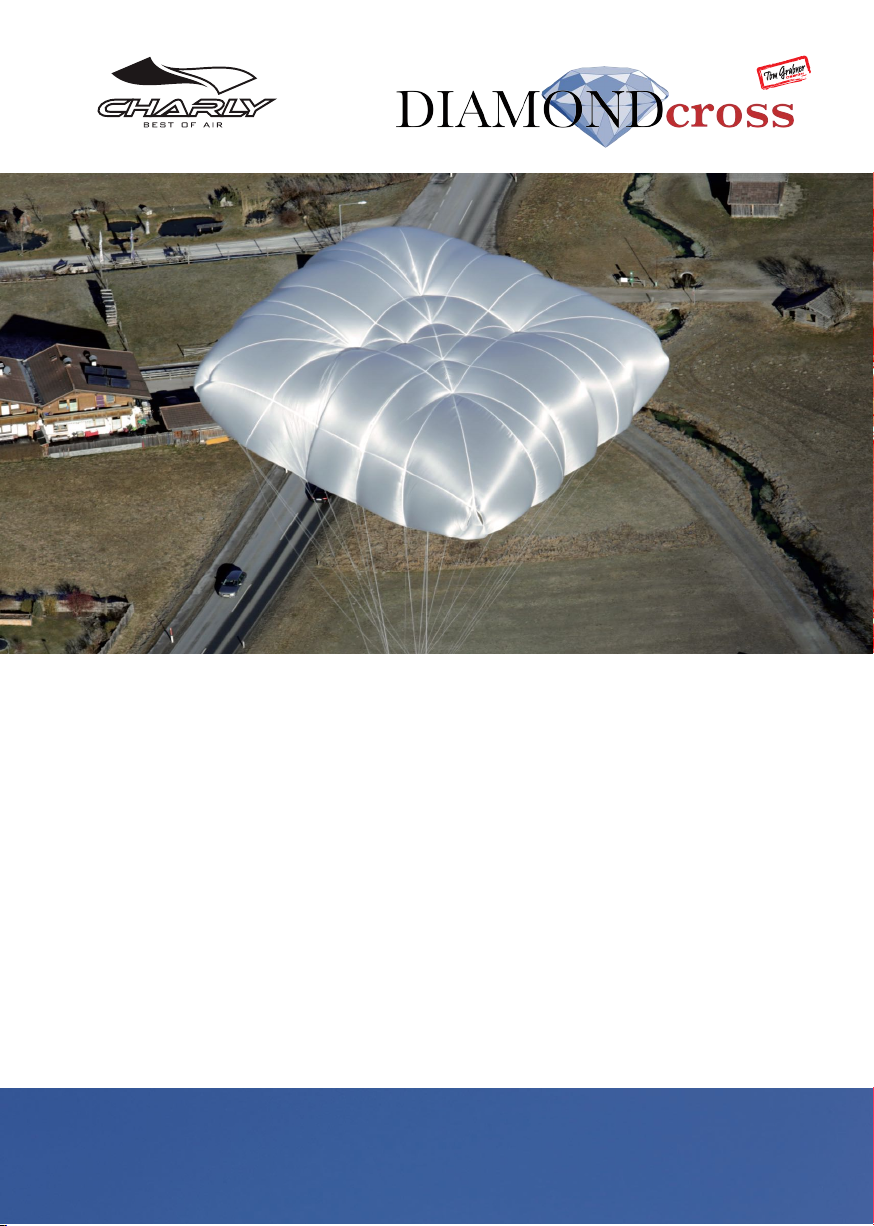

CHARLY DIAMONDcross HG Series User manual

Operating instructions

Rescue systems

DIAMONDcross HG (hang gliding)

Type Certication

DIAMONDcross 125 HG (non steerable) EP 184.2017

DIAMONDcross 160 HG (non steerable) EP 185.2017

DIAMONDcross 220 HG (non steerable) EP 186.2017

Norm: N II 91/09 and LTF 35/03

Revision 0

Effective from: Production year 2018

Last update: Nov. 2018

Finsterwalder GmbH - Charly Produkte

Pagodenburgstr. 8 | D - 81247 München | Tel.: +49 (0)89 811 65 28 | Fax: +49 (0)89 814 41 07

Mail: ofce@nsterwalder-charly.de | Web: http://www.nsterwalder-charly.de

3

Thank you for your condence!

