Autrol ALT-6100 Series User manual

O

p

eration Manual

O

p

eration Manual M6100-K01D

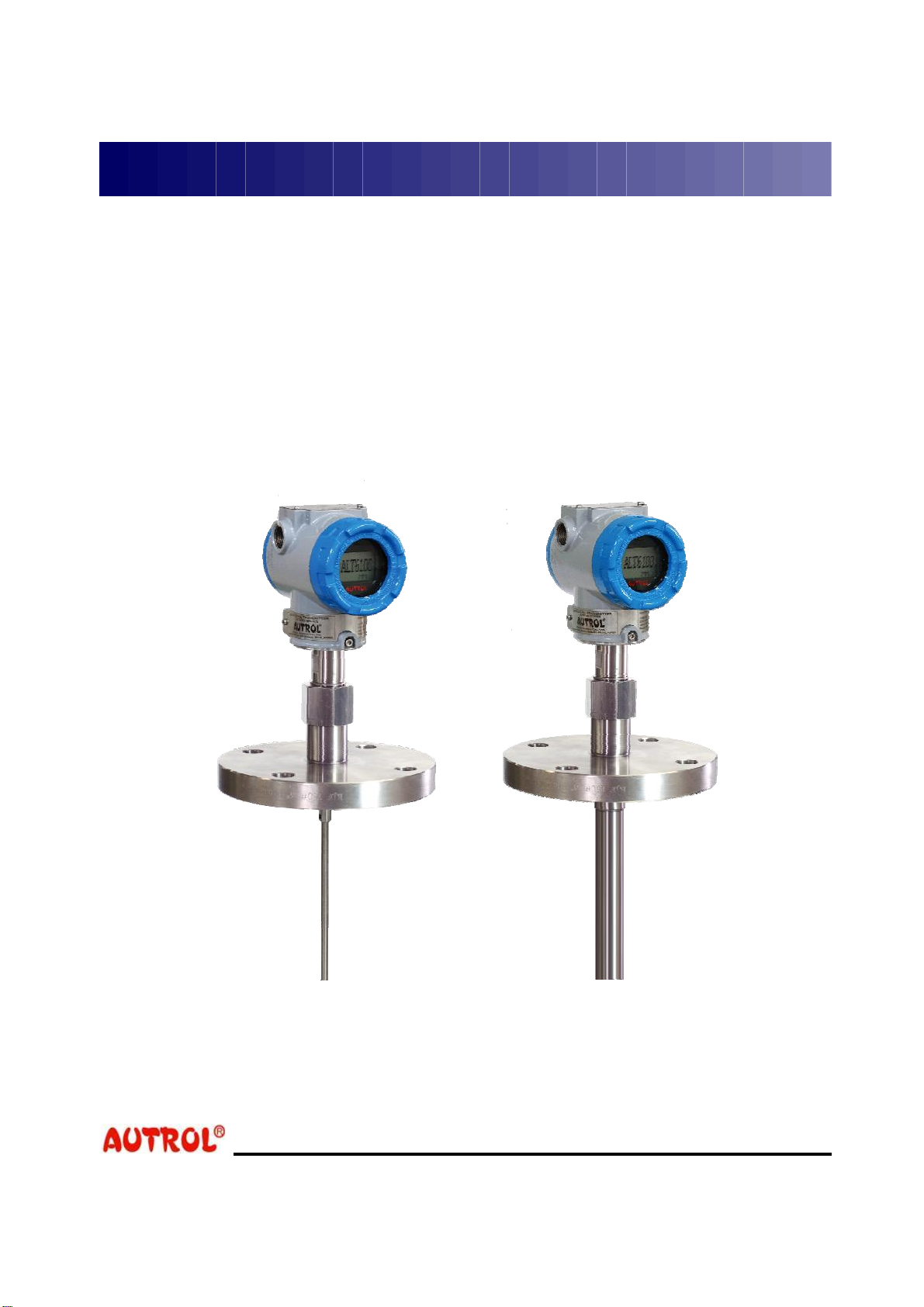

ALT-6100

ALT-6100

Series

Series

Smart Guided Wave Radar Level Transmitter

Smart Guided Wave Radar Level Transmitter

since 1989

두 온 시 스 템 (주)

Duon System Co., Ltd. www.autrol.com

Notice

This document was prepared for efficient handling of

ALT-6100, such as installation and use.

Prior to handling ALT-6100, read and understand this

document sufficiently.

The information and specification included in this

document may change without prior notice.

Ownership and copy right of this document belong to

Duon System Co., Ltd., and reprint without permission,

modification, and distribution without permission are

prohibited.

Table

Table

Table

Table

Table

Table

Table

Table

Table of

of

of

of

of

of

of

of

of Contents

Contents

Contents

Contents

Contents

Contents

Contents

Contents

Contents

Table of Contents

Duon System Co., Ltd.

