TruTrak Vizion C182E User manual

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

1

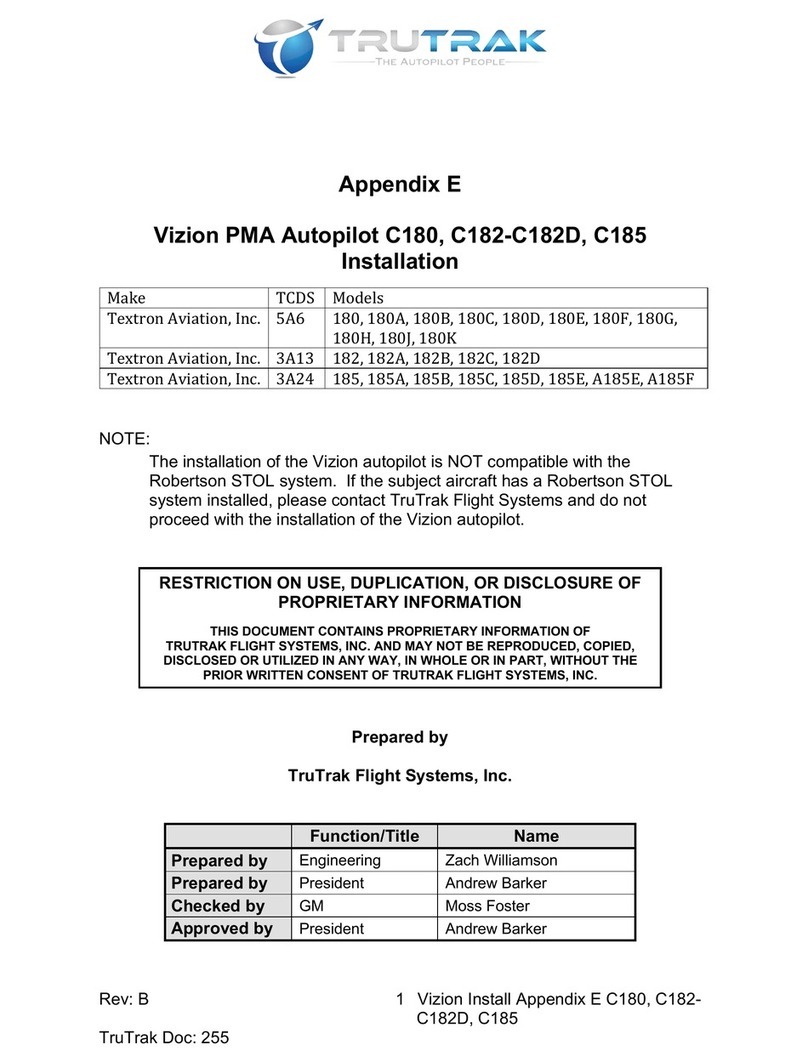

Appendix F

Vizion PMA Autopilot C182E-C182T Installation

RESTRICTION ON USE, DUPLICATION, OR DISCLOSURE OF

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

TRUTRAK FLIGHT SYSTEMS, INC. AND MAY NOT BE REPRODUCED, COPIED,

DISCLOSED OR UTILIZED IN ANY WAY, IN WHOLE OR IN PART, WITHOUT THE

PRIOR WRITTEN CONSENT OF TRUTRAK FLIGHT SYSTEMS, INC.

Prepared by

TruTrak Flight Systems, Inc.

Function/Title

Name

Prepared by

Engineering

Zach Williamson

Prepared by

President

Andrew Barker

Checked by

GM

Moss Foster

Approved by

President

Andrew Barker

Make

TCDS

Models

Cessna Aircraft Company

A42EU

F182P, F182Q, FR182

Textron Aviation, Inc.

