AVA WEIGH 334PRINTER User manual

09/2020

1

334PRINTER

Thermal Label Printer

for Price Computing Scales

USER MANUAL

2

TABLE OF CONTENTS

FCC Compliance Statement ....................................................................................3

Safety............................................................................................................................3

Unpacking....................................................................................................................4

Overview .....................................................................................................................5

Quick Setup Guide ....................................................................................................6

Powering On ...............................................................................................................8

Loading Media ............................................................................................................8

Printer Operaons.....................................................................................................9

PrintingMediaCalibrationConguration..................................................................... 9

ResettingPrintertoFactoryDefaults .......................................................................... 10

Printer Controls & Indicators ........................................................................................... 10

TroubleshootingLED&BuzzerIndicators................................................................. 11

Miscellaneous........................................................................................................................... 11

Recovery ..................................................................................................................................... 12

Communicaons ..................................................................................................... 12

InterfacesandRequirements............................................................................................ 12

CommunicatingwiththePrinteronaComputer.................................................... 13

Caring For Your Printer.......................................................................................... 16

Print Head Maintenance Guide........................................................................... 16

Product Specicaons........................................................................................... 16

Interface Specicaons......................................................................................... 19

Thermal Print Head Replacement....................................................................... 20

Cuer Installaon................................................................................................... 21

Peeler Installaon................................................................................................... 22

3

Supplemental Information: This device complies with the requirement of FCC Part

15 Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, this device must accept and (2) any interference received,

including interference that may cause undesired operation.

The manufacturer declares under sole responsibility that this product conforms to the

following standards or other normative documents:

EMC: EN 55022:2010 class A

EN55024:2010

Avaweigh certifies that the following products and/or components are compliant with

the current requirements of the European Union Restriction on the use of Hazardous

Substances (RoHS) Directive, 20111/65/EC.

Please only use adapters with the following electrical characteristics that are certified by

current legislation. Using other adapters may damage the device, void the warranty, and

cause risks to the user.

Features Output: 24VDC, 2.4A

INDUSTRY CANADA NOTICE:

This device complies with Industry Canada ICES-003 class A requirements.

Cet equipement est conforme a ICES-003 classe A de la norm Industrielle Canadian.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that the interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into a different outlet on a different circuit.

• Consult the dealer or an experience Radio/TV technician for help.

This unit was tested with shielded cables on the peripheral devices. Shielded cables must

be used with the unit to insure compliance. The user is cautioned that any changes or

modifications not expressly approved by Avaweigh could void the user’s authority to operate

the equipment.

SAFETY

FCC COMPLIANCE STATEMENT

4

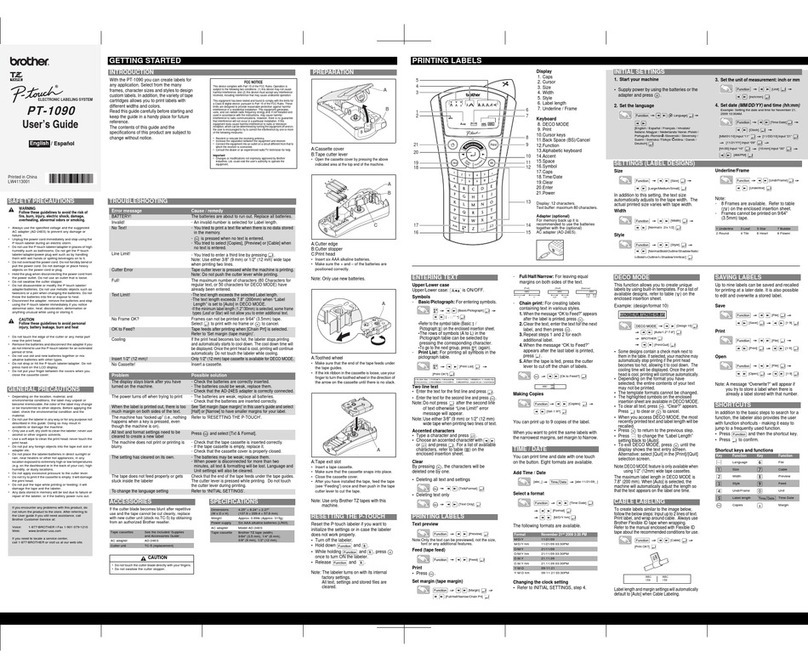

• After receiving your printer, please check for possible shipping damage.

Inspect both the box and the printer.

