Auto Mate ValveLink 8.2 User manual

ValveLink8.2®

User’s Manual

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

©2005-2015 AutoMate Scientic, Inc.

All rights reserved.

ValveLink8.2®

User’s Manual

The ValveLink8.2 is intended for research use only.

Table of Contents

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

Introduction........................................................................................3

Hardware Overview

ValveLink8.2 Laboratory Applications

Accessories

ThermoClamp™-1 Temperature Control System

Pressure Regulated Perfusion System

Perfusion Pencil® Multi-Barrel Manifold Tip

System Set-up Diagrams............................................................8

Standard PTFE Perfusion System (without pressure)

Pinch Valve, Pressurized and Luer-Lock Perfusion Systems

Installation Tips

Bubbles and Degassing

Perfusion Cheat Sheet

PTFE Micro-manifold Use

Pinch Valve Tubing

Valve Care

Perfusion Pencil Flow Rates

Perfusion Pencil Multi-barrel Manifold

Perfusion Pressure Kit

Josef Kewekordes II, Heath Lukatch

Dave Blau

ValveLink8.2 - Part #01-18

For indoor use only from 5° to 40°C.

Do not get wet or subject to visible condensation.

Clean with a mild soap solution with a damp cloth only.

This equipment must be earth grounded. Use any of the screws on the side

or bottom of the case. See page 23.

Do not unplug valves while on!

Do not attempt to repeatedly cycle valves on and o in under

one millisecond.

If this equipment is used in a manner not specied by the manufacturer,

the protection provided by the equipment may be impaired.

Supply voltage:

ValveLink8.2 controller = 12V AC up to 3.3 amps @ 50-60Hz

External power supplies:

USA & Japan = 110V AC up to 0.36 amps @ 60Hz

European = 230V AC up to 0.17 amps @ 50Hz

!

* TTL stands for Transistor-Transistor Logic, a +5/0 volt standard for representing

on and o – used by the ValveLink8.2 for computer valve control.

Introduction

FOR RESEARCH USE ONLY

The ValveLink8.2 is designed for solution-switching use in research

applications ONLY. AutoMate Scientic, Inc. cannot be responsible for

injury or death resulting from medical or pharmacological use.

Hardware Overview

The ValveLink8.2® is a digital/manual valve controller designed for use

with research automation software. Valves can be controlled by digital

TTL* signals from any I/O card or device or a single analog voltage input.

Eight pushbuttons allow manual user control with eight bi-colored LED

indicators. A USB (Universal Serial Bus) port is provided for further valve

control and networking by computer. All four input sources (digital,

analog, USB, and pushbuttons) are simultaneously active, and the LEDs

constantly display the current valve status. ValveGuard™ technology

detects bad valves. It prevents damage to your ValveLink8.2 and let's you

easily observe problem valves. A spill sensor protects your equipment

when a leak is detected.

The ValveLink8.2 is designed to drive 12 volt DC solenoid valves plugged

into RCA jacks on the back of the box. Why not connect valves directly to

your computer? Several reasons:

1) Most computer interfaces provide +5V signals – not strong enough

to drive most valves (6 to 12V DC and higher).

2) Computer interface signals are often too noisy for

electrophysiology amplication. The ValveLink8.2 is designed

with special low-noise circuitry to minimize interference with

high-gain amplication.

3) Finally, many solenoid valves are designed to be opened with a

short, full-voltage pulse, then “held-in” with a lower voltage to

keep the valves from heating. The ValveLink8.2 automatically

provides dual-voltage hold-in.

Chromatography

Gel/Blot Washing System

Operation..................................................................................17

Manual Control

Digital Inputs

Digital Input Port Pin-out

Analog Input

Simultaneous Edge-triggered Inputs

LED Indicators and ValveGuard™

Event Marker

Spill Sensor

Where is the power switch? Sleep

3-way Valves

Back Panel

Power Supply

Case and Valve Grounding

Modes .......................................................................................24

Mode Descriptions

Multiple Modes

USB Communications & Software ..........................................27

Installation

Software Operation

Computer Interfacing...............................................................32

Techniques................................................................................34

Dead Volume

Small-bore PTFE Tubing

Backow

AutoPrime™ System

Faulty Valves

Stuck Pinch Valves

Valve Cables

Valve Returns & Replacing a Valve

Leaks and Replacing Valve Fittings

Hardware Troubleshooting

Safety Instructions ...................................................................40

Warranty ...................................................................................42

Table of Contents Continued

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

3

2

Perfusion Systems

AutoMate Scientic builds ValveLink8.2 and ValveBank perfusion systems

with several choices of valves (below) in 4, 8, or 16 channels. Systems

include reservoirs, drippers, stopcocks, brackets, ow regulator, ringstand,

tubing and micro-manifold. Please visit http://www.autom8.com/build_

your_own.html to congure a custom system to your specications and

generate a quotation.

Valves

Solenoid valves are available as part of perfusion systems or sold

separately. We sell 12V DC PTFE and Pinch valves with indicator LEDs

built-in. PTFE valves are faster (open and close in 10 ms.), but pinch valves

are cheaper and easier to clean (open and close in 30-50 ms). PTFE valves

include three choices of

ttings: hose barb (standard),

luer lock, or nut & ferrules for

connecting hard PTFE tubing.

Luer lock ttings allow

direct connection of syringes

as shown. This method

eliminates wasted solution in

tubing between the reservoirs

and valves. Small 2-way

stopcocks are included

with all AutoMate Scientic

perfusion systems. Luer lock PTFE valves

ValveLink8.2 Accessories

BNC cables and rack-mounting brackets make it easier

to connect your ValveLink8.2 to your digital outputs

and to mount the controller in a 19" rack with your

other equipment.

4-BNC cable Part #01-19

AutoMate Scientic also sells

a full range of manual and

motorized micro-manipulators,

ampliers, stimulus isolators,

data acquisition systems, lter

wheels and pipette pullers.

ValveLink8.2 Laboratory Applications

Perfusion

A ValveLink8.2 can be programmed to precisely switch solutions perfusing

over biological samples for physiological research. The ValveLink8.2’s

circuitry is designed to open valves with low noise for electrophysiological

amplication. Several features called ‘Modes’ have been built into the

ValveLink8.2 for advanced perfusion use.

Washing

Combined with an AutoMate Scientic ported washing tray, the

ValveLink8.2 can automate washing of electrophoresis gels and blots, and

developing of x-ray or photographic lm or prints. You have complete

control over which washing steps of your Western, Northern, Southern,

Coomassie Blue and Silver staining runs are automated and which

are handled conventionally. Unattended washing can save a busy lab

countless hours of tedious monitoring.

Liquid Chromatography

A ValveLink8.2 can be easily programmed to automate solution selection

in multi-step ion exchange, gel ltration or anity chromatography runs

with excellent reproducibility. The ValveLink8.2 is especially useful in

preparative work when a protocol has been established and programmed

to repetitively isolate your valuable molecule.

