Autopilot Kanardia User manual

Autopilot — Installation Manual

Kanardia d.o.o.

November 2020

Revision 2.1

Autopilot Installation Manual

Contact Information

Publisher and producer:

Kanardia d.o.o.

Lopata 24a

SI-3000

Slovenia

Tel: +386 40 190 951

Email: info@kanardia.eu

A lot of useful and recent information can be also found on the Internet. See

http://www.kanardia.eu for more details.

Copyright

This document is published under the Creative Commons, Attribution-Share-

Alike 3.0 Unported licence. Full license is available on http://creativecommons.

org/licenses/by-sa/3.0/legalcode web page and a bit more human read-

able summary is given on

http://creativecommons.org/licenses/by-sa/3.0/. In short, the license

gives you right to copy, reproduce and modify this document if:

you cite Kanardia d.o.o. as the author of the original work,

you distribute the resulting work only under the same or similar license

to this one.

Credits

This document was written using TeX Live (L

A

T

E

X) based document creation

system using Kile running on Linux operating system. Most of the figures were

drawn using Open Office Draw, Inkscape and QCad applications. Photos and

scanned material was processed using Gimp. All document sources are freely

available on request under the licence mentioned above and can be obtained

by email. Please send requests to info@kanardia.eu.

Revision History

The following table shows the revision history of this document.

3

©

Kanardia 2016-2020

Autopilot Installation Manual

Revision Date Description

1.0 Aug 2015 Initial release.

1.1 Maj 2016 Tuning notes were added.

1.2 Jul 2016 Tuning table expanded.

2.0 Feb 2020 Complete Manual rework.

2.1 Nov 2020 Updated for changes in software version 3.8,

Amigo and Nesis/Aetos windows.

4

©

Kanardia 2016-2020

Autopilot Installation Manual CONTENTS

Contents

1 Introduction 8

1.1 Designations ............................ 8

1.2 IntendedUse ............................ 8

1.3 Operation Limitations . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Minimal Configuration . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 Nesis/Aetos Based Minimal System . . . . . . . . . . . 10

1.4.2 Horis/Emsis Based Minimal System . . . . . . . . . . . 10

1.5 Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . 11

2 Mechanical Installation 11

2.1 ServoMotor............................. 12

2.2 ServoArm.............................. 13

2.3 ServoArmLimiter......................... 13

2.4 Servo Arm Safety Pin . . . . . . . . . . . . . . . . . . . . . . . 14

3 Electrical Installation 14

3.1 ElectricalPower .......................... 14

3.2 CANBus .............................. 15

3.3 External Push Button . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 Autopilot Quick Disconnect . . . . . . . . . . . . . . . . 16

3.3.2 Autopilot Level . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 JoyuCommandStick........................ 16

4 Configuration 16

4.1 Overview .............................. 17

4.2 AutopilotSettings ......................... 17

4.2.1 Servo Configuration . . . . . . . . . . . . . . . . . . . . 18

4.2.2 GroundTest ........................ 20

4.2.3 Operation Limits . . . . . . . . . . . . . . . . . . . . . . 21

4.2.4 Controller Parameters . . . . . . . . . . . . . . . . . . . 23

4.2.5 Tuning............................ 24

5

©

Kanardia 2016-2020

Autopilot Installation Manual CONTENTS

5 Tuning 26

5.1 Controller.............................. 26

5.1.1 PIDcontroller ....................... 26

5.2 Step Change and Response . . . . . . . . . . . . . . . . . . . . 27

5.3 CascadeController......................... 28

5.4 Controller Problems . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4.1 Backlash........................... 29

5.4.2 Slip ............................. 29

5.5 TuningProcedure.......................... 29

5.5.1 On-Ground ......................... 29

5.5.2 In-Flight........................... 30

5.6 TuningRules ............................ 30

6 In-Flight Tuning 31

6.1 Elevator............................... 31

6.1.1 Pitchtuning ........................ 32

6.1.2 Vertical speed tune . . . . . . . . . . . . . . . . . . . . . 36

6.2 Ailerontune............................. 39

6.2.1 Rolltune .......................... 39

6.2.2 Headingtune ........................ 40

6.3 Finetuning ............................. 41

6.3.1 Roll feed forward . . . . . . . . . . . . . . . . . . . . . . 41

6.3.2 Motorpower ........................ 42

7 Quick Configuration 42

7.1 ConfigureServos .......................... 43

7.2 DirectionTest............................ 43

7.3 OperatingLimits.......................... 43

7.4 Tuning................................ 44

8 Safety Measures 44

8.1 Automatic Disable . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2 ManualDisable........................... 45

