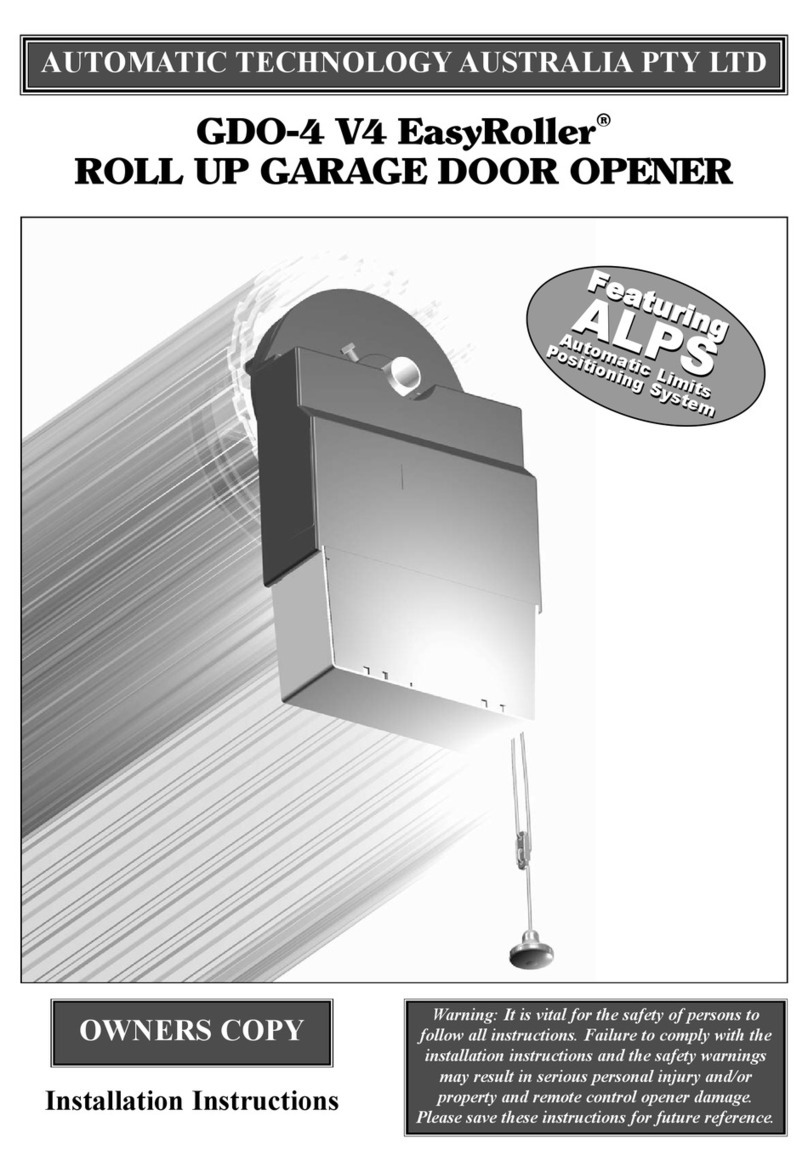

Automatic Technology Australia EasyRoller GDO-4 Quick start guide

Automatic Technology Australia Pty Ltd

EasyRoller

GARAGE DOOR

OPENER

lnstallation

lnstructions and Owners

Manual for GDO,4

Garage Door Opener

Gontents

USER SAFETY INFORMATION

FEATURES

OPERATING CONTROLS

PACKAGE CONTENTS

SEOUENCE OF INSTALLATION

INSTALLATION

FAULTS AND REMEDIES

PARTS LIST

TECHNICAL SPECIFICATIONS

OPTIONS AND ACCESSORIES

WARRANTY AND EXCLUSION OF LIABILITY

PAGE

I

I

2

4

4

5

1t

12

13

t3

14

U

User Safety lnformation

lnstall the wall switch in a

location/position where the

garage door is yisible and

A Garage door must be well out of reach ol children. objects including motor vehicles

/t\ oaranced. Sticking or binding fi only operate the garage within the doorway'

4\ (e6;s must be repaired by a / I \ door opener when the garage A When using auto close mode a

qualified garage door installer Adoor is in.futl view and free /I\ photo electric beam must be fitted

prior to operator installation. from obstructions. / ' \correctly and tested for operation

A Connect the operator to a

fl\ prop"rry grounded general

A purpos e 24oV outlet installed by

r oualified electrical contractor

v

and/or property damage, This, A Keep hands anct any loose

test must be repeated at reoular /il . ..'.

intervals and the n*"*""*-'"'*' /I\ clothinq clear of door and door

Featufies

PLEASE READ

THESE IMPORTANT

SAFETY RULES

Do not attempt to repair door

yourself as hardware is under

extreme tension and

can cause serious personal

injury and/or property damage

Remove or disengage all

garage door locks prior to

installation of operator.

