Autrol APT3200 Series User manual

*Information in this manual can be changed without advance notice.

Operation Manual: 111508-3200-OM01AUTROL Series

Operation Manual:201403-3200-OM00 V7x AUTROL®3200 Series

APT3200 Smart Pressure Transmitter

Operation Manual

AUTROL® APT3200 Series Operation Manual: 201403-3200-OM00 V7x

AUTROL CORPORATION OF AMERICA

www.autroltransmitters.com

published in USA

Operation Manual: 111508-3200-OM01AUTROL Series

Operation Manual:201403-3200-OM00 V7x AUTROL®3200 Series

APT3200 Smart Pressure Transmitter

This manual is made available to assist general users with instructions for proper installation and

operation of an Autrol® APT3200 Smart Pressure Transmitter.

Before handling the APT3200 transmitter, all users should read this manual to familiarize with

recommended practices.

Please note that information in this manual can be changed

without any advance notice. Please contact Autrol America Inc or our local representatives for any updates.

AUTROL CORPORATION OF AMERICA (AAI)

Corporate: Woodfield Preserve, 10 N. Martingale Rd, Suite 400, Schaumburg, IL60173

Operations: 2521 Technology Dr, Suite 200, Elgin, IL 60124

Tel.: +1 847-857-6062, 847 779 5000 Fax: +1 847-655-6062

www.autroltransmitters.com

i

Operation Manual: 111508-3200-OM01AUTROL Series

Operation Manual:201403-3200-OM00 V7x AUTROL®3200 Series

Table of Contents

Chapter 1.Introduction

1.1. Using this manual

1.2. Overview of the transmitter

1.3. Firmware compatibility

1.4. Transmitter Components

Chapter 2.Handling

2.1. Unpacking and specifications check

2.2. Model Code and specifications check

2.3. Storage

2.4. Selecting a suitable location for installation

2.5. Performing Zero Trim after first installation

2.6. Process Connection

2.7. Waterproofing of cable conduits

2.8. Restrictions on use of Radio Transceivers

2.9. Insulation Resistance Test and Dielectric Strength Test

2.10.Installation of Explosion Proof Transmitters in Classified Areas

2.11.EMC Conformity Standards

Chapter 3.Transmitter Functions

3.1. Overview

3.2. Safety Messages

3.3. Warning

3.4. Fail Mode Alarm

3.5. EEProm-Write Enable and Disable Mode Jumper

3.6. Configuration of Alarm and Security Jumper Procedures

3.7. Configuration using Zero and Span Push Buttons

3.8. Commissioning on the bench with a HHT (Hand Held Terminal)

Chapter 4.Installation

4.1. Overview

4.2. Safety Messages

4.3. Warning

4.4. Commissioning on the bench with a Hand-Held Terminal

4.5. General Considerations

4.6. Electrical Considerations

4.7. Wiring

4.8. Mechanical Considerations

4.9. Environmental considerations

ii

Operation Manual:110210-3200-OM01v7x AUTROL® Series

Chapter 5.On-line Operation

5.1. Overview

5.2. Safety Messages

5.3. Configuration Data Review

5.4. Check Output

5.5. Basic Setup

5.6. Detail Setup

5.7. Tag Information Setup

5.8. Diagnostic Services

5.9. Calibration

5.10.Advanced Setup

Chapter 6.Maintenance

6.1. Overview

6.2. Safety Messages

6.3. Hardware Diagnostics

6.4. Hardware Maintenance

Appendix I

APT3200 Smart Pressure Transmitter

LCD Display Codes

Appendix II

APT3200 Smart Pressure Transmitter

Quick Push Button Menu guide (Menu Tree)

Appendix Ⅲ

HHC HART® Handheld Communicator User’s Guide

HART®is a registered Trademark of HART Foundation

3

Operation Manual: 111508-3200-OM01AUTROL Series

Operation Manual:201403-3200-OM00 V7x AUTROL®3200 Series

Chapter 1 Introduction

The APT3200 Smart Pressure Transmitter is accurately calibrated at the factory

before shipment. If attempting to recalibrate these transmitters in field please use a

calibration source at least five times more accurate than transmitter published

specifications. In case of re-ranging please cosndier using the benefits of doing this

using the integral push buttons first prior to attempting any PV source to avoid

adding any unnecessary bias to the factory calibration. In case of of need to adjust

the factory calibration we suggest using the pushbuttons and –1 TRIM menus to

make the necessary Trim adjustments. To ensure correct and efficient use of the

instrument, please read this manual thoroughly and fully understand how to operate

the instrument before installation.

The contents of this manual are subject to change without prior notice.

All rights reserved. No part of this manual may be reproduced in any form

without AUTROL® AMERICA’s written permission.

For questions, errors or missing information found in this manual, please

inform the nearest AUTROL® AMERICA sales office or email

support@autroltransmitters.com.

The specifications covered by this manual are limited to standard configured

items as specified within published ordering codes and do not cover custom-

made instruments designated with code “X” or “L” within the model code.

Please note that changes in the specifications, construction, or component

parts of the instrument may not immediatelty be reflected in this manual at the

time of change, provided that postponement of revisions will not cause difficulty

to the user from a functional or performance standpoint.

1.1.Using This Manual

The Chapters in this operating manual provide information on installing,

operating, and maintaining an AUTROL® Model APT3200 Smart Pressure

Transmitter. Chapters within this manual are organized as follows.

Chapter 1: Introduction

Chapter 2: Handling

Chapter 2 provides instructons on software functions, configuration

parameters, and on-line variables.

Chapter 3: Transmitter Functions

Chapter 3 contains instructions for configuring and commissioning an Autrol®

APT series Smart Pressure Transmitter.

Chapter 4: Installation

Chapter 4 contains mechanical, environmental, and electrical installation

instructions for Autrol® APT series Smart Pressure Transmitters.

Chapter 5: On-line Operation

Chapter 5 describes the configuration process and how to use basic and

advanced Autrol® APT series Smart Pressure Transmitter software functions

during configuration. Included in these sections are details on using:

①Sensor or Output Trim

②Changing range configuration, Output Type, Damping, measurement units,

etc.

