AutomationDirect SOLO SLM Series User manual

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

Quick Start Guide

Quick Start Guide

Quick Start Guid

eQuick Start Guide

Quick Start Guid

e

SOLO Modular Temperature Controllers

SLM Series

Specications

Input

Input Sensor Register Value Available Range

0 ~ 50mV linear voltage input 17 0 ~ 50mV

4 ~ 20mA linear current input 16 4 ~ 20mA

0 ~ 20mA linear current input 15 0 ~ 20mA

0 ~ 10V linear voltage input 14 0 ~ 10V

0 ~ 5V linear voltage input 13 0 ~ 5V

Platinum RTD (Pt100) 12 -200 ~ 600°C (-328 ~ 1,112°F)

Platinum RTD (JPt100) 11 -20 ~ 400°C (-4 ~ 752°F)

Thermocouple TXK type 10 -200 ~ 800°C (-328 ~ 1,472°F)

Thermocouple U type 9 -200 ~ 500°C (-328 ~ 932°F)

Thermocouple L type 8 -200 ~ 850°C (-328 ~ 1,562°F)

Thermocouple B type 7 100 ~ 1,800°C (212 ~ 3,272°F)

Thermocouple S type 6 0 ~ 1,700°C (32 ~ 3,092°F)

Thermocouple R type 5 0 ~ 1,700°C (32 ~ 3,092°F)

Thermocouple N type 4 -200 ~ 1,300°C (-328 ~ 2,372°F)

Thermocouple E type 3 0 ~ 600°C (32 ~1,112°F)

Thermocouple T type 2 -200 ~ 400°C (-328 ~ 752°F)

Thermocouple J type 1 -100 ~ 1,200°C (-148 ~ 2,192°F)

Thermocouple K type 0 -200 ~ 1,300°C (-328 ~ 2,372°F)

Note 1: Install the supplied 249 ohm resistor between terminal #1 and #2 for linear current inputs.

Note 2: Default setting: Pt100 input.

The range of linear input and feedback value is adjustable. Range of input feedback: -999 ~ 9,999. Take 0 ~ 20mA input as

example, -999 refers to 0mA input, and 9,999 refers to 20mA input. If we change the range to 0 ~ 2,000, 0 will refer to 0mA

input, and 2,000 will refer to 20mA input. 1 display scale = 0.01mA.