Thank you for choosing a CHARLY product!

These operating and packing instructions provide important information on how to

use your rescue system. Please read this manual carefully before installation! It has

been written to serve as a comprehensive guide for the proper handling of your

reserve parachute. If you have any questions related to the use of this rescue

system, please contact CHARLY PRODUKTE directly. If you need professional

packing or repair service, please contact your local dealer or CHARLY PRODUKTE.

For more information about this and other CHARLY products, please visit

www.nsterwalder-charly.de. We wish you great ights and always safe landings.

CHARLY product design / test pilot

Tom Grabner

4

Table of contents

1.

Overall illustration

...................................................................................................5

2.

Safety instructions

..................................................................................................6

3.

Technical data

..........................................................................................................6

4.

Intended use

............................................................................................................7

5.

Operating limits

.......................................................................................................7

6.

Required documents

... ............................................................................................7

7.

Mode of operation

...................................................................................................7

8.

Specic characteristics of the DIAMONDcross HG rescue system

....................8

8.1

Reserve parachute

........................................................................................................8

8.2

Inner container

...............................................................................................................9

8.3

Constructive characteristics

......................................................................................12

8.4

Flight behaviour

...........................................................................................................13

9.

Maintenance, Cleaning

..........................................................................................14

10.

Storage

................................ ................................................................................15

11.

Packing and inspection intervals

.......................................................................15

12.

What to do when damage is detected

................................................................16

13.

Repairs

.................................................................................................................16

14.

Checkup and packing preparations

...................................................................17

15.

Packing

.................................... ............................................................................18

16.

Installation on the harness

.................................................................................18

17.

Placement inside a harness rescue system container

....................................18

18.

Compatibility test

................................................................................................19

19. Transport................................ .............................................................................20

20.

Pre-ight checklist

...............................................................................................20

21.

Specics for hang gliding winch launch

...........................................................20

22.

Flying by the seaside

..........................................................................................20

23.

Environmentally responsible disposal

..............................................................21

24.

Environmentally responsible disposal

.............................................................21

25.

Packing instruction

............................................................................................22

5

1. Overall illustration

Front tip

Main lines Rotor (optional) Hybrid riser

Stabilo Canopy Upper center lines Bottom center lines

6

2.

Safety instructions

This reserve parachute must not be used for skydiving!

The Charly DIAMONDcross HG is certied according to the german and european

standards N II 91/09 und LTF 35/03. The use of this rescue system is at your own

risk. The manufacturer cannot be held liable for any personal injury or material

damage related to the use of this reserve system.

The correct installation of the reserve parachute on the harness is essential and a

compatibility test must be conducted by a competent person. Only a properly

installed rescue system will function as intended and thus contribute to safety.

3.

Technical data

DIAMONDcross delta light

(non steerable)

DC 125 HG DC 160 HG DC 220 HG

Surface

30,7 m² 41,0 m² 59,2 m²

Line length incl. risers

9,96 - 10,32 m 9,96 - 10,35 m 10,60 - 10,90 m

Centre line length incl.

risers

10,37 - 10,47 m 10,47 - 10,57 m 10,85 - 11,02 m

Number of lines/panels

18/16 22/20 26/24

Number of centre lines

5/2 8/2 9/2

Overall length

8,25 m 8,50 m 9,00 m

Max. load EN/LTF

125 kg 160 kg 220 kg

Min. recommended load

60 kg 80 kg 100 kg

Sink rate at max. load

4,5 m/s 4,8 m/s 4,6 m/s

Volumen in ccm 4700 5300 7300

Musterprüf-Nr. EP 184.2017 EP 185.2017 EP 186.2017

Type certicate no.

1,43 kg 1,83 kg 2,57 kg

Weight incl. rotor (optional)

1,60 kg 1,97 kg 2,71 kg

Manufacturer

:

Finsterwalder GmbH - Charly Produkte

Pagodenburgstraße 8

D - 81247 München

Phone

: +49 (0)89 811 65 28

Mail: ofce@nsterwalder-charly.de

Web: www.nsterwalder-charly.de

7

4.

Intended use

Manually deployed emergency parachute for single seat and tandem hang gliders.

5.