1 Introduction 1

Manual Composition 1

Technical Support 2

2 Transmitter Overview 3

Operation Principle 3

Features 4

Application 4

Transmitter component 4

System Composition 6

3 Directions for Handling 7

Unpacking 7

Checking Model and Specification 7

Storage 7

Selection of Installation Location 7

4 Installation 9

Precautions 9

Preliminary Examination before Installation 9

Installation on Nonmetal Vessel 11

Installation on Concrete 12

Solid Measured Medium 12

Installation on Bypass Pipe 12

Liquid Measured Medium 13

Transition Zones 14

Housing Rotation and Lock Screw 15

Mounting 15

Probe Fixing 17

Housing extension cable installation 17

5 Electrical Installation 19

Directions for Wiring 19

Cable Material Selection 19

Conditions of Power Supply Voltage and Load Resistance 20

Power Supply Examination for Transmitter replacement 21

Transmitter Wiring 21

Test Terminal 23

Loop Composition 23

Wiring 25

Installation 25

Earth 28

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

www.autol.com

6 Configuration 29

Parameters for Level Measurement 29

Distance 30

Level 30

Tank Height 30

Level Adjustment 30

Probe Length 30

Probe Angle 30

Analog Output 30

Output Unit Set-up 31

LCD Engineering Mode 31

Level Set-up Excercise 33

Damping Time Set-up 33

Transmitter Information Set-up 34

Fail Mode Alarm Set-up 35

EEPROM Write Enable 36

Function and Set-up using Button 37

Numeric Input Method 40

Alphabetic Input Method 40

Execution Excercise for each Function 41

Set-up Function Method and Difference 52

PV is changed 52

Tank Height Change 52

7 Maintenance 53

Calibration 53

D/A Trim 54

Loop Test 54

Hardware Maintenance 54

Hardware Failure Diagnosis 57

Appendix I 58

1

1

1

1

1

1

1

1

1

1 Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Duon System Co., Ltd. 1

1 Introduction

Manual

Composition

This manual contains contents of Installation /Operation /Maintenance

necessary for optimal use of ALT-6100.

Transmitter may be affected by the ambient conditions of installation.

Hence, read and understand this manual completely prior to installation and

activation.

WARNING

◈ Educated and qualified personnel only are authorized to install

Transmitter.

◈ It is very dangerous and may cause accident for the un-

authorized to handle Transmitter.

◈ When the Transmitter power is on, do not open the Transmitter

cover under Explosive Atmospheres.

◈ Prior to connecting HHT under Explosive Atmosphere, check if

measurement equipments connected to power-line is installed in

accordance with intrinsic safety regulations.

◈ Avoid contact between power-line and terminal. High voltage of

lead wire may cause electric shock.

This Operating Manual explains contents necessary for installing, activating,

and maintaining ALT-6100.

Chapter 2: This chapter describes understanding, features, and system

composition of the Guided Wave Radar Level Transmitter.

Chapter 3: This chapter describes mostly core items from purchasing

Transmitter to its site installation including directions for handling

and storage of Transmitter, selection of installation location, and

insulation, and flameproof structure.

Chapter 4: This chapter describes installation work and procedure, design

drawing, and considerations at installation of Transmitter.

Chapter 5: This chapter describes electrical installation work and procedure,

wiring method and drawing, and other electrical considerations of

Transmitter.

Chapter 6: This chapter describes the function and method to set up

Transmitter, Button manipulation, and Electronic Circuit Module

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

2 www.autol.com

set-up.

Chapter 7: This chapter describes failure diagnosis and maintenance of

Transmitter.

1

1

1

1

1

1

1

1

1

1 Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Introduction

Duon System Co., Ltd. 3

Technical

Support

For technical support to Transmitter, all ways are possible including

telephone or ON/OFF Line, and for detailed contact address of each

service area, refer to www.autorol.com

Company Head Office Address

Tel. : 02) 860-7900

Address : Duon System Co., 60-31, Gasan-dong,

Deuncheon-gu, Seoul

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

4 www.autol.com

2 Transmitter Overview

Operation

Principle

ALT-6100 Smart GWR Level Transmitter (Autrol® Smart Guided Wave Radar

Level Transmitter) is the micro-processor based Transmitter, and measures

level based on TDR (Time Domain Reflectometry) technology. It has the

function to print out a measured value as 4~20mA analog current in the

2-wire type or a digital value by HART communication, and transmit it to

be used by control system such as DCS or PLC.

The pulse generated by Transmitter is transmitted through probe and

reflected at the surface of the measured material to come back. Here, the

back and forth time from when the pulse was transmitted to when it is

received after reflection is measured and converted to distance and level.

Reflection of pulse occurs due to the difference of dielectric constant

between air and measured material, and the reflected pulse strength is

proportional to dielectric constant. Hence, as dielectric constant of

measured material is higher, stable measurement is possible.

24 VDC, 4-20mA

Loop Powered

Transmit

Pulse

Air dk = 1

Media dk > 1.4

A small amount of energy

continues down the probe

in a low dielectric fluid,

e.g. hydrocarbon

A reflection is

developed off

the liquid surface

[Figure 2-1] Measurement Method

2

2

2

2

2

2

2

2

2 Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter Overview

Overview

Overview

Overview

Overview

Overview

Overview

Overview

Overview

2 Transmitter Overview

Duon System Co., Ltd. 5

Transmitter

Component

Features

Application

• High precision of +/- 3mm.

• Materials of very low dielectric constant of 1.4 such as butane and LNG

are measurable.