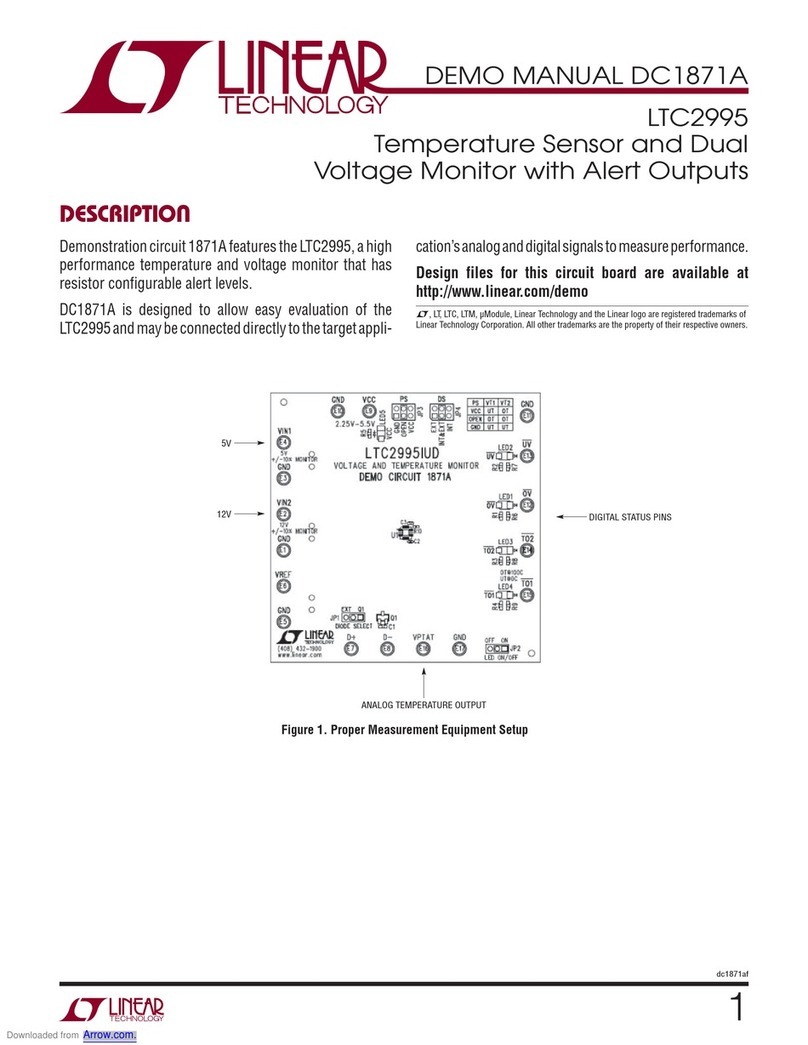

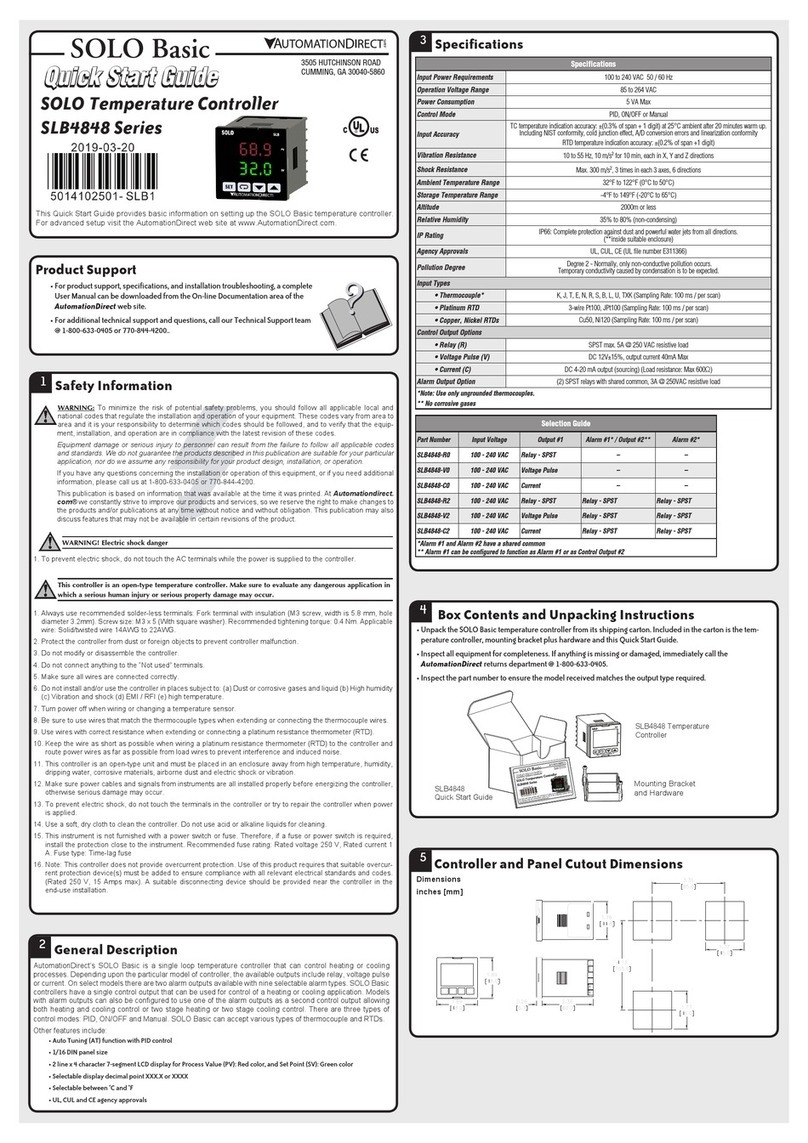

This Quick Start Guide provides basic information on setting up the SOLO SLM temperature

controllers. For advanced setup visit the AutomationDirect web site at www.AutomationDirect.com.

Specifications

Operating Voltage

Range 21.6 to 26.4 VDC

Power Consumption Rated 24 VDC, Max. 24 W combined, 3W + 3W x number of SLM2 controllers (Max. 7)

Input Sensors

Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK

Platinum RTD: Pt100, JPt100

Linear DC input: 0 ~ 5V, 0 ~ 10V, 0 ~ 20mA, 4 ~ 20mA, 0 ~ 50mV

Sampling Rate Analog input: 0.15 sec. Thermocouple or platinum RTD: 0.4 sec.

Control Method PID, ON/OFF, Ramp / Soak control or Manual

Output Types

Relay: SPST, Max. load 250VAC, 3A resistive load

Voltage pulse: 12VDC, Max. output current: 40mA

Current: DC 4 ~ 20mA (Load resistance: < 500Ω)

Analog voltage: 0 ~ 10V (Load resistance: > 1,000Ω)

Output Function Control output, alarm output, retransmit output

Retransmit output is available only when output 1 is linear voltage or current output.

Alarm 12 alarm modes

Communication RS-485 communication, 2,400 bps ~ 38,400 bps

Communication

Protocol Modbus protocol, ASCII/RTU format

Vibration Resistance 10 ~ 55Hz, 10m/s2 for 10mins, each in X, Y and Z direction

Shock Resistance Max. 300m/s2, 3 times in each 3 axes, 6 directions

Ambient Temperature 0 to 50°C (32 to 122°F)

Storage Temperature -20 to +65°C (-4 to 149°F)

Altitude 2,000m or less

Ambient Humidity 35% ~ 85% RH (non-condensing)

Pollution Degree 2

Safety Information

WARNING! ELECTRIC SHOCK DANGER

1. The SLM series is an OPEN-TYPE device and therefore should be installed in an enclosure free of

airborne dust, humidity, and vibration. The enclosure should prevent non-maintenance sta from

operating the device (e.g. key or special tool is required to open the enclosure).

THIS CONTROLLER IS AN OPEN-TYPE TEMPERATURE CONTROLLER. MAKE SURE TO EVALUATE ANY DANGEROUS

APPLICATION IN WHICH A SERIOUS HUMAN INJURY OR SERIOUS PROPERTY DAMAGE MAY OCCUR.

1. Be sure to tighten terminals to the correct torque of 0.19 Nm. Use solid or twisted wire from 14AWG

to 28AWG.