APT3200

APT3200

4

Operation Manual:110210-3200-OM01v7x AUTROL® Series

③Change of general data such as Tag No.,Date,Message, etc.

Chapter 6: Maintenance

•Chapter 6 contains hardware diagnostics ,troubleshooting and maintenace

tasks.

Appendix I :

List of Error Codes available on LCD display

Appendix II:

Push Button Menu guide (Menu Tree): configuration of operating settings

using pushbuttons built into exterior of transmitter, allowing change of settings

whenever transmitter is powered.

Appendix III:

HHC HART® Handheld Communicator User’s Guide

1.2.Overview of Transmitter

The Autrol® APT 3200 Smart Pressure Transmitter is a microprocessor based

“smart” pressure transmitter. It uses a piezoelectric pickup optimized &

accurately characterized to compensate for ambient temperature effecs with a

patented temperature compensation algorithm that ensures for high precision

& long term stablilty in gauge and absolute pressure measurements over a

wide range of operating conditions. APT3200 is a two wire loop power

transmitter and has a standard 4/20mA output scaled for desired output

pressure range. In addition it also offers digital HART® (digital signal

superimposed over the analog output) communication that allows transmitting

additional digital parameters/diagnostic information for advanced control

systems like DCS, PLC, SCADA, RTU, AMS etc. All APT series transmiters

have an explosion proof rated housing (standard cast aluminum–copper free

epoxy coated, or optional SUS316) protected for outdoor NEMA 4X/IP 67 and

classified hazardous areas Class I, II, III / Division 1 or 2 use. When installaing

in hazardous areas user must follow relevant electrical codes and wiring

practices per prevailing electrical standards.

This transmitter can be configured for its included smart functions (re-ranging,

damping, engineering mode, square root-linear transfer functions etc. ) using

local push buttons or remotely via HART® commmunication through a HART®

MASTER Host (AMS,PDM, PKS etc) , a HHT (HART® Hand-Held Terminal

using DDL or DOF technology) or any HART® enabled PC Configurator

supporting DDL technology. This allows critical variables to be changed,

configured and tested locally or remotely by users. Note: for HART®

Communication a minimum 250 Ohm loop resistance is mandatory.

1.3.Software Compatbility

Autrol® Smart Pressure Transmitters are shipped from the factory with the

most up to date firmware. However, as product developments and new

features are released a firmware update becomes necessary to incorporate

these new changes. Transmitters with older firmware may restrict certain

functions when communicating with local pusgbuttons and/or an external

HHT(Model 275 /375 or 465 HART® Communicator).

•Supported.ⅹ: Not Supported∆: Supported but updated FDR5 DDL required

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

5

APT

APT3200

APT3200

APT3200

APT3200

In this case contact AAI for a recommended firmware update or uselatest FDR

DDL (Device Description Library) to ensure compatibility of the transmitterwith

connected HHT, PDM etc.

Important Note: There may also be some differences in supported functions on

the local push button menu based on the installed firmware revision of the

transmitter. This manual is based on Firmware Revision 7.0 and higher. Actual

firmware revision installed on transmitters can be identified by

(a)Firmware version printed on neck plate (below LCD module) .

(b)On LCD display imemdiately during initial power up/Boot up sequence.

(c)Via HHT or HART® UMPC in Info menu.