Make sure that the reversing

sensitivity is adjusted correctiy on

installation so that the door

reverses to the open position

when obstructed. Failure to

adjust this setting propedy could

result in serious personal injury

Your EasyRoller Automatic Garage

Door Opener has many features

which you will appreciate. The

Components and Materials used in

'his Automatic Opener are of the

\ratest Technology and highest

Quality. Below are listed some of

the features.

OPERATION

To operate the door simply press

the hand held transmitter or the

wall mounted switch for two

seconds and the door will

automatically open or close. The

door can be stopped during an

opening or closing cycle by

pressing the wall switch or

handheld transmitter. The next

actuation will move the door in the

opposite direction.

SAFETY OBSTRUCTION

REVERSE

While the door is doing a closing

cycle and it should hit an obstacle

or be restricted in some manner, it

will automatically reverse. The

amount of force the door should

encounter before reversing is

adjustable. The door also if

restricted whilst opening will

Do not allow children to sperate

the garage door opener.

Serious personal injury and/or

property damage can result from

failure to follow this warning. A

Do not operate the garage door ll_\

opene r when children/persons

are near the door- Children must

be supervised near garage door

at all times and when door

operator is in use. Serious

personal injury andlor property

damage can result irom failure to

follow this warning.

Disconnect power cord from

mains power before making any

repairs or removing covers.Only

qualified service personnel can

remove coverg from opener.

stop. The Safety Obstruction

Forces should be checked at least

once a month.

AUTOMAT!C

COURTESY LIGHT

The Courtesy Light on the Opener

comes on automatically whenever

the door is activated to do an

opening or closing cycle. The light

will stay on for approximately ihree

minutes then turns off

automatically. The Light can also be

switched on and off without

operating the door. This is done by

pressing the Light button on the

Wall Switch. The Light turns off

after three minutes.

MANUAL OPERATION

The Opener is equipped with a

unique Manual Disengaging

Device. lf the power to the Opener

is disrupted for any reason the door

can be put into Manual Mode by

pulting down on the string handle,

then releasing. This will allow you to

manually open or close the door.

When power is restored, by pulling

down on the string handle and

releasing, the Opener is put back

into Automatic Mode.

Do not disengage the door

opener to manual operation with

children/persons or any other

at regular intervals. Extreme

caution is recommended when

using auto close mode. All safety

rules above must be followed.

Automatic Technology Australia

Pty. Ltd. to the extent that such

may be lawfully excluded hereby

expressly disclaims all conditions

or warranties statutory or othen|ise

which may be implied by law as

conditions or warranties of

purchase of an Automatic

Technology Australia Roll-Up-

Door Opener and Automatic

Technology Australia Pty. Ltd.

hereby further expressly excludes

all or any liability for any injury.

damage, cost, expense or claim

whatsoever suffered by any

person as a result whether

directly or indirectly from failure to

install the ATA Easy Roller Roll-

Up-Door in accordance with these

installation instructions.

SECURITY GODE STORE

The Opener uses state of the art

technology in storing your selected

Transmitter Security Code. Up to

sixty different codes can be stored

in the non volatile memory device.

To store any code simply press and

hold the Code Store button on the

Opener and press the Transmitter

button twice. Each or all codes can

be deleted and changed at any

time. Security is enhanced because

there are no Dip switches on the

Opener which can be visually seen

and copied.

cAs (colouR

ASSTSTED SETTTNGS)

To make the installation of the

Automatic Opener more user

f riendly Automatic Technology

Australia developed the CAS

(Colour Assisted Settings) System.

This unique system allows for all

the Open and Close adjustments

and settings to be colour

coordinated, Red for Close and

Green for Open. The colour

coordination makes it easier and

quicker for the user or installer to

complete the installation.

Featurgs cont...

OPEN AND CLOSE

DRIVE BUTTONS

Another feature developed by

Automatic Technology Australia in

aiding in the installation of the

Opener are the Open and Close

Drive Buttons. These buttons are

used to help set the open and close

limit positions. The quicker

setting time and a more precise

limit position can be achieved

using this system.

AUTO CLOSE MODE

The Opener can be programmed

to automatically close

approximately thirty seconds after

the door has opened. A Photo

Electric Beam must be installed if

this mode is selected.

AUTO RUN TIME

lf the Motor is left running in the

Opener for any reason the Auto

Run Time will turn the motor off

after thirty seconds.

PHOTO ELECTRIC BEAM

The Opener has an input for a

Photo Electric Beam to be

connected for extra safety protection.

15. AUTO CLOSE (J2) lnput is

used for selecting the auto

close mode. lf auto close is

selected the door will

automatically close

approximately 30 seconds after

opening. To select, remove

shunt from P.E. input connector

and place on auto close

connector pins. NOTE: a P.E.

Beam must be used when auto

close is selected.

16. SEGURALIGHT lnput is used

for connecting a Securalight

(optional extra) Monitor. A

Securalight is a monitor unit

which is mounted inside your

home and is connected to the

Opener by wire cable. The

monitor indicates the status of

the door, for example if the

door is moving, is opened or

closed, etc. An audible beeper

sounds whenever the door is

moved by the Opener. The

door can also be controlled

from the monitor unit.

