Autrol APT 3000 Series User manual

Quick Start Guide

APT 3000 Series

© Autrol Corporation of America

02

03

This manual covers mainly the functional needs for powering and configuring 3100 A/D/G/H &

3200 A/G series transmitters, including the 3100 MP & 3100 L/ 3200 L sealed assemblies.

For full instructions on installation, configuration and other features/option sets available with these trans-

mitters please read the full product manuals available under the download tab of

www.autroltransmitters.com.

Additional instructional videos outlining programming and configuration functionalities can also be found

on www.autroltransmitters.com. First time users are encouraged to make use of these support resources

made available at no cost online.

For additional technical support or advanced troubleshooting please contact your nearest Autrol office or

call 1-847-779-5000.

04

05

Getting Started

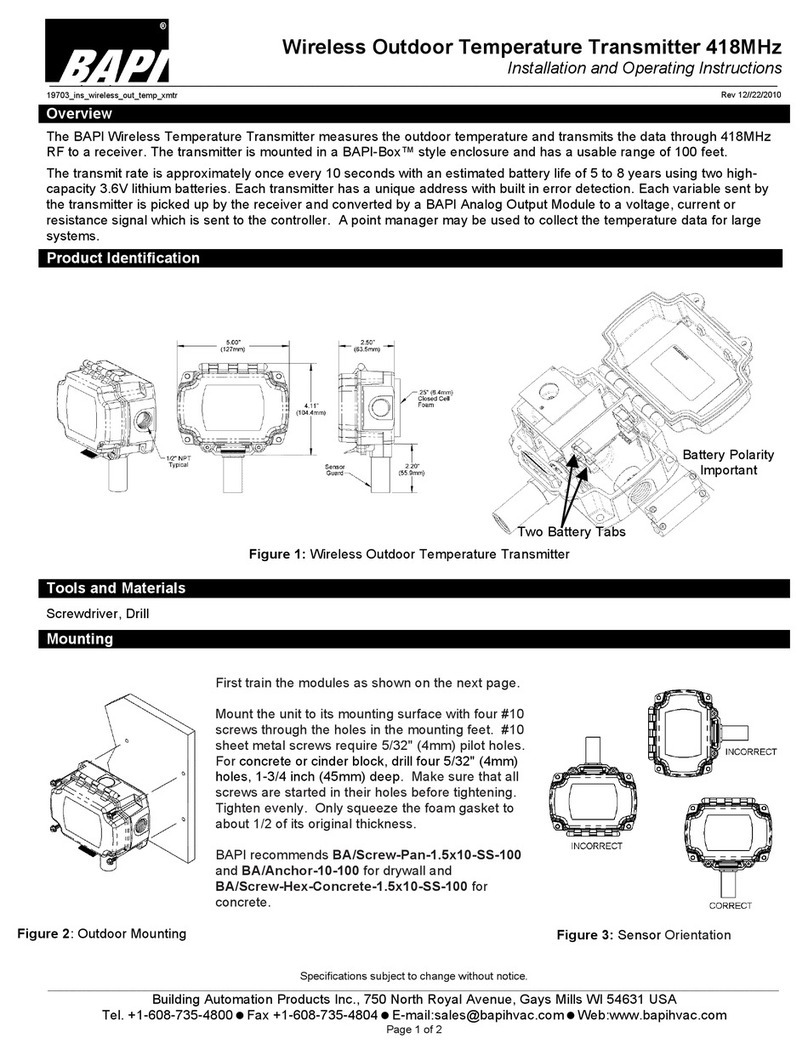

Before installation check the model, specifications, and installation location for the transmitter. Install

using proper engineering practice.

Mount transmitter securely and stabilize any impulse piping.

Follow the published pressure and temperature limits for ordered transmitter and options.

For process temperatures ≥212°F, use of adequate impulse lines, capillaries (diaphragm seals), or

cooling elements are recommended.

Set Units, URL, and LRL (in menus 21, 22, and 23 respectively). See full menu tree at end of manual.