Operating limits

• Maximum operating speed: 115 km/h (32 m/s)

• Packing interval: 12 months; subsequently, re-packing is required and must be

documented in the packing and inspection record.

• Inspection interval: We recommend a full inspection of the rescue system every 24

months; re-inspections must be documented in the packing and inspection record

• Permissible operating time: 10 years; subsequently up to 12 years when re-

inspected yearly

6.

Required documents

• Operation instruction

• Packing and inspection record

• The enclosed engineering specications for this air sports equipment is part of

these operating instructions

7.

Mode of operation

In the case of an emergency situation during ight, deploy the reserve parachute by

pulling the release handle with a rm and quick motion. This causes the outer

container to open and the parachute (still packed inside the inner container) is

deployed into the airstream. The release handle is thereby thrown away together with

the reserve system!

The inner container is constructed in such a way that it releases the suspension lines

and the canopy with a little time lag. This way, unintended early opening is prevented

8

and the risk of the lines becoming tangled with the glider, the pilot or another object

or person (e.g. in the case of a crash with another pilot) is minimised. Moreover, the

inner container must gain enough speed after release to provide for a fast opening of

the emergency parachute.

In general, the quicker you throw the reserve system, the faster can its canopy unfold

and open.

After the inner container has been deployed, the suspension lines are released from

their separate compartment. The canopy is released only after the suspension lines

are fully stretched.

The DIAMONDcross HG is designed with slight forward movement, that is

signicantly responsible for a low sink rate and the high pendulum stability.

8.

Specic characteristics of the DIAMONDcross HG rescue

system

8.1

Reserve parachute

The trim of the DIAMONDcross HG is adjusted so that there is a short stall phase

immediately after opening during which rotational energy is instantly reduced in an

emergency situation. Subsequently, the DIAMONDcross HG automatically switches

over to a slight, very stable and pendulum-free forward movement.

The lines of the DIAMONDcross HG are clearly asymmetric in length so that the

base panels do not exactly overlap as usual when packing the canopy but are a bit

staggered. This fanned-out pattern allows for better air inow after the release and

thus leads to an increased opening speed, particularly if the pilot is rotating at high

speed in an emergency situation.

9

The DIAMONDcross HG features a special hybrid riser, to attach the reserve

parachute without an additional belt to the main attachment pont of the hang glider.

This hybrid riser has a high strength dyneema core that is covered with a heat- and

scratch resistant aramid (kevlar) shield.

A coloured marking (triangle) at the front canopy corner of the DIAMONDcross HG

indicate the ight and packing direction. When packing the reserve system, the

markings also serve as helpful reference points.

8.2

Inner container

The inner container has been developed on the G-Force Trainer and is the result of

5 years of experience with rescue system deployments under centrifugal force.

These are its most important characteristics:

Flat construction design, but not necessarily with the least possible volume

Tests have shown that the container can be pulled out of the harness’ rescue

compartment much easier and with less effort than cube-like shaped containers,

sometimes even if they have a smaller volume.

Also, the at container deforms much more when it is pulled out by the pilot in

upward direction. It bends up so that the risk of getting caught in the harness is

reduced as far as possible and the reserve parachute can be deployed with

considerably less effort.

Tapered shape with rounded edges

The tests have also shown that pulling out the rst third of the container requires the

most effort. Accordingly, the likelihood of the inner container getting stuck inside the

harness is highest during the rst phase of deployment. The inner container of the

DIAMONDcross is thus designed to have a very low prole without rough edges in

the front area so that the risk of getting caught in the harness is minimised.

10

However, it must be noted that problems associated with deployment are also

signicantly inuenced by harness design.

No dangerous gaps on the surface of the closed container

The container of the DIAMONDcross has been designed in such a way that the line

bundles cannot get outside the closed container. There are currently many systems

in the market that cannot guarantee this. Especially the popular clover leaf style

containers are prone to this. When the line bundles exit the container too early during

deployment, this can lead to dangerous situations. The closed DIAMONDcross

container does not have any gaps on the surface so that its functionality is

guaranteed even under high centrifugal forces and in extreme conditions.

Redundant container lock

The container with the line bundles is double-locked for improved operational safety

and to prevent an early and thus uncontrolled opening of the rescue system.

