© MOOG 2010

This document is subject to MOOG INTELLECTUALAND PROPRIETARY INFORMATION LEGEND . The details are on page II.

IV MRJ04410

TABLE OF CONTENTS

1. DigiPackⅡ Manual, Installation and Maintenance .............................................................1

1-1. Change from J141-214.............................................................................................1

1-2. INTRODUCTION.........................................................................................................2

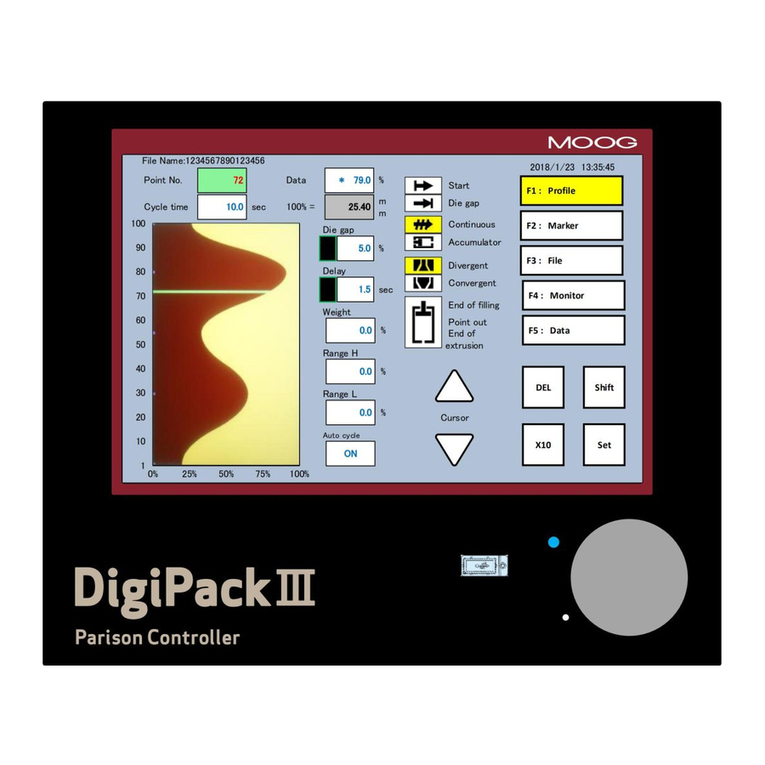

1-2-1. GENERAL DESCRIPTION ...................................................................................................2

1-2-2. WHO CAN INSTALL THE DigiPackⅡ ..................................................................................4

1-2-3. INSTALLATION TIME .........................................................................................................5

1-2-4. SOFTWARE UPDATE .........................................................................................................5

1-2-5. BACKUP BATTERY............................................................................................................6

1-2-6. DISPLAY LIMITED INDICATION PROTECTION ...................................................................6

1-3. DigiPackⅡ SPECIFICATION ......................................................................................7

1-4. CHECK LIST ..............................................................................................................8

1-4-1. INSTALLATION CHECK LIST .............................................................................................8

1-5. MECHANICAL INSTALLATION ...................................................................................9

1-5-1. GENERAL ..........................................................................................................................9

1-5-2. TOOLING ADJUSTMENT .................................................................................................10

1-5-3. MOOG DIE GAP TOOLING ACTUATORS..........................................................................11

1-5-4. CYLINDER INSTALLATION ..............................................................................................12

1-5-5. CUSTOMER SUPPLIED CYLINDER REQUIREMENTS ........................................................12

1-5-6. MANIFOLD.......................................................................................................................13

1-5-7. SERVOVALE MOUNTING .................................................................................................13

1-5-8. TOOLING ADJUSTMENT .................................................................................................13

1-5-9. ACCUMULATOR POSITION MEASUREMENT ...................................................................14

1-5-10. INSTALLATION REQUIREMENTS ...................................................................................14

1-5-11. THE IMPORTANCE OF FILTRATION...............................................................................15

1-5-12. FILTER INSTALLATION..................................................................................................15

1-5-13. HYDRAULIC POWER SUPPLY ........................................................................................16

1-5-14. HYDRAULIC POWER SUPPLY START UP INSTRUCTIONS.............................................16

1-5-15. CONTAMINATION CONTROL.........................................................................................17

1-6. ELECTRICAL INSTALLATION...................................................................................18

1-6-1. GENERAL ........................................................................................................................18

1-6-2. TB-1, TB-2 WIRING .........................................................................................................18

1-6-3. COMMUNICATION AND SSI SNSOR WIRING ....................................................................19

1-6-4. TB-2 I/O CIRCUITRY.......................................................................................................25

1-6-5. NOISE AND GROUND ISOLATION....................................................................................26

1-7. TOOLING SYSTEM SETUP.......................................................................................29

1-7-1. GENERAL ........................................................................................................................29

1-7-2. MACHINE SETTINGS (F4+Set) .........................................................................................29

1-7-3. MACHINE SETTING (F4+Set) FUNCTION..........................................................................31

1-7-4. DigiPackⅡ FRONT PANEL ..............................................................................................32

1-7-5. SET UP PROCEDURE ......................................................................................................34

1-7-6. DCDT / SSI SETUP .........................................................................................................35

1-7-7. GAIN SETUP....................................................................................................................38

1-7-8. ACCUMULATOR MACHINE SETUP ..................................................................................39

2. DigiPackⅡ Manual, User...............................................................................................42