2000 TOYOTAMOTOR CORPORATION

All rightsreserved. This CD may not be repro-

duced or copied, in whole or in part, without the

written permission of Toyota Motor Corporation.

First Printing: Jun. 28, 2000 01--000628--00

FOREWORD

ThisRepair Manual has been prepared to provide information covering general service repairs for the

1KZ-TE Engine equipped on the TOYOTA HILUX,4RUNNERandLAND CRUISER/ PRADO.

Applicablemodels:KZN165 series (HILUX)

KZN185series(4RUNNER)

KZJ90,KZJ95series(LAND CRUISER/LAND CRUISERPRADO)

Please note that the publications below have also been prepared as relevant service manuals for the

components and system inthisengine.

All information in this manual is based on the latest product information at the time of publication. However,

specifications and procedures are subject to change without notice.

RM790E-D

TOYOTAMOTOR CORPORATION

CAUTION

This manual does not include all the necessary items about repair and service. This manual is made

for the purpose of the use for the persons who have special techniques and certifications. In the

cases that non--specialized or uncertified technicians perform repair or service only using this manu-

al or without proper equipment or tool, that may cause severe injury to you or other people around

and also cause damage to your customer’s vehicle.

In order to prevent dangerous operation and damages to your customer’s vehicle, be sure to follow

the instruction shown below.

SMust read this manual thoroughly. It is especially important to have good understanding all the

contents written in the PRECAUTION of ”IN” section.

SThe service method written in this manual is very effective to perform repair and service. When

performing the operations following the procedures using this manual, be sure to use toolsspe-

cified and recommended. If using non--specified or recommended tools and service method,

be sure to confirm safety of the technicians and any possibility of causing personal injury or

damage to the customer’s vehicle before starting the operation.

SIf part replacement is necessary, must replace the part with the same part number or equivalent

part. Do not replace it with inferior quality.

SIt is important to note that this manual contains various ”Cautions” and ”Notices” that must be

carefully observed in order to reduce the risk of personal injury during service or repair, or the

possibility that improper service or repair may damage the vehicle or render it unsafe. It is also

important to understand that these ”Cautions” and ”Notices” are not exhaustive, because it is

important to warn of all the possible hazardous consequences that might result from failure to

follow these instructions.

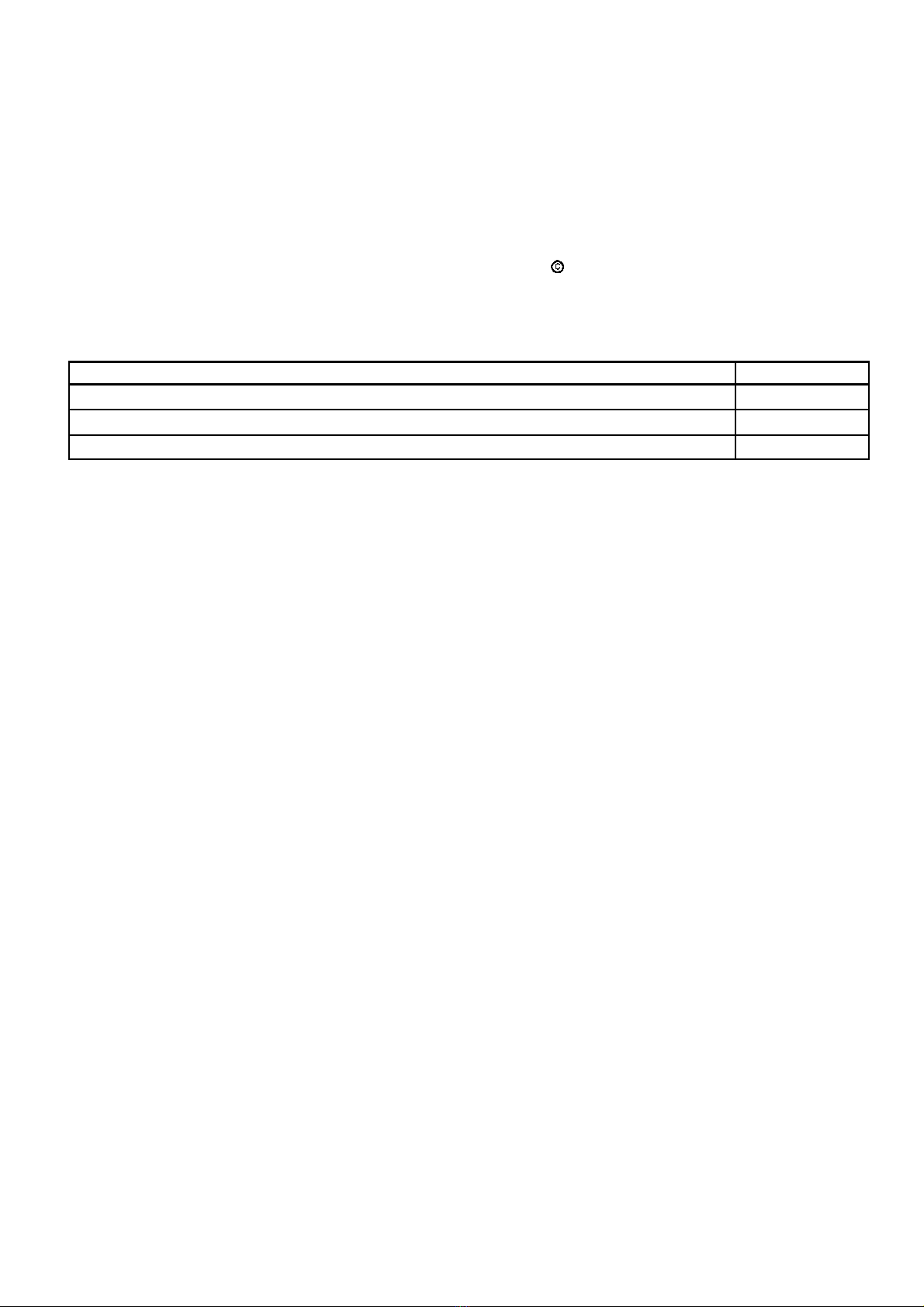

S1KZ--T Engine Repair Manual

S1KZ--TE Engine Repair Manual

S1KZ--T, 1KZ--TE Engine Repair Manual Supplement RM522E

RM710E

RM353E

Pub.No.Manual Name