3A13

182E, 182F, 182G, 182H, 182J, 182K, 182L, 182M, 182N,

182P, 182Q, 182R, 182S, 182T, R182,T182, TR182,

T182T

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

2

Table of Contents

1. Document Revision History ................................................................................ 3

2. Cessna 182E-182T Controller / Wiring Harness Installation.................................. 4

2.1. Wiring Harness Materials List................................................................................................................ 4

2.2. Wiring Harness / Controller Mounting Instructions................................................................... 5

3. Cessna 182E-182T Servo Installation..................................................................11

3.1. Roll Servo Materials List..........................................................................................................................11

3.2. Cessna 182E-182T Roll Servo Mounting Instructions..............................................................12

3.3. Pitch Servo Materials List.......................................................................................................................21

3.4. Cessna 182E-182T Pitch Servo Mounting Instructions............................................................22

3.5. Cessna 182E-182T Vizion Roll IPC.....................................................................................................28

3.6. Cessna 182E-182T Vizion Pitch IPC...................................................................................................29

4. Cessna 182E-182T Autopilot Settings.................................................................30

4.1. Lateral Autopilot Settings.......................................................................................................................30

4.2. Vertical Autopilot Settings......................................................................................................................31

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

3

1. Document Revision History

Rev

Description

Pages

Date

IR

Initial Release

30

8-16-18

A

Added BK part numbers, made changes for PV.40

software, made revisions to roll install for P model

on.

33

6-5-19

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

4

2. Cessna 182E-182T Controller / Wiring Harness Installation

2.1. Wiring Harness Materials List

Qty

Description

Part Number

1

Vizion Wiring Harness 30’

8220-033

1

Vizion 2” Controller

OR

Vizion 3” Controller

OR

Vizion Flat Pack Controller

8000-174 or 8000-183

OR

8000-176 or 8000-184

OR

8000-175 or 8000-185

100

MS3367-1-0 Cable Tie

2

Connector D-sub Female 9 Pin Crimp

2100-044

16

Female Socket Crimp Connector D-sub

2100-045

2

Connector Backshell 9 Pin

2100-010

1

Vizion Emergency Level Button Kit

8100-113

1

Vizion Limitations Placard

8300-092

1

5A AP circuit breaker (not supplied)

1

Control Wheel Steering Switch

(not supplied, but MUST be RED in color)

1

AP Master Switch (not supplied)

4

6-32 X 3/8” Instrument mounting screw

(not supplied)

N/A

Various terminals and pins for connection of

power and GPS

N/A

1/8”-27 NPT male fittings and tees for

connecting the A/P pitot and static to the

aircraft systems

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

5

2.2. Wiring Harness / Controller Mounting Instructions

1. Begin by disconnecting the aircraft battery.

2. Select a mounting location for the autopilot controller.

2.1. Consider the overall mounting depth of the controller with pitot, static, and

electrical connections and allow clearance where necessary, especially

surrounding the moving yoke assembly.

2.2. Ensure that mounting location does not require autopilot servo lines to run

near com antenna coax.

2.3. Ensure that there is sufficient space near the autopilot controller to install the

Vizion Limitations Placard (Trutrak P/N 8300-092)

3. Remove the instrument panel and panel overlays as necessary.

4. Remove the seats.

5. Remove the left A-pillar and kick panel trim.

6. Remove carpeting.

7. Wiring harness routing.

7.1. Route the pitch (white) and roll (black) servo harnesses from the controller

to the left side of the panel.

7.2.Route the roll (black) servo harness up the left A pillar and out the leading