8.3 Electrical Disable . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.4 Mechanical Disable . . . . . . . . . . . . . . . . . . . . . . . . . 46

6

©

Kanardia 2016-2020

Autopilot Installation Manual CONTENTS

A Autopilot Installation And Tuning Form 47

B Parameters For Known Airplanes 48

B.1 EkolotTopaz ............................ 48

B.2 PipistrelSinus ........................... 48

B.3 Aeropilot Legend 540 . . . . . . . . . . . . . . . . . . . . . . . . 49

B.4 Evector Eurostar EV97 . . . . . . . . . . . . . . . . . . . . . . 49

B.5 Aerospool Dynamic WT9 . . . . . . . . . . . . . . . . . . . . . 50

B.6 RokoAviation ........................... 50

B.7 Aeroprakt.............................. 51

B.8 DirectFly.............................. 51

B.9 ComcoIkarus............................ 52

7

©

Kanardia 2016-2020

Autopilot Installation Manual 1. Introduction

1 Introduction

First of all, we would like to thank you for purchasing our product.

This chapter describes the basic principle on which autopilot operates. After

reading it, you will be familiar with basic knowledge you will need to properly

install and tune the autopilot.

CAUTION: The autopilot is not TSO approved as a flight instrument.

1.1 Designations

A few icons appear on the side of the manual, which have special meanings:

This icon denotes information that needs to be taken with special

attention.

This icon denotes background information about the subject.

This icon denotes a tip.

In the text, Shall & Should appear frequently.

Shall . . . the use of this term indicates a requirement!

Should . . . the use of this term indicates a characteristics that is not required,

but it is highly recommended.

1.2 Intended Use

The autopilot is designed to help a pilot in stable, controllable flight conditions

during cruising. If such conditions are met, the autopilot can be engaged to

take some relief from the pilot, who can perhaps focus a bit more on ATC

communication or to do some navigation task. Nevertheless, it is still pilot’s

responsibility to monitor the autopilot and airplane behavior all the time.

8

©

Kanardia 2016-2020

Autopilot Installation Manual 1.3 Operation Limitations

1.3 Operation Limitations

Always respect the following limitations.

The autopilot shall be only used in VFR (Visual Flying Rules) condi-

tions.

Information from the Aircraft Operating Handbook always supersedes

information given in this manual.

The autopilot is designed to be used only in cruising conditions. It will

not work at low and high speeds. It can’t fly approaches and departures

and it can’t do takeoffs and landings.

The autopilot shall not be used in turbulence.

Do not use the autopilot with flaps extended.

In any case of abnormal activity, the autopilot must be deactivated and

the pilot must take over the commands immediately. Never wait for

autopilot to deactivate itself automatically.

Autopilot does not use any information from Magu (magnetic compass).

1.4 Minimal Configuration

Most modern light airplanes can be controlled during a stable flight by con-

trolling elevator and aileron only. An autopilot function can be achieved using

the following minimum configuration:

Two servo motors that are mechanically connected with the airplane

command system. One motor controls elevator and the other controls

aileron.

An AD-AHRS-GPS device which consists of many sensors and provides

crucial information required by the autopilot system (airspeed, rate of

climb, pitch, roll, position, direction, altitude, etc.) Such device is inside

one of our PDF instruments, for example, Nesis PFD, Aetos PFD, Horis

PFD or Emsis PFD.

A display unit takes pilot inputs like required altitude and direction. It

is also used to enter configuration parameters required to properly setup

the autopilot system.

9

©

Kanardia 2016-2020

Autopilot Installation Manual 1.4 Minimal Configuration

A servo motor controller. It monitors the pilot instructions and informa-

tion obtained from the sensors and controls the servo motor accordingly.

A communication system that connects all devices and allow information

exchange in real time.

In Kanardia autopilot case, there are two different solutions for an autopilot

minimal system.

1.4.1 Nesis/Aetos Based Minimal System

When Nesis or Aetos is used as a base, the following minimal equipment is

required for a fully functional autopilot:

Two SERU servo motors. SERU consists of a servo motor and an in-

tegrated controlling unit, which serves as a motor driver. One SERU

controls elevator and the other controls aileron.

Nesis III (or Aetos) PFD. The display has integrated AD-AHRS-GPS

device, which provides all sensor data. The display has several buttons

and a knob that allow pilot control over the system. In addition, touch

screen can be also used on Nesis III.