After installation of a 3100 D/H/G or 3200 G always perform a Zero Trim (menu 11 - note this is not the

same as Zeroing). Ensure applied process to transmitter is zero before attempting Zero Trim.

Do not perform Zero Trim for 3100 A/ 3200 A (absolute) unless a true zero PV can be applied to these

units. Instead a Zero Adjust (menu 12) is recommended.

Zero Adjust is also recommended for 3100/ 3200 L (tank level application) to compensate for tank noz-

zle offsets.

06

Functional Block/Sensor Part Diagram

APT 3100

07

APT 3200

08

APT 3100 Dimensional Drawing

09

APT 3100 Exploded View

10

APT 3100 MP Dimensional Drawing

11

APT 3100 MP Exploded View

12

APT 3200 Dimensional Drawing

13

APT 3200 Exploded View

14

LCD Screen

The 5 digit LCD screen shows:

Up to 5 digits of measured value

Error code

Units (Normal and Engineering)

Menu and Menu Option

Indication of being in Normal or Engineering mode

Indication of output being Linear or Square Root

Indication of performing a Loop Test

Indication of being in Multi-Drop mode

Mode/Output

Up to 5 Digit

Display

Unit/ Error

Menu

Menu Option

15

The 5 digit LCD screen shows:

Up to 5 digits of measured value

Error code

Units (Normal and Engineering)

Menu and Menu Option

Indication of being in Normal or Engineering mode

Indication of output being Linear or Square Root

Indication of performing a Loop Test

Indication of being in Multi-Drop mode

LCD Screen Rotation

Unscrewing the two screws on either side of the LCD

screen allows for the screen to be rotated 90° clock-

wise or counterclockwise.

16

LCD Screen Display Error Codes

17

18

Fail-Mode

AUTROL® Smart Pressure Transmitters automatically perform real time self-diagnostic routines and

display any error codes on the local LCD (M1 option if ordered) that can be used for troubleshooting.

In addition to this, the self-diagnostic routines are also designed to drive transmitter current output

outside of the normal saturation values in case a fault mode is detected. The transmitter will drive its

current 4-20mA output low (down) or high (up) based on the position of the failure mode alarm jumper

(or DIP switch) configured in line with NAMUR requirements.

19

*For Blind units using DIP

switch on MCU board .

Fail Mode Selecon Jumper

Switch on LCD Module

20

Power Supply Load Limitations

21

11.9-45 Volts DC is recommended for powering the transmitter. The external power supply ripple noise

should not be higher than 2%. When calculating loop resistance please include resistance of all devices

added in the loop. For intrinsic safety applications when using an Intrinsic Safety Barrier, please also in-

clude the resistance of the barrier into the max loop resistance calculations.

Max. Loop Resistance [Ω] = (E-11.9) [Vdc] / 0.022 [mA]

Note for Standard 4-20mA output units, operating at 11.9V is possible only with Zero load connected to

transmitter analog output. HART is not supported at this low of supply voltage input.

17.5V is recommended as minimum drop across the transmitter for both HART and 250 Ohm loop re-

sistance (loads).

24V +/- 30% is the typically recommended operating range for standard 4-20mA(HART) transmitters.

For 12V and lower please refer to our 3100/3200 LV (low voltage, 1-5V output units)

22

Connection Diagram

of Signal, Power and HTT for Standard Model Transmitters

1. HHT (HART Communicator) or PC Configurator may be connected at

any terminal point in the signal loop

2. HART Communication requires a loop resistance between 250 and

550 Ohm at 24 Vdc

3. Power Supply

Voltage Range: 12 to 45 Vdc

Voltage Rating: 24 Vdc ± 30%

23

Connection Diagram

For Low Voltage Transmitters

Minimum operating input of 9V (with no loading), recommended 12V (48V maximum).