17. O/S/C lnput is for connecting

the Wall Switch.

18. WALL SWITCH is usuatty

mounted inside the garage.

Pressing the Open / Close

button on the wall switch will

open, close or stop the door.

Pressing the Light button will

turn the light in the Opener on

or off. lf the light comes on and

you do not press to turn off, the

light will turn off automatically

after about 3 minutes.

19, ENGAGVDISENGAGE

HANDLE when pulled down

and released will select

manual mode when there is a

power failure. Pulling down and

releasing again will select

automatic mode.

20. STANDBY BATTERY SHUNT

must be removed when using

Battery Back Up Option.

1.

2.

3.

4.

5.

6.

v

Operating Gontrols

O/S/C Button (yellow) is used

during installation to test the

open, close and stop

commands to the Opener.

Pressing this button will open,

close or stop the door.

CODE SET Bufton (blue) is

used for storing or erasing your

selected security code from

your transmitter(s) into the

Openers memory device.

OPEN DRIVE Button (green)

is used during installation to

help set the open limit stop

position. Pressing and holding

this button will move the door

in the open direction.

Movement stops when the

button is released or when the

open limit switch is activated.

NOTE: The open obstruction

detection is inoperable

whenever the Open Drive

button is used to move door.

OPEN LIMIT Led (green)

illuminates whenever the open

limit switch is activated. The led

is very helpful during installation.

CLOSE DRIVE Button (red)is

used during installation to help

set the close limit stop position.

Pressing and holding this

button will move the door in the

close direction. Movement

stops when the button is

released of when the close

timit switch is activated.

NOTE: The close safety

obstruction detection is

inoperable whenever the

Close Drive button is used to

move door.

CLOSE LIMIT Led (red)

illuminates whenever the close

limit switch is activated. The led

is very helpful during installation.

OPEN FORCE ADJUSTMENT

Shaft (green) is for adjusting

the open obstruction force.

Turning the shaft in a clockwise

direction increases the force

that is required to restrict the

door before it stops when

opening. Turning anticlockwise

will decrease the force that is

required to stop the door.

8. CLOSE FORCE

ADJUSTMENT Shaft (red) is

for adjusting the close safety

obstruction force. Turning the

shaft in a clockwise direction

increases the force that is

required to restrict the door

before it reverses when

closing. Turning anticlockwise

will decrease the force that is

required to reverse the door.

NOTE: The open and close

safety obstruction forces need

to be tested at regular intervals

(once a month) and the

necessary adjustments made.

9. OPEN LIMIT CAM (green) is

used to set the open limit stop

position. Check lnstallation

section on how to adjust.

10. OPEN LIMIT ADJUSTMENT

SCREW (green) is used to fine

adjust the open limit stop

position. Check lnstallation

section on how to adjust.

11. CLOSE LIMIT CAM (red) is

used to set the close limit stop

position. Check lnstallation

section on how to adjust.

12. CLOSE LIMIT ADJUSTMENT

SCREW (red) is used to fine

adjust the close limit stop

position. Check lnstallation

section on how to adjust.

13. P.E. lnput is for connection of

Photo Electric Beams (optional

extra) for extra safety

obstruction protection. The P.E.

shunl must be removed when

a PE. is connected.

14. P.E. SHUNT must not be

removed othenarise the Opener

wilt not function correctly.

Remove only when a P.E. is to

be connected

7.

Operating Gontrols

IPIRATlNG CINTRNLS

?ffi

tt

m"ll

ll

)g

1. O/S/C button

2. Code set button

3. Open drive button

4. Open limit LED

5. Close drive button

6. Close limit LED

7. Open force adjustment shaft (green)

8. Close force adjustment shaft (red)

9. Open limit cam (green)

10. Open limit adjustment screw (green)

11. Close limit cam (red)

12. Close limit adjustment screw (red)

13. PE. input

14. PE. shunt

15. Auto close input

16. Securalight inout

17. O/S/C input

18. Wall switch

19. Engage/disengage handle

20. Battery shunt

Package Gontents

ITEM

DRIVE UNIT

HAND TRANSMITTER

WALL SWTTCH (WrrH WrRE)

BATTERY (9VOLTS)

WETGHT BARS (NOT TNCLUDED rN SOME COUNTRTES)

SELF TAPPING SCFIEWS (M4 X 25mm)

INSTALLATION MANUAL

qUANTITY

1

1

1

1

2

4

1

Sequence of lnstallation

f,

HAND

TRANSMI T TER

VALL

SVITCH

DRIVE UNIT STRING

HANDLE

BATTERY

VEIGHT BARS

lnstallation

SIDE ROOM REQUIREMENTS

Figure 1 shows the minimum side room that is required.

The distance between the edge of the door curtain and the inside of the

bracket is B5mm and the distance between the edge of the door and the

outside of bracket is 135mm.