Simple RJ45 cables (a.k.a. Ethernet cables) are needed to connect them

together. The devices are communicating using the CAN bus system,

which is integral part of almost all Kanardia devices.

In this combination Amigo is optional, but recomended nevertheless.

1.4.2 Horis/Emsis Based Minimal System

When Horis or Emsis is used as a base, the following minimal equipment is

required for a functional autopilot:

Two SERU servo motors. SERU consists of a servo motor and an in-

tegrated controlling unit, which serves as a motor driver. One SERU

controls elevator and the other controls aileron.

Horis 80/57 (or Emsis 80/3.5“) PFD unit with integrated AD-AHRS-

GPS device, which provides all sensor data.

Amigo display, which acts as a command panel for the autopilot.

10

©

Kanardia 2016-2020

Autopilot Installation Manual 1.5 Principle of Operation

Simple RJ45 cables (a.k.a. Ethernet cables) are needed to connect them

together. The devices are communicating using the CAN bus system,

which is integral part of almost all Kanardia devices.

In this combination, Amigo is essential.

1.5 Principle of Operation

When autopilot is active, pilot selects requested altitude, direction and rate of

climb or descend. AD-AHRS-GPS device provides current values for almost

all flight parameters. Controller units compare the requested values with

actual values and give appropriate commands to the servo motors. The PID

controller principle is used together with the cascade control system.

The autopilot drives two separate controls: aileron and elevator. In general

these two controls are independent, though minor dependency may exists.

Each control has two control loops1. Elevator control has pitch loop and

vertical speed loop. The two loops are regulated by cascade. This means that

requested altitude sets wanted vertical speed and the vertical speed loop sets

wanted pitch. The pitch loop then controls the elevator by minimizing the

difference between requested and actual pitch. Aileron works in a similar way.

Requested direction sets the required roll angle and the roll loop controls the

aileron trying to minimize the difference between requested and actual roll

angle.

This means that autopilot has four loops: pitch and vertical speed loops are

used for elevator, while heading and roll loops are used for aileron. All these

loops must be properly tuned to achieve requested autopilot operation. Var-

ious experimental values in the form of tuning parameters are provided at

the end of the document. These values represent good starting point for first

autopilot tests.

2 Mechanical Installation

This section provides information about the installation of autopilot servo mo-

tors (the SERU device) into an airplane. It contains important rules which

1The control loop is basic term from control theory. In simple terms – the control

loop tries to move the actuator in such a way that difference between WANTED and

ACTUAL value becomes minimal.

11

©

Kanardia 2016-2020

Autopilot Installation Manual 2.1 Servo Motor

must be obeyed to have a working and safe autopilot system. The installa-

tion information in this section is extremely important and must be clearly

understood by the installer.

Improper servo installation or failure to observe and diagnose installation

problems prior to flight can result in extremely serious consequences, including

loss of ability to control the aircraft. If there are any questions on the part

of the installer it is mandatory to resolve these questions prior to flight of the

aircraft.

CAUTION: Improper installation could result in lost aircraft controls,

injury or death!