• Usable in both Liquid and Solid.

• This is direct measurement method of Top-down, and not affected by

state change of process ( density, conductivity, temperature, pressure,

humidity etc...).

• Effects of dust, vapor, and turbulence are minimized.

• Because signal is guided, this is not affected by disturbance and Tank

Structure.

• Easy Calibration and Maintenance.

• Oil, gas and refining

• Chemical and petrochemical

• Power

• Pulp and paper

• Water and sewage treatment

• Food and beverage

• Pharmaceutical

Components of ALT-6100 are shown in the Figure below.

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

6 www.autol.com

Probe

Rotation Lock

Screw

Cover Lock Screw Cover Lock

Screw

Front Cover Rear Cover

Certification Label

Conduit connection

Nameplate

Conduit connection

Digital Indicator

(Optional)

Housing Lock

Screw

[Figure 2-2] Composition of the Transmitter Exterior

• Loosening and taking out Cover Lock Screw, you can fix Front and Rear

Cover not to be loosened.

• Tightening Rotation Lock Screw, you can fix housing not to be rotated,

and to rotate housing you have to loosen Rotation Lock Screw. Housing

is rotatable to the maximum of 360 degree.

2

2

2

2

2

2

2

2

2 Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter

Transmitter Overview

Overview

Overview

Overview

Overview

Overview

Overview

Overview

Overview

2 Transmitter Overview

Duon System Co., Ltd. 7

[Figure 2-3] Exploded View

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

8 www.autol.com

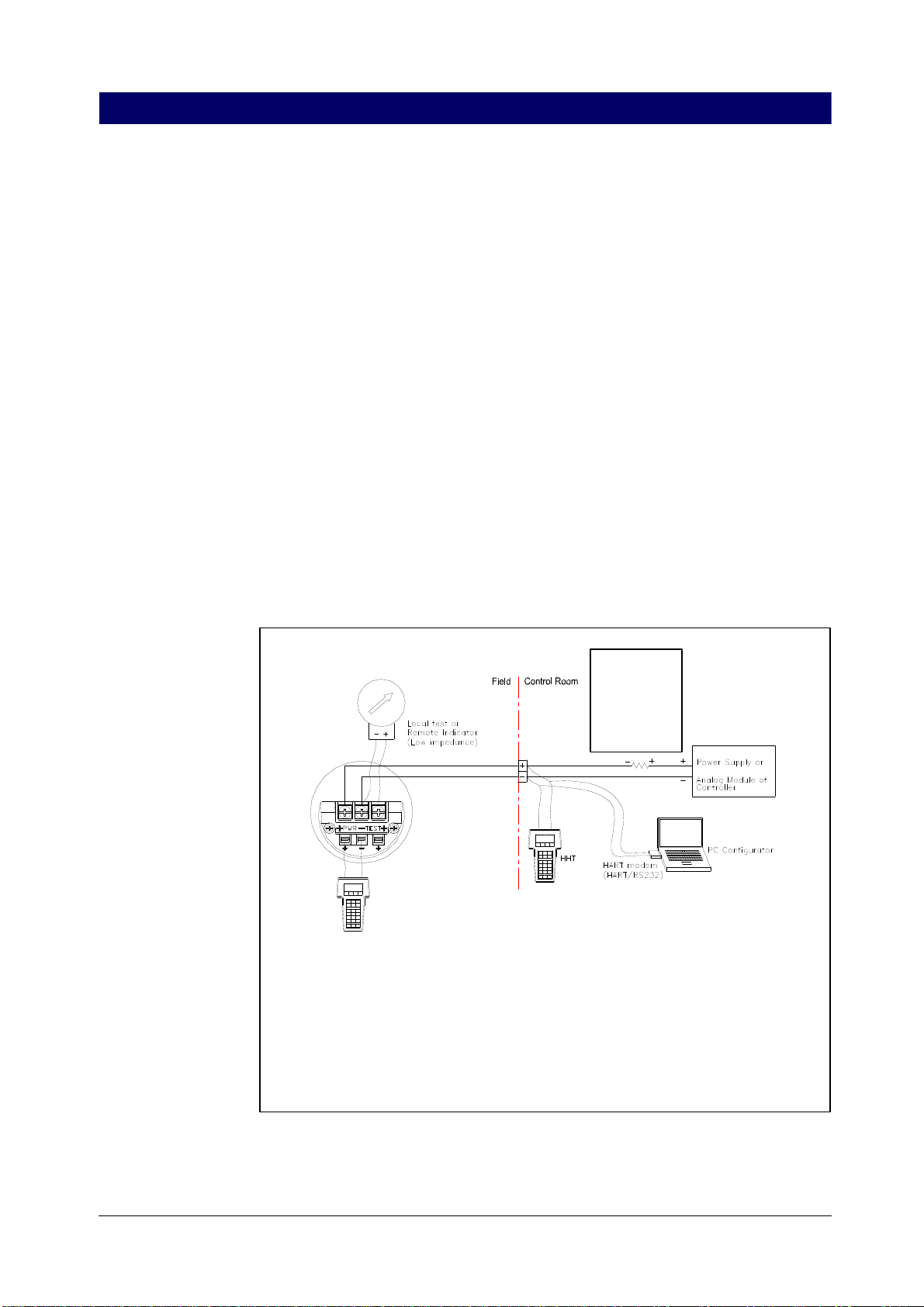

System

Composition

ALT-6100 has flameproof structure and its precision (precision and

accuracy) is very high with outstanding reliability and, because digital

communication is enabled, is suitable for the system that requires high

reliability and telecommunication.

