Autoquip Eco-2M User manual

www.aqautomation.com

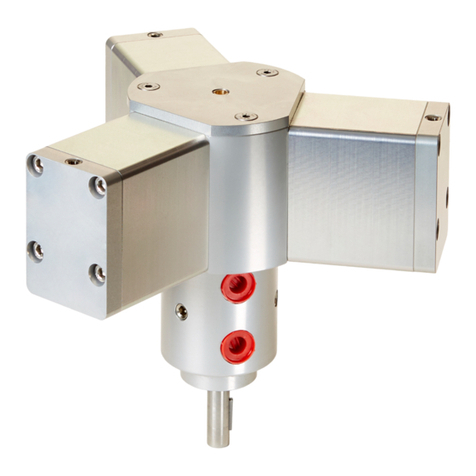

Eco-2M Piston Air Engine™

Series III

Piston Air Engine™Installation

and Operating Instructions

www.aqautomation.com

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in

serious injury.

•This equipment is for professional use only.

•Read all instruction manuals, tags, and labels before operating the

equipment.

•Use the equipment only for its intended purpose. If you are not sure, call

your Autoquip distributor.

•Do not alter or modify this equipment. Use only genuine Autoquip parts.

•Check equipment daily. Repair or replace worn or damaged parts

immediately.

•Use fluids and solvents that are compatible with the equipment wetted parts.

Refer to the Technical Data section of all equipment manuals. Read the

fluid and solvent manufacturer’s warnings.

•Always wear protective eyewear, gloves, clothing, and respirator as

recommended by the fluid and solvent manufacturer.

•Comply with all applicable local, state, and national fire, electrical, and safety

regulations.

•Rotating parts may cause injury potential.

www.aqautomation.com

Piston Air Engine Installation and Operating Instructions

Operating Recommendations

1. Autoquip Piston Air Engines™are designed and built to be safe and reliable when

properly used. Advice and approval should be sought from authorized Autoquip

Automation personnel before any of our products are used in circumstances other than

recommended herein.

2. Compressed air is the only medium to be used.

3. Air pressure should not exceed 6.9 bar (100 psi)

4. Each engine should be supplied with air that is adequately filtered to remove fluids

and particles above 40 microns.

5. An operating temperature range of -10˚C to +80˚C (14˚F to 176˚F) is

recommended.

6. Engines should be sited and mounted to avoid excessive vibration.

7. Safety or system integrity should not depend upon the assumption that leakages

cannot or will not occur.

8. Actual response times for air engines can vary according to ambient conditions and

service life.

9. Adequate regular maintenance is essential to ensure continuous satisfactory and safe

performance.

Installation

1. Autoquip Piston Air Engines™are precision machines and are susceptible to damage

by dirt particles. Cleanliness is essential during installation and servicing.

2. To prevent ingress of dirt or grit do not remove the red protective caps (10) from the

ports until installed.

3. When the engine has been mounted and the shaft connected, air supply tubes should

be fitted to the ports ensuring that no dirt or grit can enter the ports

www.aqautomation.com

Start-Up

1. Set air pressure to zero.

2. Set any speed restrictor valves to the fully open position

3. Slowly increase air pressure until the shaft rotates under load.

4. For low load applications, increase air pressure by a further 1 –1.25 bar (15 –20

psi). This may not be necessary for high load applications.

5. Adjust the speed restrictor to give the required speed.

6. The air engine will now be running at the optimum and most efficient setting.

Note: It is bad practice to apply excessive line air pressure and then have a tight restriction on the

exhaust port. This can cause excessive wear on the base of the pistons.

Recommended Lubricants

Shell Gadus S2 V100 3

Maintenance Procedures

Autoquip Piston Air Engines™are precision engineered and are designed for a long

working life. The wearing parts are the pistons, cylinder liners and seals, which can be

replaced as part of a routine maintenance schedule.

For this purpose, spare parts kits can be purchased from Autoquip Automation or our

authorized distributors, comprising three pistons, three liners, three piston seals and

three O Rings.

The drive shaft and rotary valve assembly are matched during manufacture and should

not be removed from the engine body. If they are removed, they will require

replacement with new parts in our factory.

As with all precision engineered machines, cleanliness is essential during dismantling

and assembly. Before dismantling, the air supply ports must be covered with plastic

caps and the workbench should be clean and free of debris.

www.aqautomation.com

Disassembly

1. Ensure that all air lines are disconnected from the engine

2. Remove the three countersunk screws holding the rear cover to expose the

crank area.

Remove the three-cylinders by withdrawing the two bolts on each cap.

www.aqautomation.com

3. The three exposed ports of the air flow route (2 on each cylinder cap and

3 on the body) must be protected to prevent any ingress of dirt/grit. This

is critical.

4. Push out the three piston/liner assemblies; push outwards from the

crankcase with the seals and the O Rings.

www.aqautomation.com

5. Clean the crank area and cylinder bores using a suitable solvent to ensure

it is free from dirt particles.

Shaft and bushings are assembled as a unit and should not be

removed.

If you find the shaft will not rotate freely, we recommend you

contact Autoquip prior to any further work.

www.aqautomation.com

4. The three exposed ports of the air flow route (1 on each cylinder)

must be protected to prevent any ingress of dirt/grit. This is critical.

Reassembly

1. Ensure all parts are clean and grit free

2. Insert replacement piston/liner/seal assemblies ensuring that the seal

is at the cylinder cap end.

3. Fit the O Ring in the groove on cylinder depending on the type.

www.aqautomation.com

5. Apply a small amount of grease to the crank bearing. Piston kits are

supplied greased. Do not fill the crankcase with grease, as this impairs

operation. New engines are supplied greased with approximately 16

grams (0.5 oz.)

6. Re-connect the air supply, making sure the pressure is at zero.

7. Slowly increase the air pressure to approx 1 –1.25 bar (15-20 psi) the

engine should start to rotate slowly.

8. Disconnect air supply and replace rear cover.

www.aqautomation.com

Eco-2M Piston Air Engines™

Size 2 Engine 3077-HAE2-000

Service Options

Size 2 Engine Body Sub-Assembly Kit 3077-BSA2-000

Size 2 Rebuild Kit 3077-RKT2-000

Recommended Installation Kit

Size 2 Installation Kit = 3077-INST-000

www.aqautomation.com

www.aqautomation.com

3077-HAE2-000

Item

Description

1

Body

Body Sub-Assembly. Modification by customer not

recommended. Replacement Body Sub-Assembly

3077-BSA2-000

Items included:

1-13 and 23

2

Drive Shaft

3

Ball bearing

4

Ball bearing

5

Oilite bush

6

Air Seal

7

Washer

8

Screw hex head

9

Pin

10

Dust Cap

11

Plug

12

Seal Plate

13

Screw csk head

16

Cover

Items 16, 17 & 18 not available for individual purchase

17

Vent air silencer

18

Screw csk head

19

Piston Liner

Piston Sub-Assembly, Rebuild Kit 3077-RKT2-000

[3 Pistons]

Item included:

19-23

20

Piston

21

Piston Seal

22

O ring seal

23

O ring seal

24

Cylinder

Items 24 & 25 not available for individual purchase

25

Screw cap head

#3077 - Rev C

This manual suits for next models

1

Table of contents

Other Autoquip Engine manuals