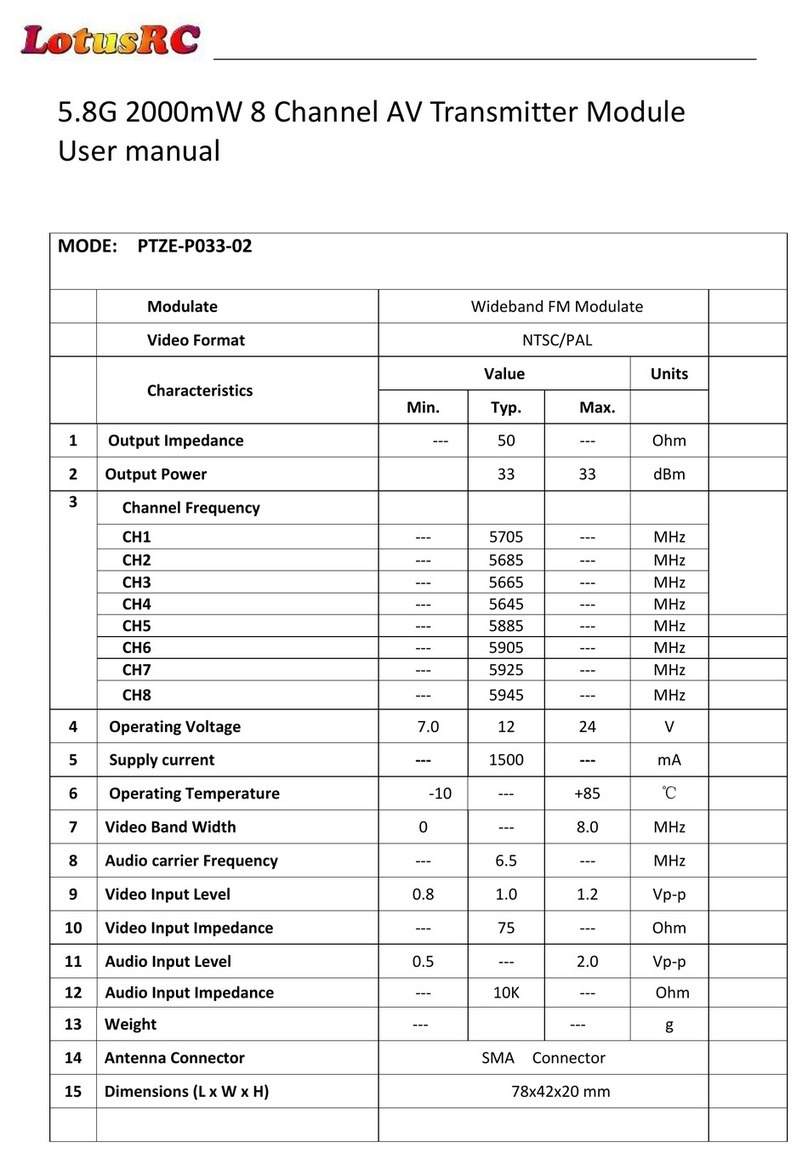

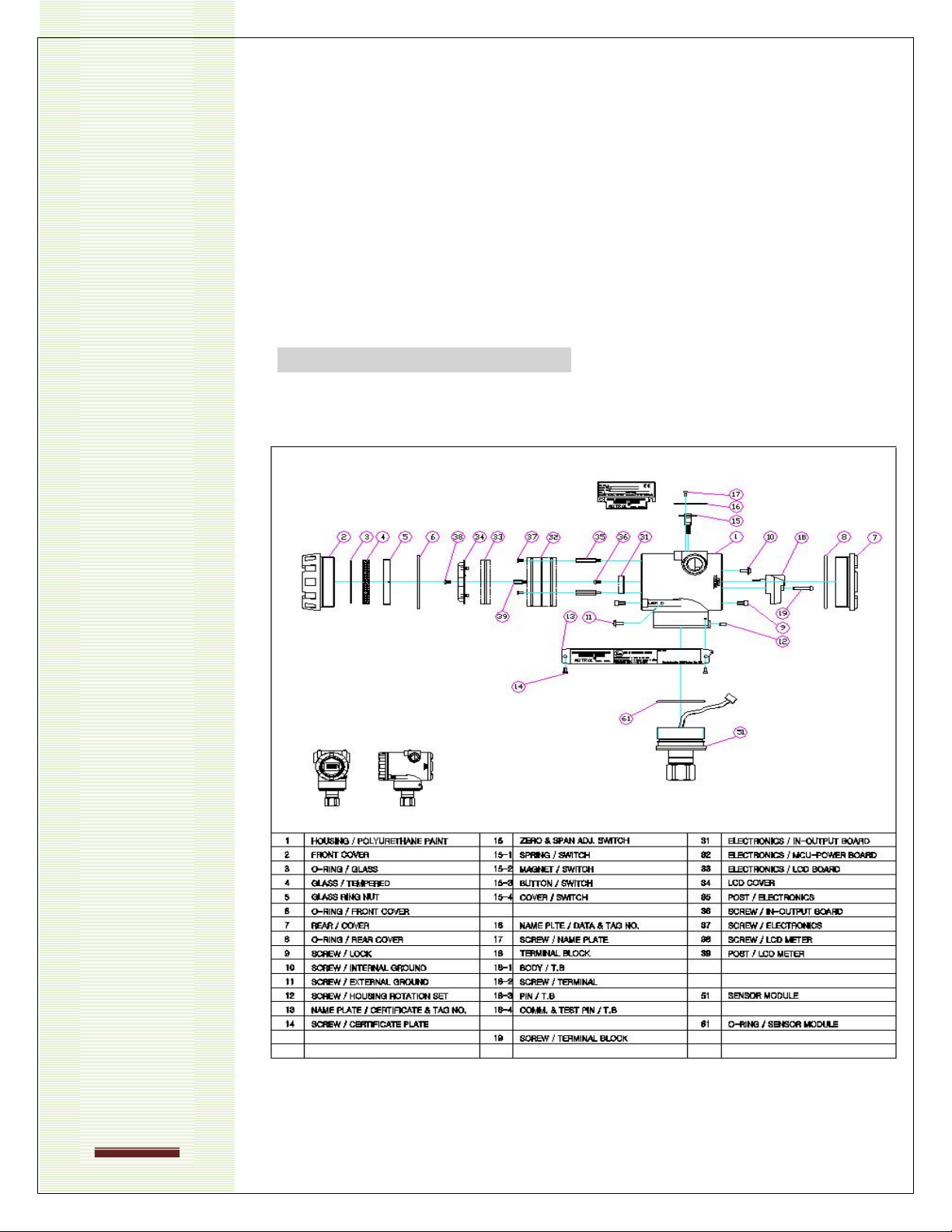

1.4.Transmitter Components

The various components of an Autrol® APT 3200 Series Smart Pressure

Transmitter are shown in Figure 1-1 below.

Figure 1-1. Model APT3200 Transmitter Exploded View

APT3200

6

Operation Manual:110210-3200-OM01v7x AUTROL® Series

Chapter 2 Handling

This chapter includes instructions for transmitter handling, storage, selection of

appropriate installation locations, insulation and cautions for hazardous area

installation.

[Quick Reference Table 2.0]

Step

Job

Job Details

Instrument

1

Unpacking

-Unpack transmitter from its packing

As applicable

2

Model and

Specifications

Check

-Make sure the delivered transmitter is same as

ordered and meets application requirements

Visual

Nameplate

3

Storage

-Please do not expose to rain, water, high humidity,

excessive vibration and high-impact areas

-Store under ambient temperature 70F and relative

humidity 65% RH

None

4

Bench

Calibration

- Configuration of Range, Zero/Span, Unit, Tag,

Damping Time, Transfer Function, DA Trim and other

parameters.

HHT/ Pressure

calibrator-(if

available)

- Ammeter for

output trimming.

5

Installation

Locations

-Where ambient temperature is not fluctuating.

-Where chemical corrosion is minimal.

-Where vibration and impact is not severe

-Where hazardous area is matched with explosion

proof classifications defined by local regulatory

bodies.

-Where maintenance access is easy

(Engineering)

6

Mechanical

Considerations

-Where transmitter can be handled easily

-Be cautious of pressure leaks.

(Engineering)

7

Electrical

Considerations

-Connect 24 Vdc (Recommended power supply is

11.9 Vdc –45 Vdc)

-For HART® communication, total resistance on

transmitter terminal loop should be 250 –550

Ohm.

(Engineering)

8

Mounting and

Installation

-For mounting transmitter, an appropriate bracket

(BA or BF type) should be used.

-Transmitter should be fixed firmly to its bracket.

(Mounting and

Installation)

9

Calibration

upon

installation.

-Sensor Zero Trim is highly recommended during

first installation and start-up. During a Zero trim the

zero baseline of transmitter is established.

-Before initiating zero trim make sure that PV value

of transmitter is zero and current output is at 4 mA.