This Transmitter is the 2-wire Loop Powered Transmitter and uses power

line for power supply along with output signal line. In other words,

because 4~20 mA and HART communication signal are sent along the

2-wire for power supply, its installation and Maintenance is easy.

Transmitter can do HART communication with the host control system, HHT

(HART Hand-Held Terminal), or PC and PDA control Software (PC & PDA

Configurator). Therefore, it can execute functions such as change,

configure, test, and calibration of each Transmitter parameter through HART

communication. In the case that Transmitter is connected to analog input

port or output port of control system, it has its own resistance of 250ohm.

Hence, separate loop resistance is unnecessary for HART communication.

In the case that Transmitter is connected to simple 24V DC Power Supply

only, HART communication is enabled by connecting 250~360 Ohm loop

resistance in series.

COMM TESTCOMM TEST

Indicator

Recorder

Controller

DCS..

etc,

250~360 Ohm

(24Vdc)

1.HTT (HART Communicator) or PC Configurator may be connected at any termination

point in the signal loop.

2.HART Communication requires a loop resistance between 250 and 360 ohms(24Vdc).

3.Transmitters operate on 16.0 to 45.0 Vdc transmitter terminal voltage.

[Applied Power]

* 16.0 ~ 45.0 Vdc for general operation

* 21.5 ~ 45.0 Vdc for HART communication ( @ 250 ohm )

* 21.5 ~ 42.0 Vdc for CSA approval ( On Processing )

[Figure 2-4] System Composition Drawing

3

3

3

3

3

3

3

3

3 Directions

Directions

Directions

Directions

Directions

Directions

Directions

Directions

Directions for

for

for

for

for

for

for

for

for handling

handling

handling

handling

handling

handling

handling

handling

handling

3 Directions for handling

Duon System Co., Ltd. 9

Unpacking

Checking

Model and

Specification

Storage

Selection of

installation

location

3 Directions for Handling

This chapter describes directions for handling and storage of Transmitter,

selection of installation location, and insulation, and flameproof structure.

In the event of unpacking Transmitter, be careful not to damage packing

box, the Transmitter and parts in the box, and protector. In the event of

transporting Transmitter to other place, transport after re-packing in the

original state, and be careful not to make a damage during transporting.

The Transmitter model name and specification are indicated on the

nameplate attached to the Transmitter exterior. Check if it is the desired

specification and model.

The following precautions should be observed when the Transmitter is

stored, especially for a long period.

(1) Select a storage area that meets the following conditions:

(a) No exposure to rain or water.

(b) Minimum vibration and shock.

(c) If possible, ambient temperature of 25°C and humidity of 65% RH

is desired, but the condition should at least be

-Ambient

temperature:

-40~85℃ (without LCD module)

-30~80℃ (with LCD module)

-Relative

Humidity:

5%~100% RH (40℃)

(2) Store transmitter in the same packing state of delivery.

(3) In the case of storing a transmitter that has been used, remove every

measuring material from the surfaces of probe and Transmitter. In

particular, when dealing with contaminating materials, handle with care

in accordance with the permitted procedure.

The transmitter is designed to operate under severe environmental

conditions. However, to ensure stable and accurate long term operation,

the following precautions must be observed in selecting an installation

location.

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

10 www.autol.com

(1) Avoid locations subject to wide temperature variation or a significant

temperature rate of change. Choose where the operation ambient

temperature of the Transmitter specification is satisfied. If the location

is exposed to severe radiant heat, adequate insulation or ventilation

should be provided.

(2) Select such a place that corrosion does not occur due to chemicals. In

case of installing in a corrosive environment, select such materials for

the Transmitter senor and probe that can withstand the corresponding

corrosive environment. Also, to prevent corrosion due to rain drops

staying in wire pipe, which is not a corrosive environment though, there

has to be appropriate ventilation.

(3) Select an installation site of minimum shock and vibration. In the case

of installing under severe vibration, it is better to install Transmitter

using auxiliary support.

(4) In the case of installing in a flameproof region, select the location

suitable for flameproof standard and check if the Transmitter

certification is appropriate for the corresponding gas.

(5) Select the place maintenance is easy. Maintenance needs a space

where housing can be rotated 180 degree. Also, there should be a

space where you can open terminal block cover and Transmitter front

cover to manipulate interior parts.

NOTE

◈ Transmitter is designed to withstand electric noise of high fre-

quency wave, but if wireless transmitter & receiver is used near

Transmitter or Transmitter exterior wiring, Transmitter may be af-

fected by high frequency wave noise. To test this influence,

observe the noise effect moving the wireless transmitter & re-

ceiver slowly from a long distance of a few meters from

Transmitter. After this observation, always use wireless trans-

mitter & receiver outside the noise effect region only.