Accessories

AutoMate Scientic oers a number of products which compliment

the ValveLink8.2 controller: valves, pressure upgrades, Perfusion

Pencils®, ThermoClamp™ temperature controllers, perfusion chambers,

manipulators, rack mounting brackets,

BNC cables and entire perfusion systems.

Oocyte Chamber Petri Dish Chamber Pinch Valves (set of 4)

Part #OPC-1 Part #PCP-1 Part #02-pp-04 Rack brackets Part #01-17

5

4

Pressure Regulated Perfusion System

AutoMate Scientic oers a Pressurized Perfusion Upgrade with four,

eight or sixteen channels for:

• Faster switching • Steady ow-rate

• Microliter ne delivery • Microinjecting

• Small diameter pipette delivery

The package can be added to any

new or existing perfusion rig -

from AutoMate Scientic, any

third-party manufacturer, or even

homemade. Connect to house

air, tank, or compressor (30 to 100

psi). Precision regulator delivers

zero to 10 psi to pressurized

syringe reservoirs.

Part #09-04 4-channel

Part #09-08 8-channel

Part #09-16 16-channel

For Single-cell or Whole-cell Superfusion

Perfusion Pencil®Multi-Barrel Manifold Tip

4-16 micro-bore tubes into 1 outow

• Rapid solution change with micro-liter

dead volume. No piezo or stepper

motor translation. No clumsy

rotating valves.

• Single-cell and patch delivery.

For mounting on any

micromanipulator.

• 100, 250 & 360µm

removable tips

available

ThermoClamp™-1 Temperature Control System

• Combination inline heater plus multi-channel focal drug delivery

maintain bath temperature and rapid drug wash-out with a high-ow bath

line while quickly switching 4-8 preheated solutions through the Perfusion

Pencil.® Maintain steady 37°C at 5ml/minute ow rates through both the

bath line and tip.

• Advanced auto-tuning temperature lock

Fuzzy logic PID software maintains chamber or reagent temperature

to within 1°C of setpoint or better. The ThermoClamp calibrates

its own tuning for ideal temperature control - no need to guess

“loop speed” settings.

• Designed for physiology research

No metal anywhere in the ow path - unlike some competitors. Low noise

for electrophysiology with internal and external grounding plus electrical

isolation between liquids and heating elements.

• Ready to use

Includes everything you need for heated perfusion: power

supply, temperature sensors, and inline heater with easy luer

lock tube connections.

Part #03-14-xxx ThermoClamp-1 Temperature Control System [4 Channel]

Part #03-18-xxx ThermoClamp-1 Temperature Control System [8 Channel]

Controller, heated Perfusion Pencil, removable tip & bath sensor

xxx = Specify removable tip i.d. size: 100, 250, or 360µm

7

6

To chamber

& vacuum

trap (8)

(2)

(3 & 4)

(6)

(5)

1) Assemble ringstand rod and base.

2) Attach valve unit.

3) Attach reservoir bracket(s).

4) Insert syringes with stopcocks.

5) Insert short pieces of 3/16" i.d. tubing

over tops of drippers, then insert

over syringe ttings.

6) Attach dripper tubing to upper valve

barb. Cut as desired, but leave

long enough to move reservoirs.

7) Insert green clamps on pieces of

1

/16" tubing between bottom valve

barbs and manifold.

8) Connect manifold outow into

your perfusion chamber.

9) Plug numbered valve cables into

ValveLink8.2 ports.

(7) Green clamps

close to manifold

System Set-up Diagrams

Instructions on this page are for Economy perfusion systems, PTFE luer

lock valves, pressurized systems or pinch valve systems. Regular hose

barb PTFE perfusion systems please see the previous page. Luer lock

systems should also see the photo on page 5. Find additional photos and

diagrams of the pressure system on page 15.

(2)

(3)

(4)

1) Assemble ringstand base and rod.

2) Attach valve unit.

3) Insert syringes with stopcocks.

Pinch valves have no ttings.

Simply slide larger tubing over

small pinch valve tube above and

below the valves.

4) Connect tubing between bottom

valve tube and manifold.

5) Connect manifold outow into

your perfusion chamber.

6) Plug numbered valve cables into

ValveLink8.2 ports.

Pinch Valve, Pressurized and Luer-Lock Perfusion Systems

Standard PTFE

Perfusion System

(without pressure)

Also see the "Installation Tips"

section on the next page.

Drippers are NOT included

with these systems because the

syringes are inserted directly into

valves.

Pressurized systems - no room for

drippers and may interfere with

pressure in tubes. Use provided

male luer locks to connect tubing

above each valve.

Roller "thumb" clamps

can be used here

(1)

(1)

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

(5) To perfusion chamber

and vacuum trap

9

8

Valves

Adjust flow rate by height of syringe reservoirs.

Watch flow rate in drip chambers

Adjust flow rate with thump clamp

Inflow manifold

Ground

electrode

slots

Suction tube

Flow rate

adjustment

screw

Good liquid level

BAD! GOOD

May suck chamber dry,

but may stop oscillations.

Caution:

Suction tube well:

Cover and ground

suction tube with

aluminum foil

to minimize noise

As long as these tubes are prefilled (primed)

with solution, then opening valves upstream

starts liquid flowing inside the manifold here.

Perfusion Cheat Sheet

Your perfusion system may not include optional drip chambers, thumb

clamps or the Petri dish chamber, but these hints from Woods Hole

may still help.

Installation Tips

• Flow rate is adjusted by the relative height of reservoirs and manifold

ow regulator plus optional air pressure.

• Leave the tubing between the reservoirs and valves long enough to raise

and lower the reservoirs.

• Unused lines should be replaced with plugs on manifold, or temporarily

clamped-o just above manifold to avoid back bleeding into empty lines.

They MUST also be lled with solution.

• Priming one line at a time reduces bubbles.

• Connect your vacuum trap line directly to the outow of the manifold

for running cleaning solutions and drying your lines quickly.

• Determine dead volume from the manifold to prep by measuring time

and volume required to ush a colored liquid with a clear one. Calibrate

ow rates by running one line into a graduated cylinder for a xed

period of time.

• Filter solutions down to 5-10 microns when using PTFE or Lee valves.

• See more tips in the "Techniques" chapter later in this manual.

Bubbles and Degassing

Bubbles are often caused by outgassing. This is particularly true when

media is stored cold overnight and allowed to warm to room temperature

in the perfusion system tubing. Since warm liquids hold less gas, bubbles

will form in the tubing and valves as gas leaves the media. The best

solution is to pre-warm your solutions by at least 2-3 degrees above

room temperature even if you are adding gas (CO2, Carbogen, etc.) to

your reagents. If you are using an inline heater like the ThermoClamp,

it is a good idea to warm solutions 2-3 degrees above your inline heater

temperature to prevent bubbles from forming there. If possible, keep

the solutions in the reservoirs at this higher temperature all day using

reservoir heaters.

Degassing can also be facilitated by applying a slight vacuum to the

reservoirs, although this is not recommended if you are purposely gassing

your media.