2. Protect the controller from dust or foreign objects to prevent controller malfunction.

3. Do not modify or disassemble the controller.

4. Do not connect anything to the unused terminals.

5. Make sure all wires are connected to the correct polarity of terminals.

6. Do not install and/or use the controller in places subject to: (a) Dust or corrosive gases and liquid (b)

High humidity (c) Vibration and shock (d) EMI / RFI (e) high temperature.

7. Power must be turned o when wiring, installing or uninstalling expansion modules (SLM2), or

changing a sensor.

8. Be sure to use wires that match the thermocouple types when extending or connecting the

thermocouple wires.

9. Use wires with correct resistance when extending or connecting a platinum resistance thermometer

(RTD).

10. Keep the wire as short as possible when wiring a platinum resistance thermometer (RTD) to the

controller and route power wires as far as possible from load wires to prevent interference and

induced noise.

11. This controller is an open-type unit and must be placed in an enclosure away from high temperature,

humidity, dripping water, corrosive materials, airborne dust and electric shock or vibration.

12. Make sure power cables and signals from instruments are all installed properly before energizing the

controller, otherwise serious damage may occur.

13. To prevent electric shock, do not touch the terminals in the controller or try to repair the controller

when power is applied.

14. Use a soft, dry cloth to clean the controller. Do not use acid or alkaline liquids for cleaning.

15. This instrument is not furnished with a power switch or fuse. Therefore, if a fuse or power switch

is required, install the protection close to the instrument.

16. Note: This controller does not provide overcurrent protection. Use of this product requires that

suitable overcurrent protection device(s) must be added to ensure compliance with all relevant

electrical standards and codes. A suitable disconnecting device should be provided near the

controller in the end-use installation.

WARNING: To minimize the risk of potential safety problems, you should follow all applicable local

and national codes that regulate the installation and operation of your equipment. These codes

vary from area to area and it is your responsibility to determine which codes should be followed,

and to verify that the equipment, installation, and operation are in compliance with the latest

revision of these codes.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable

codes and standards. We do not guarantee the products described in this publication are suitable

for your particular application, nor do we assume any responsibility for your product design,

installation, or operation.

If you have any questions concerning the installation or operation of this equipment, or if you

need additional information, please call us at 1-800-633-0405 or 770-844-4200.This publication is

based on information that was available at the time it was printed. At Automationdirect.com® we

constantly strive to improve our products and services, so we reserve the right to make changes

to the products and/or publications at any time without notice and without obligation. This

publication may also discuss features that may not be available in certain revisions of the product.

Product Support

•For product support, specications, and installation troubleshooting, a

complete User Manual can be downloaded from the On-line Documentation

area of the AutomationDirect web site.

•For additional technical support and questions, call our Technical Support

team @ 1-800-633-0405 or 770-844-4200..

AutomationDirect’s SOLO Modular units are a single loop temperature controller that can

control heating or cooling processes. Depending upon the particular model of controller, the

available outputs include relay, voltage pulse, linear voltage, or current. Available with twelve

selectable alarm types. SOLO Modular controllers have two control outputs that can be used

for control of a heating or cooling applications, alarm output, or for retransmitting the process

variable. Using both outputs for control output allows for both heating and cooling control or

two stage heating or two stage cooling control. There are four types of control modes: PID,

ON/OFF, RAMP/SOAK and Manual. SOLO Modular can accept various types of thermocouple

and RTDs as well as 0-10V or 4-20 mA anaolog input signals.

Other features include:

•Auto Tuning (AT) function with PID control

•DIN rail mountable

•LEDs for indication and diagnostics

•Easy conguration using SL-SOFT SOLO conguration software or Modbus

communications

•Selectable between °C and °F

•cULus and CE agency approvals

General Description

SOLO SLM

3

1

2

Alarm Output

Alarm Output

Mode Alarm Type Alarm Output Operation

0No alarm OFF

1

Alarm output will be enabled when the

temperature reaches upper and lower limits.

• Alarm will be enabled when the PV exceeds SV

+ AL-H or falls below SV – AL-L.

ON

OFF

AL-L SV AL-H

2

Alarm output will be enabled when the

temperature reaches the upper limit.

• Alarm will be enabled when the PV exceeds SV

+ AL-H.

ON

OFF

SV AL-H

3

Alarm output will be enabled when the

temperature reaches the lower limit.

• Alarm will be enabled when the PV falls below

SV – AL-L.

ON

OFF

AL-L SV

4• Alarm will be enabled when the PV is between

SV + AL-L and SV – AL-L.

ON

OFF

AL-L SV AL-H

5

Alarm output will be enabled when the

temperature reaches the absolute value of the

upper and lower limits.

• Alarm will be enabled when the PV exceeds

AL-H or falls below AL-L.

ON

OFF

AL-L AL -H

6

Alarm output will be enabled when the

temperature reaches the absolute value of the

upper limit.

• Alarm will be enabled when the PV exceeds

AL-H.

ON

OFF

AL-H

7

Alarm output will be enabled when the

temperature reaches the absolute value of the

lower limit.

• Alarm will be enabled when the PV falls below

AL-L.

ON

OFF

AL-L

8

Standby upper/lower limit alarm

• Alarm will be enabled when the PV reaches SV

and exceeds SV + AL-H or falls below SV –AL-L.

ON

OFF

AL-L AL -H

SV

9

Upper limit standby alarm

• Alarm will be enabled when the PV reaches SV

and exceeds SV + AL-H.