Figure 2 shows the recommended side room. The distance between the

edge of the door curtain and the inside of the bracket should be 11Omm

minimum and the distance between the edge of the door and the outside

of bracket should be 160mm minimum.

I. CHECK OPERATION OF DOOR

BEFORE BEGINNINGTHE INSTALLATION OFTHE EASY ROLLER

AUTOMATIC OPENER CHECKTHE OPERATION OFTHE DOOR.

The door must be well balanced and be in a reasonable operating

condition. The door should not stick or bind in the guide tracks. The ideal

operational effort in raisrng or lorvering the door should not exceed a force

'rf 15 kgs (33 lbs.). The maximum effort should not exceed a force of 25

U(gs (55lbs.).

2. FIXING OF DOOR WEIGHT BARS

Move the door manually to mid open position. Place the weight bars

equally apart on the bottom rail of the door and secure them with the

fasteners provided (see Fig. 3). Check the operation of the door again. lf

the door feels heavy it may require exira tension to be added to the door

springs. Refer to the Door lnstallation Manual from the manufacturer on

how to tension the door.

3. IEFT OR RIGHT HAND INSTALLATION

The Easy Roller Automatic Opener can be installed on the left or right

hand side of the door (when looking out from the inside of the garage). lf

your opener is to be installed on the RIGHT HAND side of the door then

go on to Step 4. lf the left hand side is your selected side for installation

the next siep is to move the motor wire connector (labelled J12 on the

control board). The connector has to be removed and reconnected to the

i-EFT side of J12 which is marked A:B (see Fig. 4).

ttlT you have made an error in selection and wish to install to the RIGHT

HAND side of the door then reconnect the connector to the RIGHT side oI

J12 marked B:C (see Fig. 5).

M]NIMUM SIDf RtrtrM

RECIMMENDED SIDE RINM

160 mm

\/EIGHTS

MOTOR VIRE CONNECIED

rOR LEFT HAND SIDE

INSTALLATION (AB)

ABC

FIG.4

MOTOR VIRE CBNNECTED

FOR RIGHT HAND SIDE

INSTALLATION (BC)

lnstallation cont...

4. FIXING DRIVE ASSEMBLY TO DOOR

The Easy Roller Drive Assembly can be fixed to the Roll Up Garage Door

in a variety of ways. Below we will describe one method of fixing. Make

sure there is enough room (135mm from end of door shaft to the wall) to

slide drive assembly onto shaft.

PLEASE NOTE: THE INSTRUCTIONS FOR FIXING OF THE DRIVE

ASSEMBLY TO THE DOOR IS FOR RIGHT HAND INSTALLATION.

FITTING DRIVE ASSEMBLY TO DOOR

(see Fig.6,Fig.7, and Fig.8 ).

(a) Check that the door shaft U bolt is securely tightened on the left hand

side of the door.

(b) Baise the door and tie a rope around the centre to secure the roll.

(c) Support the right hand end of the door with a suitable prop, e.g. step

ladder and soft padding to protect door surface.

STOP. WARNING: DO NOT ALLOW CHILDREN/PEFISONS

AHOUND THE DOOR WHEN PROPPED. SERIOUS PERSONAL INJURY

AND / OR PROPERTY DAMAGE CAN RESULT FFIOM FAILURE TO

FOLLOW THIS WARNING.

(d) Check that step 3.1a was completed. Carefully loosen and remove the

right hand door shaft U bolt.

(e) Make sure that the door supporting prop is secure. While the door is

supported remove the right hand door mounting bracket from wall.

(f) Remove the Drive Assembly from packaging. Try and rotate the drive

gear by pushing on the fork. lf the gear does not rotate the manual

mode has to be selected. To select pull on the string handle

downwards, then release slowly. The drive gear should now rolate.

(g) Slide Drive Assembly over the door axle making sure that the fork

extends into and over one of the spokes of the door drum wheel.

(h) Refit the door mounting bracket to the wall. ln some cases the bracket

may have to be repositioned. Retighten the door shafi U bolt.

Remove door supporting prop and untie rope from curtain.

Straighten the Drive Assembly and position as per figure B. Tighten

the two locking bolts firmly to secure Drive Assembly.

Check the manual operation of the door by raising and lowering the

door. The door should run smoothly and not catch on any part of the

Drive Assembly.

5. SETTING LIMIT SWITCHES

The Limit Cams, Limii Fine Adjustment Screws and Door lnch Buttons are

colour coded to make the setting of the limits as user friendly as possible.

The GREEN colours for OPEN LIMIT SETTING. The RED colours for

CLOSE LIMIT SETTING.

5.1 SETTING LIMITS FOR RIGHT HAND INSTALLATION

(a) With the Drive Assembly in manual mode (disengage, see Fig. 12),

move the door up by hand to the desired open position.

(b) Remove the Light Diffuser (see Fig. 9). Rotate by hand in an

anticlockwise direction the green limit cam (see Fig. 10) until the cam

clicks the open limit switch.