DC Power

Input Power Supply Connection

and Hang Jack Connection

1-5V Output Connection

24

Input Power Supply

Pulse Output

Connection Diagram

For 3100F (Pulse Out/ Flow Transmitters)

25

Pulse Output Hook Up

Minimum operating 17.5V (with no loading), Recommended 24V minimum for pulse and 4-20mA 2-

wire loops.

Pulse Specification

Scaled Pulse: A single pulse is output for a

specified flow amount

Pulse Width: 10ms, 50ms, 100ms se-

lectable

Duty Cycle: 49 Pulse/Second maximum

Output Type: Open Collector, 30V, 500mA

maximum

Relay or Impulse

Counter

Terminal Block

Port “1”

Terminal Block

Port “2”

DC Power

Supply

26

Housing Rotation

Unscrewing the housing rotation screws in the front

and back of the transmitter allow the housing to be

rotated 90° counterclockwise.

360° rotation possible, however please take care that

the sensor cable (inside neck) is not pinched or dam-

aged during re-orientation.

27

Lock Front/Rear Covers

Allen Screw provided on each side of Front and Rear Cover allows for locking the

covers for tamper proofing.

Front

Rear

28

Grounding

Please provide for proper grounding (earth ground) at designated points (external or internal).

29

Please provide for proper grounding (earth ground) at designated points (external or internal).

Vent/Drain Plugs

Optional with F1 or F2 Code Standard with Bleed

30

Fully Functioning Push Buttons

To access the magnetic push buttons loosen one of the screws holding down the nameplate on the top of

the transmitter. Turn the nameplate out of the way; underneath are two push buttons labeled Zero and Span.

These magnetic push buttons are fully functioning (see menu tree in following pages).

31

To access the magnetic push buttons loosen one of the screws holding down the nameplate on the top of

the transmitter. Turn the nameplate out of the way; underneath are two push buttons labeled Zero and Span.

These magnetic push buttons are fully functioning (see menu tree in following pages).

Re-Ranging and Applying External PV

Press Zero (5 sec)

When display shows “–ZR–” re-

lease the button

Apply PV corresponding to de-

sired LRV (4mA) setting

Press Zero again. Display will

show –Z or –ZE if error occurs.

To adjust SPAN press SPAN button (5

sec)

When display shows “–SP–” re-

lease the button

Apply PV corresponding to de-

sired URV (20mA) setting

*IMPORTANT

It is highly recommended to use a PV source that is at

least +/- 0.005% accurate to avoid adding negative

bias to factory calibration. If accurate PV source is not

available please use push button menu 2.2 & 2.3 to re-

range accurately without need of applying an external

PV source.

32

Menu Functions of the push buttons are controlled by the firmware version of the transmitter.

Please check the specific firmware version listed on the neck tag of the transmitter (under

LCD screen), as this may limit the available features.

As new features are continuously added please check with the most current manual online

for any specific updates on new firmware's and functionality included.

All available menus are divided into 4 primary sections

1(TRIM) - for trims, loop test etc.

2(SETUP) - for user configuration (units, range settings, output, damping etc.)

3(LCD) - for display resolution, multi-parameter display, engineering mode

4(Device) - for reset, password lock, Hart Device ID, etc.

Local Push Button Menu (Ver7.x and Higher)

33

Menu Tree for Version 6.x and Lower

Local Push Button Menu (Ver7.x and Higher)

34

Fully Functioning Push Buttons

*Continued on next page

*

35

Fully Functioning Push Buttons

Version 7.x and Higher

36

*Continued on next page *

37

Version 7.x and Higher

38

*Continued on next page

*

39

Version 7.x and Higher

This manual suits for next models

9

Table of contents

Other Autrol Transmitter manuals

Autrol

Autrol APT 3100 Series User manual

Autrol

Autrol APT 3100 Series User manual

Autrol

Autrol ALT-6100 Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol APT3200 Series User manual

Autrol

Autrol ATT2100 User manual

Autrol

Autrol ATT Series User manual

Autrol

Autrol APT3200 Series User manual