11

10

Pinch Valve Tubing

Pinch valves have no ttings. Simply slide larger tubing over small pinch

valve tube above and below the valves. The tubing in each pinch valve

can be replaced for easy cleaning. It is 1

/32" i.d. x 1

/16" o.d. silicone tubing.

We have only found one type of tubing this size which works well in these

pinch valves. AutoMate Scientic sells this replacement tubing as part

#05-14. The tubing can be removed from the valves even when they are

closed. Remember that any liquid remaining in the tube may spill when it

is removed from the valve. New tubing can be installed while the valves

are closed, but it is much easier if they are opened/energized. If you are

concerned about the same piece of tubing being squeezed for long periods

of time, you can slide the silicone tubing up or down in the valve by a

few millimeters to expose a new section to the plunger. The same piece of

tubing can be used for years without fatigue.

Valve Care

Rinse PTFE valves every day. Do not get pinch valves wet. See sections

on Faulty Valves, Stuck Pinch Valves, Valve Cables, Replacing Valves and

Leaks in the "Techniques" chapter later in this manual.

Perfusion Pencil Flow Rates

360µm Removable Tips (reservoir height 40cm)

Gravity (full reservoir) 1.15ml/min +/- .04

2psi air pressure 3.98ml/min +/- .08

8psi air pressure 10.66ml/min +/- .27

250µm Removable Tips (reservoir height 40cm)

Gravity (empty reservoir) 0.35ml/min +/- .05

Gravity (full reservoir) 0.45ml/min +/- .05

2psi air pressure 1.66ml/min +/- .14

8psi air pressure 5.16ml/min +/- .04

100µm Removable Tips (reservoir height 40cm)

Gravity 0

2psi air pressure 0.07ml/min = 4.6ml/hour

8psi air pressure 0.25ml/min = 15ml/hour

PTFE Micro-manifold Use

To use the micro-manifold, you either need pinch valves or PTFE valves

equipped with 1

/16" o.d. outow hose barbs. Micro-manifolds are shipped

with a short piece of 1

/16" o.d. tubing in each hole (inputs and outow).

You can either connect the valves to manifold inports with a piece of 1

/16"

i.d. tubing over both the valve barbs (or pinch tubing) and short pieces of

manifold tubing:

Valve with 1

/16" o.d. barb or pinch tubing

v

1

/16" i.d. tubing over barb/pinch tube

and over manifold short tubing

v

Manifold with short pieces of 1

/16" o.d. tubing in each port

... or, for even less dead volume, use a short piece of 1

/16" i.d. tubing over

the valve barb (or pinch tubing), and piece of smaller 1

/16" o.d. tubing

inserted inside the secondary tube and manifold ports (you may need to

supply extra small PE-160 or PTFE tubing for this option):

Valve with 1

/16" o.d. barb or pinch tubing

v

Short piece of 1

/16" i.d. tubing over valve barb/pinch

v

Small diameter 1

/16" o.d. tubing inserted inside valve tube

and inserted inside manifold ports

v

Manifold without connector tubing. 1

/16" holes.

Cutting the tubing at an angle and wetting it will make insertion easier.

Cutting the tubing square, however, will minimize dead volume when

inserted as far as possible into the manifold – being careful not block at the

point of convergence. Remember to keep all tubing as short as possible.

Use the provided Allen wrench and small screw near the manifold outow

to adjust ow rate. AutoMate Scientic now sells small PTFE manifold

'stoppers' for plugging unused manifold ports as part #05-05 for a set of

four.

13

12

Perfusion Pressure Kit

(Sold separately)

Hoses should continue from syringes to valves.

Syringes may also be placed in a water

bath for temperature control.

Brass input connector hose barb size 1/4”

5 micron bowl lter.

Press bottom button to empty.

Be very careful with these

plastic hose connections.

Press regulator knob down to lock.

Pull up to unlock.

Individual air lines can be

adjusted or turned-o.

2-way stopcocks and luer-lock to 1

/16” hose ttings are

included for each channel to connect syringes to hose.

Max. input

pressure 100 psi!!

Perfusion Pencil Multi-barrel Manifold

(Sold separately)

Tighten removable tip for

minimum dead volume.

One of the eight lines may be connected to

vacuum through a valve programmed to suck

the dead-volume clear between solutions.

Chemical Information

The tubing inside the manifold body is polyimide (nylon). The removable tips

include a polycarbonate luer lock tting with a fused silica (quartz) needle coated

with polyimide. These materials are resistant to most acids, bases and organic

solvents. To avoid dust contamination, we recommend pre-rinsing the Perfusion

Pencil and tip with distilled water. Also, it is good practice to discard the rst few

microliters of solution before using the device. The Perfusion Pencil and removable

tips are shipped non-sterile. They can be chemically sterilized or autoclaved.

However, repeated autoclaving may weaken the adhesive bond between the luer

lock tting and the needle.

Maintenance

You can expect several years of useful lifetime for your tip if you wash it daily.

Use a syringe or vacuum to pull water, then alcohol three times each through the

tip. If the Perfusion Pencil is lled with pure salt solution, leaving it in the syringe

overnight will not usually cause the tip to block. However, if it is used for high

viscosity uids, ushing after each use is recommended.

Cutting

The removable tips are shipped with 0.5" (1 cm) length polyimide needles.

They can be cut shorter by rolling a razor blade on them against a hard surface.

However, this may leave a small crack or barb on the tip. To get a at cut, score the

coating of the needle with a ceramic cleaving stone or a diamond cutter and pull

directly apart, making sure not to pull at an angle. You may notice a larger outer

tube enclosing the lower part of our smaller, 100µm needles. This is simply for

added rigidity, and can be cut if needed.

Replacement Tips:

#04-xxx Specify i.d. size:

100, 250, or 360µm

All inow tubes must be lled with solution

before use even if some lines are not needed, or

liquids will backow into empty lines!

Part No.

#04-04-xxx 4-into-1 Pencil with tip

#04-08-xxx 8-into-1 Pencil with tip

#04-16-xxx 16-into-1 Pencil with tip

(xxx = 100, 250, or 360µm) 15

14

Operation

With a ValveLink8.2, a researcher can turn valves on and o using:

• front-panel manual pushbuttons

• digital inputs

• analog input

• or USB port and software (see USB chapter).

LED lights on the front of the controller indicate valve status. The

ValveLink8.2 sends an analog voltage out the "event marker" BNC on the

front panel every time a valve is opened or closed. This marker can be

recorded using a single channel for a permanent record of valve activity

synchronized with a physiological recording. Also, a spill sensor is

monitored to close all valves in case a liquid overow happens. This can

save precious reagents and protect valuable microscope equipment in

the event of a spill. With no power switch, the ValveLink8.2 can be put

to sleep by holding the "Mode/Sleep" button for three seconds. Press the

same button to wake from sleep. Descriptions of these features follow...

Manual Control

Each press of a front-panel pushbutton toggles its valve on and o subject

to Mode settings described in the next chapter. The buttons can be pressed

even when the ValveLink8.2 is being controlled by an external device or

computer. Press the "Mode/Sleep" button for three seconds to close all

valves quickly (and put the ValveLink8.2 to sleep - see below).