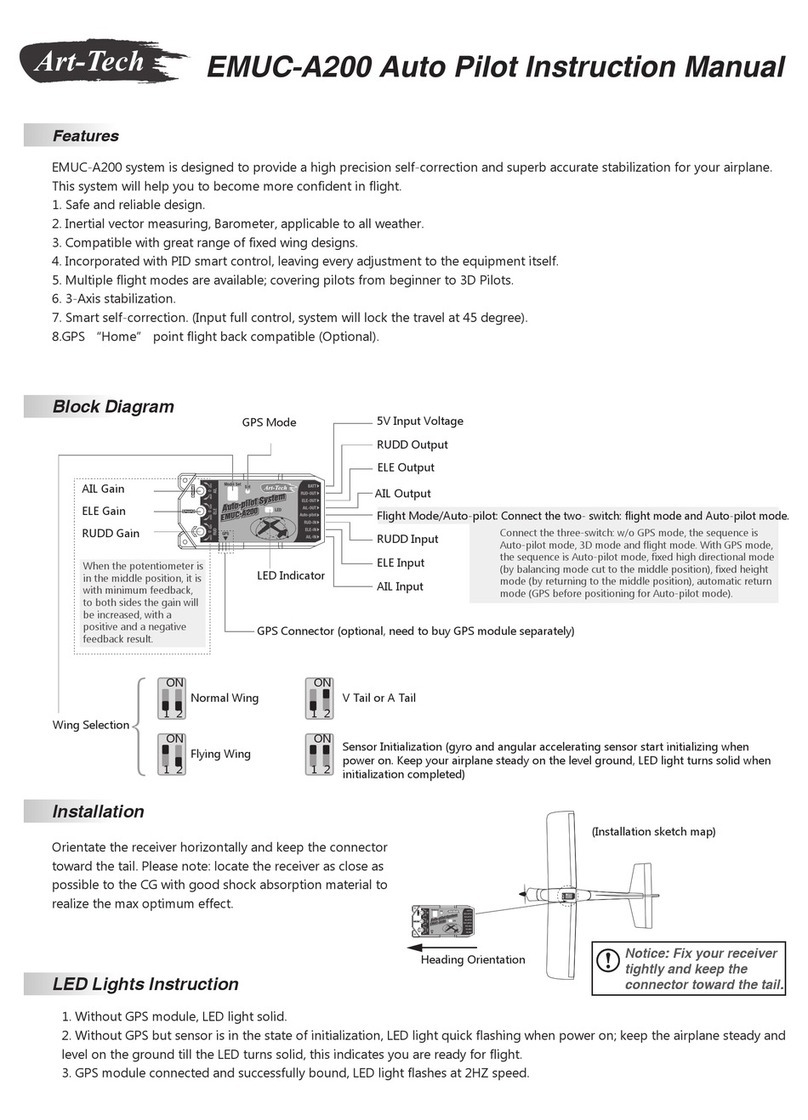

edge of the left wing as shown in Figure 2-1, Figure 2-2, and Figure 2-3.

Extend the excess harness out the inspection hole just forward of the

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

6

inboard end of the left aileron. The excess length will be trimmed and the

harness terminated when the roll servo is installed.

Figure 2-1

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

7

Figure 2-2

Figure 2-3

7.3. Route the pitch (white) servo harness down the left kick panel and under the

floor. Continue running the harness to the pitch servo mounting location as

shown in Figure 2-4 and Figure 2-5. The excess length will be trimmed and

the harness terminated when the pitch servo is in place.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

8

Figure 2-4

Figure 2-5

8. Select appropriate mounting locations for the AP Master, AP Circuit Breaker,

Emergency Level and control wheel steering switches. Connect these items per

the Vizion wiring diagram in the Vizion PMA Installation Guide (TruTrak Doc.

166).

8.1. All items in this step are required to be installed. The AP Master Switch,

AP Circuit Breaker, and Control Wheel Steering switches must be

labeled. The Control Wheel Steering Switch must be RED.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

9

9. Connect GPS inputs per the Vizion wiring diagram in Vizion PMA Installation

Guide (TruTrak Doc. 166)

10.Conduct pitot / static check of aircraft system before opening any pitot/

static connections!

11. Mount autopilot controller in panel using 4 6-32 X 3/8” screws. Connect wiring

harness and connect pitot and static per Vizion PMA Installation Guide (TruTrak

Doc. 166).

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

10

12. Install Vizion Limitations Placard (Trutrak P/N 8300-092) near the Vizion

autopilot. A sample panel with potential placard location is shown below:

13. Reinstall the instrument panel and panel overlays.

14. Reinstall interior trim.

15. Reinstall carpeting.

16. Reinstall seats.

17. Reconnect battery.

18. Once autopilot settings are confirmed, perform autopilot system test per the

Vizion PMA Installation Guide (TruTrak Doc. 166).

Potential location of

Limitations Placard

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

11

3. Cessna 182E-182T Servo Installation

3.1. Roll Servo Materials List

QTY

PART NUMBER

DESCRIPTION

1

8100-064 (12

Volt) 8100-065

(24 Volt)