ON

OFF

SV AL-H

10

Lower limit standby alarm

• Alarm will be enabled when the PV reaches SV

and falls below SV – AL-L

ON

OFF

AL-L SV

11

Upper limit hysteresis alarm

• Alarm will be enabled when the PV exceeds SV

+ AL-H and disabled when the PV falls below

SV + AL-L.

ON

OFF

AL-H

AL-L

12

Lower limit hysteresis alarm

• Alarm will be enabled when the PV falls below

SV – AL-H and disabled when the PV exceeds

SV – AL-L.

ON

OFF

AL-H AL-L

Note: AL-H and AL-L include AL1H, AL2H, AL1L and AL2L. When Output 1 is set to Alarm Output, use AL1H (1024H) and AL1L

(1025H). When Output 2 is set to Alarm Output, use AL2H (1026H) and AL2L (1027H).

SLM series oers 12 alarm modes. See the alarm table below for a description of types of alarm.

90.0

3.0

60.03.4

25.2

4.0

3.0

1

2

3

4

5

6

7

8

9

10

3

11

12

13

90.0

3.0

60.03.4

25.2

4.0

3.0

1

2

3

4

5

6

7

8

9

2

10

SLM1

SLM2

[0.99]

[0.16]

[0.12]

[0.12

]

[3.54]

[0.13]

[0.13]

[0.12] [0.12]

[3.54]

[0.16]

[0.99]

[2.36]

[2.36]

5

4

Controller Dimensions

Dimensions

mm [in]

SLM1 SLM2

1RUN/STOP switch Wiring and

Model name

2Wiring and Model

name DIN rail clip

3DIN rail clip I/O terminals

4I/O terminals LED indicators

5LED indicators Mounting hole

6Mounting hole Specication

label

7Specication label Extension port

8Extension port Extension clip

9Extension clip DIN rail

10 DIN rail Extension port

11

RS-485

communication

port

N/A

12 Extension clip N/A

13 DC power input N/A

LED Display

1. When power is normal, POWER LED will be on.

2. After SLM is switched on, all LEDs will be on. The communication protocol will be displayed for one

second. See table below for LED values.

3. RUN LED is on when the controller is active.

4. ERROR LED is on when errors occur in input, memory or communication.

5. When an output is active, its corresponding output LED will be on.

6. AT LED ashes when PID parameters are being auto-tuned.

7. RX LED ashes when SLM receives communication signals. TX LED ashes when SLM sends out

communication signals. Communication protocol displayed on the LEDs after the power to the SLM

is switched on:

WARNING! ELECTRIC SHOCK DANGER

To prevent electric shock, do not connect AC

power to your device until all input and output

connections are completed.

Terminal Identication

7

For 4-20 mA sensor input

install supplied 249Ω resistor.

Install jumper when using

2-wire RTD

0 - 10 VDC 4 - 20 mA

2-wire RTD

Thermocouple (Tc) 3-wire RTD

Vinin

Input and Outputs (SLM1 & SLM2 Front Terminals)

Power Input (SLM1 Bottom Terminals)

RS-485 (SLM1 Bottom Terminals)

Sensor Input

1

2

3

4

5

6

7

8

9

+

+

-

-

DC 21.6 to 26.4

24V

0V

Tc

OUT2

OUT1

+

+

+

+

-

-

-

-

+

+

+

+

-

-

-

-

1

2

1

2

1

2

3

1

2

1

2

3

Box Contents and Unpacking Instructions

•Unpack the SOLO SLM temperature controller from its shipping carton. Included in the carton is

the temperature controller, a 249 ohm resistor, and this Quick Start Guide.

•Inspect all equipment for completeness. If anything is missing or damaged, immediately call the

AutomationDirect returns department @ 1-800-633-0405.

•• Inspect the part number to ensure the model received matches the output type required.

SLM Temperature

Controller

SLM

Quick Start

Guide

249 ohm

resistor

6

5

48

LED Baud Rate

2400 4800 9600 19,200 38,400

AT Off Off Off Off On

TX Off Off On On Off

RX Off On Off On Off

LED Parity

01 Off Off On

02 Off On Off

LED Modbus Format

Err Off On

LED Stop Bits

RUN Off On

RS-485 Communication

9

Address Setting Parameter R/W Description

1000H Present temperature

value (PV) R

Unit: 0.1 degree. Analog input: 1EU.

The read values below indicate the occurrence of

errors: 8002H: Temperature not acquired yet

8003H: Temperature sensor not connected

8004H: Incorrect sensor type

8006H: Unable to acquire temperature, ADC

input error

8007H: Unable to read/write the memory

1001H 0 Set point (SV) R/W Unit: 0.1 degree. Analog input: 1EU.

1002H 6,000 Upper-limit of temperature

range R/W The content shall not be bigger than the range.

Unit: 0.1°

1003H -200 Lower-limit of temperature

range R/W The content shall not be smaller than the range.

Unit: 0.1°

1004H 12 Input type R/W See the table in “Input” section.

1005H 0 Control method R/W 0: PID, 1: ON/OFF, 2: Manual, 3: RAMP/SOAK

1006H 0Control selection of

Output 1 R/W 0: Heating, 1: Cooling, 2: Alarm, 3: Retransmit

output

1007H 4 Control cycle of Output 1 R/W 0 ~ 99, 0: 0.5sec

1008H 4 Control cycle of Output 2 R/W 0 ~ 99, 0: 0.5sec (Invalid when the 2 outputs are

the same control.)