Digital Inputs

Eight TTL pins (wires) can be used to listen to outputs from interface

hardware on a personal computer or other digital sources. The

ValveLink8.2 will open and close valves mirroring the computer signals

(low = o, high = on) with one millisecond accuracy. Usually data

acquisition software like pClamp, Pulse, LabView, etc. or custom user

software is programmed to send digital signals to open and close valves

at specied times. Each input pin (1-8) represents one valve. This way all

eight valves can be operated independently by eight computer outputs.

See the description of Modes #2 and #3 in the next chapter to control

eight or sixteen valves using only three or four TTL outputs. Read the

"Computer Interfacing" chapter for more information on connecting the

ValveLink8.2 to data acquisition software and hardware.

Chromatography

12 34

Fraction

collector

or waste

Without a pump, ow rate

is determined by relative

height of reservoirs.

1) Position reservoirs above

column ringstand.

2) Attach valve unit to

column stand.

3) Run tubing from

upper valve barbs into

reservoirs.

4) Connect short pieces of

tubing between lower

valve barbs & manifold.

5) Connect manifold outow

to your pump with 1

/16"

i.d. tubing.

6) Pump outow connects to

column inlet as usual.

7) Plug numbered valve cables

into ValveLink8.2 ports.

12 34

Flow rate is determined by

relative height of reservoirs.

1) Position reservoirs above

washing area.

2) Attach valve unit to

ringstand.

3) Run tubing from upper valve

barbs to reservoir nipples.

4) Connect tube from lower

valve barbs to tray inlets.

5) Connect tray outow to

fourth upper valve barb.

6) Connect this valve’s outow

to vacuum trap.

7) Plug numbered valve cables

into ValveLink8.2 ports.

Vacuum trap

Gel/Blot Washing System

Rocker

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

17

16

from low to high, that valve opens. Then the ValveLink8.2 ignores that

input until it changes (high back to low) again. If that valve's manual

pushbutton is pressed, it toggles the valve from open to closed or vice

versa - regardless of the state of its other inputs. Therefore, whichever

input happens last determines the state of the valve.

LED Indicators and ValveGuard™

The eight numbered valve LEDs on the front of the ValveLink8.2 give you

the current status of each valve. They can each be in one of four dierent

states:

Red = Valve plugged-in but closed

Green = Valve plugged-in and open

O = No valve plugged-in or broken valve wire

Flashing red = Short-circuit detected in valve wire

These last two states represent our ValveGuard technology. Special

circuitry detects a good valve resistance or short-circuit. Broken or shorted

(crossed) valve wires used to be the biggest cause of valve failure and

controller damage. Now these two problems are easily observed and

isolated before they can damage the controller. See the "Valve Cables"

section in the "Techniques" chapter later in this manual to repair a broken

valve cable yourself.

Press the valve button to clear a ashing short signal and try opening the

shorted valve again. If all LEDs are ashing it means the spill sensor has

been tripped. See the Spill Sensor section below. The ValveLink8.2 will not

even try to open a valve which is not plugged-in (its LED is o).

Event Marker

The ValveLink8.2 outputs a 10 millisecond voltage pulse on its front-panel

analog output BNC as an event marker every time a valve opens or closes.

The marker voltage occurs regardless of how the valve was opened or

closed (i.e. manual pushbutton or computer digital input). This voltage

can be easily recorded with a single channel of your data acquisition

software for a permanent, synchronized record of valve activity. Here are

the voltages sent by the ValveLink8.2:

+2.5 volts is the baseline when nothing is happening. Valves opening

create a 10 millisecond pulse upwards, while closing valves cause a

Digital Input Port Pin-out

[Back panel diagram view]

Standard female DB-9 connector

pin# pin#

1 = ground 6 = TTL8

2 = TTL7 7 = TTL6

3 = TTL5 8 = TTL4

4 = TTL3 9 = TTL2

5 = TTL1

AutoMate Scientic sells BNC cables with four or eight TTL inputs

wired to BNCs for you. Parallel port and Heka EPC / ITC cables are

also available.

Analog Input

The front panel "Analog Input" BNC accepts a 0-5V DC signal to open a

valve using only a single analog output from your computer. Here are the

voltages it accepts:

0 (zero) volts = All o

Ch 1 2 3 4 5 6 7 8

Voltage 0.5 1.1 1.6 2.1 2.7 3.3 3.9 4.6V

Changing from one voltage to another closes ALL other valves.

Simultaneous Edge-triggered Inputs

You may be wondering how the ValveLink8.2 can respond to so many

inputs simultaneously -- digital, analog and pushbuttons all at the same

time. If a digital input is "high," then shouldn't that valve be open? How

can you close it by pushing the button? The answer lies in an electronics

concept called "edge triggering." Rather than watching the state of an

input (i.e. high or low TTL input), the ValveLink8.2 watches for a change in

state (i.e. rising or falling edge of TTL input). When a TTL input changes

15

96

19

18

This ValveLink8.2 analog output graph shows the voltage resulting from

valve #7 (4.67V) opening at time 8.07 seconds, then valve #3 (3.43V)

opening with Mode #6, "1-On" active. This immediately closes valve #7

(0.33V). The output returns to "baseline" of 2.5 volts after each 10ms pulse.

Spill Sensor

A two-pin socket on the ValveLink8.2 back panel accepts a 3mm Molex

"Microt" female plug for a spill sensor. The spill sensor circuitry watches

any wires plugged-into this ValveLink8.2 port for a drop in electrical

resistance representing a liquid spill. In perfusion work spills usually

occur when the chamber vacuum stops or the vacuum trap lls-up. The

spill sensor circuitry immediately closes all valves and begins blinking

all LEDs to notify you of the spill. The ValveLink8.2 remains in this state

until you press any button to override the spill. After you clear the spill

warning, you may immediately begin opening valves again.

AutoMate Scientic provides a spill sensor made of Mylar tape and two

closely-spaced copper contacts. When liquids cross this tape, they make

contact with both copper strips simultaneously and complete an electrical

path for the spill sensor circuitry. In this way a drop of liquid passing

the sensor strip appears as a sharp drop in electrical resistance between

the two, otherwise disconnected copper conductors. Even distilled water

will conduct enough current to trigger the sensor. The adhesive tape

is designed to be placed around the at outside edge of your perfusion

negative pulse. The voltage is 2.5 ± (valve# x 0.31V). For example,

whenever valve 4 opens, a 10 millisecond pulse appears on the analog

output at 2.5 + (4 x .31) = 3.74V. When the same valve #4 closes, it creates a

pulse of 2.5 - (4 x .31) = 1.26V.

This graph shows the analog output voltage vs. time resulting from each

valve opening and closing twice.