Local Zero/Span

button or HHT

10

Pressure

-Do not apply differential and/or full line pressure

suddenly.

-Close equalizing valve of 3/5 valve manifold, then,

open stop valve on high and low side slowly and

simultaneously.

(Manual)

11

Operation

- Verify transmitter is operating within specifications.

Visual or HHT

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

7

APT

APT3200

APT3200

APT3200

APT3200

2.1.Unpacking

When moving the transmitter to the installation site transfer it in its original

packaging. Only unpack the transmitter on site of installation to avoid damage

during transit.

2.2.Models and Specifications Check

The model name and specifications are indicated on the top nameplate fixed

to the transmitters. Please check your specification and model supplied for

your installation. Please ensure LRL (Lower Range Value) / URL (Upper

Range Value), min/max span specifications and MWP (Max. Working Pressure)

of sensor range codes are in line with your application requirements.

2.3.Storage

The following precautions must be observed when storing the instrument,

especially for long periods.

(1)Select a storage area that meets the following conditions:

a)It is not directly exposed to rain, water, snow or sun light.

b)It is exposed to minimum vibration and shock.

c)If possible, it is advisable to store at normal temperature and

humidity (approx. 70°F, 65% RH). However, it can also be

stored under ambient temperature and relative humidity within

the following published ranges.

Ambient Temperature:-40 ~ 85°C (without LCD) * or-

30 ~ 80°C (with module)*

* General use only. For explosion proof versions follow

product certification reqmts.

Relative Humidity: 5% ~ 98% RH (at 40°C)

(2)When storing the transmitter, repack with original (or similar)

packaging that was shipped from the factory.

(3)If storing a transmitter that has already been used, thoroughly clean

all wetted parts including diaphragm seals (if installed), process

connections/manifolds in contact with process fluid. In addition, make

sure before storing the transmitter that remote seal (if supplied)

assemblies are securely mounted.

2.4.Selecting a Suitable Location for Installation

The transmitter is designed to withstand severe environmental conditions.

However, to ensure stable and accurate operation for extended years, the

following precautions must be observed when selecting an installation location.

(1)Ambient Temperature:

Avoid locations subject to wide temperature variations or a significant

temperature gradient. If the location is exposed to radiant heat from

plant equipment, provide adequate insulation or ventilation.

(2)Ambient Atmosphere

Avoid installing the transmitter in a corrosive atmosphere. If the

transmitter must be installed in a corrosive atmosphere, there must be

adequate ventilation as well as preventive measures to minimize

intrusion or stagnation of rainwater or condensation build up through

its electrical conduits. Moreover, there should be appropriate

precautions taken to prevent corrosion build up due to condensation or

moisture collected within conduits and terminal boxes over extended

APT3200

8

Operation Manual:110210-3200-OM01v7x AUTROL® Series

periods of operation. Inspect periodically as required.

(3) Shock and Vibration:

Select an installation site subject to minimum shock and vibration.

Although the transmitter is designed to be relatively resistant to shock

and vibration, we highly recommend following good engineering

practices.

(4) Installation of Explosion Proof rated Transmitters

Explosionproof rated transmitters must be installed in hazardous areas

according to the area classification for which they are certified.

(5) Accessibility

Select location that provides easy access formaintenance & calibration.

(6) Selecting Power supply

Ensure proper supply voltages are calculated per maximum available

load and minimum required voltage requirements across supply input

of a two wire transmitter to avoid “loop loading” issues.

(7) Grounding

Select proper grounding techniques to avoid ground loops and

external noise influences.

2.5.Performing Sensor Zero Trim after Installation

(1) Sensor Zero Trim should be done immediately after transmitter is

installed because zero point can shift due to mounting status of the

sensor pick up. This can be done using local push buttons provided

on top of transmitter housing (underneath the SS nameplate)

(2) For Sensor Zero Trim, make input pressure of transmitter zero prior to

initiating zero trim calibration. Any Sensor Trim done in field must be

carried out after installation is finalized and with transmitter position

fixed. Also, if applying external pressure source (recommended for

absolute models only) ensure the display is sufficiently stabilized

(after approximately 10 to 15 seconds) before initiating any Trim

function.

(3) There are two recommendations for making input pressure “zero”.

One is to apply a “zero” pressure source (mandatory for absolute

pressure models). The second option is to open equalizing valve of

manifolds and venting to atmospheric pressure (allowed only for

Gauge type models).

(4) Sensor Zero Trim can be performed using an external HHC (Hand

held calibrator), PC or PDA configurator, and/or using Zero/Span local

push buttons provided on the transmitter.

(5) When using local push buttons please refer to Chapter 3.7 of this

manual for detailed instructions. If using an external HHT or HART®

PC configurator please refer to the user manuals supplied by the third

party supplier.

2.6.Pressure Connection

▲ Warning

◈Instrument installed in the process is under presure. Never loosen or tighten the

flange bolts as it may cause leakage of process fluid.

◈If the process fluid may be toxic or otherwise harmful, take approriate care to

avoid contactand/or exposure to direct vapors even after dismounting the

instrument from process line for maintenance.

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

9

APT

APT3200

APT3200

APT3200

APT3200

Standard Process connection is ½” NPT. Optional ¼”NPT Process connection

is available with use of adapters (O option) if ordered with the transmitter.

The following precautions must be observed in order to safely operate the

transmitter under pressure.

(1)Never apply a pressure higher than the maximum working pressure

specified on the nameplate.

(2)Use adequate seals for leak tight process connections and use only

quality and standardized parts.

(3)Regularly inspect for signs of leakage and apply corrective actions

when necessary.

2.7.Waterproofing of Cable Conduit Connections

Apply a non-hardening sealant (viz. silicone or Teflon tape, etc.) to the threads

to water proof the cable conduit entry connections.

2.8.Restrictions on Use of Radio Transceivers

▲ Warning

◈Although the transmitter has been designed to resist high frequency electrical

noise, if a radio transceiver is used near the transmitter or its external wiring, the

transmitter may be affected by high frequency noise pickup. To test for such

effects, bring the transceiver in use slowly from a distance of several meters from

the transmitter, and observe the measurement loop for noise effects. Thereafter,

always use the transceiver outside the area affected by noise.