This is a further measure to avoid the entangling of the reserve in the paraglider lines

as it contributes to a dened deployment after the release.

Fabric-coated rubber bands

If the container is locked using packing rubber bands or rubber bands without

protection, there is a risk of early breakage as they are often not strong enough –

especially at high centrifugal forces – and might thus release the lines or the canopy

from the inner container too early or the reserve parachute might even remain inside

the harness while only the container is pulled out of the compartment.

Therefore, the inner container of the DIAMONDcross is equipped with fabric-coated

rubber bands with a diameter of 3 mm. The rubber bands can be easily replaced

when necessary due to aging.

Offset release shackle at the inner container

Rescue system deployments on the G-Force Trainer showed that the intuitive pulling

direction of a pilot in a stressful situation is often upward, as with the handbrake of a

11

car. However, this direction is disadvantageous to pull the reserve parachute out of

the harness and it increases the release force signicantly. The release shackle at

the inner container of the DIAMONDcross is designed in such a way that the release

force remains low even in this „worst case“ so that the reserve system can be pulled

out of the harness reliably and fast.

Separate canopy lock

The rescue system container of the DIAMONDcross is designed in such a way that it

rst releases the lines, and the canopy is released only after the lines are fully

stretched. This provides for a dened canopy opening and further reduces the risk of

an entangling of the reserve in the hangglider.

URGENT RECOMMENDATION

Today, also some harness manufacturers offer containers suitable for their

harnesses. The DIAMONDcross has been certied in combination with its inner

container and many of the container’s details contribute to an optimal performance of

the system. Tests showed that the DC container performs signicantly better in many

aspects than the container that comes with a harness. 5 years of experience with

rescue system deployments on the G-Force Trainer (a centrifugal force simulator)

have been incorporated into the development of the container. We therefore urgently

recommed the use of the original DC inner container and to let the release handle be

attached to it by an authorised specialist if necessary. Should sewing be required,

you can contact CHARLY for assistance. We are offering this extra service as the

interfaces of the different components are not standardized in paragliding. A careful

adjustment of all components in addition to the obligatory compatibility test thus

optimises your system signicantly!

12

WARNING (according EN certication rules)

Use of this parachute with any alternative inner container: the speed

of opening and opening shock test has been completed using the

inner container supplied. Use of any other inner container may

produce different results (including failure)

8.3 Constructive characteristics

Diagonal suspension and ight direction

The diagonal „diamond-conguration” is one of the main innovations. Due to the

diagonal ight direction, the calculative aspect ratio increases from 1 (square) to 2

(diagonal square). As the DIAMONDcross has a dened forward movement, the low

sink rates are not only inuenced by the drag coefcient but, similar to a wing, also to

the lift coefcient. The higher aspect ratio that results from the diamond conguration

is essential for the resulting ight and gliding qualities.

No pendulum tendency immediately after the opening

By contrast to other reserve parachute systems, the DIAMONDcross does not exhibit

a pendulum tendency.

The pendulum tendency can lead to severe injuries, particularly in the case of

deployments at low altitudes.

To avoid this effect by design, the DIAMONDcross has a special trim that leads to a

strong S-shape in the cross section of the parachute. As tests have shown, this

causes a righting momentum that reliably dampens pendulum immediately after the

opening.

When the DIAMONDcross opens, after a short deep stall phase, the canopy reliably

changes into a steady, pendulum stable ight phase with very low sink rates.

13

Optional installation of the Charly Rotor

We recommend the optional installation of the Charly Rotor Art No. HFa160. The

rotor can be installed without additional sewing between the riser and the main lines.

For installation contact CHARLY PRODUKTE.

8.4

Flight behaviour

Forward speed reduces risk of injury

The human body is most vulnerable to injury when the velocity vector is directed

towards the spine and the impact area is at right angles to that axis.

A forward speed in combination with considerably lower sink rates is thus always

associated with a lower risk of injury than an impact at right angle and higher vertical

speed, even if forward speed is increased by tailwind.

Lower sink rates allow for more time to react

The low sink rate gives the pilot more time to prepare for landing.

We thus recommend the following course of action after rescue system deployment:

1)

Pull handle, remove inside container from harness or outside container, throw

the container down, direction legs. Check after 5 seconds if the canopy has

opened properly.