ValveLink8.2 Modes #2, #3 and #6 (see next chapter) and the analog input

automatically close other valves when a new one is opened to insure that

only one liquid is owing at a time. If the user opens a valve in this way,

then any others will close at the same time. In order to indicate valves

opening and closing simultaneously on the event marker output, the

controller will give a short voltage spike upwards representing the valve

which opened, and immediately spike downwards to the appropriate

voltage for the remainder of the 10 millisecond pulse to signify the valve

which closed.

Valve #5 closing =

2.5 - (5 x .31) = 0.95V

21

20

3-way Valves

The ValveLink8.2 also supports 3-way, single-solenoid valves (2 wires

each). Operate the ValveLink8.2 as you normally would for 2-way valves,

after determining which of two inlets or outlets are opened with the on and

o states. Note that one inlet will always be open with these valves.

Power Supply

The ValveLink8.2 is normally supplied with a 1.5 amp wall transformer.

This is adequate for any valves provided by AutoMate Scientic or a

total of 1 amp of valves opened simultaneously. Please contact AutoMate

Scientic to request a larger power supply if you wish to exceed 1 amp of

valve power (i.e. two 12 watt valves opened at once).

Case and Valve Grounding

This equipment must be earth grounded. Use a #6 screw in any hole

on either side of the ValveLink8.2 case for grounding. Order AutoMate

Scientic part no. 01-05 “Low noise, valve and case grounding package”

for an extra grounding wire attached to each individual valve extending

back to the controller. Each of these items grounds four (4) valves. Please

order two for eight channel perfusion systems. This item must be ordered

at the same time as the valves. Connect the ground wire from the valves to

a screw on the side of the controller case or to your rig's ground point.

chamber where liquid would pass if it overows. It can also be wrapped

around the outside of a light condenser or inverted microscope objective

turret where liquid would ow if it drips out of the perfusion chamber.

Researchers may create or use their own spill sensors with the

ValveLink8.2. Conductive mats or other commercially-available spill

sensors generally use the same principle as AutoMate Scientic's copper

strips. Likewise, you can easily create your own custom sensor using two

bare wires or conductive pens or epoxy. Inexpensive conductive pens

like those from "Circuit Works™" are designed for repairing circuit boards.

They leave lines which quickly dry into silver traces. A similar conductive

epoxy is also available. It makes the connection of two wires to your silver

traces even easier. Simply draw two parallel silver lines approximately

1

/16" (1 mm) apart on any surface where leaking liquids would pass. Make

sure the lines do not touch, or draw one wide line and etch a gap down the

middle once it has dried. Then connect a small wire from each trace back

to the spill sensor port on the ValveLink8.2.

Another nice feature of the ValveLink8.2 spill sensor circuit is its dynamic

recalibration. Competing spill sensors simply watch for a low resistance

and trigger. Unfortunately, their conductive mats keep a low resistance

and cannot be reused until they dry. The ValveLink8.2 lets you press

any button to override the spill. Because it is microprocessor-based, the

controller keeps a running value for the sensor resistance and watches for

a 5% drop in resistance. Therefore, even a damp sensor can be used again

immediately as the controller adjusts to the new resistance and watches for

any subsequent leaks by another proportional resistance drop. As the mat

dries, the ValveLink8.2 is constantly monitoring the increasing resistance

and watching for a drop from the latest value.

Where is the power switch? Sleep

The ValveLink8.2 does not have a power switch. As long as it is plugged-

in, it is on. The ValveLink8.2 is perfectly happy being left on forever

and consumes very little power when all valves are closed. However, an

optional sleep mode has been included. Press and hold the "Mode/Sleep"

button until the blue and yellow Mode LEDs begin ashing (about three

seconds) to put the ValveLink8.2 to sleep. In this state all valves and valve

LEDs are o, and all inputs (buttons, TTLs, USB, etc.) are ignored. Press

the Mode button again to wake the controller. Sleep mode can also be used

as an emergency "o" switch if you need to quickly close all valves and

stop the computer inputs.

12V AC Power (up to 2.4 amps @ 50-60Hz)

USB Port and address

(see USB chapter)

Digital inputs

(see earlier section)

Back Panel

12 volt DC valves

1A (12W) max per channel

2A (24W) max total

Spill

sensor

(prev. pages)

23

22

Modes

The ValveLink8.2 includes several useful features as auxiliary ‘Modes.’

The user changes the current mode settings by pressing the "Mode" button.

The yellow "Set" LED will light. Individual modes are toggled on and o

by pressing their button. The LED associated with each button should

toggle from red to green, with green representing ON. All of the modes

can be used simultaneously, except numbers #2 and #3 which cannot both

be on. Press the "Mode" button to return to normal ValveLink8.2 operation

with any modes activated.

Mode Descriptions

#2 Binary Demultiplexed Addressing Mode

(Valves 1-8 for two ValveLink8.2s)

TTL inputs 1-3 decode into a binary number 0-7 representing which

valve to open (see chart below). Example: TTL input 0000 0101 opens

valve 6 (its decimal equivalent + 1). When this 3-bit number changes, the

previous valve is closed. When Mode #2 or #3 is used, TTL inputs 1-4 are

used for addressing and no longer directly control valves 1-4. For two

ValveLink8.2s, bit 4 is used as described below to further select bank 1 or 2.

Binary chart (showing TTL inputs 4321)

Digital bit pattern Decimal Valve

0000 0 1 (decimal + 1)

0001 1 2

0010 2 3

0011 3 4

0100 4 5

0101 5 6

0110 6 7

0111 7 8

1000 8 + 0 1 on second ValveLink8.2

See Mode #3 below.

The only drawback to either addressing mode is that only one valve can

be opened by TTL inputs at a time. Without Mode #2 or #3, each TTL

input corresponds to a single valve and multiple valves can be opened

simultaneously. Because Modes #2 and #3 need several TTL inputs to

select a single valve, only one can be opened in this manner at once. The

ValveLink8.2 will automatically activate Mode #6, "1-On" whenever Mode

#2 or #3 is used.

#3 Addressing Mode - Valves 9-16 (2nd ValveLink8.2)

This is the same binary decoding of bits 1-3 as Mode #2, but bit 4 is used to

select between two ValveLink8.2s and control up to 16 valves with a single

4-bit TTL source. Set the rst ValveLink8.2 to Mode #2, set the second to

Mode #3, and connect TTL input bits 1-4 from both ValveLink8.2s to your

digital output. Bits 1-3 decode which valve is opened on the ValveLink8.2

selected by the fourth bit (high = ValveLink8.2 in Mode #3 & low =

ValveLink8.2 in Mode #2). Example: TTL input 0000 1001 opens valve 10

(valve 2 on the second ValveLink8.2.) As in Mode #2, TTL inputs 1-4 are

used for addressing and no longer directly control their respective valves.

BNC "tee" connectors will facilitate connection of BNC cables from two

ValveLink8.2s to a common set of digital outputs.

#4 Pre-selected Valve Mode

When Mode #4 is activated, the user is prompted to select a channel 1-8

when leaving mode selection. All LEDs will ash waiting for a channel

selection. Press "Mode" again to nish. Thereafter, the selected valve is

toggled on and o by TTL input bit #8. This mode allows a researcher to

permanently connect a single TTL output to ValveLink8.2 input eight, and

select which of eight valves to activate with that single TTL signal. This

mode prevents input #8 from controlling valve #8 as it normally would,

unless valve #8 is chosen as the ‘pre-selected’ Mode #4 valve.