2.9.Insulation Resistance Test and Dielectric

Strangth Test

All APT series transmitters are subjected to insulation resistance and dielectric

strength tests (at the factory) prior to shipment. Normally these tests are not

required to be duplicated in field. However, if required, observe the following

precautions in the field test procedures.

(1)Do not perform such tests more frequently than is absolutely

necessary. Even test voltages that do not cause visible damage to the

insulation may degrade the insulation and reduce safety margins.

(2)Never apply a voltage exceeding 500 Vdc (100 Vdc with an internal

lightning protector--LP option) for insulation resistance test, or a

voltage exceeding 500V AC (100V AC with an internal lightning

protector option) for dielectric strength tests.

(3)Before conducting these tests, disconnect all power and signal lines

from the transmitter terminals. Follow procedures outlined below to

initiate these tests.

I. Insulation Resistance test

a)Short the (+) and (-) SUPPLY terminals inside the transmitter

terminal box.

b)Turn OFF the insulation tester. Then connect the insulation

tester positive (+) lead wire to the shorted SUPPLY terminals

on the transmitter and the negative (-) lead wire of tester to

the ground terminal on transmitter.

APT3200

10

Operation Manual:110210-3200-OM01v7x AUTROL® Series

c) Turn ON the insulation tester power and measure the

insulation resistance. The voltage should be applied for a

short duration sufficient enough only to verify that insulation

resistance measured is at least 20 MΩ.

d)After completing the test and being very careful not to touch

exposed conductors disconnect the insulation tester and

connect a 100kW resistor between the grounding terminal and

the short-circuiting SUPPLY terminals. Leave this resistor

connected for at least three seconds to discharge any static

potential. Do not touch the terminal while it is discharging.

II. Dielectric Strength Test

a)Short-circuit the (+) and (-) SUPPLY terminals marked in

the terminal box.

b)Turn OFF the dielectric strength tester. Then connect the

tester between the shorted SUPPLY terminal and the

ground terminal of transmitter.

c) Be sure to connect the grounding lead of the dielectric

strength tester to the ground terminal.

d)Set the current limit on the dielectric strength tester to

10mA, then turn ON the power and gradually increase the

tester voltage from '0' to the specified voltage. When the

specified voltage is reached, hold it for one minute.After

completing this test, slowly decrease the voltage to avoid

any voltage surges.

2.10.Installtion of Explosion Proof Transmitters in

Classified Areas

Installation

All wiring shall comply with local installation requirements.

Cable Glands shall be suitable for the environment and shall be

certified as explosion proof.

Unused conduit openings shall be properly sealed with certified

metallic plugs.

Grounding procedure must be followed in compliance with “local

electrical codes”. Recommended: use a qualified grounding earth

with least impedance.

Grounding options:

Internal Ground Connection: An Internal ground connection screw is

located inside the terminal housing accessible by opening the rear

cover. The ground screw can be easily identified from its ground

symbol marking.

External Ground Lug: This is located on the right side of housing and

accessible from outside. This ground screw can also be easily

identified from its ground symbol marking.

When using metallic conduits, stuffinging boxes/glands must be used.

All Cable Glands must be certified as explosion proof for area

classification.

Conduit thread must be engaged with a minimum of 5 thread

connections.

Process Connection should also be engaged with a minimum of 7

thread connections and housing rotation set screw (below front cover)

tightened to prevent housing from rotating.

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

11

APT

APT3200

APT3200

APT3200

APT3200

Operation

Wait one minute after disconnecting power before opening the

enclosure.

Take care not to generate mechanical sparks when accessing the

instrument and peripheral devices in a hazardous location.

Maintenance and Repair

Instrument modification or parts replacement by other than authorized

factory representatives is prohibited and will void flameproof

certification.

2.10.1.KOSHA Certification

Caution for KOSHAFlameproof is following type.

[Note1]Model APT3200 sealed for potentially explosive atmosphere:

Type of Protection and Marking Code: Ex d ⅡC T6

Temperature Class: T6

Ambient Temperature: -20 ~ 60'C

Process Temperature: Max. 80'C

[Note2]Electrical Data

Supply Voltage: Maximum 45 Vdc

Output signal: 4 ~ 20mA, maximum 22mA

2.10.2.KEMA/ATEX Certification

ATEX Certification number : KEMA05ATEX2244

CE XXXX II 2 G

Note 1. Model APT3200 for potentially explosive atmosphere

Ex d IIC T6

Operating Température : -20℃≤

Note 2. Electrical Data

Supply Voltage : 45 Vdc Max

Output Signal : 4 to 20 mA + HART®

Note 3. Electrical Connection: 2 x 1/2-14NPT Female

Note 4. APT3200 ATEX Certification is according to the below

standards EN 60079-0

EN 60079-1

2.10.3.Factory Mutual (FM)USA Certification to NEC Codes

HAZARDOUS LOCATION ELECTRICAL EQUIPMENT

APT3200-abclgjkm. Pressure Transmitters.

APT3200-abcdefgijklm. Pressure Transmitters.

APT3200-abcdfghiklm. Pressure Transmitters.

XP/I/1/ABCD/T6 Ta = 60℃;

DIP/II, III/1/EFG/T6 Ta = 60℃;

APT3200

12

Operation Manual:110210-3200-OM01v7x AUTROL® Series

NI/I/2/ABCD/T4 Ta = 60℃;

S/II/2/EFG/T4 Ta = 60℃;

S/III/1/T4 Ta = 60℃;

Type 4X/IP67.

a = Transmitter Type D, G, H, LEC, LED, LES, LFC, LFD or LFS.

b = Ranges : 3, 4, 5, 6, 7, 8 or 9.

c = Mounting Flange Size & Material : C1, C2, C4, M11, M12, M13,

M14, M21, M22, M23, S2, S3 or S4

d = Mounting Flange Rating :A1, A2, D1, D2, J1, J2 or XX.

e = Extention Length : 05, 10, 15 or XX.

f = Wetted Parts Material : H, S or X.

g = Fill Fluid : 1, 2, 7 or X

h = Capillary Length : 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11 or 12.

i = Material of Construction : CS or SS.

j = Low Side : N, W or X.

k = Electrical Connection : 1.

l = Hazardous Location Certification : F1.

m = Option : BA, BF, C6, CA, CF, K, M1, P, S or TW.