(c) Move the door down by hand to the desired closed position.

(d) Rotate by hand in a clockwise direction the red limit cam (see fig. 11)

until ihe cam clicks the close limit switch.

(e) Connect power lead from

the Drive Assembly into a general purpose power outlet installed by a

licensed qualified electrical contractor. Turn the Power On.

(0 Fle-engage the drive gear by pulling down on the string handle and

then releasing slowly (see Fig. 12)

6

(i)

(i)

(o) CHECK IF

,U' BOLT IS

TI6HTENED

(d) REMOVE RIGH'I

-U' BOLT

\

FIG. 7

TO REMT]VE

LIGHT DIFUSER

FIG. 9

FI6. 8

OPEN LIMIT ADJUSTMENT

(g) Press in and hold the Green Open lnch Button. The door should start

opening. Release the inch button when the door reaches the desired

open position. lf the Green LED (see Fig. 10) is illuminated and the

desired limit position has been reached then the limit adjustment is

complete. lf the Green LED is illuminated but the door has not

reached, or has gone past the desired position, you have to adjust the

Green Fine Adjustment Screw (see Fig. 10). Adjust the screw

anticlockwise to open the door more. To open the door less adjust the

screw clockwise. Each complete revolution of the adjustment screw is

equal to approximately .1 Omm of door travel.

NOTE: lf the door has not reached the desired limit position by more

than 30mm, it is recommended that the green limits cam be adjusted

again before the green fine adjustment screw is adjusted.

CLOSE LIMIT ADJUSTMENT

(h) Press in and hold the Red Close lnch Button. The door should start

closing. Release the inch bution when the door reaches the desired

y closed position, lf the Red LED (see Fig. I1) is illuminated and the

desired position has been reached then the limit adjustment is

complete. lf the Red LED is illuminated but the door has not reached,

or has gone past the desired position, you have to adjust the Red

Fine Adjustment Screw (see Fig. 11). Adjust the screw anticlockwise

to close the door less. To open the door more adjust the screw

clockwise. Each complete revolution of the adjustment screw is equal

to approximately 1Omm of door travel.

NOTE: if the door has not reached the desired limit position

by more than 30mm, then it is recommended that the red

limits cam be adjusted aQain before the red fine adjustment

screw is adjusted.

5.2 SETTING LIMITS FOR LEFT HAND INSTALLATION

(a) With the Drive Assembly in manual mode, move the door up by hand

to the desired open position.

(b) Remove the Light Diffuser (see Fig. 9). Rotate by hand in a clockwlse

direction the Green Limit Cam (see Fig. 13) until the cam clicks the

open limit switch.

b) Move the door down by hand to the desired closed position.

St(d) Rotate by hand in an anticlockwise direction the red limit cam (see

Fig.14) until the cam clicks the close limit switch.

(e) Connect Power Lead from the Drive Assembly into a general purpose

power outlet installed by a licensed qualified electrical contractor.

Make sure that the Power Lead is safely fastened away from any

moving parts. Turn the Power On.

(f) Re-engage the drive gear to door by pulling down on the string handle

and then releasing slowly (see Fig. 12).

OPEN LIMIT ADJUSTMENT

(S) Press in and hold the Green Open lnch Button. The door should

start opening. Release the inch button when the door reaches the

desired open limit stop position. lf the Green LED (see Fig. 13) is

illuminated and the desired limit stop position has been reached then

the limit adjustment is complete. lf the Green LED is illuminated but

the door has not reached the desired position, you have to adjust the

Green Fine Adjustment Screw (see Fig. 13). To open the door more,

adjust the screw anticlockwise. To open the door less adjust the screw

clockwise. Each complete revolution of the adjustment screw is equal

to approximately 'lomm of door travel.

NOTE: lf the door has not reached the desired limit position by more

than 30mm, it is recommended that the green limits cam be adjusted

again before the green fine adjustment screw is adjusted.

FIG, 11

OR

RE-EN6A6E

FIG. 12

^NIICLEXVISE rO @EN @E

cL&xvtsE ro @N LEss IOIAIE 6FEEN 'N

@Hp

F1G, 13

lnstallation conr...

CLOSE LIMIT ADJUSTMENT

(h) Press in and hold the Red Close lnch Button.The door should start

closing. Release the inch button when the door reaches the desired

closed limit stop position. lf the Red LED (see Fig. 14) is illuminated

and the desired limit position has been reached then the limit

adjustment is complete. If the Red LED is illuminated but the door has

not reached, or has gone past the desired position, you have to adjust

the Red Fine Adjustment Screw (see Fig. 14). Adjust the screw

clockwise to close the door less. To close the door more adiust the

screw anticlockwise. Each complete revolution of the adjustment screw

is equal to approximately 1Omm of door travel.

NOTE: lf the door has not reached the desired limit position

by more than 30mm, then it is recommended that the red

limits cam be adjusted again before the red fine adjustment

screw is adjusted.