1009H 476 Proportional band value R/W 1 ~ 9,999, Unit: 0.1°. Analog input: 1EU

100AH 260 Integral Time R/W 0 ~ 9,999

100BH 41 Derivative Time R/W 0 ~ 9,999

100CH 0 Integral Offset R/W 0 ~ 1,000, Unit: 0.1%

100DH 0 PD Control Offset R/W

Offset compensation value for proportional control

(when I=0)

0 ~ 1,000, Unit: 0.1%

100EH 100 Proportion Band Coefcient R/W COEF setting when in dual control output

1 ~ 9,999, Unit: 0.01

100FH 0 Dead Band R/W Dead band setting when in dual control output

-999 ~ 9,999, Unit: 0.1° or 1EU

1010H 0 Hysteresis of Output 1 R/W 0 ~ 9,999, Unit: 0.1° or 1EU

1011H 0 Hysteresis of Output 2 R/W 0 ~ 9,999, Unit: 0.1° or 1EU

1012H 0 Output 1 Level R/W

Read/write output percentage of Output 1

Unit: 0.1%. “Write” is only applicable in manual

mode.

1013H 0 Output 2 Level R/W

Read/write output percentage of Output 2

Unit: 0.1%. “Write” is only applicable in manual

mode.

1014H 0Upper-limit regulation for

analog linear output R/W 1 scale = 2.8μA = 1.3mV

1015H 0Lower-limit regulation for

analog linear output R/W 1 scale = 2.8μA = 1.3mV

1016H 0 PV Offset R/W Temperature offset regulation value

-999 ~ +999, Unit: 0.1° or 1EU

1019H 10 Temperature Filter Range R/W Range of temperature lter: 1~100, unit: 0.1°C

101AH 8 Temperature Filter Factor R/W Setting range: 0~50

1020H 0 Alarm 1 R/W 0 = Alarm 1 is disabled.

1- 18 = Alarm type number

1021H 0 Alarm 2 R/W 0 = Alarm 2 is disabled.

1- 18 = Alarm type number

1023H 0Control selection of

Output 2 R/W 0: Heating, 1: Cooling, 2: Alarm

1024H 40 Alarm 1 High Limit R/W See “Alarm Output” section.

1025H 40 Alarm 1 low Limit R/W See “Alarm Output” section.

1026H 40 Alarm 2 High Limit R/W See “Alarm Output” section.

1027H 40 Alarm 2 Low Limit R/W See “Alarm Output” section.

102AH Read/write status R

Bit 0 = Not Used

Bit 1 = ALM2

Bit 2 = °C

Bit 3 = °F

Bit 4 = ALM1

Bit 5 = OUT2

Bit 6 = OUT1

Bit 7 = AT

102CH 0Positive/negative retransmit

output R/W 0: positive, 1: negative

102EH LED Status R

Bit 0 = RUN

Bit 1 = ERR

Bit 2 = O2

Bit 3 = O1

Bit 4 = RX

Bit 5 = TX

Bit 6 = AT

Bit 7 = Not Used

102FH Firmware version R V1.00 is indicated as 0x100

1030H 0Starting Ramp / Soak

Pattern R/W 0 ~ 7

1032H Current Step Time

Remaining in Seconds R 0 ~ 54000

1033H Current Step Time

Remaining in Minutes R 0 ~ 900

1034H Current Step Number R 0 ~ 7

Address Setting Parameter R/W Description

1035H Current Pattern Number R 0 ~ 7

1036H Ramp Set Point R Unit is 0.1 (°C or °F)

1037H 1,000 Upper limit of retransmit

output R/W 0 ~ 100% upper limit of analog output, Unit: 0.1%

1038H 0Lower limit of retransmit

output R/W 0 ~ 100% lower limit of analog output, Unit: 0.1%

1040H~

1047H 7 Last Step Number R/W 0 ~ 7 = The last step number of the pattern

1050H~

1057H 0 Additional Cycles R/W 0 ~ 199

1060H~

1067H 0 Next Pattern Number R/W 0 ~ 7 = Next pattern number

8 = There is no next pattern

1068H 1 Run/Stop setting R/W 0: Stop, 1: Run, 2: Program end, 3: Program hold

1069H

(Duplicate

Address)

0 Control selection of Output 1 R/W 0: Heating, 1: Cooling, 2: Alarm, 3: Retransmit

output

106AH

(Duplicate

Address)

0 Control selection of Output 2 R/W 0: Heating, 1: Cooling, 2: Alarm

1071H 1Network Address R/W 1 ~ 247

1072H 0 Modbus Protocol R/W 1: RTU, 0: ASCII

1073H 2 Baud Rate R/W 0 ~ 4: 2,400 ~ 38,400

1074H 1 Bit Length R/W 0: 8 bits, 1: 7 bits

1075H 1 Parity R/W 0: None, 1: Even, 2: Odd

1076H 1 Stop Bit R/W 0: 2 stop bits, 1: 1 stop bit

2000H~

203FH 0 Ramp / Soak SV R/W -999 ~ 9999

2080H~

20BFH 0 Ramp / Soak Time R/W 0 ~ 1500 (15 hours 0 minutes)

1. Supports transmission speed: 2,400, 4,800, 9,600, 19,200, 38,400 bps;

2. Communication protocol: Modbus ASCII/RTU;

3. Function code: 03H (read Max. 8 words in register), 06H (write 1 word into register), 01H

(read Max. 16 bits of data), 05H (write 1 bit into register).