4

4

4

4

4

4

4

4

4 Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

4 Installation

Duon System Co., Ltd. 11

4 Installation

Preliminary

Examination

before

Installation

Precautions

This chapter describes installation work and procedure, design drawing,

and considerations at installation of Transmitter.

Prior to installing a Transmitter, read chapter “Selection of Installation

Location” and examine suitability of the installation location.

WARNING

◈ Educated and qualified personnel only are authorized to install

Transmitter.

◈ It is very dangerous and may cause accident for the un-

authorized to handle Transmitter.

◈ When the Transmitter power is on, do not open the Transmitter

cover under Explosive Atmospheres.

◈ Prior to connecting HHT under Explosive Atmosphere, check if

measurement equipments connected to power-line is installed in

accordance with intrinsic safety regulations.

◈ Avoid contact between power-line and terminal. High voltage of

lead wire may cause electric shock.

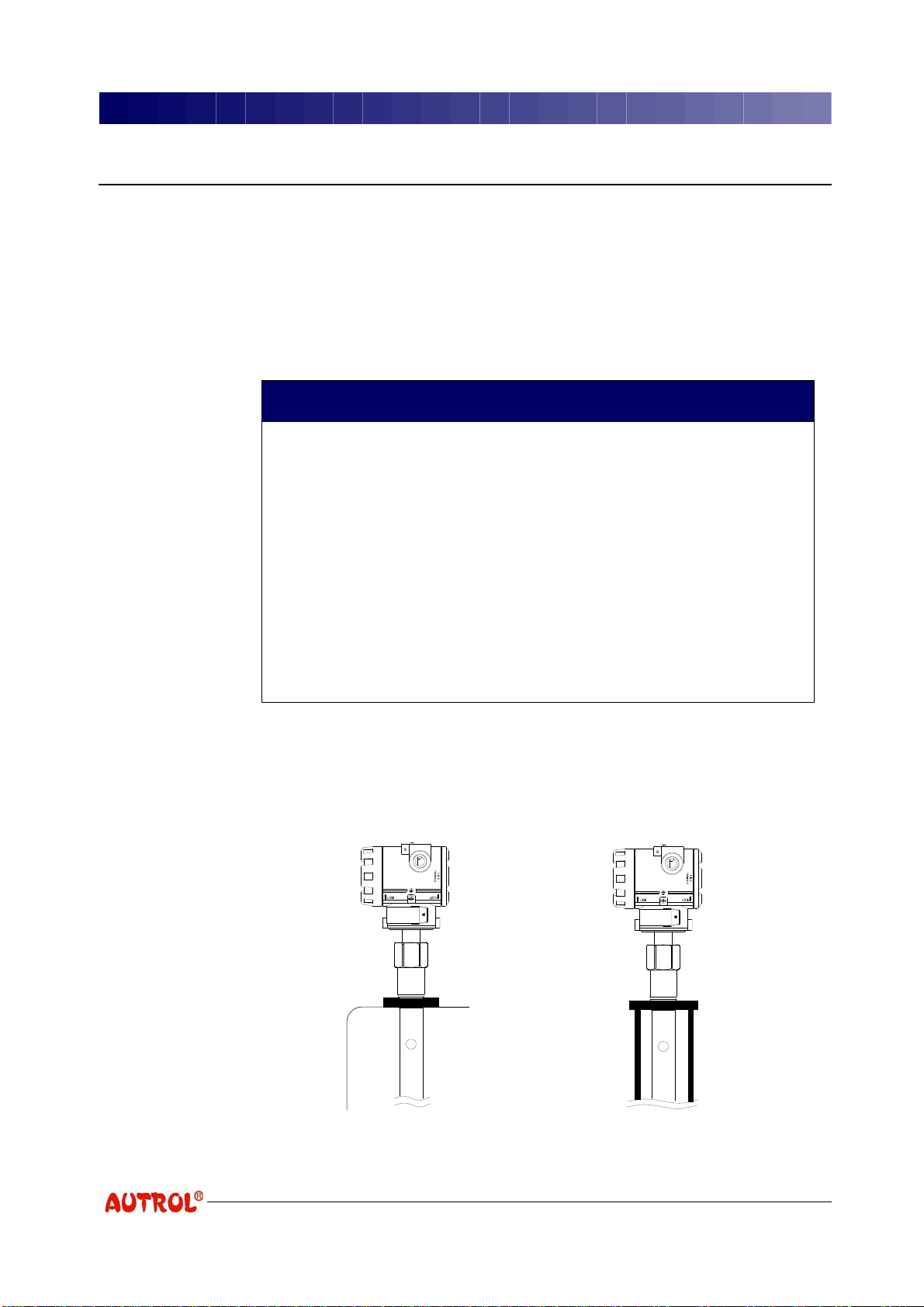

ALT-6100 is easy to mount on tank roof or threaded pipe using thread of

the Transmitter body, and provides various flanges for mounting on nozzle.

Mounting on tank roof. Mounting in threaded pipe.