6. FIXING OF DOOR CURTAIN TO DRUM WHEEL

The Door Curtain has to be secured to the drum wheel with

suitable fasteners.

(a) With the door in the fully closed position mark the curtain (as per Fig.

15) on both ends of the door.

(b) Open door slightly to have access to the marked positions. Secure the

curtain to drum wheel using self drilling screws (two on each end). The

screws should be at least 90 degrees apart as per Fig. 15.

7. SETTING OF CLOSE SAFETY OBSTRUCTION AND

OPEN FORGE

lmportant: The setting for the open and close obstruction forces are the

most important adjustments that are made in the whole installation

procedure. Make sure that the force (load ) is adjusted correctly as per the

installation instructions. Failure to adjust these settings correctly could

result in serious personal and /or property damage. The end user musl be

informed that they must test at regular intervals (once a month is

recommended) these settings and the necessary adiustments

made if required.

Note: The Open and Close Obstruction Force ad.lustments procedure are

the same for Left or Right Hand installation.

7.1 CLOSE SAFETY OBSTRUCTION FORCE ADJUSTMENT

(a) Fully open the door by pressing in and holding the green

inch button. The door will stop automatically when the open limit

position is reached.

(b) Turn the Red Close Force Shaft fully clockwise. Press the Yellow

O/S/C (open, stop,close) button (see Fig. 16) momentarily, the door

should stgrt closing. As the door is closing turn the Red Shaft slowly

anticlockwise until the door stops momentarily then reverses to the

open position.

(c) Turn the Red Shaft 10' clockwise, Press the Yellow button to close the

door. lf the door reverses by itself, readjust the Red Shaft a further 5"

clockwise. Keep adjusting in this manner until the door can complete

the full closing cycle.

FIG. i4

DRUI,,I VHETL

+-+

(o) (b)(c)

l/

FIG. 16

u

7.2 OPEN OBSTRUCTION FORCE ADJUSTMENT

(a) Fully close the door by pressing in and holding the green

inch button. The door will stop automatically when the closed limit

position is reached.

(b) Turn the Green Close Force Shaft fully clockwise. Press the Yellow

O/S/C (open, stop, close) button (see Fig.17) momentarily, the door

should start opening. As the door is opening turn the Green Shaft

slowly anticlockwise until the door stops.

(c) Turn the Green Shaft 10" clockwise. Press theYellow button to open the

door. lf the door stops by itself, readjust theGreen Shaft a further 5"

clockwise. Keep adlusting in this manner until the door can complete

the full opening cycle.

7.3 CLOSE SAFETY OBSTRUCTION TEST

The door now has to be tested for response to an obstruction while it is

opening and closing. With the door in the opened position, place a solid

object approximately I metre in height underthe door (see Fig. 18). Press

"the Yellow button to close the door. When the door reaches and pushes on

\-.ie object it should pause then reverse up to the open position. Repeat

the above and observe the action of the door as it pushes against the

solid object. Undue load should not be applied to the door. The load

imposed by the door should be around I to 10k9. The load can be tesied

by placing a bathroom scale on the floor under the door, start a close

cycle and read the scale as the door pushes down against the scale. lf the

reading is too high. readjust the Red Close Force Shaft. Turning shaft

clockwise increases the load applied to the door. Turning shaft

anticlockwise decreases the load applied to the door.

IMPORTANT: IF THE DOOR IS UNABLE TO REVERSE WHEN

OBSTRUCTED DISCONTINUE USE. SELECT MANUAL MODE AND

CONTACT AUTOMATIC TECHNOLOGY AUSTRALIA PTY LTD.

8. SETTING OF TRANSMITTER AND RECEIVER

SECURITY CODE

8.1 SETTING THE TRANSMITTER

(a) Remove the sliding cover from the back of the Transmitter (see

Fig.19). The coding switches are located under the slide of back

-. cover (see Fig. 19).

\o) Using a pen or similar instrument, move the code switches so as to

form a random looking pattern. For example switches i,2,5,7,8,10

and 11 in the off position and 3,4,6,9,12 in the on position (see Fig.

19). The selected pattern forms the Transmitter Code.

(c) Connect the 9V Battery to Transmitter. Slide the back cover

back into position.

8.2 STORING THE TRANSM!fiER CODE INTO THE

CONTROLLER'S RECEIVER

The memory in the controller's receiver can store up to 60 different

transmitter codes.

(a) Press and hold the Blue Code Set Button on the Control

Panel (see Fig. 20).

(b) Press the Transmitter Button for approximately two seconds.

Pause for 2 seconds. Press the Transmitters Button again for

approximately two seconds.

(c) Release the Code Set Button.

(d) Press the Transmitter Button to see if it operates the door.

(e) Uncoil the Antenna Wire and stretch it out against the Garage Wall in

a horizontal or vertical direction (try and keep the antenna wire away

from metal objects). Secure wire with suitable fasteners. Do not cut

the antenna wire or coil up.