Equipment Rating :Explosionproof for use in Class I, Division 1, Groups

A, B, C &D; Dust-Ignitionproof for Class II, Division 1, Groups E, F and

G; Nonincendive for use in Class I, Division 2, Groups A, B, C and D;

Suitable for use in Class II, Division 2, Groups E, F and G; and Suitable

for Class III, Division 1; Hazardous(classified) location, indoor and

outdoor (NEMAType 4X/IP67).

2.10.4.FM Canada Certification confirming to CSA Standards

HAZARDOUS LOCATION ELECTRICAL EQUIPMENT

APT3200-abclgjkm. Pressure Transmitters.

APT3200-abcdefgijklm. Pressure Transmitters.

APT3200-abcdfghiklm. Pressure Transmitters.

XP/I/1/ABCD/T6 Ta = 60℃;

DIP/II, III/1/EFG/T6 Ta = 60℃;

NI/I/2/ABCD/T4 Ta = 60℃;

S/II/2/EFG/T4 Ta = 60℃;

S/III/1/T4 Ta = 60℃;

Type 4X/IP67.

a = Transmitter Type D, G, H, LEC, LED, LES, LFC, LFD or LFS.

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

13

APT

APT3200

APT3200

APT3200

APT3200

b = Ranges : 3, 4, 5, 6, 7, 8 or 9.

c = Mounting Flange Size & Material : C1, C2, C4, M11, M12, M13,

M14, M21, M22, M23, S2, S3 or S4

d = Mounting Flange Rating :A1, A2, D1, D2, J1, J2 or XX.

e = Extention Length : 05, 10, 15 or XX.

f = Wetted Parts Material : H, S or X.

g = Fill Fluid : 1, 2, 7 or X

h = Capillary Length : 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11 or 12.

i = Material of Construction : CS or SS.

j = Low Side : N, W or X.

k = Electrical Connection : 1.

l = Hazardous Location Certification : F1.

m = Option : BA, BF, C6, CA, CF, K, M1, P, S or TW.

Equipment Rating : Explosionproof for use in Class I, Division 1,

Groups A, B, C &D; Dust-Ignitionproof for Class II/III, Division 1,

Groups E, F and G; Nonincendive for use in Class I, Division 2, Groups

A, B, C and D; Suitable for use in Class II, Division 2, Groups E, F and

G; and Suitable for Class III, Division 1; Hazardous(classified) location,

indoor and outdoor (NEMAType 4X/IP67).

2.11.EMC Conformity Standards

EMI (Emission): EN55011

EMS (Immunity): EN50082-2

AAI recommends that customer follow installation requirements conforming to

EMC Regulations or to plant standards.

APT3200

14

Operation Manual:110210-3200-OM01v7x AUTROL® Series

Chapter 3 Transmitter Functions

2.

3.1.Overview

This chapter includes instructions to facilitate pre-installation set up

procedures for an AUTROL®APT series SMART Pressure transmitter. Tasks

that can be performed on the bench prior to installation in the field are also

explained in this chapter.

3.2.Safety Message

Procedures and instructions in this chapter may require special precautions to

ensure the safety of the personnel performing these operations. Information

that raises potential safety issues is indicated by warning symbol (▲). Refer to

the following safety messages before performing an operation preceded by

this symbol.

3.3.Warning

▲ Warning

Electrical shocks can result in death serious injury:

◈Avoid contact with the leads and terminals. High voltage that may be present on

leads can cause electrical shock.

◈Only qualfied & trained personnel should be allowed to operate these

transmitters

▲ Warning

Explosions can result in death or serious injury:

◈Do not remove the transmitter covers in hazardous locations when the circuit is

live.

◈Transmitter covers must be fully engaged to meet explosionproof approval

requirements.

3.4.Fail Mode Alarm

AUTROL® Smart Pressure Transmitter automatically performs real time self-

diagnostic routines and displays any error codes on its local LCD (Liquid

Crystal Display) (M1 option if ordered) that can be used for troubleshooting. In

addition to this, the self-diagnostic routines are also designed to drive

transmitter current output outside of the normal saturation values in case a

fault mode is detected. The transmitter will drive its current 4/20mA output low

(down) or high (up) based on the position of the failure mode alarm jumper(or

DIP switch) configuredin line with NAMUR requirements. See Table 3.1 for

available Current Output values.

[Table 3-1 StandardAlarm and Saturation Value]

Level

4~20mA Saturation

4~20mA Alarm

Low/Down

3.9 mA

≤ 3.75 mA

High/Up

20.8 mA

≥ 21.75 mA

Note: When connecting multiple transmitters in HART® multidrop mode the

current output is automatically parked at 4mA. In such installations Fail Mode

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

15

APT

APT3200

APT3200

APT3200

APT3200

Alarm on Current output is automatically disabled; however, error indication is

still available via digital HART® communication as a Status Flag.

Fail Mode Selection (Fail High/UP or Low/DOWN) can be configured using the

appropriate jumper switch provided on the LCD Module or DIP switches

included on the Main CPU Module. For units provided with a LCD module one

can select desired fail safe mode directly from the jumper switch included in

the front display and this setting overrides the DIP settings on the back-end

Main CPU module. However, in the case of blind units please select your

required DIP switch settings from the DIP switch labeled (2) marked on the

Main CPU board. Recommended jumper & DIP settings are listed in Table 3-2

below for ready reference. To move jumper, pull out, then move to new

location and push in.