• Open the top cover of the printer to see if all parts are in order.

• Check whether you have received the following accessories together with the printer.

If there are any items missing, please contact your local dealer.

• Printer

• Power Cord

• Power Supply

• Quick Installation Guide

• Media Hanger & Media Shields

• USB Cable

• DVD

• RS232 Cable

PACKAGE CONTENTS

UNPACKING

5

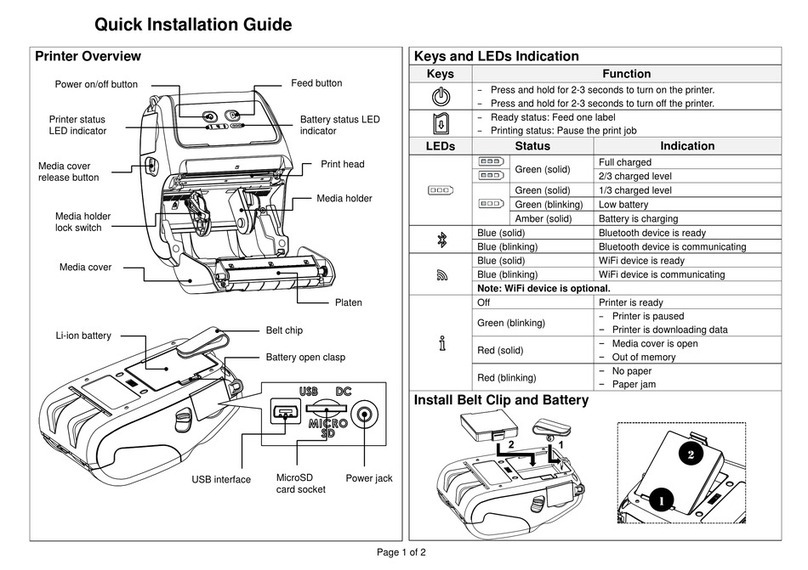

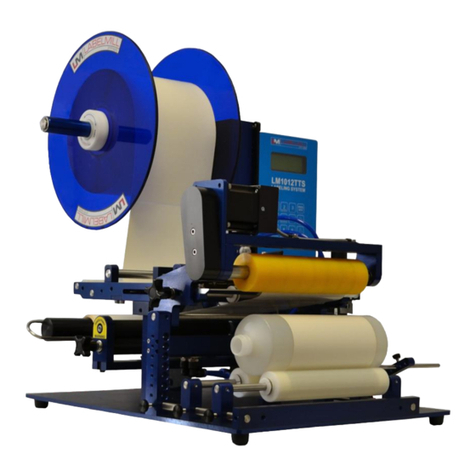

Top Cover

Paper Outlet

Power Switch

Cover Lock

Feed Button

Power Indicator

Ready Indicator

RS-232 Serial

USB

Power Jack

Cash Drawer Port

Media Hanger

Release

Levers

Thermal

Print Head

Media Guides

OVERVIEW

6

• This Quick Set-Up Guide will connect the Avaweigh (PCS40/PCS40T) to the Avaweigh Printer

(OS-2130D) using default settings, allowing for quick set-up and printing. Additional set-up

options can be found on pages 11-13 in the scale manual.

1. Connect RS232 to scale and printer:

Use the RS232 cable that came with the printer and connect it to the RS232 inserts that are

located on the back of the printer and the left side of the scale.

2. Power on the scale:

Locate the power switch on the right side of the machine and toggle it to the on position.

Wait about 5 seconds for the scale to load and calibrate.

3. Getting to setup mode:

Press the red power button and the number 4 simultaneously for a few seconds until the

machine beeps. You are now in setup mode.

4. Label Length:

Unit price screen should read ‘232.oUt.’ Once you have confirmed you are on the label length

screen please select the number associated with the length and type of label you will be using.

• Press 1: 40mm length/ date will print on label

• Press 2: 60mm length/ date will print on label

• Press 3: 40mm length/ NO DATE will print on label

• Press 4: 60mm length/ NO DATE will print on label

• Press Enter to confirm your selection.

5. Bits Per Second Connection:

Unit price screen should read ‘232.bPs,’ confirming that you are on the BPS screen.

• Press 4: (9600bps)

• Press Enter to confirm your selection.

6. Data Type:

Unit price screen should read ‘232.dFt,’ confirming that you are on the data type screen.

• Press 1: (8N1 8 bits data)

• Press Enter to confirm your selection

7. Date Format:

Unit price screen should read ‘Prtd.dt,’ confirming that you are on the date format screen.