#5 Master Valve

When Mode #5 is selected, the user is prompted to select a channel 1-8

when leaving mode selection (like Mode #4 above). This valve then

becomes the master valve. Whenever all other valves have been closed

through pushbuttons or any inputs, the master valve will automatically

open. This feature is useful if a control solution is required whenever all

other solutions are stopped.

#6 One-at-a-time or "1-On" Mode

When active, Mode #6 automatically closes all other valves whenever a

valve is opened – either by pushbutton, TTL, analog or USB input. This

guarantees that no more than one valve is open at a time. This mode is

automatically activated when Mode #2 or #3 is used.

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

25

24

USB Communications & Software

The ValveLink8.2 includes a USB-1 port for easy connection to a computer.

The connector is a USB "B" style female socket. AutoMate Scientic sells

USB "A" male to "B" male cables and 4-port USB hubs for use with the

ValveLink8.2. AutoMate Scientic oers a free program for Microsoft

Windows 2000 and above called "ValveLink8.2 User Interface." This

program allows manual control of valves from your PC and networking

of up to eight ValveLink8.2s. It can be downloaded from AutoMate

Scientic's web site at http://www.autom8.com/valvelink.html.

Screen shots show Windows XP, but ValveLink software also works on Vista to Windows 10.

Installation

If you have one, insert the ValveLink8.2

CD into your computer and follow

the instructions to install the main

application. Or double-click the "setup.

exe" installer you have downloaded

from AutoMate Scientic's web site.

Once the program is installed you can plug a USB A-B cable into the

ValveLink8.2 (powered ON) and into your running computer.

Depending on your version of Windows, the rst time a ValveLink8.2 is

installed by USB cable, Windows will "nd new hardware." A dialog box

will appear asking if you want Windows to connect to Windows Update to

search for the necessary software drivers. Select "Yes" and click "Next" to

continue.

If Modes #4 and #5 are both active, the user will be prompted for the Mode

#4 ‘pre-selected’ valve rst, then the Mode #5 ‘master’ valve when leaving

mode selection. If Modes #2-4 are turned-o, then the TTL inputs resume

direct control of their respective valves.

Multiple Modes

As mentioned above, most of the ve modes above can be active

concurrently, such as Mode #2 - Addressing, Mode #5 - Master Valve, and

Mode #6 - One-at-a-time. Valves are opened or closed accordingly. Only

Modes #2 and #3 cannot both be on simultaneously.

Example mode selection LEDs (red = o, green = on):

1 2 3 4 5 6 7 8

Dark Red Grn Red Grn Grn Dark Dark

#3 on = Addressing Mode valves 9-16 (2nd ValveLink8.2)

#5 on = Master Valve

#6 on = One-at-a-time Mode

In this example, when the "Mode" button is pressed to leave mode

selection, all LEDs will ash waiting for the master valve (Mode #5) to be

selected. Select a valve and press "Mode" again to nish.

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

27

26

In the next dialog box, select "Install automatically" and click "Next." Your

computer may need to access the internet.

You may see a warning box explaining:

"The software you

are installing for this

hardware:

FTDI FT8U2XX

Device

has not passed

Windows Logo

testing to verify

its compatibility

with Windows.

Continuing your

installation of this

software may impair

or destabilize the correct operation of your system..." Click "Continue

Anyway" and "Finish" the hardware installation.

Your computer may "Find new hardware" a second time. Repeat the two

steps abaove again, and your computer will be ready to run the ValveLink

sofware.

Software Operation

After the ValveLink8.2 software and USB drivers are installed on your

computer, you may run the program. Any ValveLink8.2s currently

plugged-into the

computer or USB hubs

will appear in the System

Status box as "Online"

next to their USB address.

This address comes from

the 8-position rotary

switch on the back

of each ValveLink8.2

next to its USB port. If

you connect multiple

ValveLink8.2s to the

computer, be sure to set

each one to a dierent

address.

If you connect a ValveLink8.2 to the computer while the User Interface

program is already running, click "Discover Controllers" under the System

menu to add it. The System Status window also shows the current version

of the rmware (internal programming) of each ValveLink8.2. You can

visit AutoMate Scientic's web site to check the latest rmware version,

but it can only be updated by AutoMate Scientic at its oce.

Each ValveLink8.2 will display its own control window with its Address

and eight LED buttons of each valve. These buttons should mirror those

on the front of the ValveLink8.2 and clicking the buttons should toggle

valves exactly like the real buttons.

Depending on your computer's speed and USB bus, there may be a

noticeable delay between the real ValveLink8.2 buttons and LEDs and

updates on your computer screen. USB communications in Windows

are not necessarily real-time. A 100 millisecond delay is not uncommon.

29

28

If the CPU is busy with other programs, printing, or lots of trac on

the USB bus, then signals to and from the ValveLink8.2 may suer. For

maximum performance, plug the ValveLink8.2 into a USB port connected

to its own USB bus. Remember that computers with multiple USB ports

may simply be splitting a single USB bus internally. Check with your

computer's manufacturer or add a separate USB card to your computer for

minimum latency.

The System Status window has a large switch labeled "Local Control"

and "Remote Control." When set to "Local," each ValveLink8.2 follows

its own Mode settings as

described in the "Modes"

chapter earlier in this

manual. When set to

"Remote Control," all

networked ValveLink8.2s

behave according to a single

common "Mode" setting

made on the System Status

window. In this way, up

to eight ValveLink8.2s can

be networked into a single,

virtual 64-channel controller.

A single "Master Valve" can

be selected on a "Master

Controller" like Mode #5 on the ValveLink8.2. Also "1-on" Mode means

only one valve will be open at-a-time on all of the networked controllers.

When the System Status switch is set to "Local Control" you can click the

"Mode" button on any ValveLink8.2 sub-window to access a dialog box

of Modes for that ValveLink8.2 along with eight text "labels" which will

display under each button. These labels can be used to help identify which

solutions are being delivered through each valve.

The same comments about USB communications speed above also apply

to multiple-ValveLink8.2 networking. If "1-on" Mode is used and a button

is pressed on one ValveLink8.2, that signal must travel to the User Interface

program on the PC and back to all other ValveLink8.2s to close any

open valves. The double delay may be noticeable on slower computers

or USB busses.

AutoMate Scientic chose the older USB-1 protocol over the newer, high-

speed USB-2 architecture for three reasons: 1) less expensive, 2) older

computers don't have USB-2 ports, and 3) USB-2 has more bandwidth

(transfers large amounts of data faster), but the same latency (delay) as

USB-1. The ValveLink8.2 needs short bursts of data quickly, so USB-2

would not help.

*This software requires Windows .NET version 4.0 or higher be

installed.