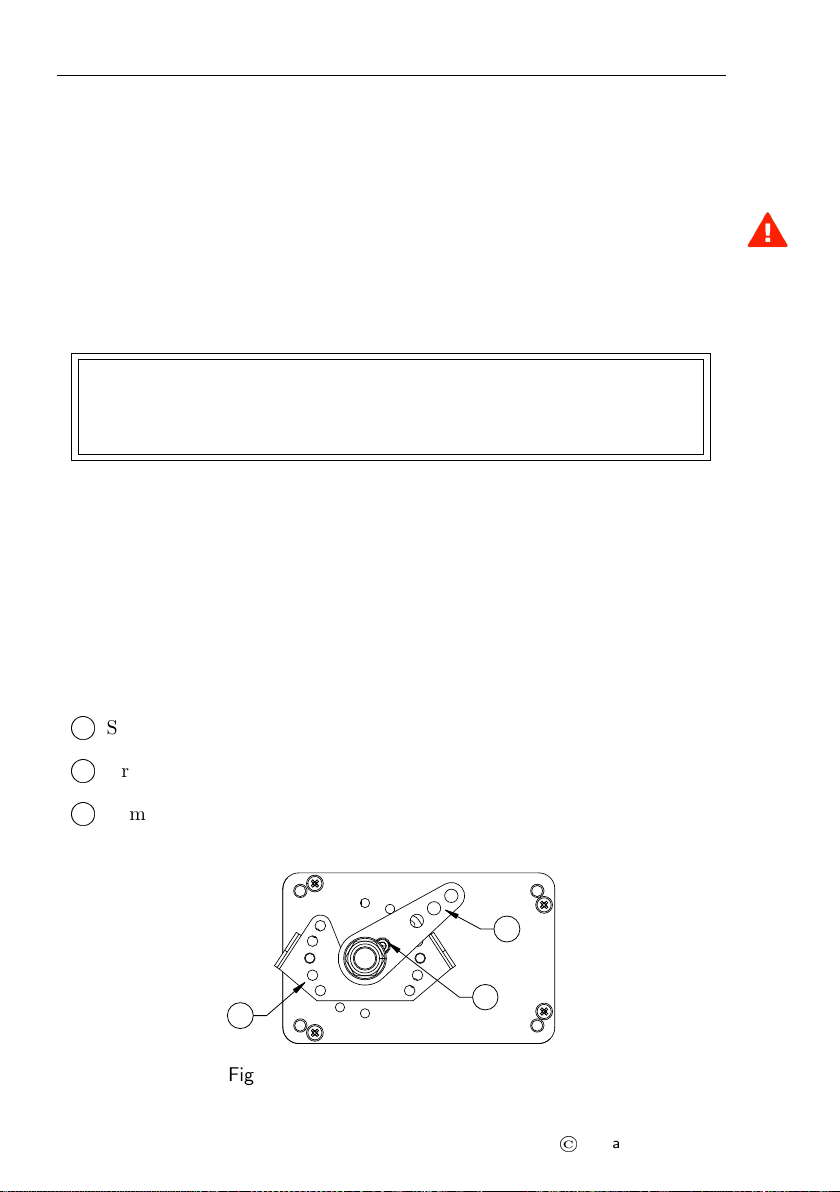

2.1 Servo Motor

The servo motor must be installed in a fixed position. It must be attached with

all four mounting screws. The motor mount should be provided by aircraft

manufacturer and has to be adapted to specific airplane model. The motor

should be oriented parallel with longer edge regarding control rod connected

to the servo arm. The servo schematics is given in Figure 1. It defines three

important elements:

1

O

Safety pin,

2

O

Arm movement limiter,

3

O

Arm.

1

2

3

Figure 1: Safety pin, limiter and arm.

12

©

Kanardia 2016-2020

Autopilot Installation Manual 2.2 Servo Arm

2.2 Servo Arm

Servo arm has multiple holes for mounting control rod. The hole in use should

be chosen to maximize the arm rotation. Servo arm should not be removed or

replaced without Kanarida advise. The removal of servo arm includes removal

of safety pin. Please contact Kanarida before replacing safety pin for latest

instructions.

Extreme command position

150° or less!

90° is ideal case for

neutral command position

Extreme command position

30° or more!

Figure 2: Main servo dimensions.

Figure 2 illustrates valid relative positions between command rod and servo

arm. When command is in neutral position, the angle between rod and arm

shall be 90◦or at least very close to this ideal case. When command is in

its extreme position the angle between the command rod and the arm must

never be more than 150◦or less then 30◦.

Under no circumstances the servo arm is allowed to come into position called

over center – the position at which the primary aircraft control would lock up

and can result in fatal crash. A mechanical stops must be applied to prevent

this to happening. Mechanical stops must limit the arm movement at least

30◦before the over center situation.

2.3 Servo Arm Limiter

To protect against control lock up, a mechanical arm limiter is supplied with

servo. The limiter is drilled so that it can be mounted at different angles as

required (18◦intervals).

The limiter must not prevent aircraft command movements. Always make

sure that the controls can have their full travel and they never reach the servo

limiter.

13

©

Kanardia 2016-2020

Autopilot Installation Manual 2.4 Servo Arm Safety Pin

2.4 Servo Arm Safety Pin

Safety pin is a safety mechanism which prevents blocking of the aircraft com-

mand system for the case of blocked servo motor. If servo blocks the command

system, pilot must apply high force on the command stick. This force will

break the pin and release the servo from command system. Once the pin is

broken, the autopilot system is not operational until the pin is replaced.

If safety pin is broken or it gets slack the whole autopilot system must be

checked. Only after the cause of the problem was found and corrected, safety

pin can be replaced with a new pin. Always use original safety pin.

The safety pin is made from high grade steel and it is intentionally weaken to

break at specific torque applied on servo arm.