[Figure 4-1] Threaded Connection

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

12 www.autol.com

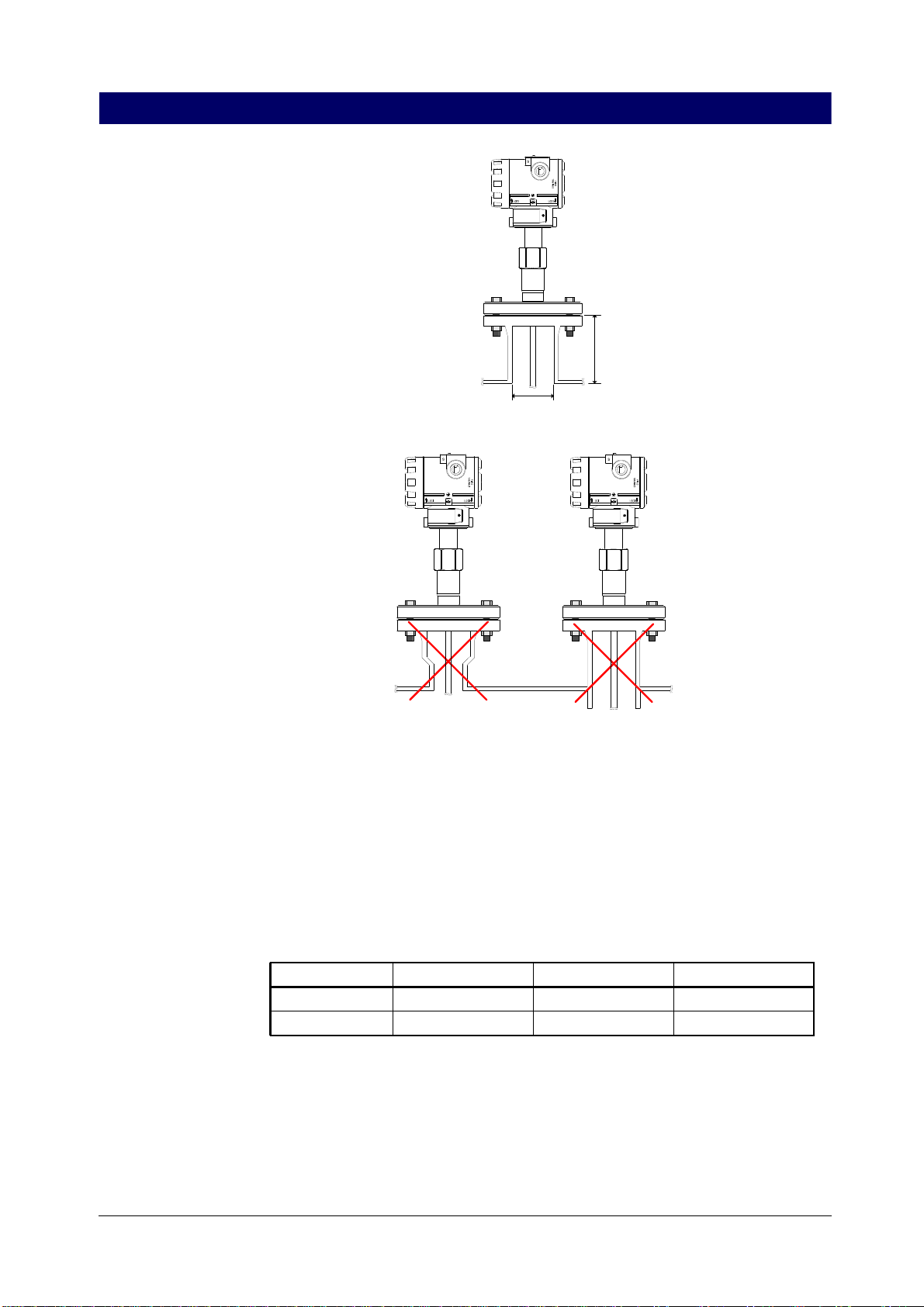

Diameter

Height

Avoid nozzles with reducer

(unless using Coaxial probe) The end of the nozzle must not

have an extension into the tank.

[Figure 4-2] Flange Connection on Nozzles

Transmitter can be mounted on nozzle using a suitable flange. But, the

nozzle should satisfy conditions of Table 4-1 such as minimum diameter

and maximum nozzle height.

[Table 4-1] Minimum nozzle diameter and maximum nozzle height (mm)

Single Rod Twin Rod Coaxial

Diameter MIN. 150 150 >Probe diameter

Heigh MAX. 100 + Diameter 100 + Diameter

Also, the nozzle height should be less than nozzle diameter, if possible,

and the nozzle end should not be extended into Tank.

4

4

4

4

4

4

4

4

4 Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

4 Installation

Duon System Co., Ltd. 13

Installation on

Nonmetal Vessel

In case there is a structure over the installation location, Rigid Rod and

Coaxial probe can hardly be inserted for installation. Hence, Flexible probe

should be used.

[Figure 4-3] Installation problems caused by structure

In the case of using a Single Rod probe for nonmetal vessel, metal flange

of at least 2 inches should be used fro optimized performance. To use the

thread connection method for nonmetal vessel, metal sheets should be

installed additionally. But, Coaxial probe can be used limitlessly for

nonmetal vessel.