[Table 3-2 Jumper/DIP settings for Fail Mode Selections]

Selected Fail

Mode

Jumper status on LCD and

DIP Switch (2) on CPU

Module

DIP Switch (2)

setting on CPU

Module

CPU Module

LCD Module

Fail Down

Down

D

Down

Fail Up

Down

U

Up

Up

U or D

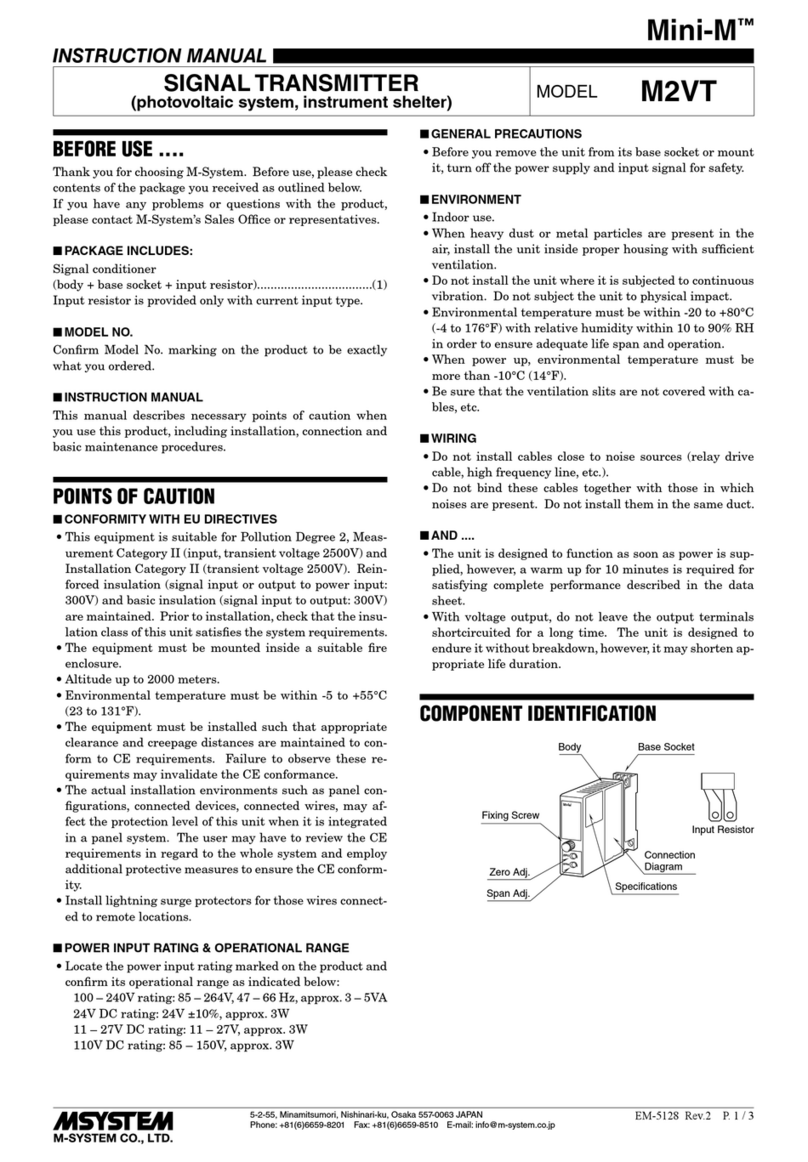

3.4.1.< Fail Mode Selection Jumper Switch of LCD Module >

Figure 3-1 Fail Mode Selection Jumper Switch of LCD Module

U

O

O

O

D

Fail Mode Select

Jumper Switch

APT3200

16

Operation Manual:110210-3200-OM01v7x AUTROL® Series

FAIL MODE UP –

(place jumper to left)

U

O

O

O

D

FAIL MODE DOWN –

(place jumper to right)

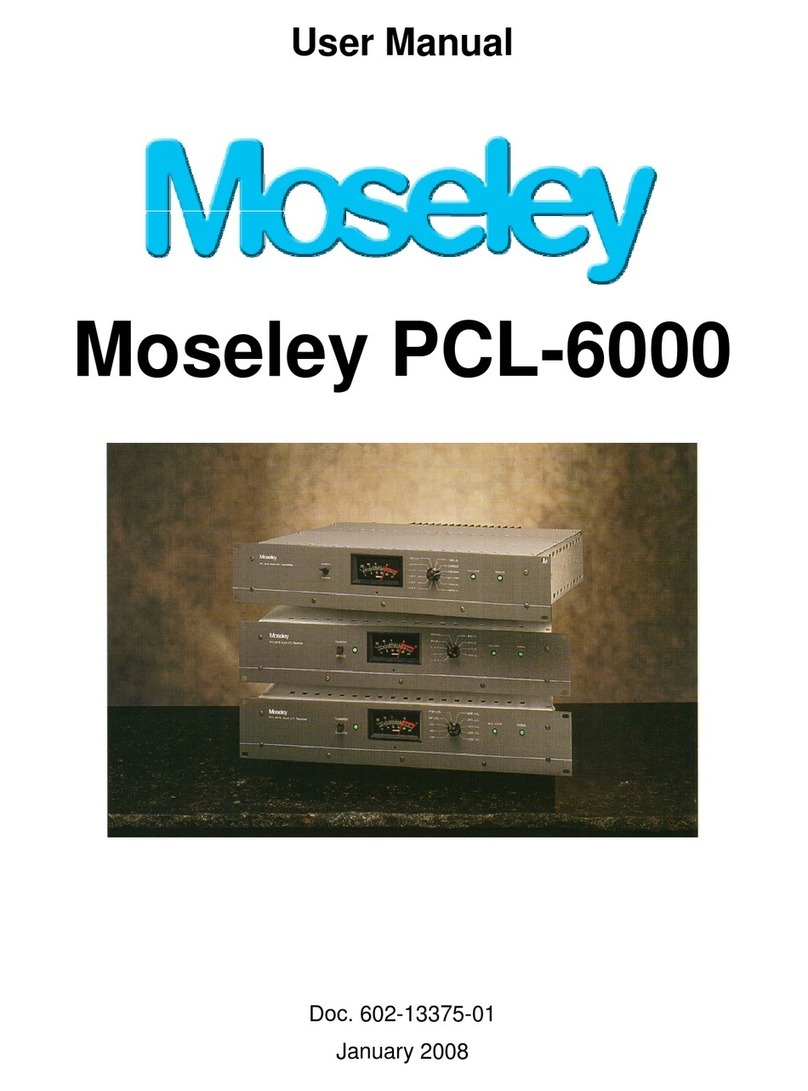

3.4.2.<Fail Mode Selection DIP Switch on CPU Module >

Figure 3-2. Fail Mode Selection DIP Switch location on CPU Board

Note: Use DIP switch (2) on right shown in Fig 3-4 for Fail Mode

Selection. DIP Switch (1) on Left in Fig 3-4 is for Write Enable/Disable

explained in Chapter 3.5 below.