The airplane command system must be capable to withstand the forces in the

command system required to break the safety pin.

3 Electrical Installation

Servo motor has two electrical connections. The first one provides power for

the electrical motor and the second one connects controlling device with the

CAN bus. (The controlling device is hidden inside the servo motor).

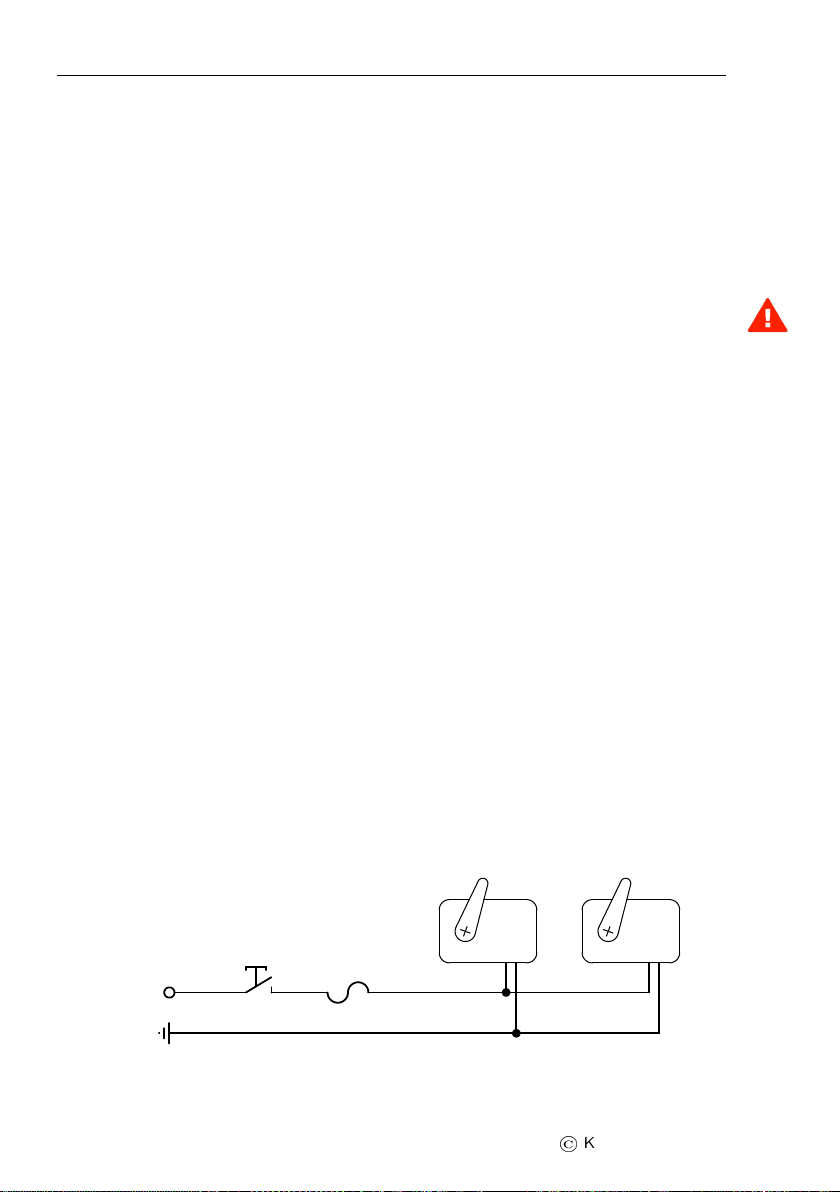

3.1 Electrical Power

The autopilot servo motor must be connected to a 12 V DC standard aircraft

power source. It is also possible to use 24 V DC power. The maximum current

consumption for one servo motor is 1.5 A (at 12 V). Always protect servos

with an automatic/replaceable fuse and a switch. The fuse protects against

over-current and the switch allows quick disconnect by taking power from the

motor. Figure 3 shows typical connection.

Fuse 5A

Autopilot

switch

+12V

Ground

Figure 3: Typical connection of servo motor electrical power.

14

©

Kanardia 2016-2020

Autopilot Installation Manual 3.2 CAN Bus

The autopilot switch must be easily accessible by the pilot. The pilot must

be able to reach it in any moment.

3.2 CAN Bus

Servo motor must also be connected to the CAN bus. The controller module

is built in the servo housing. The controller exchanges the information over

the CAN bus. In addition, CAN bus is also used to power the controller. This

means that controller works even when servo motors are without power.