• Press 1: (DD-MM-YY)

• Press Enter to confirm your selection

QUICK SETUP GUIDE

CONNECTING YOUR AVAWEIGH PRINTER (OS-2130D)

TO THE AVAWEIGH PCS40/PCS40T SCALE

SCALE CONNECTION

7

• Once this process has been completed the scale will reset itself and will now be connected to

the printer. For more detailed information about connection options such as barcode formats,

date layouts and bps communications please refer to pp. 11-13 in the scale manual.

8. Printer Connection:

Unit price screen should read ‘USb.oUt’ total price screen will read ‘HOST,’ confirming you are

on the printer connection screen.

• Press Enter to confirm your selection

9. Bits Per Second Connection:

Unit price screen should read ‘USb.bPs,’ confirming you are on the BPS screen.

• Press 4: (9600bps)

• Press Enter to confirm your selection

10. Data Type:

Unit price screen should read ‘USb.dFt,’ confirming you are on the data type screen.

• Press 1: (8N1 8 bits data)

• Press Enter to confirm your selection

11. Department Code:

Unit price screen will read ‘d.CodE’ confirming you are on the department code screen.

• Choose a desired two-digit department code between (00-99). (Example: 08)

This will show as the prefix of barcodes.

• Press Enter to confirm your selection

12. Barcode Format:

Unit price screen will read ‘b.Prt.FE,’ confirming you are on the barcode format screen.

• Press any two digits between 00-13 to select a barcode format.

05 is the recommended barcode format.

• Press Enter to confirm your selection

13. Finish:

Unit price screen will read ‘Urt.CFt’ confirming that you are on the final screen.

• Press 2 to finish

• Press Enter to confirm your selection

PRINTER CONNECTION

8

1. Make sure the printer's power switch is in

the OFF position.

2. Insert the AC power cord into the power supply.

3. Insert the power supply's power connector into

the printer's power jack.

4. Plug the other end of the power cord into an

appropriate grounded AC electrical outlet.

1. Open top cover of the printer.

2. Put the Media Hanger through

Media Supply Roll, then

centrally align with the (2)

Media Shields so they lean

against the roll.

3. Place the Media Supply Roll

into the Media Compartment

of the printer.

4. Push the Release Levers to

open the Printer Module.

5. Pull a short length of media

until it reaches the Platen Roll

of the printer. Adjust the Media

Guide on the right so the roll is

left-aligned.

6. Close the Printer Module,

then press both sides firmly

until you hear a click.

In case the paper roll becomes dirty during shipment, handling, or storage, begin by removing the

outside length of media, which helps prevent dirt from coming in contact with the print head and

platen roller. Load the media by placing onto the media hangers.

POWERING ON

LOADING MEDIA

• Do not operate the printer and power supply

in an area where they might get wet.

Media Roll

Media Hanger

Release Levers

Media

Compartment

Print Head

Test Patterns

Fonts

Main Board

DIP Switch Settings

Calibration Type

Cutter/Peeler Setting Offset

Peeler Setting

Cutter Setting

Backfeed Setting

Media Type Setting

Print Speed & Darkness

Serial Port Settings

Printed Label Length

Internal Fonts

Real Time Clock (RTC) Setup

Print Method

Memory Capacity

Firmware Version

& Date Code

9

1. Make sure the media is properly loaded

and the top cover of the printer is closed.

2. Turn off the printer power.

3. Press and hold the FEED button while

turning on the power, until print motor

is activated.

4. Media is calibrated while the printer

automatically feeds the label stock for

a certain length; then the printer motor

suspends for one second, then prints

out the configuration profile. Release

the FEED button as soon as the printer

starts to print.

NOTE: If printer is set up with PPLB printer

language, printer will enter Dump mode after

printing configuration. In Dump mode, all

characters will be printed in 2 columns: the right

shows characters received from you system, and

the left are the corresponding hexadecimal values

of the characters. This allows users or engineers to

verify and debug the program.

To return to normal operation mode from Dump

mode, press the FEED button again, or turn off

printer power and then restart the printer.

7. Close the Top Cover and turn

on the printer.

8. Press the Feed Button to feed

labels out of the printer.

Before connecting the printer to your

computer, to make sure that the printer

works properly, conduct media calibration

and print a self-test/configuration label.