IMPORTANT: Only operate the Garage Door Opener when the

Garage Door is in full view and free from obstructions.

(o) (b)(c)

AUTO

CLOSE

@

@

FIG. 17

FIG. 18

FIG. 19

1,.:,r$,,r

lnstallation cont...

8.3 DELETING THETRANSMITTERS CODE FROMTHE

CONTHOLLERS RECEIVER

lf you only want to delete one transmitter code stored then use step 8.3a

to d. Use step B.3e to h if you want to delete all the stored transmitter

codes.

(a) Select the transmitte(s) you want to delete from memory.

(b) Press and hold the Blue Code Set Button on the Control

Panel (see Fig. 20).

(c) Press the Transmitter Button for approximately two seconds.

Pause for two seconds. Press the transmitters Button again for

approximately two seconds.

(d) Release the Code Set Button. The code should now be deleted.

Confirm this by pressing the transmitter button to see if it can

operate the door.

Turn the Power Off to the Drive Unit.

Press and hold the Blue Code Set Button on the Control panel.

Turn the Power back On again.

Release the Code Set Button after three seconds. All the Stored

codes should be now deleted. Confirm this by trying to operate the

door by pressing one of the deleted transmitters.

(e)

(0

(s)

(h)

9. FITTING WALL SWITCH

(a) Remove the front cover from the Wall Switch. Take note of the

orientation of the Switch, the Open/Close Button must be to the top

when mounting to the wall.

(b) Locate the Wall Switch in a convenient position. Make sure thai you

mount the Switch higher than a child can reach and in a position

where the door is clearly visible.

(c) Connect the three wires, and secure to wall with the two screws

provided (see Fig. 21).

(d) Connect plug from the-.wai-switch wire to the connector marked

O/S/C (J6) on the control board.

NOTE: The descriptions (e), (f) and Fig.22 are for Right Hand lnstallation.

For Left Hand lnstallation break the tab and use the cable restrainers on

the opposite side.

fl)

Secure wall switch wire to the control board with the cable

restrainer provided.

Break away the plastic tab with a pair of pliers to create an exit point

for the wire from the Drive Unit (see Fig. 22)

Check the exit point of the wire from the switch base and remove

material from the front cover of switch,so that the cover does not cut

through the wire.

Reposition the two buttons in the front cover and refit over the switch

base by pushing on cover.

Fasten wire to wall with suitable fasteners. Make sure not to break

through tle wire insulation when fastening. Breaking the insulation

will create a short in the wire.

Refit the light diffuser.

Test the operation of the switch by pressing the Open/Close Button to

move the door.

While the door is siationary press the Light Button to turn the light on

the opener On and Off.

(e)

(f)

(s)

(h)

(i)

(i)

(k)

@*p

.I

El

'i

FIG. 21

10

Faults and Remedies

SYMPTOMS POS,SIBLE CAUSE REMEDY

tr Door will not operate tr Main power not turned on

tr Door is obstructed Turn on

Remove obstruction

tr

tr

tr Door is locked or

motor jammed tr Unlock door

tr Door will not reverse

tr Door moves downwards and

reverses itself upward

. . 1 Door ooerates from

t drive unit but not from

hand transmitter

tr Door reversing sensitivity not

adjusted properly

Door reversing sensitivity

not adjusted properly

lndicator on transmitter

not lighting

Code not stored in

controlling receiver

Drive unit aerial wire

not extended

Battery flat

Radio interference

Fle-adjust reversing sensitivity

(Ref installation instructions

Step 7.1)

Re-adjust reversing sensitivity

(Ref installation instructions

Step 7.1)

Battery flat or battery

leads broken

Refer to installation

instructions-Step 8.2

Extend aerial wire

Replace battery

Return operator to place of

purchase for frequency

upgrade (charges apply)

tr

tr

tr

tr tr

tr

1tr

o

tr

tr

tr

tr

D Door open/closes by itself

v,

tr lncorrect coding D Change the numerical

coding on transmitter

and receiver (please

ensure at least 4 switches are

in the on position)

tr Door does not close fully tr Limit microswitch

incorrectly adjusted tr Re-adjust limit switch

(refer to installation

instructions-Step 5)

tr Door does not open fully tr Limit microswitch

incorrectly adjusted tr Re-adjust limit switch

(refer to installation

instruction-Step 5)