Figure 4 shows CAN bus connections for the minimal autopilot configuration.

In reality more devices can be connected to the CAN bus. The CAN bus goes

trough Nesis or Aetos, where it is internally connected to AD-AHRS-GPS

module. On the servo side, T junction is needed and a short connection is

made from T to the servo controller.

Airu

AD-AHRS-GPS

T T

CAN bus

to other devices to other devices

Nesis III or Aetos

CtrlCtrl

Figure 4: Typical CAN bus connection for Nesis/Aetos based minimal autopi-

lot configuration.

Please note that CAN bus must be terminated with a 120 Ohm terminator

on both ends of the main line. Terminators are not shown on Figure 4.

3.3 External Push Button

It is advisable to install an external push button, which allows for quick

autopilot disconnect and level commands. The push button shall be installed

on the command stick, where it is easily accessed by pilot. Two wires from

15

©

Kanardia 2016-2020

Autopilot Installation Manual 3.4 Joyu Command Stick

the push button must be connected to the Nesis/Aetos service port or to

Amigo auxiliary port. The connection details are given in the Nesis/Aetos

installation or in Amigo manual, see the External Push Button section.

3.3.1 Autopilot Quick Disconnect

Nesis/Aetos must be then configured to react on the push button event. When

the button is pushed, the autopilot disconnect command is sent via CAN bus

to both servo controllers, which will cut power of both servo motors.

In the case of Amigo, no configuration is necessary.

3.3.2 Autopilot Level

The same button can be used also used for the autopilot level command. This

command will activate Track Hold mode for aileron and Altitude Hold mode

for elevator.

In the case of Nesis/Aetos, this function must be configured. In the case of

Amigo, it is activated by a long press on the external button. No configuration

is necessary.

3.4 Joyu Command Stick

Alternatively, Joyu command stick can be also used. Joyu has multiple pro-

grammable buttons and one or more of its buttons can be assigned to operate

the autopilot.

Short press on the button should be used for autopilot disconnect and long

press for the autopilot level function.

Please see the Joyu manual for more details.

4 Configuration

For the autopilot to operate properly, controllers inside the servo motors must

be configured. Once the configuration is complete, the whole system must be

also tuned. In general, tuning is needed for every airplane. In most cases air-

planes of the same type may use the same autopilot configuration if autopilot

mechanical installation is identical.

Any accidental change of any of parameters in this section and subsections

may result of autopilot being inoperative.

16

©

Kanardia 2016-2020

Autopilot Installation Manual 4.1 Overview

4.1 Overview

These configuration and tuning can be done either with Nesis/Aetos or with

Amigo. This section includes several figures. Each figure illustrates Ne-

sis/Aetos solution on the left and Amigo solution in the right.

If you have both Nesis/Aetos and Amigo, do not use the Autopilot configura-

tion or tuning on both instruments at the same time. Use either Nesis/Aetos

or Amigo.

Next steps reveal typical workflow:

1. Configure both servos. Each servo has several parameters that must

be set properly. Its function (what it moves – ailerons or elevator) and

movement direction are two examples.

2. Ground test is performed. It tells weather servos are moving commands

(elevator and ailerons) in correct directions.

3. Autopilot operation limits are set. They define an envelope of values,

which must be met for AP to operate. This is a very important safety

feature.

4. Autopilot controller parameters are set. Most of them can be set on the

ground, but some must be adjusted during flight tests.

5. Autopilot is tuned, which is the most difficult part. This can be per-

formed only in flight. Several controller values must be determined.

First three steps shall be set on the ground. Most of the fourth step can be

also set on the ground, but may be necessary to change some of parameters

during the flight test. Final step can be only done in flight.

Section 7 reveals the workflow for airplanes where autopilot parameters are

already known.

4.2 Autopilot Settings

Please refer also to the Nesis/Aetos or Amigo manual.

In Nesis/Aetos, the settings are accessible from Service options page in the

display. Special password (provided with the instrument) must be entered to

access the Service options page. The password can be also found under the

Info icon.

17

©

Kanardia 2016-2020

Autopilot Installation Manual 4.2 Autopilot Settings

In Amigo, press and hold the ALT knob and then select the Autopilot from

the menu.