PRINTER OPERATIONS

PRINTING MEDIA

CALIBRATION

CONFIGURATION

10

1. Turn on the printer and wait until both the "Ready" and "Power" indicators are solid green.

2. Press the FEED button for 5 seconds. The "Ready" and "Power" indicators will go off in order.

NOTE: If the FEED button is held for 10 seconds; Printer will reset, feed blank labels as media

calibration, then print configuration/self-test labels.

3. Once "Power" indicator becomes lit again, release the FEED button.

4. Once "Ready" indicator becomes lit again, the printer has resumed its factory default settings.

RESETTING PRINTER TO FACTORY DEFAULTS

PRINTER CONTROLS & INDICATORS

The printer factory default settings are stored in the printer's flash. These settings remain stored,

without being erased even if the printer power is disconnected.

Power Switch

Feed Button

Power Indicator

Ready Indicator

CONTROL/INDICATOR FUNCTION

POWER SWITCH

ON: Turns on normal operaon (I Posion)

OFF: Turns power o (O Posion)

NOTE: Turn power OFF before connecng or disconnecng cables

POWER INDICATOR

OFF: Printer power OFF

GREEN: Printer power ON

BLINKING: "Media Out" or "Media Gap Not Found" error

BLINKING: Cuer is jammed with paper or not installed

BLINKING: RS-232 communicaon error

READY INDICATOR

OFF: Printer is not ready for prinng

GREEN: Printer is ready for prinng

BLINKING: Printer starng up

BLINKING: Receiving data from host PC

BLINKING: Prinng is paused

BLINKING: "Media Out" or "Media Gap Not Found" error

BLINKING: Printer Module is opened

BLINKING: Print Head is overheated and printer's thermal protecon

funcon has put the unit into PAUSE status. Prinng will resume auto-

macally when Print Head cools down.

FEED BUTTON

BEFORE PRINTING: Press to advance label media to prinng posion.

DURING PRINTING: Press to pause.

DURING START UP: Press and hold to conduct media calibraon and

print a conguraon prole.DURING PAUSE: Press to resume prinng

aer "Media Out" errors have been resolved.

11

1. Check if the communication cable (serial) is connected securely to your serial port on the

PC and to the connector on the printer.

2. Check if the printer power is turned on.

1. Check the active printer driver.

2. Verify Seagull driver for your Windows system and label printer has been selected.

• If the host shows "Printer Time Out":

• If the data has been sent, but there is no output from the printer:

TROUBLESHOOTING LED & BUZZER INDICATORS

MISCELLANEOUS

The printer has built-in monitors for the status. The status and error indications will

be displayed via the front panel LED indicators and the alert buzzer. Generally, when a

malfunction or an abnormal condition is detected, tthe alert buzzer will beep three times, and

the ERROR LED INDICATOR will also blink. The list below shows the buzzer and LED indicators

and their corresponding errors.

*Buzzer can be disabled by Printer Utility.

POWER READY PROBLEM SOLUTION BUZZER*

BLINK BLINK

Media sensor cannot index label gaps

Check the label path and label sensor.

NOTE: If a connuous label roll is in use, set

"connuous media" prinng in driver sengs

or commands.

NO

Media out Install a new label roll. YES

Paper jam Recover the jam. NO

BLINK ON

Serial IO error

Check the serial baud rate in both the

system and printer.

NOTE: For serial interface only.

NO

Cuer has failed, or there is a paper

jam inside the cuer

Check the cuer or recover paper jam.

NOTE: Only applicable when cuer mod

is enabled.

YES

Memory full

Check the format of loaded so fonts,

graphics, or forms.

Contact vendor for service.

YES

Other possible hardware errors Contact vendor for service. NO

ON BLINK

Print head needs to cool down

Prinng will stop unl the print head cools to

normal prinng temperature. Once it com-

pletes, the printer will automacally resume

prinng.

NO

Printer is in PAUSE status Press FEED buon to resume prinng. NO

Printer is receiving data

As soon as all data has been received,

"Ready" LED indicator will stay solid green

and automacally resume normal operaon.

NO

12

1. Clean the print head.

2. If the problem persists, replace the print head.

1. The media may not be qualified.

2. Adjust the darkness (heat temperature).

3. Slow down the print speed.

4. Refer to the next chapter and clean the related spare parts.

• Vertical streaks in the printout usually indicate a dirty or faulty print head.

• Poor printout quality:

After correcting problems:

• Simply press the panel button or restart the printer to continue your print jobs.

• Make sure the LEDs are not blinking and remember to resend your files.