Metal sheet phi > 8 inch

[Figure 4-4] Installation on nonmetal vessel

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100

ALT-6100 Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation

Operation Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

Manual

ALT-6100 Operation Manual M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

M6100-K01D

14 www.autol.com

Installation on

Concrete

Solid Measured

Medium

Installation on

Bypass Pipe

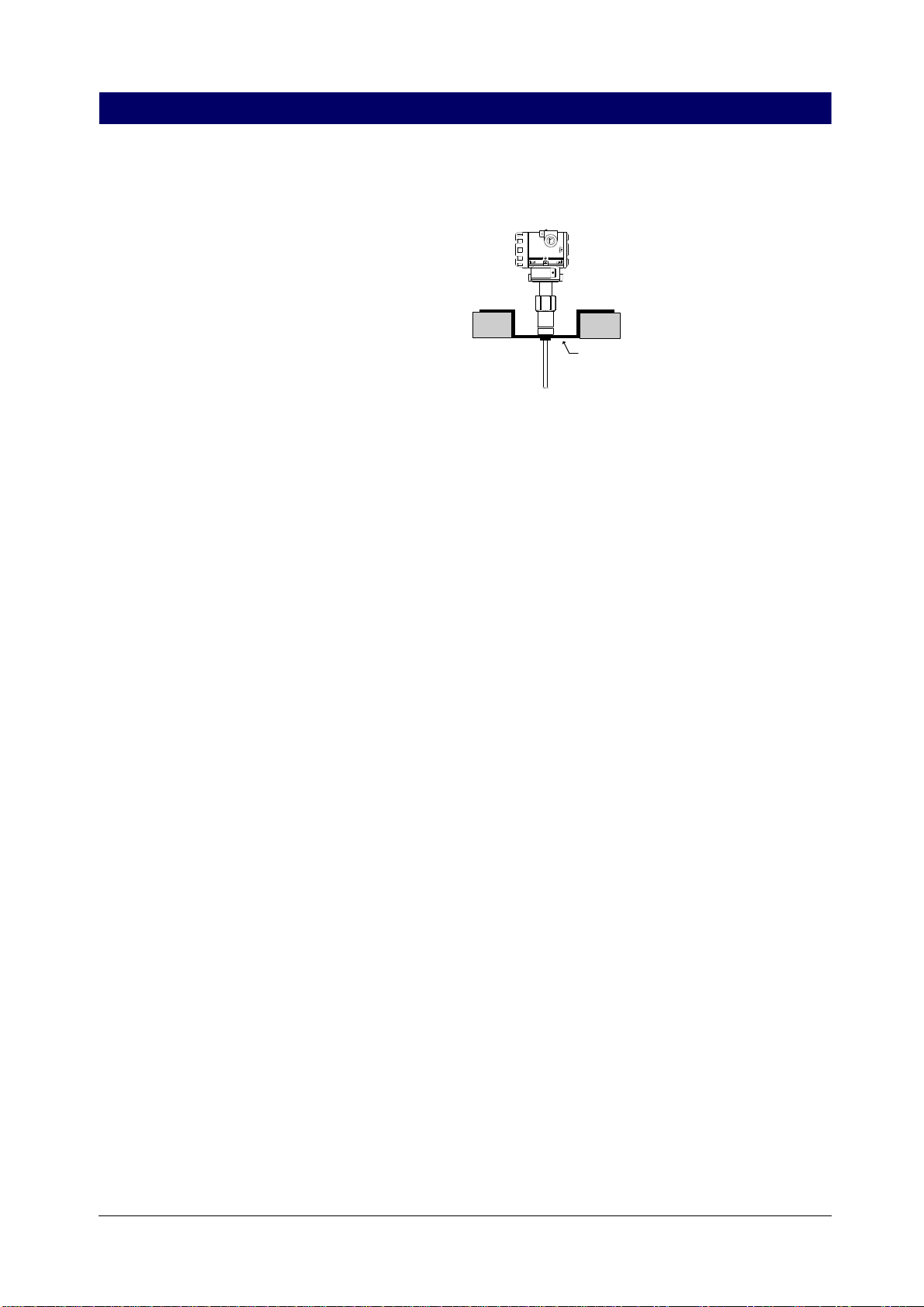

In the case of installation on concrete, concrete diameter should be bigger

than concrete width. Otherwise, it can be installed as the Figure below.

Metal

[Figure 4-5] Installation on concrete

In the case that measured medium is solid, Flexible Single Rod probe is

most appropriate, and install in accordance with the following directions:

(1) Prior to installing, vacate Silo.

(2) The probe end should be at least 300 mm above the Silo floor or fixed

on the floor.

(3) Silo and Transmitter earth terminal should earth.

(4) When the flange is used, install without a nozzle, if possible. If any,

the nozzle should be bigger than 100mm.

(5) Install Transmitter at a position that is away from the Tank wall by the

distance of “Tank radius/2", if possible, and the distance should be at

least 500 mm.

Because the medium is solid, the silo roof will get load, and care should

be taken for the followings:

(1) The silo roof should be designed to bear load.

(2) The load is determined by silo size, media density, and friction

coefficient.

(3) Flexural strength of the probe should be checked.

In the following cases, bypass pipe should be installed.

(1) High conductivity bubbles exist in tank.

(2) Severe turbulent exist in tank.

(3) Excessively many complicated structures exist in tank.