60 in-lb PMA Servo

1

7200-091

C172 Roll Servo Arm

1

2520-062

41" Push Rod .5" OD Tapped 10-32

12

2510-192

Rivet MS20426A3-4

1

2510-073

.250 L X .375 OD X .199 ID Aluminum Spacer

2

2510-051

Small Rod End Bearing MM-3-300

3

2500-216

8-32 x 3/8 Flat Head Socket Cap Screw SS

6

2500-122

MS21051-08 8-32 Anchor Nut

1

2500-120

AN3-14A

4

2500-081

MS35333-39 Internal Lock Washer

3

2500-076

AN960-10

4

2500-075

AN3-3A

1

2500-071

AN3-10A

6

2500-069

8-32 X 5/8 Screw AN526C832R10

1

2500-068

AN3-7A

2

2500-055

AN345-10

2

2500-047

AN970-3 Washer

2

2500-042

MS20364-1032

1

1450-128

18X Lower Roll Bracket

1

1450-127

18X Upper Roll Bracket

1

1420-216

Servo Bolt Pattern Plate

1

1420-209

1.5” PMA Servo Arm

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

12

3.2. Cessna 182E-182T Roll Servo Mounting Instructions

NOTE: Apply torque seal to all bolts after final torquing is achieved.

1. The roll servo will be mounted in the left wing just forward of the inboard end of

the aileron.

1.1. Begin by removing the inspection cover on the lower wing skin located forward

of the inboard end of the aileron.

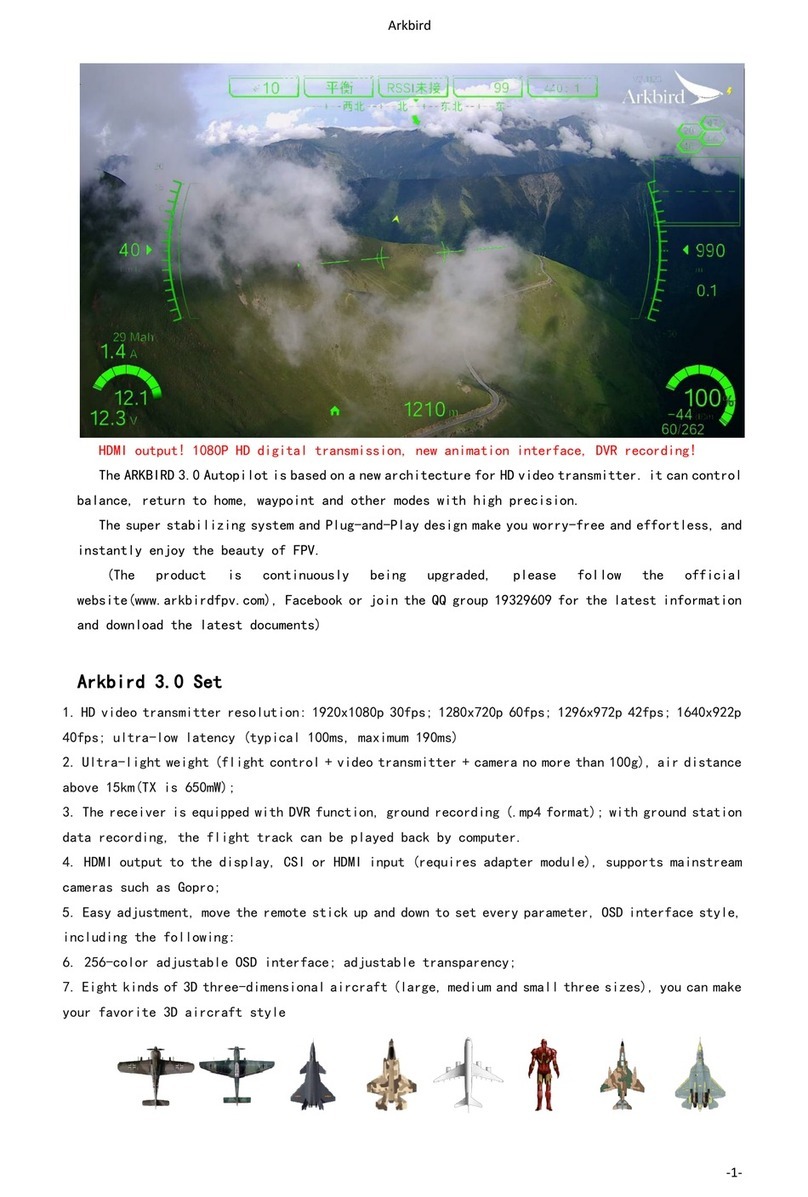

1.2. Figure 3-1shows the roll servo mounting location from below the left wing.

Figure 3-1

2. The Cessna 18X Upper Roll Bracket (P/N 1450-127) will be mounted to the flange

of the rear wing spar using 3 ea. AN526C-832R8 screws.