Your Avaweigh printer comes with a nine-pin Electronics Industries Association (EIA) RS-232

serial data interface, a USB interface, and Cash drawer interface. A variety of interface options are

suitable for versatile applications:

334PRINTER: Cash drawer, USB, and Serial interfaces

NOTE:

• You must insert the power supply's barrel connector into the power jack on the back of the

printer before connecting communication cables.

• This printer complies with FCC Rules and Regulations, Part 15, for Class A Equipment, for

use with fully shielded six-foot data cables. Use of longer cables or unshielded cables may

increase radiated emissions above Class A limits.

The Universal Serial Bus (USB) interface is version 2.0 and 1.1 compliant and provides a full-

speed (12Mb/s) interface that is compatible with your existing PC hardware. The USB's "plug and

play" design makes installation easy. Multiple printers can share a single USB port/hub.

The required cable must have a nine-pin "D" type male connector on one end, which is plugged

into the mating serial port located on the back of the printer. The other end of the signal interface

cable connects to a serial port on the host computer.

RECOVERY

INTERFACES AND REQUIREMENTS

USB INTERFACE REQUIREMENTS

SERIAL (RS-232) INTERFACE REQUIREMENTS

COMMUNICATIONS

13

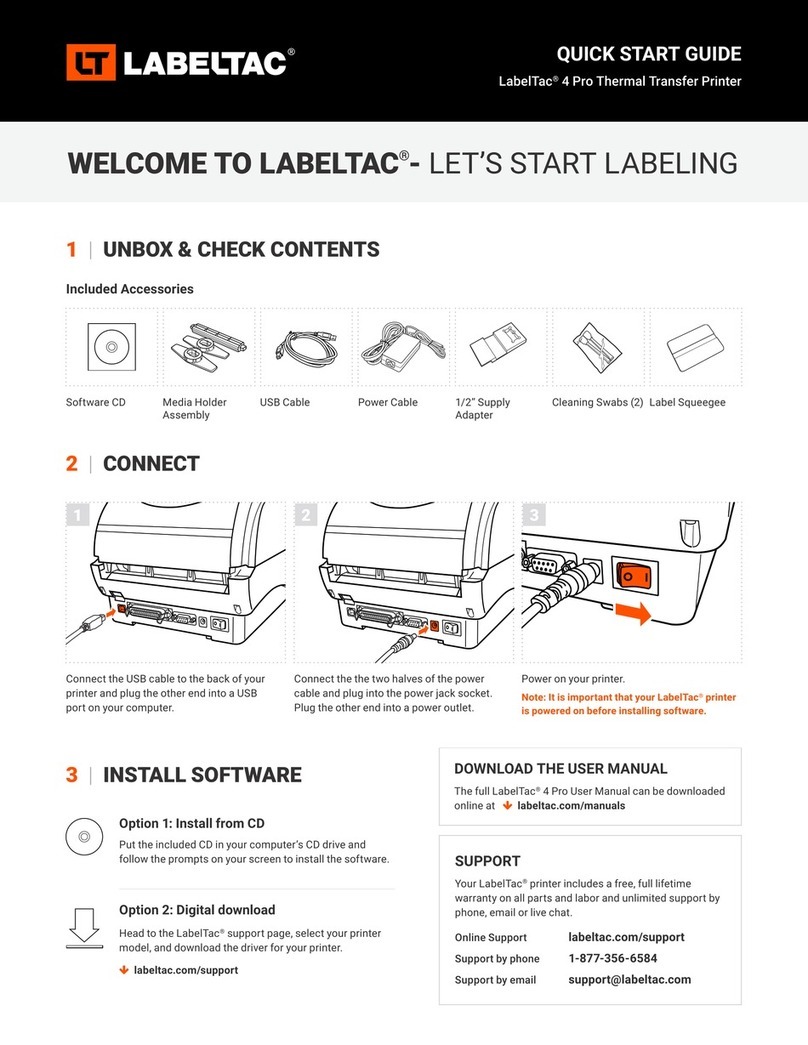

1. Turn off the printer.

2. Plug the power cable into the power socket on the wall.

3. Connect the other end of the power cable to the printer's power socket.

4. Connect the USB cable to the USB port on the printer and on the PC.

5. Turn on the printer.

6. If the printer supports Plug-and-Play, and you have successfully connected it using a USB

cable, the Windows Add Hardware Wizard will automatically detect the printer and display a

dialog that allows you to install a driver. Click Cancel and DO NOT INSTALL the driver using

this wizard.

