feature is optimized

with dedicated CFD engineering software.

The air intakes are placed on the lower surface close to the leading edge,

placed so that max pressure point remains in the area at possibly many

states of flight. They are designed and executed in Shark-

nose technology, meaning specific, concave shape of the

reinforced profile area at its leading edge (the name comes

form the very shape, reminding shark's nose). Due to such

shape the intakes can be smaller and moved a bit back, so that leading edge

remains undisturbed and offers smooth airflow. The internal pressure of the

canopy stays stable within wide speed range. In everyday flying this results in

greater resistance to stalls (e.g. when thermalling) and front collapses at high

speeds.

The suspension points areas are additionally reinforced with laminated fabric

so that loads are equally distributed on three planes: vertically (with the ribs),

diagonally (with VSS system) and level through RSS.

All crossports have been prepared with application of OCD (Optimised

Crossports Design). Carefully designed shapes of the openings and their

optimal placement between stress lines guarantee efficient pressure

distribution in the canopy and its quick inflation. These openings are scaled

together with the ribs, so that their replicability is flawless and they do not

disturb the aerofoil in any way.

Another feature of the Nemo XX is the Flexi-Egde

technology. The leading edge is closed to the airflow, and

its precise shape is kept with laminated cloth

6