2)

Orientation – check altitude

3)

Open the zip fastener of the harness and move legs out of the harness

14

4)

Bring your hang glider in a stabile position and if possible stand onto the ight

control with both feet.

5)

Landing

Look into direction of the most possible landing area and prepair for a landing

fall. Put your knees together and roll to the side when you touch the ground.

Never stretch the legs, this can cause injuries during the touch down!

6)

Inform the rescue services

Since very often search operations are initiated by observers after rescue

system deployments, we highly recommend to contact the police or the rescue

immediately after landing even if there is no personal injury.

However, the most important measure in an emergency situation is DEPLOY!!! It is

never too late for the rescue parachute. As long as there is a chance to deploy,

it is ALWAYS the better alternative!

If your altitude is low, keep watching the ground and prepare for landing.

With the DIAMONDcross, you are provided with the largest possible passive safety a

rescue system can currently offer!

You have purchased a rescue system you can always rely on. It went through a large

number of on-ight tests that far exceed the regulatory requirements.

The tests were conducted almost exclusively above ground and thus under real-life

conditions, they included all available sizes and there were no injuries.

Therefore, never wait too long to deploy your rescue system in a problematic

situation during ight.

9. Maintenance, Cleaning

The DIAMONDcross rescue sytem by CHARLY has been designed for heavy-duty

use and to withstand extreme conditions. Accordingly, we have selected only

15

especially durable high strength quality materials. However, durability strongly

depends on the care and maintenance by the pilot.

Soiled canopies and containers can be cleaned using clear tap water.

Attention: Acid marks or mould spots might affect the strength of the parachute.

Rescue parachutes that are soiled in that way must be sent to the manufacturer for a

check-over and possibly a repair. Never wring or brush the wet canopy!

Particular attention should be paid to the following points:

• Do not expose the packed rescue system to large variations in temperature

and provide for sufcient air circulation to avoid the formation of condensation.

• Avoid unnnecessary exposure to the sun (UV radiation).

• Unpack the wet or damp canopy and let it dry at room temperature or outside

in a shady place.

• After salt water exposure, immediately rinse the canopy thoroughly with fresh

water.

• Clean all components only with fresh water and if needed using neutral soap;

never use chemicals containing solvents!

10.

Storage

Oils, greases, acids and dyes must not be stored in close proximity to the rescue

system. Store in a well-ventilated, dry room. Rescue systems that are not used for a

long time should be stored unpacked.

11.

Packing and inspection intervals

The rescue system must be aired and re-packed according to valid packing

instructions every twelve months to guarantee its reliable and fast opening at any

16

time. If the rescue system was exposed to wet conditions, moisture or extreme heat,

it must be re-packed immediately.

If the rescue system has been deployed in an emergency situation or during a safety

training, it has to be re-checked by the manufaturer or by an authorised service

centre. It must also be thoroughly inspected by a competent person after every larger

stress exposure (e.g. a tree landing).

12.

What to do when damage is detected

When damage is detected during inspection, the rescue system must be sent in to

CHARLY PRODUKTE for repair. This also applies to damages whose effects on

airworhiness cannot be unambiguously determined. In either case, the manufacturer

must be involved in the repair process!

13.

Repairs

Generally, repairs of emergency parachutes must never be carried out. Repaired

seams can have signicant inuence on material strength. Damages must be

assessed in each individual case. Therefore, only the manufacturer or an authorised

service centre after consultation with the manufacturer may carry out repairs using

original materials. Manufacturer-approved repair instructions must be enclosed in the

packing and inspection record after the repair has been carried out and have to be

handed on as part of the rescue system in the case of release.

The preparation of repair instructions by the manufacturer is subject to a fee. In the

case of non-compliance with the suggested repair procedure, airworthiness

according to EN or LTF expires automatically.

Acis marks and stains as well as rips and chafes may affect the stability of the

components. Such damages must be inspected and, if necessary, repaired by the

manufacturer or by an authorised service centre.

17

We recommend to regularly check the rescue system for signs of wear and to let

CHARLY or an authorised service centre repair it if necessary before the next use.

14.

Checkup and packing preparations

Before packing, hang up the canopy so that it does not touch the ground for at least 6

hours in a well-ventilated room without direct UV exposure. If the canopy got wet,

please make sure that the suspension lines, that have become considerably heavier

due to the moisture, are unburdened and cannot stretch. Do not use heating

radiators for drying!