7. Run the driver from Argox website (www.Argox.com/product/os-2130d/).

On the prompt, Windows Printer Driver, select "I Accept..." and click "Next".

8. Assign the directory to keep Seagull driver, and click "Next".

9. Click Finish.

NOTE: We strongly recommend that you use the Seagull Driver Wizard instead of the Microsoft

Windows Add Printer Wizard when installing and updating your Drivers by Seagull.

(Even though the "Add Printer Wizard" is from Microsoft, it too easily performs a number of tasks

incorrectly when updating.

The bundled printer driver can be applied to applications under Windows XP/Vista/Windows 7/8

& 10, supporting 32-bit/64-bit operating systems. With this driver you can operate any popular

Windows software applications including Argox Bartender UL label editing software or MS Word,

etc. to print to this printer.

When communicating with Argox Drivers, use Argox OS-2130D PPLB

Drivers can be downloaded from www.Argox.com/product/os-2130d/

ARGOX SEAGULL DRIVER 2019.2 M-2

Windows Vista, Windows 7, Windows 8 and 8.1, and Windows 10. Windows Server 2008, 2008 R2,

2012, 2012 R2, and 2016. 32-bit and 64-bit (x64) editions.

ARGOBAR PRO V2.08

Windows Vista, Windows 7, Windows 8.1, Windows 10 (32-bit or 64-bit) Windows Server 2008,

Windows Server 2008 R2, Windows Server 2012, Windows Server 2012 R2 (32-bit or 64-bit).

Support languages: English, Simplified Chinese, Traditional Chinese

COMMUNICATING WITH THE PRINTER ON A COMPUTER

INSTALLING A PLUG AND PLAY PRINTER DRIVER

14

1. Turn off the printer.

2. Plug the power cable into the power socket on the wall.

3. Connect the other end of the power cable to the printer's power socket.

4. Connect the Parallel or serial cable to the port on the printer and on the PC.

5. Turn on the printer.

6. Run the driver from Argox website (www.Argox.com/product/os-2130d/).

On the prompt, Windows Printer Driver, select "I Accept..." and click "Next".

7. Assign the directory to keep Seagull driver, and click "Next".

8. Click Finish.

13. Check all the data on the showing screen, if it is correct, click "Finish".

14. After the related files have been copied to your system, click "Finish".

15. After driver installation is complete, click "Close". The driver should now be installed.

INSTALLING A PRINTER DRIVER (FOR OTHER INTERFACES EXCEPT USB)

10. Select "Install printer drivers" and Click "Next"

11. On the Seagull Driver Wizard prompt, select the first radio button to "Install a driver for a Plug

and Play printer", then click "Next"

12. Enter Printer name (Avaweigh 334PRINTER) and select "do not share this printer", click "Next".

15

9. Select Install printer drivers and click "Next".

10. Make sure printer is connected to PC, select "Other" and click "Next".

11. Select model & emulation - OS-2130D PPLA

12. Select the port of the printer and click "Next".

13. Enter printer name (Avaweigh 334PRINTER) and select "Do not share this printer", click "Next".

14. Check all the data on the showing screen, if it is correct, click "Finish".

15. After the related files have been copied to your system, click "Finish".

16. After driver installation is complete, click "Close". The driver should now be installed.

16

• When cleaning the Print Head, always

wipe in one direction - from left to right

only or right to left only - to prevent

excessive stress to the Print Head.

• DO NOT WIPE BACK AND FORTH - to

prevent dust and dirt on cleaning cloth

from being redeposited on the Print Head.

CLEANING DIRECTION

PRODUCT SPECIFICATIONS

SPECIFICATION

DIMENSIONS 8.98 in. L x 5.28 in. W x 6.42 in. H (228mm L x 134mm W x 163mm H)

WEIGHT 2.65 lb. (1.2 kgs)

PRINT METHOD Direct Thermal

PRINTING RESOLUTION 203 DIP (8 dots/mm)

PRINTING SPEED 2ips - up to 4ips (51-102mm/s)

PRINTING LENGTH Max. 100 in. (2540mm)

PRINTING WIDTH Max. 2.83 in. (72mm), Min. 1 in. (25.4mm)

GENERAL

• Surface of Print Head's heating element is very fragile.

• To prevent any possible damage, please use the Print Head Cleaning Pen or soft cloth/cotton

buds with Ethanol or Industry Alcohol to clean Print Head surface.