31

30

Computer Interfacing

The ValveLink8.2 can be controlled from a computer using its digital

inputs, analog input or USB port. AutoMate Scientic supplies free

software for communicating over the USB port, but the digital and analog

inputs require you to provide software to generate the signals. Most

customers use their data acquisition software like Axon Instruments'

"pClamp" or Heka's "Pulse." General I/O software like "LabView" from

National Instruments also works well.

You can directly control individual ValveLink8.2 valves from your

computer using one digital output per valve, or you can control all eight

valves with just three digital outputs using Mode #2 or 3 described in

the "Modes" chapter. Computer digital signals are also called "TTL" for

Transistor-Transistor Logic. An "on" or "high" signal is +5V and "o" or

"low" is zero volts. Almost any analog output can also produce these

two voltages. Therefore, if you do not have enough digital outputs, then

analog outputs can also be used to drive the ValveLink8.2 when set to

either +5 or 0V. When the input goes high, a valve opens, and when it

drops low, the valve closes again.

While AutoMate Scientic generally does not support software or

hardware from other companies, we have accumulated some instructions

for connecting the ValveLink8.2 to pClamp software and DigiData

hardware from Axon Instruments. These instructions may help even if you

are using other software.

1) Connect one or more pClamp/DigiData digital outputs to the

corresponding ValveLink8.2 digital inputs (and ground) using the wiring

diagram on page 18 of this manual, or an AutoMate Scientic-supplied

BNC cable. DigiData digital outputs 0-3 appear as BNC connectors on the

front panel. Digital outputs 4-7 are located on the back panel of newer

DigiData interfaces. Older DigiData 1200’s only have four outputs.

2) The ‘Modes’ chapter explains the two dierent methods of controlling

valves: Demultiplexed or not.

3) You can manually generate digital outputs 0-3 from Clampex using the

‘Real Time Control Panel’ adjacent to the ‘Scope’ window. Click the four

checkboxes to turn the outputs on or o and test your connection.

4) To program the digital outputs from pClamp you have two choices:

Sequencing Keys/User Lists or Waveform - Epochs.

Sequencing Keys/User Lists:

Clampex lets you program activities as “Sequencing Keys” (Cong menu)

which can include digital outputs (Operations tab / Parameters / Digital

Out Bit Pattern). The Sequencing Keys can be assigned to hot keys or

grouped together into “User Lists” (Acquire menu / New Protocol /

Stimulate / User List). Each Sequencing Key becomes one ‘step’ in your

perfusion/recording experiment, and can be assigned a time duration.

It is also possible to link Sequencing Keys into a series without needing

User Lists. You can also program a “Digital Holding Level” (Lab Bench /

Congure / Overrides) which maintains a valve state between protocols.

Waveform - Epochs:

The bottom of each Epoch column on the Protocol / Waveforms screen

oers a set of four digital bit patterns. This way you can program valve

activity for each recording epoch interval.

Also see the “Scenarios” section of the “Experiments” chapter of your

pClamp manual. The “Isolated Patch-Clamp Single-Channel Recording”

section (manual page 125 or 135) describes triggering with a drug

application system (DAS).

Contact AutoMate Scientic for advice on how to program your computer

to control valves, or to purchase cables for connecting the ValveLink8.2 to

your I/O hardware.

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

33

32

Techniques

Dead Volume

Dead volume should be minimized in order to switch solutions as rapidly

as possible. Dead volume for this purpose refers to the volume between

the manifold (or Perfusion Pencil) and nal destination (perfusion

chamber, 96-well plate, etc.) A certain amount of time must pass for a new

liquid to clear the previous one from this nal piece of tubing. Solution

switching takes place at the manifold - assuming each channel’s tubing has

been primed (lled) from its valve to this point. Therefore, the manifold

should be positioned as close to the ultimate destination as possible, while

the valves can be some distance away. The micro-manifolds available

from AutoMate Scientic are designed to be inserted directly into orices

in some perfusion chambers. This absolutely minimizes dead volume –

resulting in bath switching times of under a second.

AutoMate Scientic Perfusion Systems may include a disposable ow

regulator which will increase dead volume if used improperly. The

regulator can either be eliminated if controlling ow rate is not necessary,

or positioned before the manifold to eliminate dead volume. However, this

second method only controls the ow rate of individual solutions (instead

of all solutions when located after the manifold). Therefore, the researcher

can either limit the ow of a single liquid, or purchase ow regulators

for each line.

A nal method for reducing dead volume is to use smaller bore tubing,

although this may also reduce ow rate resulting in the same switching

time as for larger tubing.

Small-bore PTFE Tubing

AutoMate Scientic’s micro-manifolds use 1

/16” tube ports which can

either be used with 1

/16” o.d. tubing, or enlarged up to 1

/16” i.d. tubing for

standard Tygon tubing. Please inquire about AutoMate Scientic’s PTFE

tubing and nut and ferrule valve ttings for small bore use. Also see the

micro-manifold instructions on page 12.

Cutting PTFE tubing at an angle and wetting it makes it easier to insert.

Backflow

When a manifold is used in a plumbing arrangement, none of its ports

can be left unconnected, or liquid will simply ow backwards out of the

opening. Small, green hose clamps are included with AutoMate Scientic

Perfusion System drippers which can be easily attached to short pieces

of tubing to act as plugs for unused holes. AutoMate Scientic also sells

manifold 'stoppers' for plugging unused manifold ports.

Likewise, one must be careful not to open any valve whose reservoir

is completely empty or inow tube is disconnected. Ordinary solution

pressure in other lines will force liquid back up the outow tubing,

through the valve, and either back into the reservoir or out the

disconnected inow onto the oor. Again, clamp-o any unused lines at

the manifold or be sure all valves are closed while changing connections.

Solution will quickly backow into empty tubes even when their valves are

closed because air is so compressible. Fill all tubes down to the manifold

or Perfusion Pencil with solution even if they are not being used.

AutoPrime™System

The AutoPrime Perfusion System is

designed to deliver oxygenated (or

other gas-saturated) solutions without

administering ‘stale’ liquid which has

remained stationary in the tubing long

enough to lose its oxygenation. Unless one

uses ‘hard-walled’ (i.e. PTFE) tubing, gas

will escape through the tubing leaving the

stale solution with a ruined pH and gas

concentration. The 8-channel AutoPrime

System uses eight valves per four liquids,

with the second set used as ‘ush’ valves

to waste. Shortly before a solution is to be

switched ‘on,’ its ush valve opens and re-

primes the upper tubing with fresh solution

from the reservoir down to its delivery

valve (where a tee tting is located connected to the ush valve.) The ush

valve is then closed, and the delivery valve can be opened. The previous

solution in a delivery sequence can continue to ow while re-priming

occurs. Contact AutoMate Scientic for more details.

waste

12 34

AutoMate Scientific®

RE A D Y F O R R E S E A R C H.TM

35

34

Faulty Valves

The bane of all liquid delivery apparatus! Despite AutoMate Scientic’s

best eorts and pursuit of high quality valve manufacturers, some

valves fail. Space shuttle launches have often been delayed due to valve

problems. We can only pass along our valve sup plier’s one year warranty

with their disclaimer “Improper use or mishandling of the units, in the

opinion of the manufacturer, voids this warranty!” (their exclamation mark

too.) Please request a copy of AutoMate Scientic's "Valve Troubleshooting

Guide" to diagnose and sometimes repair valve problems. In order to

minimize valve trouble, please observe these guidelines:

1) Clean your valves after each use. Accumulated debris or precipitate

will rapidly cause leaking valves and seals. Use an in-line lter if you

expect a chance of particles in your solutions. Put your AutoMate

Scientic controller’s programmability to good use by writing a washing

protocol. At the end of the day, ll each reservoir with cleaning solution

(distilled water or appropriate liquid), and open all valves. A protocol can

be easily written to ush each valve in sequence. Saline solutions allowed

to dry in stainless steel valves will cause them to rust. This is considered

improper use. We also recommend rinsing your valves once before

their rst use.