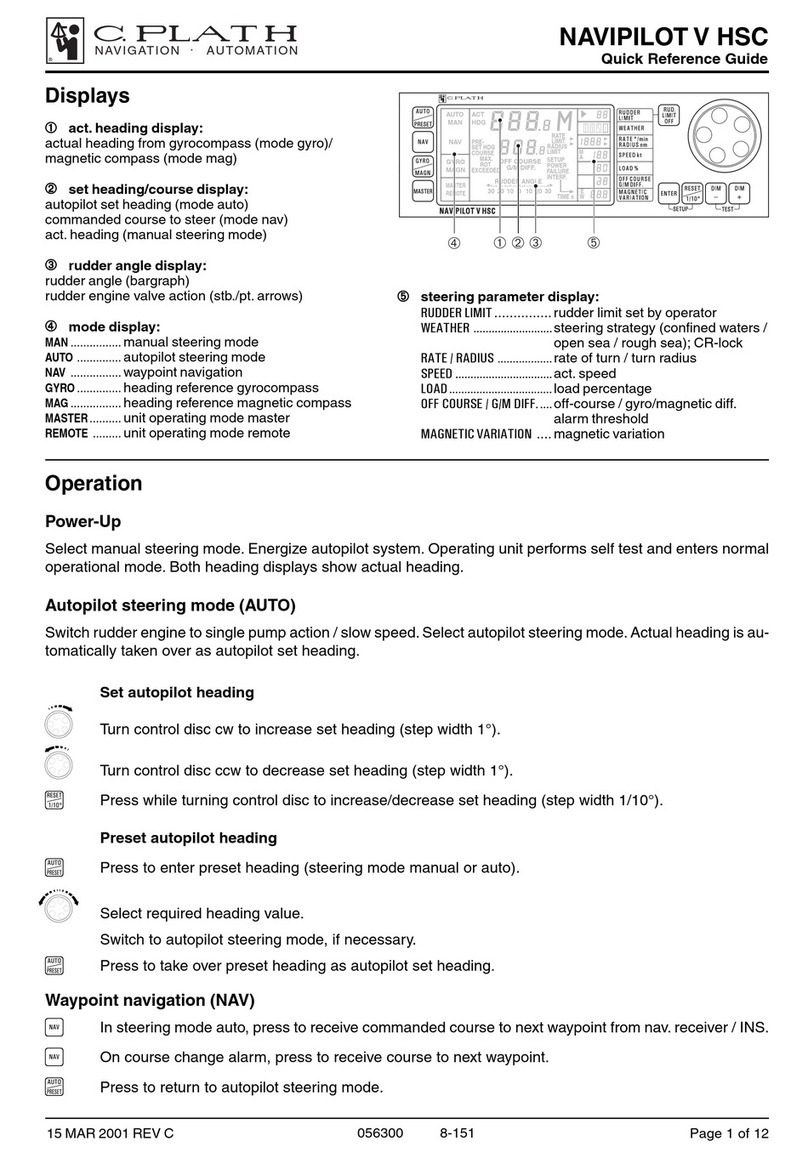

Figure 5 shows the main autopilot settings menu. Nesis/Aetos version is on

the left and the Amigo version is on the right. This pattern repeats throughout

this section.

Figure 5: Main autopilot settings menu.

The menu items follow the logic from the workflow:

Servo config is used to configure servo motors. Section 4.2.1 reveals the

details.

Ground test is used to make sure that servos are correctly moving the con-

trols. See section 4.2.2.

Limits is used to define valid operation envelope of the autopilot, section

4.2.3.

Parameters is used to define various controller parameters, section 4.2.4.

Tuning is an in-flight operation used to setup PID terms of the controller

loops for the elevator and aileron. See section 5.5.

4.2.1 Servo Configuration

When setting up an autopilot, configuring the servos is the first step. Two

servos are required: one for elevator and the other for ailerons. A servo can

perform either role. Each servo has its own serial number.

During the mechanical installation, write down the serial number of the servo

which was connected to aileron and the serial number of the servo used for

elevator.