4

4

4

4

4

4

4

4

4 Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

Installation

4 Installation

Duon System Co., Ltd. 15

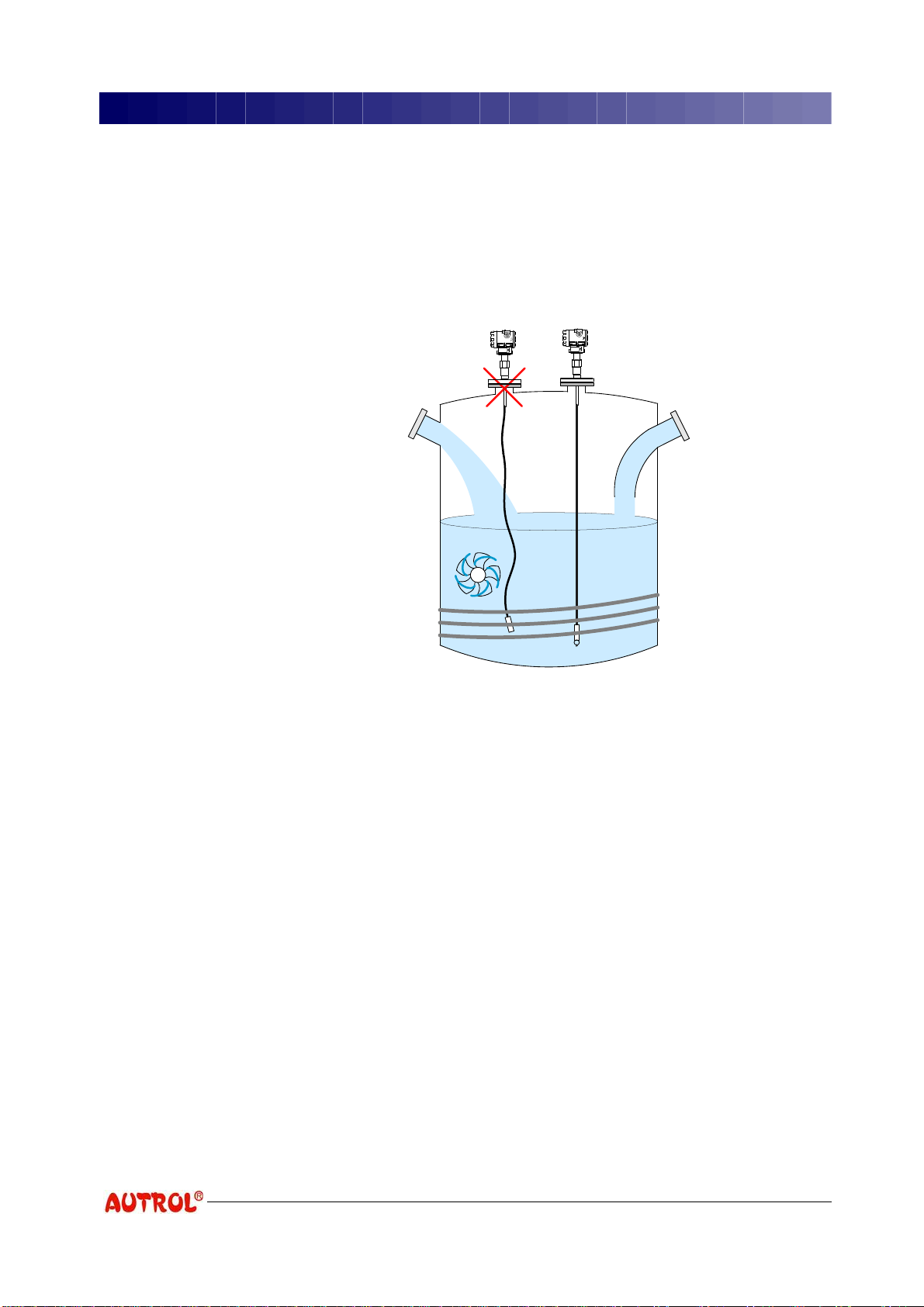

Liquid Measured

Medium

In the case of using Flexible and Rigid Rod probe, the bypass pipe

diameter should be bigger than 100mm.

The mounting location of Transmitter should be determined carefully

considering the interior state of Tank. Transmitter should be installed where

the influence of obstacles is minimized.

Agitator

Inlet pipe

Heating coils

Deflector pipe

[Figure 4-6] Condition of Tank interior

On mounting Transmitter, be careful about the followings:

(1) Do not install near the process inlet pipe.

(2) Do not install near agitator.

(3) In case turbulence occurs inside Tank, probe should be fixed on the floor.

(4) Do not install near heating coil.

(5) Prevent probe from contacting nozzle and other objects.

(6) In the case of using Flexible probe, stretch it tight to keep it parallel

with the Tank wall, and secure the distance from wall to at least

100mm (longer than 300mm is recommended).

(7) In case it is installed near the process inlet pipe, deflector pipe should

be installed.

(8) In case nozzle may develop build-up, install without nozzle.

Table of contents

Other Autrol Transmitter manuals

Autrol

Autrol ATT2100 User manual

Autrol

Autrol APT 3000 Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol ATT Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol APT 3100 Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol APT 3100 Series User manual