DIP SWITCH SETTINGS (Fig 3.4)

DIP (2) = Fail Mode(Alarm)

DOWN : FAIL LOW

UP : FAIL HIGH

CPU Module DIP Switch #

(1) EEPROM Write Selection

(2) Fail Mode Selection

Operation Manual:110210-3200-OM01 V7x AUTROL®Series

17

APT

APT3200

APT3200

APT3200

APT3200

3.5.EEProm-Write Enable/Disable Mode Switch

APT 3200 includes an EEPROM (Electrically Erasable Programmable Read

Only Memory) that allows saving and restoring various configuration data

within the transmitter on power failure. To lock configuration and protect

tchanges to stored configurationdata one can use a HHC and/or external

HART® enabled PC device to enable a software lock feature under Status

menu. Optionally, for security lock on hardware side there is a Write-Protect

Mode DIP Switch(1)on the Main CPU Module placed right next to the Fail Safe

Mode switch (2). If you push this DIP switch to UP you can lock out users from

making any changes to configuration data already saved in the EEPROM

using push buttons and/or remote HHT. Alternatively, when you push DIP

Switch(1) to DOWN you can allow changes made to configuration data in

EEPROM. Default state from factory (including with no jumper installed) is EN

(enable configuration changes).

Figure 3-3. CPU Module EEPROM-Write Selection Jumper Switch location

Note: Use DIP Switch (1) shown on Left in Fig 3-4 is for Write Enable/Disable

selection DIP switch (1)shown on right in Fig 3-4 is for Fail Mode Selection as

explained in earlier Chapter 3.4.

CPU BOARD DIP SWITCH SETTINGS (Fig 3-4)

DIP(1) = WR_EN (EEPROM Write Enable)

DOWN : ENABLE CONFIGURATION CHANGES

CPU Module DIP Switch #

(1) EEPROM Write Selection

(2) Fail Mode Selection

APT3200

18

Operation Manual:110210-3200-OM01v7x AUTROL® Series

UP : DISABLE /LOCK CONFIGURATION CHANGES

3.5.1.Security

To quickly summarize there are three options available to implement

configuration security lock out within theAPT 3200. These include:

(1)DIP settings on CPU Board

(2)Software enable/disable on Write function using HHT or

HART® PC.

(3)Physically removing Zero and Span Magnetic Push Buttons

from Transmitter thereby restricting local access to pushbutton

menus. This option will still allow changes via a remote HHT or

HART enabled configurator.

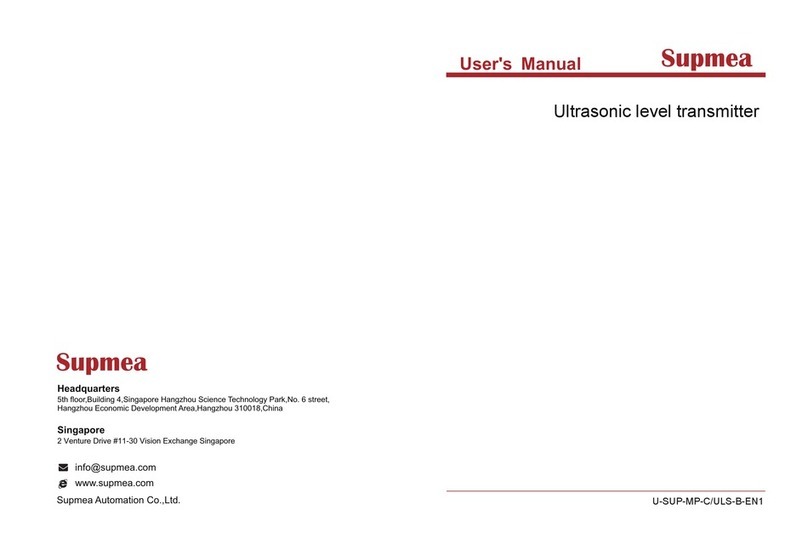

3.5.2.Zero and Span Magnetic Push Buttons

[Figure 3.5.2 Transmitter Zero/Span configuration Buttons]

To access pushbuttons please remove top nameplate to expose the

magnetic style push buttons labeled zero/span. To disable please

unscrew center retaining screw and remove these push buttons as a

module. As these are magnetic style, this will not compromise the

explosion proof integrity of housing.Access to push buttons is allowed

in a hazardous area without disconnecting power to the transmitter.

3.6.Configuration of Alarm and Security Jumper

Procedures

To change Jumper/DIP switch position in field:

1) If transmitter is already wired and installed, cut off power.

2) Open the housing front cover. Warning: In hazardous areas

DO NOT open the covers of Transmitter when power is

energized as this can create a potential dangerous situation.

Always kill power

and

De-energize the transmitter prior to opening front OR back

covers in a hazardous location.

Zero/Span

Buttons

Jumper 스위치

Other manuals for APT3200 Series

2

Table of contents

Other Autrol Transmitter manuals

Autrol

Autrol APT 3100 Series User manual

Autrol

Autrol ALT-6100 Series User manual

Autrol

Autrol APT 3000 Series User manual

Autrol

Autrol APT 3100 Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol ATT2100 User manual

Autrol

Autrol ATT Series User manual

Autrol

Autrol APT3200 Series User manual

Popular Transmitter manuals by other brands

Inovonics

Inovonics EN1223S EchoStream Installation and operation manual

Evikon

Evikon PluraSens E2638-N2O user manual

AMC

AMC WiFi Wireless Transmitter TR1a Instructions for installation and operation

Siemens

Siemens SITRANS P series Compact operating instructions

Rosemount

Rosemount 3108 Reference manual

Sennheiser

Sennheiser SR 300 IEM manual