tr Lights not functioning tr Globe blown O Replace globe

tr Replace with 24VDC '15 Watts

Festoon Globe

tr Globes keep blowing I lncorrect globe

Parts List

Item No Description

4

5

6

7

8

o

10

11

12

13

14

15

16

2

3Limits Base

Adjustment s':rer, green/red

Switch holder green\red

E circlip D1500 0040

lvliniature microswitch

Disengagement spring

l\,4otor base

Cam

Disengagement lever

Disengagement shaft

Cam spring

Limits cam guide

Limit cam green-limit cam red

Plastic base

clamp

Drive ass'y 7

Worm shaft

Gear 1

Limits shaft

Board support

Helical gear 2610

lnternal gear

I\,4ain cover

Light diifuser

Board cover

Control board assy CB-7 V1 .00

Worm support

Limits bush

Controls label

Logo label right

Worm washer

' Disengagement cap

Disengagement washer

Transf orme r TF6 1 7 06 I 1 2-3

Terminal block 500/02DS 2 Pos

Cord grip grommet SB-6R-3

String 600mm

Hex. Head screw m8x25

Hex {lange hd. Screw m6xl6

Pan. Flange hd. Screw m4x12

Taplite screw "P" m4x10

Taptite screw "P" m3x16

Cap head screw m6

Hex flange nut m6

Retaining ring stw 45

E circlip D.l500 0080

Hex nut m4

String handle

Clamp washer

Special washer

Flat washer LD.5

Hex nut Wint tooth washer m5

ldentity label

Warning label

String guide

,,..€d{'

p.,

43

,1

111

111

4

2

1

1

-I

'1

1

1

1

1t1

2

12

Req'd Order Code

*l

fu.,

lipt'

#:44

i aa

s,,

01 626

01 630/01 628

01 634i01 632

01 083

00928

01 236

00443

00487

01 640

01614

1 239A

00492

00491 /00490

0.1620

01 600

00039

01610

00446

01612

01622

00409

01 602

01 625

0051 2

01624

00099

01 636

00434

01 3s8

01 3s3

00489

00441

01117

0552D

05424

00560

01 544

01011

01017

01 038

01 057

01 055

01 001

0'101 5

01 065

0108'1

01 089

01644

01 118

01 062

01105

1 088A

01 359

01 371

01642

01176

01428

0141s

01 339

01 338

01 031

01049 14G

/"

65

73

3

'I

1

,l

1

2

4

11

12

1

3

4

1

17

18

19

20

21

22

24

26

28

29

30

31

34

JO

37

38

39

40

41

42

43

44

45

4b

48

4S

50

51

53

54

55

56

57

58

59

60

62

64

65

74

Cable clamp acc-2.5 (5/16")

Harness microswitch

Power cord 1.5M + ring

Logo label left

Cord label

Pan. Head screw m4x12

Taptite screw "S" m3.5x6

75

83

84

I

@4s

I

!

564

a

57

l8

t9

50

s"

54

12

Technical Specifications

INPUT VOLTAGE:

TRANSFORMER SPEC.:

MOTOR SPEC.:

CONTROL BOABD SPEC.:

ry'IANSMITTER SPEC.:

OPENER LIFTING CAPACITY:

23OVl 24OV AC 50 Hz

(110V AC 60 Hz or 127V AC 60 Hz available on request)

Single Phase

Current Required

Primary Voltage

Secondary Voltage

Motor Type

Voltage

Torque

Relay Contact Rating

Relay Coil Voltage

Control Board Voltage

Light Globe Voltage

Recerver Specif ication

24VDCl5VDC

24V DC / 15 Watts

Recerver Type

HF Frequency

lntermediate Frequency

Code Storage Capacity

1 Amp

230 I 240V AC

24V AC / 100 VA

Permanent Magnet D.C. Motor

24V DC

135 kg cm at 4 Amps

10Amp/30VDC

24V DC

27.145 MHz

50 mA (approx)

9 Volts

PCM 12 Bit Binary (4096 Code Combinations)

Channel

MECHANICAL

KEY RELEASE

Narrow Band FM

(Superhetrodyne)

27.145 Mhz

455 Khz

60 Different Codes

SECURALIGHT

MONITOR

Carrier Frequency

Current Consumption

Battery Voltage

Coding Format

30 kg

Accessories

TX SERIES HANDHELD

TRANSMITTERS

One,Two & Four Channel

KPX.4/KP.4 WIRELESS

DIGITAL KEYPADS

ELECTRONIC

KEY RELEASE

CRXA.I/2 SERIES

ffi?

AUTOMATIC TECHNOLOGY AUSTRALIA PTY LTD

17-19 Advantage Rd, Highett, Victoria, Australia, 3190.

Ph: (03) 95322788 Fax: (03) 95322799

E*mail: ata @ ata. net.au

Web : http://www. ata. net. au

Table of contents

Other Automatic Technology Australia Garage Door Opener manuals

Automatic Technology Australia

Automatic Technology Australia GDO-5-AS User manual

Automatic Technology Australia

Automatic Technology Australia GDO-4 V4 EasyRoller User manual

Automatic Technology Australia

Automatic Technology Australia GDO-4 V4 EasyRoller User manual

Automatic Technology Australia

Automatic Technology Australia GDO-6 V1 Slim-Drive EasyRoller User manual

Automatic Technology Australia

Automatic Technology Australia Securalift GDO 2v4 Quick start guide

Automatic Technology Australia

Automatic Technology Australia GDO-8 v1 EasyRoller II User manual

Automatic Technology Australia

Automatic Technology Australia ROLL UP GARAGE DOOR OPENER Quick start guide