• It's strongly recommended to wear gloves during cleaning.

• DO NOT touch print head surface with bare hands or with any hard equipment

• Water should be kept away in case of corrosion on heating elements.

CLEANING MATERIAL

To keep the Print Head running efficiently, and to extend the life of the printer,

regular cleaning is needed.

NOTE: Always switch off printer power before cleaning.

It's recommended to clean Print Heads regularly, at least when changing label rolls (in direct thermal

printing mode). In addition, if printers are operated under critical applications and environments, or

if it's found that print quality is degraded, please clean print heads more frequently.

PRINT HEAD MAINTENANCE GUIDE

CLEANING INTERVAL

CARING FOR YOUR PRINTER

17

SPECIFICATION

MEMORY 8MB SDRAM (6MB user available)

4MB Flash ROM (2MB user available)

CPU TYPE 32-bit RISC microprocessor 100MHz

SENSORS Reecve (Le Side)

OPERATION INTERFACE Buon (Feed) x 1

COMMUNICATION INTERFACE RS-232, USB, Cash Drawer

FONTS

PPLA:

Internal Fonts:

9 fonts with dierent point size

6 fonts with ASD smooth font

Courier font with dierent symbol sets

PPLB:

Internal Fonts:

5 fonts with dierent point size

So fonts and 2-byte Asian fonts are downloadable

Ability to print any Windows True Type font easily

1D BARCODES

PPLA:

Code 39, UPC-A, UPC-E, Code 128 subset A/B/C, EAN-13, EAN-8, HBIC, Codabar,

Plessey, UPC2, UPC5, Code 93, Postnet, UCC/EAN-128, UCC/EAN-128 K-MART,

UCC/EAN-128 Random, Weight, Telepen, FIM, Interleave 2 of 5 (Standard/with modula

10 checksum/with human readable check digit/with modula 10 checksum & shipping

bearer bars), GS1 Data bar (RSS)

PPLB:

Code 39 Std. & Extended, UPC-A, UPC-E, UPC-interleaved 2 of 5, Code 39 with check

sum digit, Code 93, EAN-13, EAN-8 (Standard, 2/5 digit add-on), Codabar, Postnet,

Code 128 subset A/B/C, Code 128 UCC (shipping container code), Code 128 auto,

UCC/EAN code 128 (GS1-128), interleave 2 of 5, interleaved 2 of 5 with check sum,

interleaved 2 of 5 with human readable check digit, German Postcode, Matrix 2 of 5,

UPC interleaved 2 of 5, EAN-13 2/5 digit andd-on, UPCA 2/5 digit add-on, UPCE 2/5

digit add-on, GS1 Data bar (RSS)

2D BARCODES PPLA/PPLB:

MaxiCode, PDF417, Data Matrix (ECC 200 only), QR code, Composite codes

GRAPHICS PPLA/PPLB:

PCX, BMP, IMG, HEX, GDI, Binary raster (PPLB Only)

EMULATION PPLA, PPLB

SOFTWARE-LABEL EDITING Windows Driver (Win XP/Vista/7/8/10), BarTender

SOFTWARE UTILITY Printer Ulity, Font Ulity

MEDIA TYPE Roll-feed, Die-cut, Connuous, Fan-fold, Tags, Ticket in Thermal Paper

MEDIA

Max Width: 3.14 in. (79.8mm)

Min Width: 1 in. (25.4mm)

Max Length: 100 in. (2540mm)

Min Length: 0.196 in. (5mm)

Thickness: 0.0025-0.01 in. (0.0635-0.254mm)

Max Capacity Core 0.5 in.: OD 4.3 in. (109mm)

Max Capacity Core 1 in.: OD 4 in. (102mm)

Max Capacity Core 1 in.: ID 1 in. (25.4mm)

18

PROGRAMMING

LANGUAGE PPLA PPLB

INTERNAL FONTS

9 fonts with dierent point size

6 fonts with ASD smooth font

Courier font with dierent symbol sets

5 fonts with dierent point size

SYMBOL SETS

(CODE PAGES)

Courier font symbol set:

Roman-8, ECMA-94, PC, PC-A, PC-B, Legal,

and PC437 (Greek), Russian

8 bits code page:

437,850, 852, 860, 863, 865, 857, 861, 862,

855, 866, 737, 851, 869, 1252, 1250, 1251,

1253, 1254, 1255

7 bits code page:

