1

MODEL TMP - FIELD CUTTABLE TEMPERATURE SENSOR PROBES

AND ACCESSORIES

Bulletin No. TMP-G

Drawing No. LP0353

Released 05/14

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

www.redlion.net

THERMOCOUPLE OR RTD

24" PROBE CUTTABLE TO 3" (76 mm)

MEASURE TEMPERATURES UP TO 1000 °F (538 °C)

MOUNTING AND WIRING ACCESSORIES

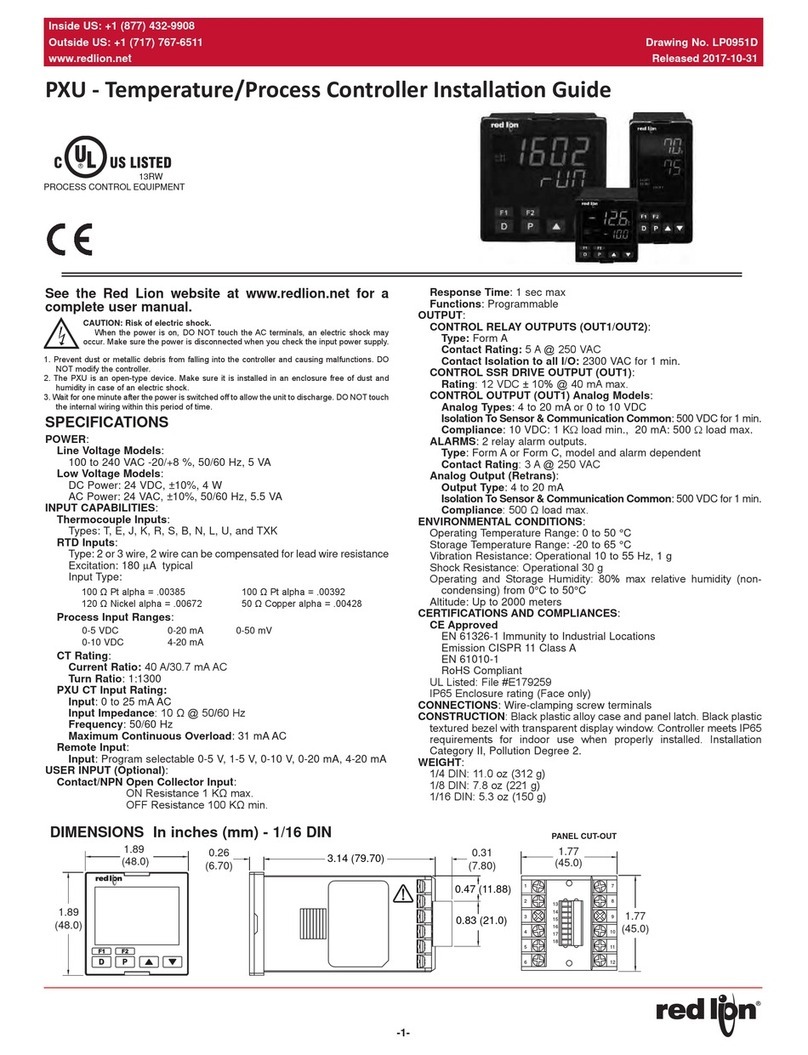

GENERAL DESCRIPTION

Model TMP Thermocouple and RTD Temperature Probes are field cuttable to

the desired length. The probes can be trimmed to within 3" (76 mm) of the probe

tip allowing for greater application flexibility. Accessory hardware is available

to wire and mount the probes in the user's existing thermowell.

Optional spring loaded fittings (sold separately) slide along the probe sheath

to proper immersion depth as determined by the user. These fittings allow for

strong contact between the probe and the thermowell to improve response.

SPECIFICATIONS

1. THERMOCOUPLE: Ungrounded J, K, T and E calibration available.

2. RTD: 3 Wire, 100Ω, Class “B” DIN Platinum (Type 385)

3. PROBE SHEATH: 0.25" (6.35 mm)

4. PROBE LENGTH: 24" (0.6 M) as supplied, can be field cut down to 3"

(76.2 mm).

5. WIRE LENGTH: 40" (1 M) thermocouple, 24" (0.6 M) RTD

6. WIRE INSULATION: PFA, Fiberglass or High Temperature Glass. As

specified by part number.