0811H Temperature unit display 0:°F, 1: °C (Default)

0813H Read/write auto-tuning status 0: End (Default), 1: Start

0814H Run/Stop setting 0: Stop, 1: Run (Default)

0815H Program hold ag 1: Program hold

0816H Program stop ag 1: Program stop

Mounting Instructions

How to connect a maximum of 8 controllers (Using a SLM1 with up to 7 SLM2 units) by using DIN rail.

rail

SLM units

10

Copyright 2023, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Notes

Other AutomationDirect Temperature Controllers manuals

AutomationDirect

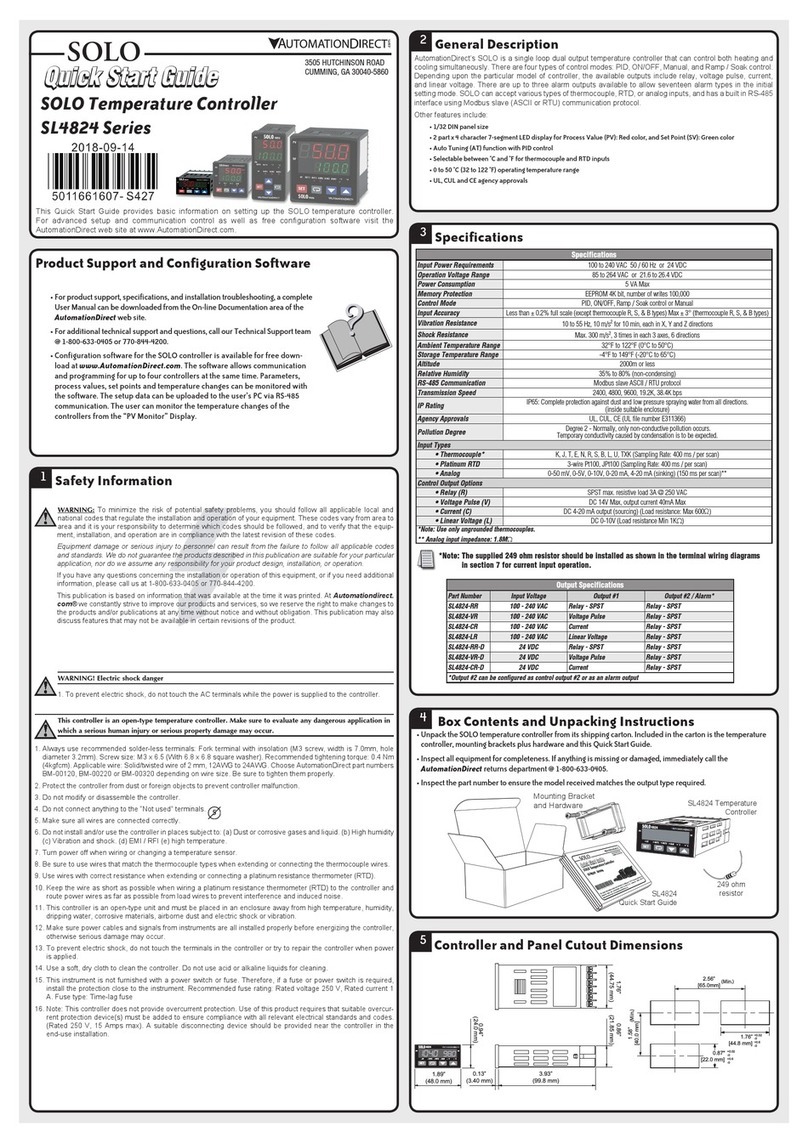

AutomationDirect SOLO SL4824 Series User manual

AutomationDirect

AutomationDirect SOLO User manual

AutomationDirect

AutomationDirect SL4848-RR User manual

AutomationDirect

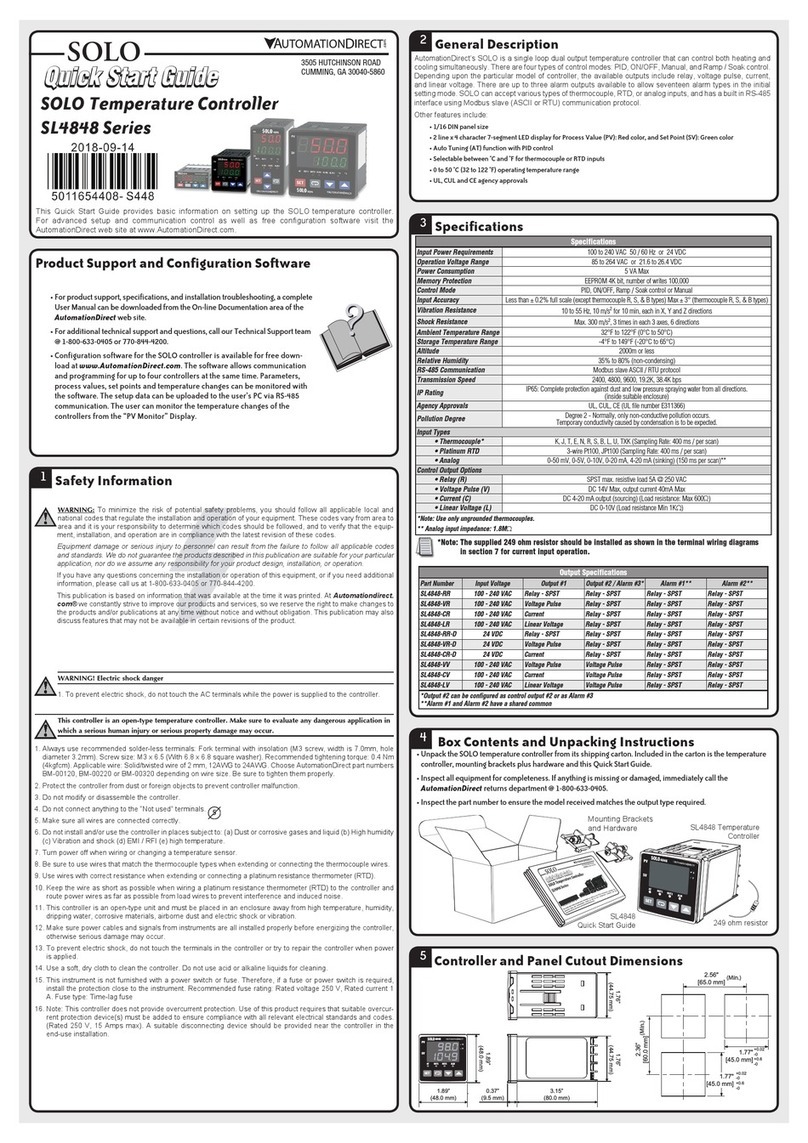

AutomationDirect SOLO SL4848 Series User manual

AutomationDirect

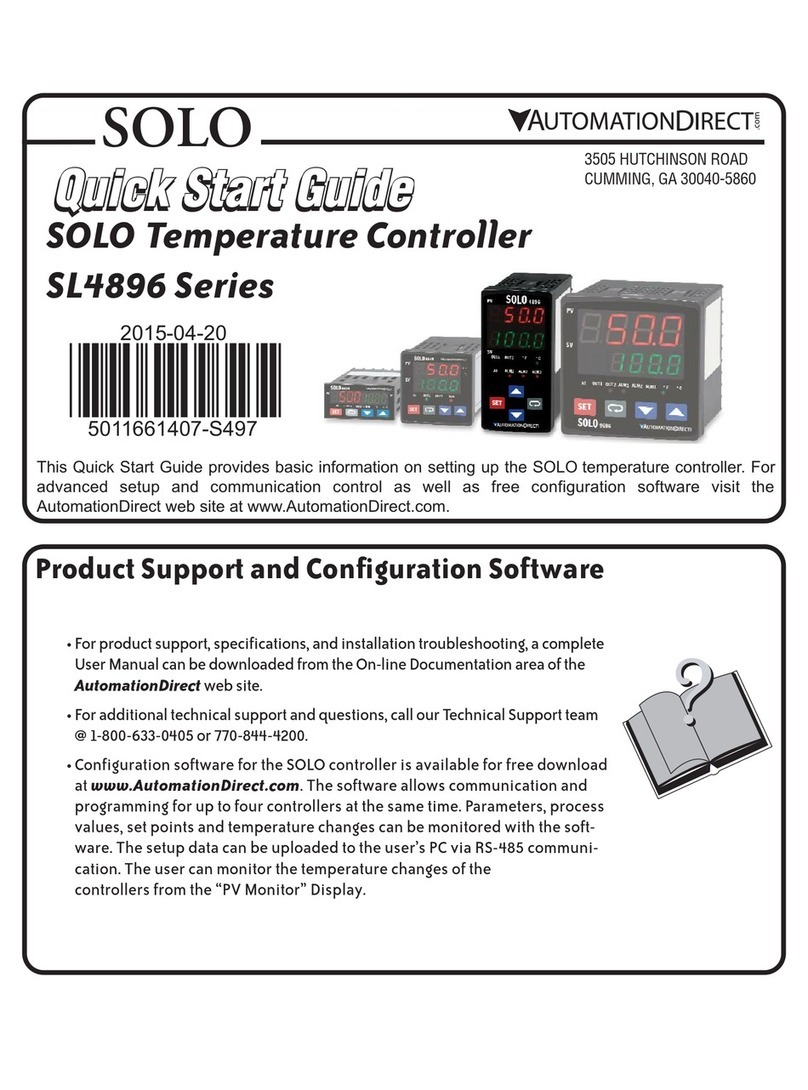

AutomationDirect SOLO SL4896 Series User manual

AutomationDirect