USA, BRITISH, GERMAN, FRENCH, DANISH,

ITALIAN, SPANISH, SWEDISH, and SWISS

SOFT FONTS Downloadable so fonts Downloadable so fonts

FONT SIZE 1x1 to 24x24 mes 1x1 to 24x24 mes

CHARACTER

ROTATION 0°, 90°, 180°, 270°, 4 direcon rotaon 0°, 90°, 180°, 270°, 4 direcon rotaon

GRAPHICS PCX, BMP, IMG, HEX, GDI PCX, BMP, IMG, HEX, GDI, Binary Raster

BARCODE TYPES

Code 39, UPC-A, UPC-E, Code 128 subset

A/B/C, EAN-13, EAN-8, HBIC, Codabar,

Plessey, UPC2, UPC5, Code 93, Postnet, UCC/

EAN-128, UCC/EAN-128 K-MART, UCC/EAN-

128 Random Weight, Telepen, FIM, Interleave

2 of 5 (Standard/with modulo 10 checksum/

with human readable check digit/with modulo

10 checksum & shipping bearer bars), GS1 Data

bar (RSS), MaxiCode, PDF417, Data Matrix

(ECC 200 only), QR code, Composite codes

Code 39 Std. & Extended, UPC-A, UPC-E,

UPC-interleaved 2 of 5, Code 39 with check

sum digit, Code 93, EAN-13, EAN-8 (Standard,

2/5 digit add-on), Codabar, Postnet, Code128

subset A/B/C, Code 128 UCC (shipping

container code), Code 128 auto, UCC/

EAN code 128 (GS1-128), Interleave 2 of 5,

interleaved 2 of 5 with check sum, interleaved 2

of 5 with human readable check digit, German

Postcode, Matrix 2 of 5, UPC interleaved 2 of

5, EAN-13 2/5 digit add-on, UPCA 2/5 digit

add-on, UPCE 2/5 digit add-on GS1 Data bar

(RSS), MaxiCode, PDF417, Data Matrix (ECC

200 only), QR code, Composite codes

FONTS, BARCODES & GRAPHICS

The specifications of fonts, barcodes, and graphics depends on the printer emulation.

The emulations PPLA and PPLB are printer programming languages, though which the host

can communicate with your printer.

SPECIFICATION

POWER SOURCE 100-240V, 1.8A, 50-60Hz Input

24V, 2.5A Typical Output

OPERATION

ENVIRONMENT

Operaon Temperature: 40-100°F (4-38°C), 10-80% non-condensing

Storage Temperature: (-4)-122°F ((-20)-50°C)

OTHER

Buzzer Internal

RTC Internal

Note: RTC Lithium Baery Specicaon CR2032, +3V, 225mAh

CAUTION: Risk of explosion if baery is replaced by an incorrect type. Dispose of

used baeries according to the instrucons.

OPTIONAL ITEMS

Guillone Cuer

Peeler

External 8" OD Media Stacker

19

PIN SIGNAL

1Ground

2-

3Drawer _Back

4+24V

5Drawer _KICK2

6Ground

PIN SIGNAL DESCRIPTION

1VBUS 5V

2D - Dierenal data signaling pair -

3D + Dierenal data signaling pair +

4GND Ground

PIN DIRECTION DEFINITION

1- Shorted to Pin 4,6

2Output TX

3Input RX

4-Shorted to Pin 1,6

5-Ground

6-Shorted to Pin 1,4

7Input CTS

8Output RTS

9Output +5V

CASH DRAWER USB

RS232

The RS232 connector on the printer side is a female, DB-9 and pin to pin standard type.

Baud rate: 2400, 4800, 9600 (default), 19200, 38400, 57600, 115200 bauds.

(Programmable by command)

NOTE: Pin 9 is reserved for KDU (Keyboard Device Unit), therefor do not connect these pins

if you are using a general host like a PC.

INTERFACE SPECIFICATIONS

20

THERMAL PRINT HEAD

REPLACEMENT

1. Turn the printer off and wait for both LEDs to go off.

2. Open the top cover.

3. Unlatch the Print Head Module and swing it up to open.

4. Push the Thermal Print Head firmly into the mounting bracket to release it from the Module.

5. Disassemble the Thermal Print Head and the metal plate by removing the screws.

6. Unplug the 2 print head cables from the connectors on the old Thermal Print Head Module.

7. Replace the Thermal Print Head.

8. Plug the 2 print head cables into the new Thermal Print Head.

9. Put the new Print Head Module onto Printer Chassis.

Table of contents