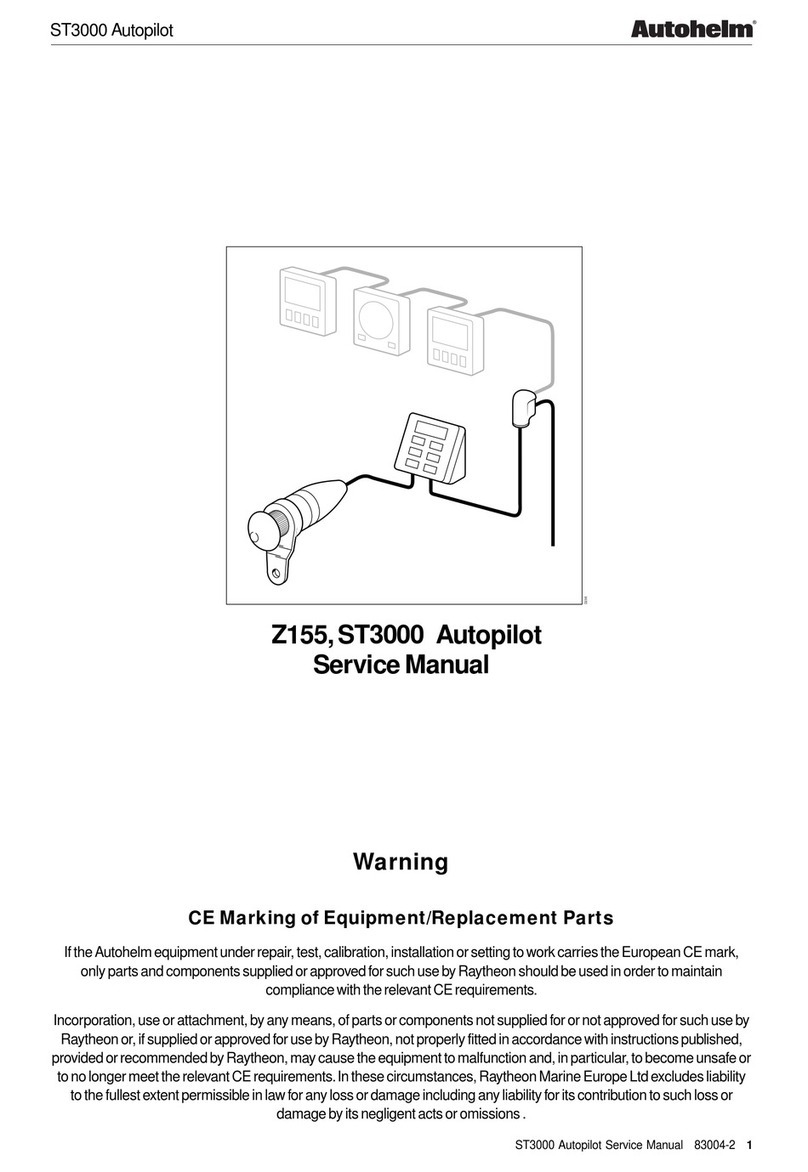

2.1. Locate the inboard screw hole as shown in Figure 3-2 on the upper wing skin.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

13

Figure 3-2

2.2. Drill the inboard hole only at this time with a #19 drill.

2.3. Invert the Cessna 18X Upper Roll Bracket (P/N 1450-127) on the upper wing

skin and cleco the inner hole on the bracket to the hole drilled in the previous

step. Rotate the bracket so that the middle and outer bracket mounting holes are

aligned with the row of rivets in the rear wing spar as shown in Figure 3-3.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

14

Figure 3-3

2.4. Match drill 2 holes as shown in Figure 3-3.

2.5. Remove the Cessna 18X Upper Roll Bracket (P/N 1450-127) from the wing and

deburr the mounting holes that were drilled.

2.6. Temporarily attach the Cessna 18X Upper Roll Bracket (P/N 1450-127) to the

Servo Bolt Pattern Plate (P/N 1420-216) using 2 ea. AN3-3A as shown in Figure

3-4.

Figure 3-4

2.7. Place the assembly shown in Figure 3-4 in the wing and cleco in place as shown

in Figure 3-5.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

16

2.9. Drill Cessna 18X Lower Roll Bracket (1450-128) mounting holes.

2.9.1. Align the lower bracket mounting holes with row of rivets on

the lower spar flange.