If possible, packing should be carried out on a packing table or at least on a clean,

antistatic underlay. As a packing aid, you need a piece of cord or a parachute line of

50 cm length and the possibility to put the canopy under tension between the

harness respectively the suspension point and the packing loop. We recommend to

attach an elastic cord with carabiner to the packing loop at the apex of the canopy.

Several small bags with lead scrap or sand can be used for weighing down the

canopy which makes packing easier and reduces the packing volume. All rubber

bands must be replaced by new ones when re-packing. Original rubber bands can be

purchased from CHARLY PRODUKTE.

We strongly recommend to let your rescue system be packed by a competent

person.

The packer must inspect the canopy for possible damage. If the rescue system has

to be re-packed after an emergency deployment, a prior check-over by the

manufacturer or an authorised service centre is compulsory.

18

15.

Packing

Packing the DIAMONDcross is described in detail starting on page 22. Make sure to

read the most recent valid version of the instructions. It is available for download in

multiple languages on Finsterwalder & Charly’s website.

16.

Installation on the harness

Volume and shape of the outer container should thereby be similar to the inner

container.

Follow the instructions from your harness manual and attach the rescue system

container at the suspension point as described. Make sure to check the container for

a rm and secure t. Also, it should not interfere with moving parts such as a speed

system, webbings running through, etc.

17.

Placement inside a harness rescue system container

Follow the instructions from your harness manual to place your rescue system inside

the container. Additionally, the following ponints must be strictly adhered to:

•

Only use the original release handle that is delivered with the harness. Other

release handles must not be used as they do not guarantee faultless

operation.

•

The container must have a suitable volume.

•

When using an inner container with asymmetric attachment loop, it must be

placed inside the harness container in such a way that the attachment loop

remains as close as possible to the release handle and that the rescue system

does not get twisted during deployment.

19

•

When placing the rescue system inside the harness container, it is absolutely

necessary to make sure the connection between release handle and safety

splint is shorter than the connection between release handle and inner

container.

•

Install the release handle at the intended position in such a way that the

connecting line is not under tension and the safety splint is not pulled out of

the closing loop.

•

After each packing, a test deployment must be carried out to ensure the

proper operation of the rescue system! Deployment from the ying position

must be possible without any difculty and according to the specications of

the manufacturer

.

18. Compatibility test

Each new combination of a rescue system and a harness must be tested for

compatibility in a k-test by an authorised person after the rst packing.

Deployment from the ying position must be possible without any difculty and

according to the specications of the manufacturer. The release force should thereby

not exceed 70 N and the inner container should deploy easily from the integrated or

externally attached outer harness container.

The tester has to conrm test execution in the packing and inspection record.

Tests and deployments during trainings on the G-Force Trainer showed that

deployments under centrifugal force can sometimes lead to considerably higher

release forces and coordination problems of the pilot. Complementary to the k-test,

we thus recommend to test the individual combination of harness and rescue system

in the course of a training under centrifugal force (4 - 5 g).

20

19. Transport

Take care that the rescue system is not exposed to extreme heat during transport

(e.g., in the boot of a car in the summer). Also, it should always be handled with care

(keep it clean, do not put any sharp or heavy items onto it, etc.). When packing it into

the paraglider pack sack, be careful not to damage the rescue system with buckles or

other items and to not accidentally open the release handle.

20. Pre-ight checklist

In addition to the standard pre-ight check (see paraglider / harness operating

instructions, possibly winch etc.), also the correct closure of the rescue system

container and the proper t of the release handle have to be checked prior to each

takeoff.

If the rescue system connecting line is unhinged after each ight (e.g., when using a

front container system), the pre-ight check has also to include the correct

attachment of the riser!

21. Specics for hang gliding winch launch

For winch launching, please pay attention to the harness, hang glider and winch

manufacturers’ provisions! When using a front container, it must be ensured that

rescue system deployment is possible at any time.

22. Flying by the seaside

Using the rescue system at the seaside or in saline air for a longer period may cause

premature material ageing. Under such conditions, the rescue system should be

checked and inspected for airworthiness more frequently.

This manual suits for next models

6

Table of contents

Other CHARLY Aircraft manuals