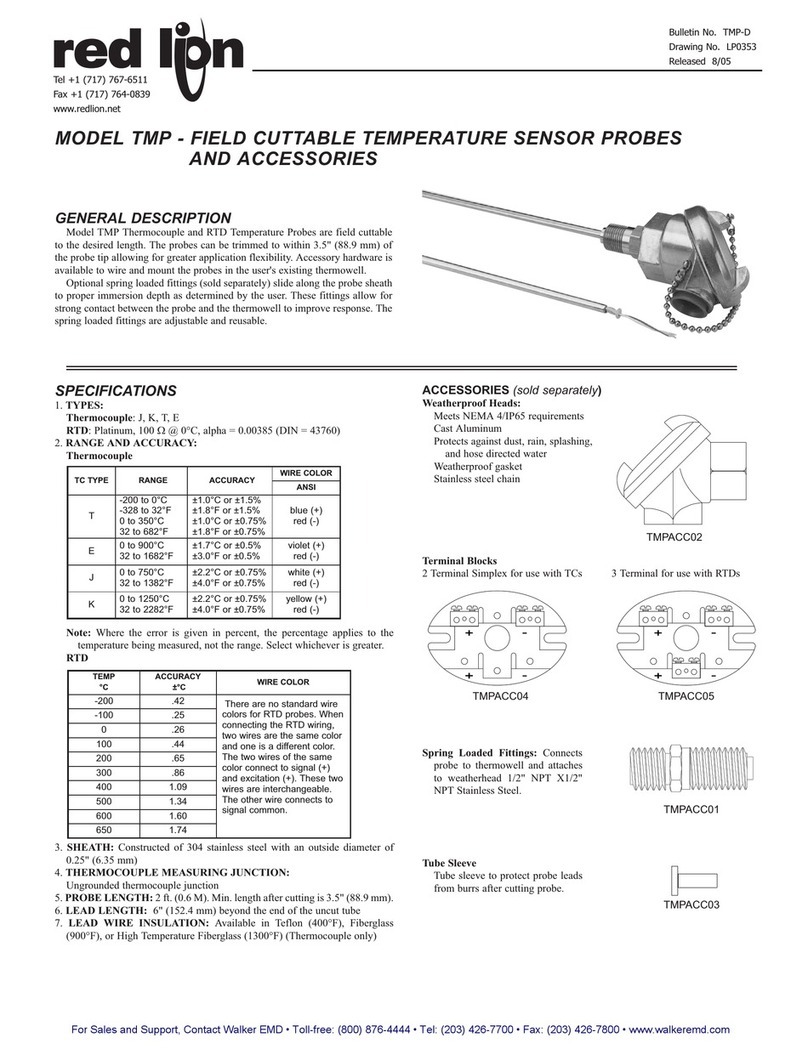

CUTTING THE TUBING

The thermocouple and RTD probes have a crimp mark located 3" (76.2 mm)

from the tip. This indicates the end of the internal seal. Damage to the probe will

occur if trimmed less than 3" from the tip.

1. Determine the desired probe length and mark it with a pen or marker. Secure

the probe within a tube vice being careful not to deform or flatten the probe.

2. Use a tubing cutter to cut the sheath at the marked location. Be careful not to

cut or damage the sensor wires.

3. Remove the excess tubing and trim the wires to the desired length.

4. Install the tube sleeve in the open end of the tube to protect the wires from

any sharp edges on the inside of the tube.

INSTALLATION

1. Orient the probe and the spring loaded fitting as shown above.

2. Screw the spring loaded fitting one complete turn into the thermowell (not

included).

3. Push the probe into the fitting until it touches the bottom of the thermowell.

4. Hold the probe to the bottom of the thermowell and tighten the fitting. This

ensures good contact between the probe and the bottom of the thermowell.

5. Completely tighten the fitting into the thermowell.

Note: The probe must be inserted only as shown above to prevent damage to

the fitting.

If it becomes necessary to separate the probe and the fitting, first disconnect

the wires and then unscrew the fitting completely from the thermowell. Pull the

probe through the fitting from the end that was screwed into the thermowell. The

fitting will present resistance to the probe removal if you attempt to remove it

from the wrong direction.