Beware of aking PTFE tape or silicone tting glue. Large debris are often

the cause of valve failure. Try backushing a valve that is suspected to

have failed for this reason by connecting a tube and syringe to the outow

of the valve and pushing liquid while it is energized. Sometimes this

ejects the clog.

2) Do not operate AutoMate Scientic valves with homemade controllers

delivering over 12V DC, or attempt to cycle them rapidly (< 1ms).

3) Do not exceed the rated operating pressure (> 30psi).

Before returning any valves to us please check:

1) That it was purchased in the last 12 months (AutoMate Scientic and

valve manufacturers record each by serial number.)

2) That the valve is faulty and not the controller channel – nd a valve that

works in a particular output channel and try the bad valve in that port

to see that it still does not function.

3) If it is leaking, see #1 above and the section below.

If it qualies for all three of the above, AutoMate Scientic will accept the

valve for subsequent return to the factory. Repair or replacement is at

their discretion, as AutoMate Scientic does not have the ability to open

the valves to determine the cause of trouble. We may be able to loan

replacement valves, which may be billed if the valve factory nds abuse on

the user’s part and refuses to honor the warranty.

Stuck Pinch Valves

Occasionally pinch valves will stick closed, especially after they have

gotten wet. Usually this is a sign that they are about to completely fail,

but sometimes they can be rejuvenated by simply prying them open or

lubricating them. First energize (turn on) the valve; then, using a at

screwdriver, gently force the white plunger open where it normally

pinches the tube closed. The valve may begin functioning normally. Also,

pinch valves will not usually work without a piece of pinch tubing

installed! You can also remove the pinch tubing and spray a drop of WD-

40 lubricant or isopropyl alcohol down the pinch valve plunger. Replace

the tubing. This will often add more life to a dying pinch valve.

Valve Cables

One problem that is easy to diagnose and x is a broken cable connection.

Use any ohmmeter to measure the resistance across the inner pin and

outer ‘barrel’ of the RCA plug end of the valve cable (while unplugged

from the controller.) A resistance of zero ohms indicates a short, or innite

resistance means one of the wires is broken in the cable assembly. This

occurs most often at the joint between the heavy black cable and the valve

lead wires – under the heat-shrink tubing, inside the outer black sheath,

a few inches from the valve itself. This can often be reached without

completely disassembling the valve enclosure.

Simply 1) remove the screw inside the black valve box holding the plastic

sheath in its hole, 2) remove the black tape at the top of the sheath and

peel it back a couple of inches, nd the oending cable (trace it back from

the bad valve), and 3) carefully slice its heat-shrink tubing longitudinally

to remove it. The wires may

have come apart or broken

here, or inside the next piece of

electrical tape isolating the two

leads, otherwise within the cable

or valve itself (which can be

12

Valve enclosure (shown without front plate)

Plastic ‘split loom’ cable sheath.

37

36

Table of contents

Popular Controllers manuals by other brands

BUSCH

BUSCH R 5 series instructions

Technische Alternative

Technische Alternative UVR 63H Operation and installation manual

Hach

Hach Polymentron 9500 Basic user manual

AIC Wireless

AIC Wireless Aurora-AX Sedona AUR-WIO-4DI installation instructions

LSI

LSI LSI53C1030 Technical manual

Shelly

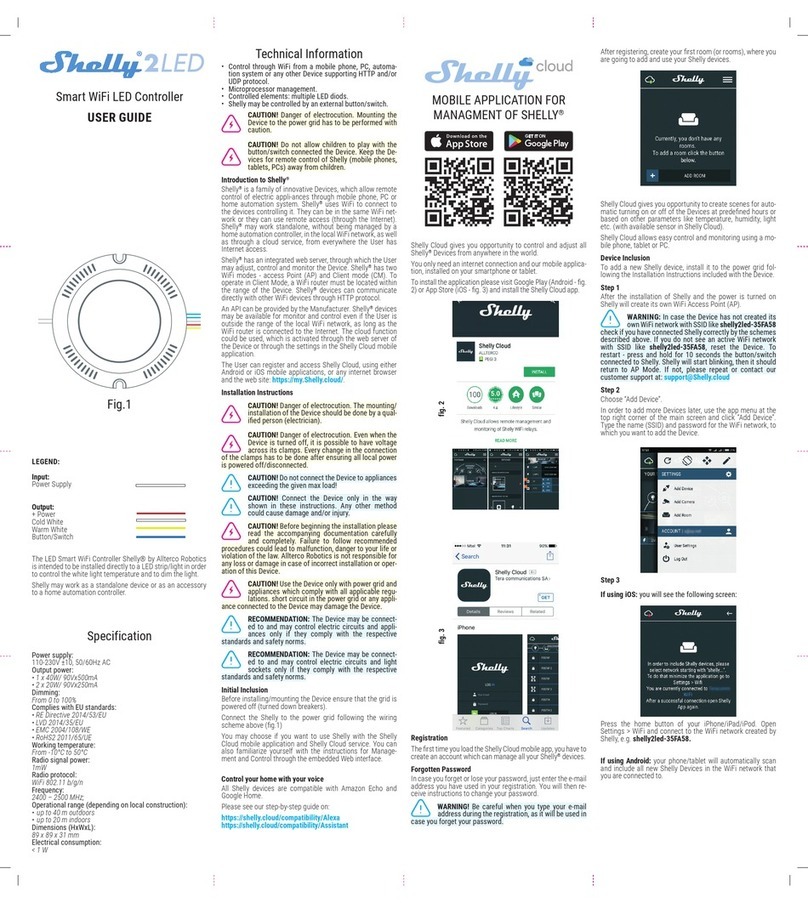

Shelly 2LED user guide

SEW-Eurodrive

SEW-Eurodrive MOVI-C Controller Power UHX85A manual

Wavetec

Wavetec Spectra installation guide

Ingersoll-Rand

Ingersoll-Rand X8I Operator's manual

Atmel

Atmel WINC1500 Getting started guide

Intermatic

Intermatic RC2000 Series Installation, operation & service manual

Richdel

Richdel 446PRi Installation and operating guide