2.9.2. Match drill the outboard mounting hole using a #19 bit from

inside the wing.

2.9.3. Secure the outboard hole with a cleco.

2.9.4. Match drill the remaining 2 holes on the Cessna 18X Lower Roll

Bracket (1450-128) installing a cleco after each hole is drilled.

2.9.5. Remove all components from the wing and debur the lower

mounting holes.

2.9.6. Remove the Servo Bolt Pattern Plate (P/N 1420-216) from the

Cessna 18X Upper Roll Bracket (P/N 1450-127).

2.10. Install anchor nuts in the Cessna 18X Upper Roll Bracket (P/N 1450-127) and

Drill Cessna 18X Lower Roll Bracket (1450-128). Rivet 3 ea. MS21051-08 anchor

nuts in place using 6 ea. MS20426AD3-4 rivets on each bracket.

2.11. Attach the appropriate roll servo arm to a 60 inch/lb PMA servo (P/N 8100-

064 for 12 volt or P/N 8100-065 for 24 volt) using the provided 8-32 x 3/8” flat

head screws. Use blue threadlocker (Loctite 242 or equivalent) and torque the

screws to 18-20 in-lb.

Aircraft model

Roll Servo Arm

182E-182M

Cessna 172 Roll Servo Arm (P/N 7200-091)

182P-182T, R182, TR182

1.5” PMA Servo Arm (P/N 1420-209)

2.12. Allow a sufficient service loop and trim the roll servo wiring harness to length.

2.13. Terminate the roll servo wiring harness per the Vizion wiring diagram in the

Vizion PMA Installation Guide (TruTrak Doc. 166) and install the 9 Pin

Connector Backshell (2100-010).

2.14. Place the Cessna 18X Upper Roll Bracket (P/N 1450-127) and Cessna 18X

Lower Roll Bracket (1450-128) in the wing in approximately the final mounting

position but do not secure them to the wing.

2.15. Connect the roll servo wiring harness connector to the roll servo.

2.16. Place the roll servo assembly in the wing and loosely attach it to the Cessna

18X Upper Roll Bracket (P/N 1450-127) and Cessna 18X Lower Roll Bracket

(1450-128) using 4 ea. AN3-3A bolts with MS35333-39 lock washers and blue

threadlocker (Loctite242 or equivalent). The next steps must be performed

quickly so that the threadlocker does not begin to cure prior to final torqueing.

The roll servo arm should be oriented upward between the servo stops.

2.17. Align the Cessna 18X Upper Roll Bracket (P/N 1450-127) with the holes in the

upper spar and start 3 ea. AN526C-832R8 screws in the associated anchor nuts.

2.18. Align the Cessna 18X Lower Roll Bracket (1450-128) with the holes in the

upper spar and start 3 ea. AN526C-832R8 screws in the associated anchor nuts.

2.19. Fully tighten the upper and lower AN526C-832R8 mounting screws.

2.20. Torque the 4 AN3-3A servo mounting bolts to 20-25 in-lb.

2.21. Remove the inspecting cover near the left aileron bellcrank.

2.22. Loosen one of the aileron cable turnbuckles to allow for easy removal and

replacement of the bolt connecting the aileron cable to the bellcrank.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