TMPACC03 * TMPXXXXX TMPACC01

(* One tube sleeve is included with each probe.)

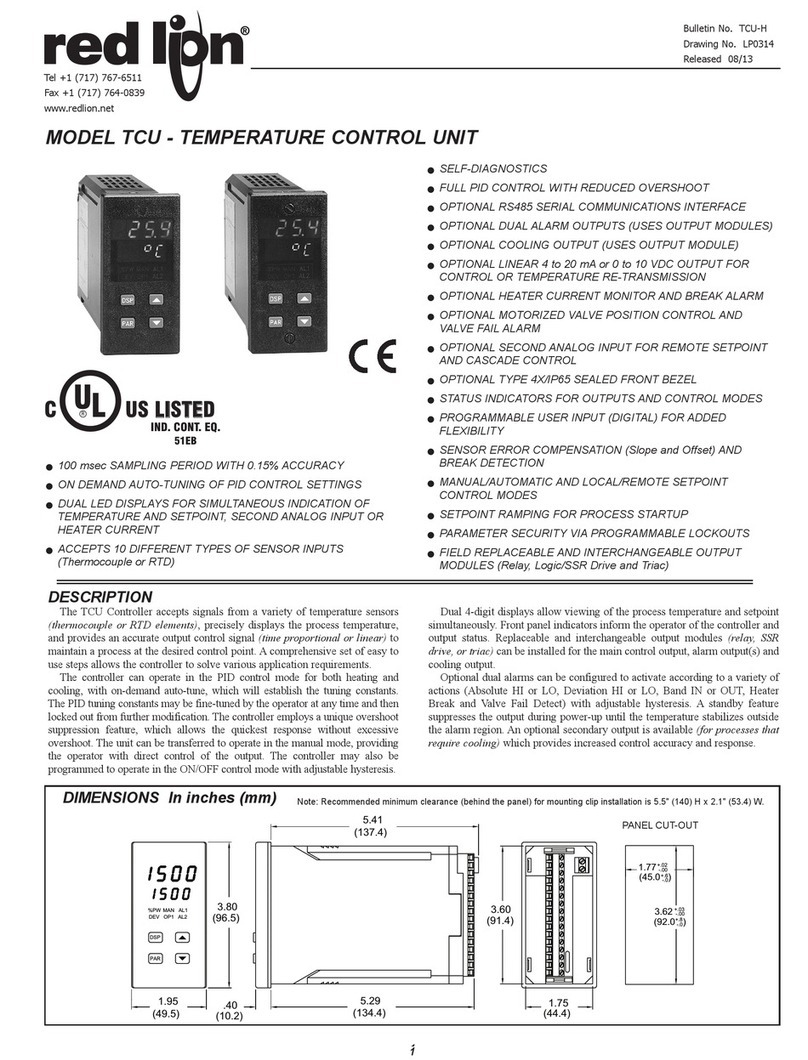

ORDERING INFORMATION

DESCRIPTION TYPE MEASUREMENT

RANGE

WIRE

COLOR WIRE INSULATION MAX PROBE TEMP. PART

NUMBER

TC Probe

J32 to +1382°F

0 to +750°C

White (+)

Red (-)

PFA 260 °C / 500 °F TMPJ2SU1

Fiberglass 482 °C / 900 °F TMPJ2SU2

High Temp Glass 538 °C / 1000 °F TMPJ2SU3

K-328 to +2282°F

-200 to +1250°C

Yellow (+)

Red (-)

PFA 260 °C / 500 °F TMPK2SU1

Fiberglass 482 °C / 900 °F TMPK2SU2

High Temp Glass 538 °C / 1000 °F TMPK2SU3

T-328 to +662°F

-200 to +350°C

Blue (+)

Red (-) PFA 260 °C / 500 °F TMPT2SU1

E-328 to +1652°F

-200 to +900°C

Violet (+)

Red (-)

PFA 260 °C / 500 °F TMPE2SU1

Fiberglass 482 °C / 900 °F TMPE2SU2

High Temp Glass 538 °C / 1000 °F TMPE2SU3

RTD Probe 385 -328 to +1562°F

-200 to +850°C

White (-)

Red (+)

Red (Exc)

PFA 260 °C / 500 °F TMPA2S01

Fiberglass 482 °C / 900 °F TMPA2S02