AutomationDirect SOLO Basic SLB4848 Series User manual

Popular Temperature Controllers manuals by other brands

Aqua Medic

Aqua Medic T 2001 CC Operation manual

Multi Channel Systems

Multi Channel Systems TC01 user manual

Aqua Medic

Aqua Medic T controller twin Operation manual

Lake Shore

Lake Shore DT-470-CU-HT installation instructions

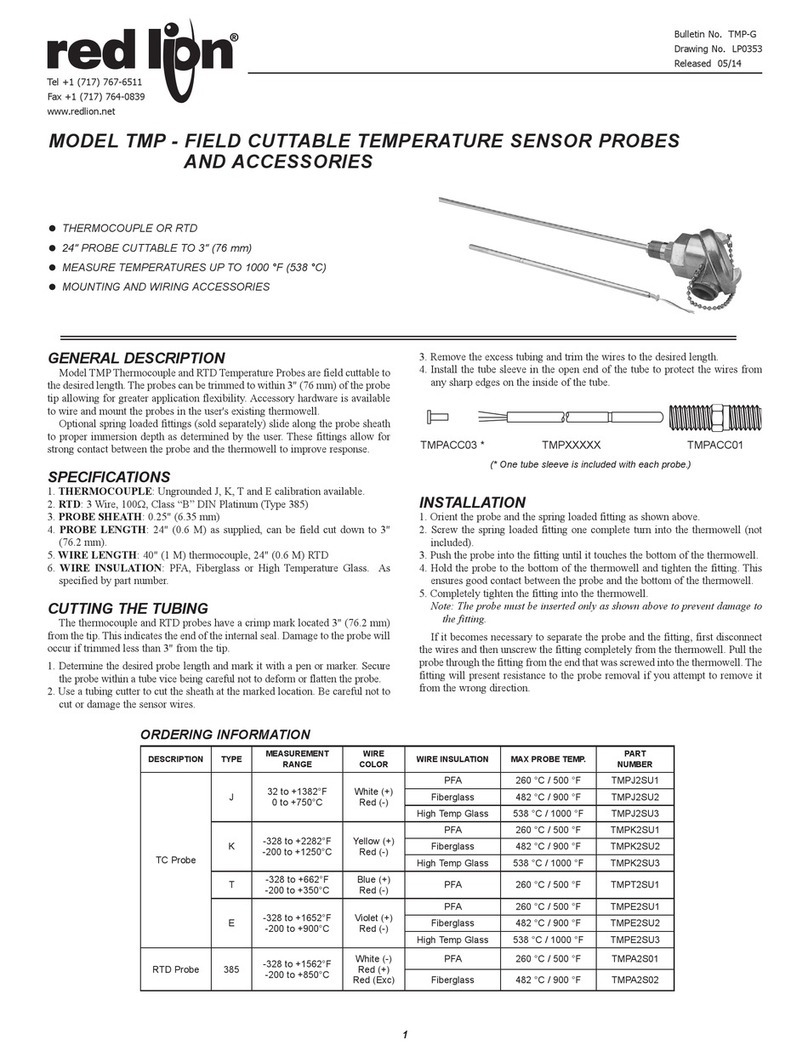

red lion

red lion TMPJ2SU1 product manual

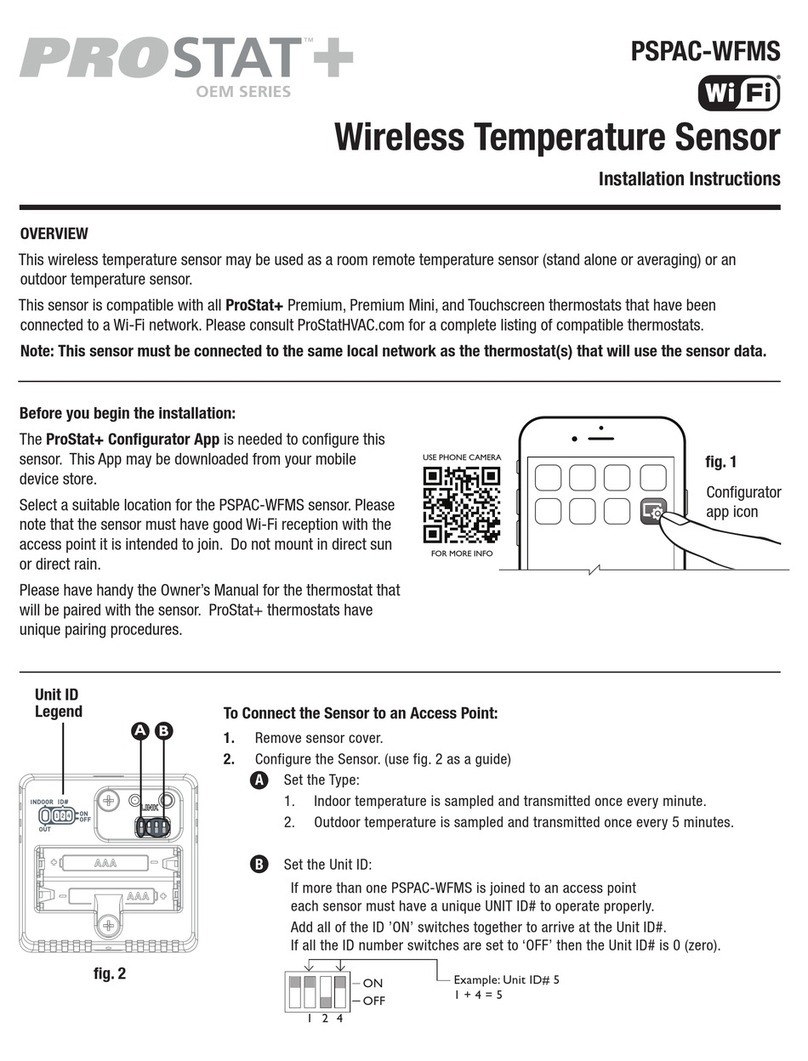

Prostat

Prostat PSPAC-WFMS installation instructions