18

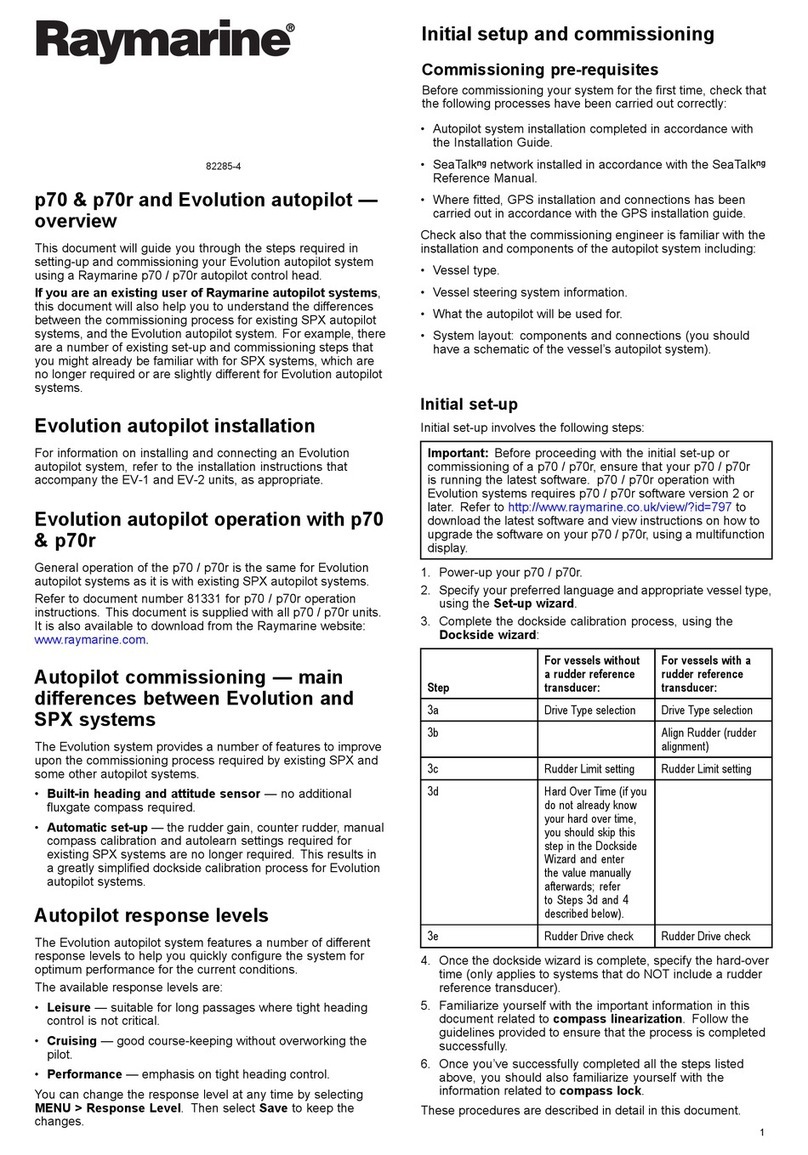

Figure 3-7

Figure 3-8

2.24. Tension the aileron cable according to the aircraft service manual.

NOTE: Proper cable tension is essential for proper autopilot performance! Use

a tensiometer to verify cable tension.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

19

2.25. Verify that aileron rigging is correct according to the aircraft service manual

and adjust as needed.

2.26. Safety wire the aileron cable turnbuckle.

2.27. Fully thread an AN345-10 on a MM3-300 rod end bearing then partially thread

the MM3-300 rod end bearing in one end of the 41” push rod (2520-062).

2.28. Insert the push rod assembly in the aileron bellcrank inspection hole with the

rod end bearing going toward the roll servo.

2.29. Ensure that the aileron cable is not wrapped around the 41” push rod (2510-

062) then partially thread the MM3-300 rod end attached to the aileron

bellcrank in the outboard end of the push rod.

2.30. Have an assistant hold the yoke in the full right position and rotate the servo

arm against the outboard stop on the roll servo bracket.

2.31. Thread the MM-3-300 rod end bearing into the servo end of the pushrod until

the pushrod is the correct length to align with the drive point on the servo arm.

2.32. Verify that the control cable is not twisted around the pushrod.

2.33. Attach the pushrod assembly to the roll servo arm as shown in Figure 3-9 for

182E-182N or in Figure 3-10 for 182P-182T, R182 or TR182 and torque to 20-

25 in-lb.

Rev: A Vizion Install Appendix F C182E-T

TruTrak Doc: 256

20

Figure 3-9

Figure 3-10

2.34. Apply blue threadlocker (Loctite242 or equivalent) to the threaded shank of

both MM3-300 rod ends. Rotate the pushrod until the rod end bearings on each

end are threaded in equally then tighten the jam nuts to 20-25 in-lb.

2.35. Move the yoke throughout the full range of travel and check for binding in the

rod end bearings. If binding exists adjust the rod end bearings and jam nuts to

eliminate it.

2.36. Ensure that aircraft stops are contacted prior to servo stops. Adjust

length of pushrod as needed until servo stops are not contacted when

controls are moved to both ends of travel.

This manual suits for next models

1

Table of contents

Other TruTrak Autopilot System manuals