18

©

Kanardia 2016-2020

Autopilot Installation Manual 4.2 Autopilot Settings

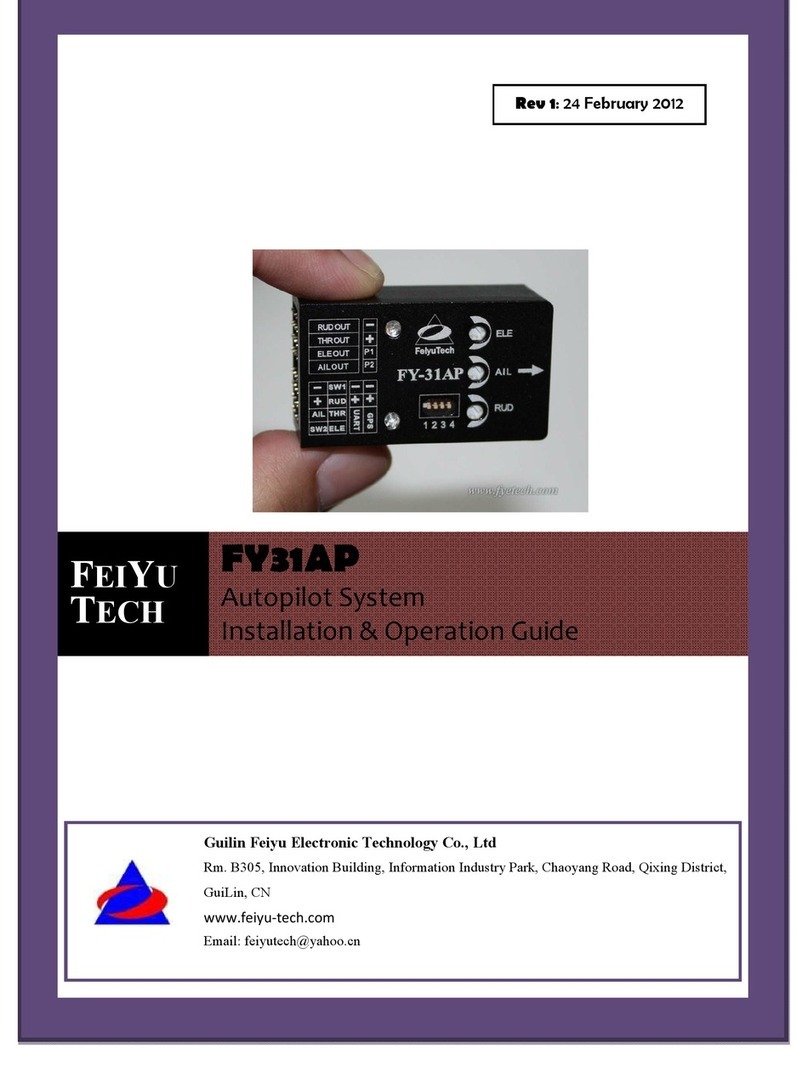

Select the servo to configure. A selection example is shown on Figure 6.

Figure 6: An example of servo selection based on serial number.

Once serial number is selected a window with servo details opens, Figure 7.

Figure 7: An example of servo settings window.

The servo configuration window defines following parameters:

Function must match the servo mechanical connection. If servo with given

serial number is connected to the aileron, then the function must also

be Aileron. Change the function if necessary. You can choose between

Aileron or Elevator.

Reversed has values No or Yes. Choosing correct value is a guessing game.

Start with No and if ground test, described in section 4.2.2 fails, change

it to Yes and vice versa.

Power defines how much power (=torque) shall be used by servo when moving

its arm. 100% means total servo capacity. Try to avoid using more than

90% due to possible servo overheating. This also depends where and

19

©

Kanardia 2016-2020

Autopilot Installation Manual 4.2 Autopilot Settings

how servo is installed. In long term, try to find the lowest value, which

still provides enough torque.

Holding power defines how much power is used when motor is not moving.

This value depends on the power value above. If it is set to 50% this

means that motor will use 50% of the torque set with the power param-

eter. For example, if power is set to 70% and holding power is set to

50%, the motor will use 35% of maximal power (torque) at standstill.

Backlash defines the amount of command system free travel, which is a com-

bination of free play and elastic command resistance. It is given in

degrees of servo arm movement. In ideal circumstances this shall be

zero, but this is seldom the case.

Max speed is the maximal speed of servo arm movement in degrees per sec-

ond. This value is usually set between 10 and 30 deg/s.

PPR tells how many pulses are needed for one rotation of internal stepper

motor (always 200 for current servos). This is servo motor characteris-

tics and shall not be changed.

Reduction is the gearbox reduction factor between the arm and stepper mo-

tor. (This factor is 4.57 for recent servos. But factors between 4 and

5 are also in use.) This is servo motor characteristics and shall not be

changed.

In general, PPR,Reduction and Max speed shall not be changed and original

values shall be kept. Change them only if Kanardia support team approves

the changes.

4.2.2 Ground Test

The ground test is used to check correct servo motor movement. Figure 8

illustrates available options.

20

©

Kanardia 2016-2020

Table of contents