3. INSTALLATION PREPARATION

3.1. Preliminary inspection

Before the installation of the set it is necessary to:

Check all the elements and materials on the possibility of their application and correspondence

to the current regulations.

Make sure that door construction is suitable for automation. The set cannot be applied in

doors with a wicket or pedestrian zone.

Make sure that door dimensions are in the acceptable limits (see part «Technical characteris-

tics»).

Check that the effort required for the movement of door curtain is less than the maximum

driving force (see part «Technical characteristics»).

Check that the effort required for the movement of door curtain makes a half from the force

exerted rating (see part «Technical characteristics»). The reserve of effort is required because

unfavorable weather conditions (such as wind, snow and others) as well as elements natural

wear can lead to application of increasing effort as a result of increase of friction in the sys-

tem.

Check the balance system of the doors that is they must stay immovable in any position.

Evaluate possible risk (stroke, squeezing, jamming, dragging and other damages). Define the

accessories required for elimination of the risks and observing the safety standards.

Make sure that places of accessories installation (photo cells, control buttons and others) are

protected from strokes and the surfaces are strong enough.

Make sure that there are no lien objects, water or other liquid inside the drive and its other

open parts.

Make sure that the drive and its components are positioned away from the source of heat and

open fire. Violation of this requirement can lead to the product damage, cause its malfunction-

ing, fire and other dangerous situations.

Make sure that there is a possibility of simple and quick manual unblocking.

Make sure that the outlet for plugging of electric drive is grounded.

Make sure that the outlet is installed so that after installation and connection of the drive the

supply cable will not be in the area of doors and other parts movement.

Make sure that the part of electrical network with the drive has a protective device from short

circuit (automatic device or any other similar device). Distance between terminals in the de-

vice should be more than 3mm.

3.2.Tools and materials for installation

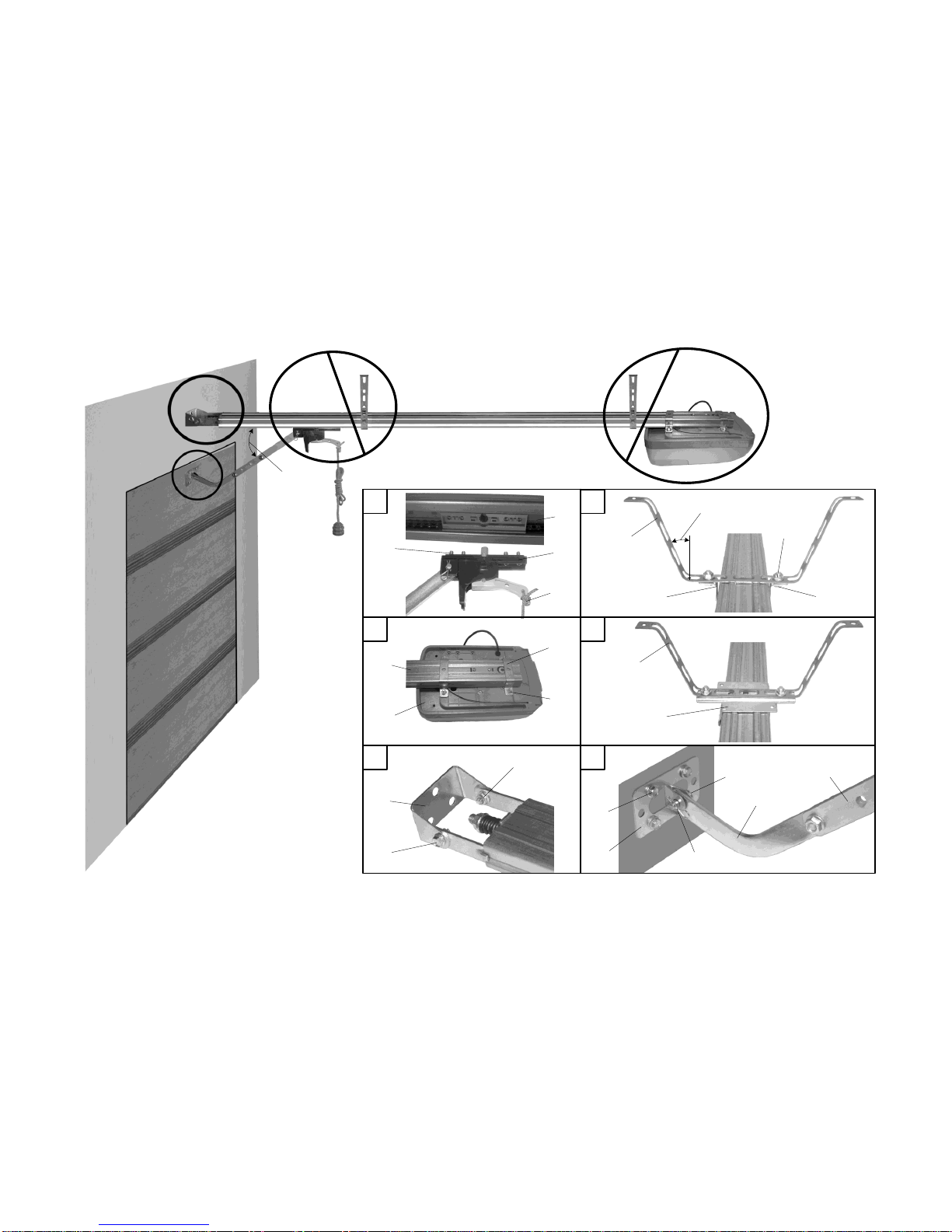

Pic. 1 shows the minimum set of tools and materials required for the product installation.

Pic. 1. Minimum set of tools and materials

While installation of accessories (photo cells, switchers, control buttons, etc.) it is recommended

to use multiconductor cable. Apply the electric cable with parameters (cutting, number of wires,

length, etc.) depending on the connection scheme, product power, insert distance, external con-

ditions according to the current norms. Cables must be in special cable tubes.